Abstract

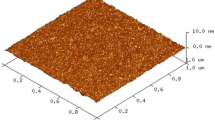

Al-based high-aspect-ratio microscale structures (HARMS) are basic building blocks for all-Al microdevices. Bonding of Al-based HARMS is essential for device assembly. In this paper, bonding of Al-based HARMS to flat Al plates using Al-Ge thin film intermediate layers is investigated. The structure of sputter codeposited Al-Ge thin films was studied by high-resolution transmission electron microscopy as a function of the average film composition. The structure of the interface region between Al-based HARMS bonded to flat Al plates is studied by combining focused ion beam sectioning and scanning electron microscopy. An extended bonding interface region, ∼100 μm in width, is observed and suggested to result from liquidus/solidus reactions as well as diffusion of Ge in solid Al at the bonding temperature of 500 °C. The extended interface region is suggested to be beneficial to Al-Al bonding via Al-Ge intermediate layers.

Similar content being viewed by others

References

M. Tanaka: An industrial and applied review of new MEMS devices features. Microelectron. Eng. 84, (5-8) 1341 (2007)

N. Miki: Wafer bonding techniques for MEMS. Sensor Letters 3, (4) 263 (2005)

S.H. Christiansen, R. Singh, U. Gosele: Wafer direct bonding: From advanced substrate engineering to future applications in micro/nano electronics. IEEE Proc. 94, (12) 2060 (2006)

K.M. Knowles, A.T.J. van Helvoort: Anodic bonding. Int. Mater. Rev. 51, (5) 273 (2006)

A. Gerlach, D. Maas, D. Seidel, H. Bartuch, S. Schundau, K. Kaschlik: Low-temperature anodic bonding of silicon to silicon wafers by means of intermediate glass layers. Microsyst. Technol. 5, (3) 144 (1999)

H. Takagi, K. Kikuchi, R. Maeda, T.R. Chung, T. Suga: Surface activated bonding of silicon wafers at room temperature. Appl. Phys. Lett. 68, (16) 2222 (1996)

M. Gabriel, B. Johnson, R. Suss, M. Reiche, M. Eichler: Wafer direct bonding with ambient pressure plasma activation. Microsyst. Technol. 12, (5) 397 (2006)

G. Kelly, A. Morrissey, J. Alderman, H. Camon: 3-D packaging methodologies for microsystems. IEEE Trans. Adv. Packag. 23, (4) 623 (2000)

J.D. Williams, W. Wang: Microfabrication of an electromagnetic power relay using SU-8 based UV-LIGA technology. Microsyst. Technol. 10, (10) 699 (2004)

F. Mei, P.R. Parida, J. Jiang, W.J. Meng, S.V. Ekkad: Fabrication, assembly, and testing of Cu- and Al- based microchannel heat exchangers. J. Microelectromech. Syst. 17, (4) 869 (2008)

M. Madou: Fundamentals of Microfabrication(CRC Press Boca Raton, FL 2000)

A. Bhushan, D. Yemane, E.B. Overton, J. Goettert, M.C. Murphy: Fabrication and preliminary results for LiGA fabricated nickel micro gas chromatograph columns. J. Microelectromech. Syst. 16, (2) 383 (2007)

D.M. Cao, W.J. Meng, K.W. Kelly: High-temperature instrumented microscale compression molding of Pb. Microsyst. Technol. 10, 323 (2004)

D.M. Cao, W.J. Meng: Microscale compression molding of Al with surface engineered LiGA inserts. Microsyst. Technol. 10, 662 (2004)

J. Jiang, F. Mei, W.J. Meng, E. Lara-Curzio: Microscale molding replication of Cu- and Ni-based structures. Microsyst. Technol. 14, 1731 (2008)

J.F. Lancaster: Metallurgy of Welding(Chapman and Hall London 1993)

A.L. Tiensuu, M. Bexell, J.A. Schweitz, L. Smith, S. Johansson: Assembling three-dimensional microstructures using gold-silicon eutectic bonding. Sens. Actuators, A 45, 227 (1994)

T.B. Massalski: Binary Alloy Phase Diagrams(ASM, Metals ParkOH 1986)116

B. Vu, P.M. Zavracky: Patterned eutectic bonding with Al/Ge thin films for microelectromechanical systems. J. Vac. Sci. Technol. B 14, (4) 2588 (1996)

F. Mei, J. Jiang, W.J. Meng: Eutectic bonding of Al-based high aspect ratio microscale structures. Microsyst. Technol. 13, 723 (2007)

F. Mei, J. Jiang, W.J. Meng: Evaluation of eutectic bond strength and assembly of Al-based microfluidic structures. Microsyst. Technol. 14, 99 (2007)

C.D. Adams, M. Atzmon, Y.T. Cheng, D.J. Srolovitz: Phase-separation during codeposition of Al-Ge thin-films. J. Mater. Res. 7, (3) 653 (1992)

W.J. Meng, T.J. Curtis, L.E. Rehn, P.M. Baldo: Temperature dependence of inductively coupled plasma assisted deposition of titanium nitride coatings. Surf. Coat. Technol. 120/121, 206 (1999)

W.J. Meng, E.I. Meletis, L.E. Rehn, P.M. Baldo: Inductively-coupled plasma assisted deposition and mechanical properties of metal-free and Ti-containing hydrocarbon coatings. J. Appl. Phys. 87, 2840 (2000)

B. Shi, W.J. Meng, L.E. Rehn, P.M. Baldo: Intrinsic stress development in Ti-C:H ceramic nanocomposite coatings. Appl. Phys. Lett. 81, 352 (2002)

C.D. Adams, M. Atzmon, Y.T. Cheng, D.J. Srolovitz: Transition from lateral to transverse phase-separation during film codeposition. Appl. Phys. Lett. 59, (20) 2535 (1991)

K.M. Unruh, C.L. Chien: Magnetic properties and hyperfine interactions in amorphous Fe-Zr alloys. Phys. Rev. B: Condens. Matter. 30, (9) 4968 (1984)

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials(Wiley New York 1996)

S.S. Lau, W.F. van der Weg: Solid phase epitaxy Thin Films—Interdiffusion and Reactions edited by J.M. Poate, K.N. Tu, and J.W. Mayer (Wiley New York 1978)

A. Thurer, G. Rummel, T. Zumkley, K. Freitag, H. Mehrer: Temperature and pressure dependence of Ge diffusion in aluminum. Phys. Status Solidi A 149, 535 (1995)

G. Raghavan, G.V. Rao, G. Amarendra, A.K. Tyagi, B. Viswanathan: Study of interdiffusion and defect evolution in thin film Al/Ge bilayers using SIMS and positron beam. Appl. Surf. Sci. 178, 75 (2001)

J. Crank: The Mathematics of Diffusion(Oxford University Press London 1975)

K. Kaneko, K. Inoke, K. Sato, K. Kitawaki, H. Higashida, I. Arslan, P.A. Midgley: TEM characterization of Ge precipitates in an Al–1.6 at.% Ge alloy. Ultramicroscopy 108, 210 (2008)

Acknowledgment

F. Mei and W.J. Meng gratefully acknowledge partial project support from the National Science Foundation (Grant CMMI-0556100) and Louisiana Board of Regents [Contract LEQSF(2008-10)-RD-B-02]. The FIB work was conducted at the Electron Microscopy Center of Argonne National Laboratory and sponsored by the Department of Energy under the national user program. Discussions with Prof. G.Y. Li of Shanghai Jiao Tung University of China are acknowledged with thanks.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mei, F., Meng, W., Hiller, J. et al. Structure of vapor-phase deposited Al-Ge thin films and Al-Ge intermediate layer bonding of Al-based microchannel structures. Journal of Materials Research 24, 544–555 (2009). https://doi.org/10.1557/JMR.2009.0055

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2009.0055