Abstract

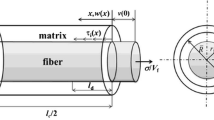

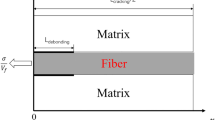

Fiber coatings have been used to modify fiber-matrix interfacial forces, and thus control mechanical properties of continuous fiber ceramic composites. It has been shown that the properties and thickness of the interlayer influence composite properties such as matrix cracking and ultimate strength, toughness and interlaminar shear. The effects of fiber coating properties and thickness on fiber-reinforced SiC matrix composites fabricated employing CVI techniques have been examined. Correlations between interface condition, mechanical properties and failure mechanisms have been made.

Similar content being viewed by others

References

R. A. Lowden, “Fiber Coatings and the Mechanical Properties of a Fiber-Reinforced Ceramic Composite,” pp. 619–630 in Ceramic Transactions, Vol.19, Advanced Composite Materials, ed. by Michael D. Sacks, The American Ceramic Society, Westerville, Ohio (1991).

R. A. Lowden, “Interface Effects and Fracture in Nicalon/SiC Composites,” pp.97–114 in the Proceedings of the Fourth Annual Conference on Fossil Energy Materials, ed. by R. Judkins, Oak Ridge, TN, May 15–17, 1990.

R. A. Lowden, Characterization and Control of the Fiber-Matrix Interface in Ceramic Matrix Composites, ORNL/TM-11039, March 1989.

R. A. Lowden and D. P. Stinton, “Interface Modification in Nicalon/SiC Composites,”Ceram. Eng. Sci. Proc. 9, 705–722 (1989).

R. A. Lowden and D. P. Stinton, The Influence of the Fiber-matrix Bond on the Mechanical Behavior of Nicalon/SiC Composites, ORNL/TM-10667, December 1987.

C. H. Hsueh, P. F. Becher, and P. Angelini, “Effects of Interfacial Films on Thermal Stresses in Whisker-Reinforced Ceramics,” J. Am. Ceram. Soc. 71(11), 929–933 (1988).

C. H. Hsueh, “Analytical Evaluation of Interfacial Shear Strength for Fiber-Reinforced Ceramic Composites,” J. Am. Ceram. Soc. 71(6), 490–93 (1988).

E. Lara-Curzio, M. K. Ferber, and R. A. Lowden, “The Effects of Fiber Coating Thickness on the Interfacial Properties of a Continuous Fiber Ceramic Matrix Composite,” Unpublished, 1994

D. P. Stinton, A. J. Caputo, and R. A. Lowden, “Synthesis of Fiber-Reinforced SiC Composites by Chemical Vapor Infiltration,” Am. Ceram. Soc. Bull. 65(2), 347–50 (1986).

D. P. Stinton, W. J. Lackey, R. J. Lauf, and T. M. Besmann, “Fabrication of Ceramic-Ceramic Composites by Chemical Vapor Deposition,” Ceram. Eng. Sci. Proc. 5, 668–76 (1984).

T. M. Besmann, B. W. Sheldon, R. A. Lowden, and D. P. Stinton, “Vapor Phase Fabrication and Properties of Continuous-Filament Ceramic Composites,” Science 253, 1104 (1991).

A. J. Caputo and W. J. Lackey, “Fabrication of Fiber-Reinforced Composites by Chemical Vapor Infiltration,” Ceram. Eng. Sci. Proc. 5, 654–67 (1984).

M. Bouquet, J. M. Bribis, and J. M. Quenisset, “Toughness Assessment of Ceramic Matrix Composites,” Composites Science and Technology 37, 223–248 (1990).

H. H. Moeller, “Determining Fracture Toughness Using The Chevron Notch Technique,” unpublished (1991).

D. G. Munz, J. L. Shannon jr., and R. T. Bibsey, “Fracture Toughness Calculation from Maximum Load in Four Point Flexure Tests of Chevron Notch Specimens,” Int. J. Fracture February (1980).

T. T. Shih, “Chevron V-Notch Bend Specimen for Klc, Measurement of Brittle Materials,” J. Testing and Evaluation, 9 (1) 50–55 (1981).

J. C. Newman, “A Review of Chevron-Notched Fracture Specimens,” Chevron-Notched Specimens: Testing and Stress Analysis, ASTM STP 855, J. H. Underwood, S. W. Freiman, and F. I. Baratta, Eds., American Society for Testing and Materials, Philadelphia, 1984, pp.5–31.62.

M. G. Jenkins, A. S. Kobayashi, K. W. White, and R. C. Brandt, “A 3-D Finite Element Analysis of a Chevron Notched, Three Point Bend Fracture Specimen for Ceramic Materials,”International Journal of Fracture 34:281–295 (1987).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Miller, J.H., Lowden, R.A. & Liaw, P.K. Fiber Coatings and the Fracture Behavior of a Continuous Fiber Ceramic Composite. MRS Online Proceedings Library 365, 403–410 (1994). https://doi.org/10.1557/PROC-365-403

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-365-403