Abstract

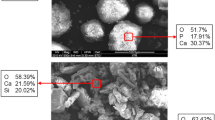

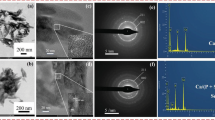

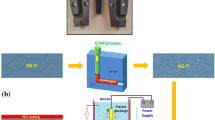

Biomimetic deposition is a low-cost method to coat complex-shaped substrates at physiological temperatures that requires long times to achieve coatings with a suitable adhesion strength. Thus, the chemical, morphological and mechanical properties of hydroxyapatite (HA) coatings on titanium obtained by biomimetic deposition using supersaturated calcification solutions (SCS) were studied. This approach also eliminates heat treatment during substrate activation and prior to HA deposition. The results showed that it is possible to obtain nanosized HA coatings on modified titanium within 4 h and the chemical composition of the coatings was affected by the pH of the SCS. Nevertheless, the final composition after post-deposition annealing treatment showed no differences in composition and coating features. Interfacial shear strength and critical loads were significantly higher than those reported using the traditional biomimetic method. However, in vitro and in vivo studies should be performed to confirm the results before clinical applications.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

A. Civantos, E. Martínez-Campos, V. Ramos, C. Elvira, A. Gallardo, A. Abarrategi, Titanium coatings and surface modifications: toward clinically useful bioactive implants. ACS Biomater. Sci. Eng. 3, 1245–1261 (2017). https://doi.org/10.1021/acsbiomaterials.6b00604

S.B. Goodman, Z. Yao, M. Keeney, F. Yang, The future of biologic coatings for orthopaedic implants. Biomaterials 34, 1–10 (2013). https://doi.org/10.1016/j.biomaterials.2013.01.074

L. Morejón-Alonso, C. Mochales, L. Nascimento, W.D. Müller, Electrochemical deposition of Sr and Sr/Mg-co-substituted hydroxyapatite on Ti-40Nb alloy. Mater. Lett. 248, 65–68 (2019). https://doi.org/10.1016/j.matlet.2019.03.141

B. Priyadarshini, M. Rama, U. Vijayalakshmi, Bioactive coating as a surface modification technique for biocompatible metallic implants: a review. J. Asian Ceram. Soc. 7(4), 397–406 (2019). https://doi.org/10.1080/21870764.2019.1669861

O.V. Savvova, L.L. Bragina, G.N. Shadrina, Properties of bioactive glass ceramic coatings on titanium alloys obtained by slip technology. Glass Ceram. 72, 145–149 (2015). https://doi.org/10.1007/s10717-015-9744-0

D.C. Draghici et al., Strontium-substituted bioactive Glass-Ceramic films for tissue engineering. Bol. Soc. Esp. Cerám. Vidr. (2020). https://doi.org/10.1016/j.bsecv.2020.09.006

F. Baino, G. Novajra, V. Miguez-Pacheco, A.R. Boccaccini, C. Vitale-Brovarone, Bioactive glasses: special applications outside the skeletal system. J. Non Cryst. Solids 432, 15–30 (2016). https://doi.org/10.1016/j.jnoncrysol.2015.02.015

J.A. Oliver et al., Bioglass coatings on metallic implants for biomedical applications. Bioact. Mater. 4, 261–270 (2019). https://doi.org/10.1016/j.bioactmat.2019.09.002

R. Teghil, M. Curcio, A. De Bonis, Substituted hydroxyapatite, glass, and glass-ceramic thin films deposited by nanosecond pulsed laser deposition (PLD) for biomedical applications: a systematic review. Coatings 11(7), 811 (2021). https://doi.org/10.3390/coatings11070811

G. Feifei, G. **, L. **aogang, Research progress on titanium-containing organic-inorganic hybrid protective coatings. Surf. Rev. Lett. 26(9), 1930002 (2019). https://doi.org/10.1142/S0218625X19300028

L.E. Valenti, L.V. Bonnet, M.R. Galiano, C.E. Giacomelli, A simple strategy to prepare hybrid coating on titanium (Ti6Al4V). Surf. Coat. Technol. 431, 128017 (2022). https://doi.org/10.1016/j.surfcoat.2021.128017

K.R. de Groot, R. Geesink, C.P.A.T. Klein, P. Serekian, Plasma sprayed coatings of hydroxylapatite. J. Biomed. Mater. Res. 21, 1375–1381 (1987). https://doi.org/10.1002/jbm.820211203

C.H. Mohammed, A review on different coating methods of hydroxyapatite on titanium implants. Int. J. Innov. Res. Sci. Eng. Tech. 6(4), 103–106 (2017)

T. Kokubo, H. Kushitani, S. Sakka, T. Kitsugi, T. Yamamuro, Solutions able to reproduce in vivo surface structure changes in bioactive glass-ceramic A-W. J. Biomed. Mater. Res. 24, 721–734 (1990). https://doi.org/10.1002/jbm.820240607

E. Palierse et al., Baicalein-modified hydroxyapatite nanoparticles and coatings with antibacterial and antioxidant properties. Mater. Sci. Eng. C 118, 111537 (2021). https://doi.org/10.1016/j.msec.2020.111537

A.C. Tas, S.B. Bhaduri, Rapid coating of Ti6Al4V at room temperature with a calcium phosphate solution similar to 10× simulated body fluid. J. Mater. Res. 19(9), 2742–2749 (2004). https://doi.org/10.1557/JMR.2004.0349

H.M. Kim, T. Miyazaki, T. Kokubo, T. Nakamura, Revised simulated body fluid. Key Eng. Mater. 192–195, 47–50 (2001). https://doi.org/10.4028/www.scientific.net/KEM.192-195.47

A. Oyane, H.M. Kim, T. Furuya, T. Kokubo, T. Miyazaki, T. Nakamura, Preparation and assessment of revised simulated body fluids. J. Biomed. Mater. Res. A 65, 188–195 (2003). https://doi.org/10.1002/jbm.a.10482

T. Kokubo, S. Yamaguchi, Chemical surface modification of a titanium scaffold, in Metallic Foam Bone. ed. by C. Wen (Elsevier, Cambridge, 2017), pp.161–179

T. Kokubo, S. Yamaguchi, Simulated body fluid and the novel bioactive materials derived from it. J. Biomed. Mater. Res. A 107(5), 968–977 (2019). https://doi.org/10.1002/jbm.a.36620

F. Li, Q.L. Feng, F.Z. Cui, H.D. Li, H. Schubert, A simple biomimetic method for calcium phosphate coating. Surf. Coat. Tech. 154, 88–93 (2002). https://doi.org/10.1016/S0257-8972(01)01710-8

P. Habibovic, F. Barrère, C.A. van Blitterswijk, K. de Groot, P. Layrolle, Biomimetic hydroxyapatite coating on metal implants. J. Am. Ceram. Soc. 85(3), 517–522 (2002). https://doi.org/10.1111/j.1151-2916.2002.tb00126.x

F. Barrére, C.A. van Blitterswijk, K. de Groot, P. Layrolle, Influence of ionic strength and carbonate on the Ca–P coating formation from SBFx5 solution. Biomaterials 23, 1921–1930 (2002). https://doi.org/10.1016/S0142-9612(01)00318-0

A. Bigi et al., Nanocrystalline hydroxyapatite coatings on titanium: a new fast biomimetic method. Biomaterials 26, 4085–4089 (2005). https://doi.org/10.1016/j.biomaterials.2004.10.034

S. Bharati, M.K. Sinha, D. Basu, Hydroxyapatite coating by biomimetic method on titanium alloy using concentrated SBF. Bull. Mater. Sci. 28(6), 617–621 (2005). https://doi.org/10.1007/BF02706352

L. Muller, F.A. Muller, Preparation of SBF with different HCO3- content and its influence on the composition of biomimetic apatites. Acta Biomater. 2, 181–189 (2006). https://doi.org/10.1016/j.actbio.2005.11.001

L. Morejón-Alonso, M.A. Bussulo, R. Debone, E. González-Martínez, J.E. González, Apatite coatings on chemically modified titanium using a new accelerated biomimetic route. Mater. Lett. 280, 128576 (2020). https://doi.org/10.1016/j.matlet.2020.128576

T. Kreller, F. Sahm, R. Bader, A.R. Boccaccini, A. Jonitz-Heincke, R. Detsch, Biomimetic calcium phosphate coatings for bioactivation of titanium implant surfaces: methodological approach and in vitro evaluation of biocompatibility. Materials. 14, 3516 (2021). https://doi.org/10.3390/ma14133516

M.D. Francis, N.C. Webb, Hydroxyapatite formation from a hydrated calcium monohydrogen phosphate precursor. Calc. Tiss. Res. 6, 335–342 (1971). https://doi.org/10.1007/bf02196214

D. Pham Minh, M. Galera Martínez, A. Nzihou, P. Sharrock, Thermal behavior of apatitic calcium phosphates synthesized from calcium carbonate and orthophosphoric acid or potassium dihydrogen orthophosphate. J. Therm. Anal. Calorim. (2013). https://doi.org/10.1007/s10973-012-2695-6

H.M. Kim, F. Miyaji, T. Kokubo, S. Nishiguri, T. Nakamura, Graded surface structure of bioactive titanium prepared by chemical treatment. J. Biomed. Mater. Res. 45(2), 100–107 (1999). https://doi.org/10.1002/(sici)1097-4636(199905)45:2%3C100::aid-jbm4%3E3.0.co;2-0

S. Tanaka, M. Aonuma, N. Hirose, T. Tanaki, The preparation of porous TiO2 by immersing Ti in NaOH solution. J. Electrochem. Soc. 149(11), D167–D171 (2002). https://doi.org/10.1149/1.1512672

H. Takadama, H.M. Kim, T. Kokubo, T. Nakamura, TEM-EDS study of mechanism of bonelike apatite formation on bioactive titanium metal in simulated body fluid. J. Biomed. Mater. Res. 57, 441–448 (2001). https://doi.org/10.1002/1097-4636(20011205)57:3%3C441::aid-jbm1187%3E3.0.co;2-b

S. Yamaguchi, P.T. Minh Le, M. Ito, S.A. Shintani, H. Takadama, Tri-functional calcium-deficient calcium titanate coating on titanium metal by chemical and heat treatment. Coatings 9(9), 561 (2019). https://doi.org/10.3390/coatings9090561

J. Forsgren, F. Svahn, T. Jarmar, H. Engqvist, Structural change of biomimetic hydroxyapatite coatings due to heat treatment. J. Appl. Biomater. Biomech. 5(1), 23–27 (2007). https://doi.org/10.1177/2F228080000700500103

D.K. Pattanayak, S. Yamaguchi, T. Matsushita, T. Nakamura, T. Kokubo, Apatite forming ability of titanium in terms of pH of the exposed solution. J. R. Soc. Interface 9, 2145–2155 (2012). https://doi.org/10.1098/2Frsif.2012.0107

ASTM C1624-05: Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramics Coatings by Quantitative Single Point Scratch Testing, 2005.

B. León, Pulsed laser deposition of thin calcium phosphate coatings, in Thin Calcium Phosphate Coatings for Medical Implants. ed. by B. León, J.A. Jansen (Springer, New York, 2009), pp.101–155

ASTM F 1044-05: Standard Test Method for Shear Testing of Calcium Phosphate Coatings and Metallic Coatings, 2005.

H.M. Kim, F. Miyaji, T. Kokubo, T. Nakamura, Bonding strength of bonelike apatite layer to Ti metal substrate. J. Biomed. Mater. Res. Appl. Biomater. 38, 121–127 (1997). https://doi.org/10.1002/(SICI)1097-4636(199722)38:2%3C121::AID-JBM6%3E3.0.CO;2-S

S.V. Dorozhkin, Calcium orthophosphate coatings, films and layers. Progress Biomater. 1(1), 1–40 (2012). https://doi.org/10.1186/2F2194-0517-1-1

S. Tiwari, S.B. Mishra, Post annealing effect on corrosion behavior, bacterial adhesion, and bioactivity of LVOF sprayed hydroxyapatite coating. Surf. Coat. Technol. 405, 126500 (2021). https://doi.org/10.1016/j.surfcoat.2020.126500

E. Zhang, Y. Wang, F. Gao, S. Wei, Y. Zheng, Enhanced bioactivity of sandblasted and acid-etched titanium surfaces. Adv. Mater. Res. 79–82, 393–396 (2009). https://doi.org/10.4028/www.scientific.net/AMR.79-82.393

J.E. González, A. Paz, D. Fernández, Procedimiento para la obtención de un recubrimiento apatítico denso y producto resultante. CU 23613 A1, 2010.

T. Kokubo, H. Takadama, How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27, 2907–2915 (2006). https://doi.org/10.1016/j.biomaterials.2006.01.017

V. Galván, G. Castellano, S.R. Bertolino, Quantification by SEM–EDS in uncoated non-conducting samples. Radiat. Phys. Chem. 88, 32–37 (2013). https://doi.org/10.1016/j.radphyschem.2013.03.033

Fumero et al., Diseño y fabricación de un equipo para medir adherencia por rayado. Ing. Mech. 21(3), 124–129 (2018)

B. Ollivier, A. Matthews, Adhesion of diamond-like carbon films on polymers: an assessment of the validity of the scratch test technique applied to flexible substrates. J. Adh. Sci. Tech. 8(6), 651–662 (1994). https://doi.org/10.1163/156856194X0040

Acknowledgments

To Alejandro Ortega-Rodés for the help provided in the composition and editing of images and figures. Also, to the Department of Metallurgy and Materials Engineering (MTM), KU Leuven, for the assistance in the cross sections characterization.

Funding

This work was supported by the National Program National of Science, Technology and Innovation (PN211LH008-044) of the Cuban Ministry of Science, Technology and Environment (CITMA).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have conflict of interest or competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Morejón-Alonso, L., Bussulo, M.A., Pérez, A.F. et al. Accelerated biomimetic nanosized apatite coatings deposition on alkali treated titanium. Journal of Materials Research 37, 4200–4210 (2022). https://doi.org/10.1557/s43578-022-00786-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00786-w