Abstract

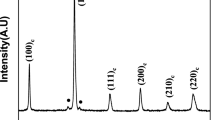

The phase evolution, nucleation, and sintered ceramics of barium titanate (BaTiO3, BT) powder prepared by solid-state synthesis with an ultrafine starting material (27 m2/g of BaCO3 and 190 m2/g of TiO2) were investigated in this study. Surface diffusion between BaCO3 and TiO2 was observed at a relatively low temperature of 400 °C by transmission electron microscopy. Rapid nucleation of the BT and cubic BT phases was observed at 500 °C by x-ray diffraction. The derivative thermogravimetry curve clearly shows a single step of BT formation at 600 °C. In short, pure BT particles with an average particle size of 250 nm and high tetragonality were prepared by solid-state synthesis, which produced X7R ceramics with high dielectric permittivity, high insulation resistance, and a clear core–shell structure.

Similar content being viewed by others

References

C. Pithan, D. Hennings, and R. Waser: Progress in the synthesis of nanocrystalline BaTiO3 powders for MLCC. Int. J. Appl. Ceram. Technol. 2, 1 (2005).

H. Kishi, Y. Mizuno, and H. Chazono: Base-metal electrode-multilayer ceramic capacitors: Past, present and future perspectives. Jpn. J. Appl. Phys. 42, 1 (2003).

C.A. Randall: Scientific and engineering issues of the state-of-art and future multilayer ceramic capacitors. J. Ceram. Soc. Jpn. 109, S2 (2001).

T. Tsurumi, T. Sekine, H. Kakemoto, T. Hoshina, S.M. Nam, H. Yasuno, and S. Wada: Evaluation and statistical analysis of dielectric permittivity of BaTiO3 powders. J. Am. Ceram. Soc. 89, 1337 (2006).

Y. Mizuno, T. Hagiwara, and H. Kishi: Microstructural design of dielectrics for Ni-MLCC with ultra-thin active layers. J. Ceram. Soc. Jpn. 115, 360 (2007).

W. Trzebiatowski, J. Wojciechowska, and J. Damm: Mechanism of synthesis of barium titanate. Roczniki Chem. 26, 12 (1952).

T. Kubo, and K. Shinriki: Chemical reaction in the solid state: III, Reaction between BaCO3 and TiO2 in solid state. J. Chem. Soc. Jpn. 55, 49 (1952).

T. Kubo, and K. Shinriki: Chemical reaction in the solid state: IV, Interface of moisture and carbon dioxide on formation of various barium titanates. J. Chem. Soc. Jpn. 55, 137 (1952).

L.K. Templeton, and J.A. Pask: Formation of BaTiO3 from BaCO3 and TiO2 in air and in CO2. J. Am. Ceram. Soc. 42, 212 (1959).

A. Beauger, J.C. Mutin, and J.C. Niepce: Synthesis reaction of metatitanate BaTiO3. Part 1. Effect of the gaseous atmosphere upon the thermal evolution of the system BaCO3–TiO2. J. Mater. Sci. 18, 3041 (1983).

A. Beauger, J.C. Mutin, and J.C. Niepce: Synthesis reaction of metatitanate BaTiO3. Part 2. Study of solid-solid reaction interfaces. J. Mater. Sci. 18, 3543 (1983).

A. Amin, M.A. Spears, and B.M. Kulwicki: Reaction of anatase and rutile with barium carbonate. J. Am. Ceram. Soc. 66, 733 (1983).

W. Hertl: Kinetics of barium titanate synthesis. J. Am. Ceram. Soc. 71, 879 (1988).

J.C. Niepce, and G. Thomas: About the mechanism of the solid way synthesis of barium metatitanate. Industrial consequences. Solid State Ionics 43, 69 (1990).

M. Rössel, H.R. Höche, H.S. Leipner, D. Völtzke, H.P. Abicht, O. Hollricher, J. Müller, and S. Gablenz: Raman microscopic investigations of BaTiO3 precursors with core-shell structure. Anal. Bioanal.Chem. 380, 157 (2004).

K. Kobayashi, T. Suzuki, and Y. Mizuno: Microstructure analysis of solid-state reaction in synthesis of BaTiO3 powder using transmission electron microscope. Appl. Phys. Express 1, 041602 (2008).

T.T. Lee, C.Y. Huang, C.Y. Chang, S.P. Lin, C.Y. Su, C.T. Lee, and M. Fujimoto: Phase evolution and nucleus growth observation of solid-state BaTiO3 powder prepared by high-energy bead milling for raw material mixing. Jpn. J. Appl. Phys. 50, 091502 (2011).

W.S. Lee, D.F.K. Hennings, and T.Y. Tseng: Effect of calcination temperature and A/B-ratio on dielectric properties of (Ba, Ca)(Ti, Zr, Mn)O3 multilayer capacitors with Ni electrodes. J. Am. Ceram. Soc. 83, 1402 (2000).

D. Hennings, Seriyati B. Schreinemacher, and H. Schreinemacher: Solid–state preparation of BaTiO3-based dielectrics using ultrafine raw materials. J. Am. Ceram. Soc. 84, 2777 (2001).

C. Ando, R. Yanagawa, H. Chazono, H. Kishi, and M. Senna: Nuclei-growth optimization for fine-grained BaTiO3 by precision-controlled mechanical pretreatment of starting powder mixture. J. Mater. Res. 19, 3592 (2004).

R. Yanagawa, M. Senna, C. Ando, H. Chazono, and H. Kishi: Preparation of 200 nm BaTiO3 particles with their tetragonality 1.010 via a solid-state reaction preceded by agglomeration-free mechanical activation. J. Am. Ceram. Soc. 90, 809 (2007).

M.T. Buscaglia, M. Bassoli, V. Buscaglia, and R. Alessio: Solid-state synthesis of ultrafine BaTiO3 powders from nanocrystalline BaCO3 and TiO2. J. Am. Ceram. Soc. 88, 2374 (2005).

M.T. Buscaglia, M. Bassoli, V. Buscaglia, and R. Vormberg: Solid-state synthesis of nanocrystalline BaTiO3: Reaction kinetics and powder properties. J. Am. Ceram. Soc. 91, 2862 (2008).

D. Hennings, and G. Rosenstein: Temperature-stable dielectrics based on chemically inhomogeneous BaTiO3. J. Am. Ceram. Soc. 67, 249 (1984).

H. Kishi, Y. Okino, M. Honda, Y. Iguchi, M. Imada, Y. Takahashi, H. Ohsato, and T. Kuda: The effect of MgO and rare-earth oxide on formation behavior of core-shell structure in BaTiO3. Jpn. J. Appl. Phys. 36, 5954 (1997).

C.A. Randall, S.F. Wang, D. Laubscher, J.P. Dougherty, and W. Huebner: Structure property relationships in core-shell BaTiO3–LiF ceramics. J. Mater. Res. 8, 871 (1993).

T. Wang, X.H. Wang, H. Wen, and L.T. Li: Effect of milling process on the core-shell structures and dielectric properties of fine-grained BaTiO3-based X7R ceramic materials. Int. J. Miner. Metall. Mater. 16, 345 (2009).

D. Hennings: Barium titanate based ceramic materials for dielectric use. Int. J. High Technol. Ceram. 3, 91 (1986).

H. Chazono, and M. Fujimoto: Sintering characteristics and formation mechanisms of ‘core-shell’ structure in BaTiO3-Nb2O5-Co3O5 ternary system. Jpn. J. Appl. Phys. 34, 5354 (1995).

ACKNOWLEDGMENTS

T-T.L. would like to thank Yageo Corporation for supporting the Ph.D. program. This work was supported by the National Science Council of Taiwan under Contract No. NSC 100-2221-E-006-134-MY3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, TT., Chang, CY., Huang, CY. et al. Phase evolution of solid-state BaTiO3 powder prepared with the ultrafine BaCO3 and TiO2. Journal of Materials Research 27, 2495–2502 (2012). https://doi.org/10.1557/jmr.2012.255

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.255