Abstract

Unexpected cross-contamination by foreign components during the manufacturing and quality control of pharmaceutical products poses a serious threat to the stable supply of drugs and the safety of customers. In Japan, in 2020, a mix-up containing a slee** drug went undetected by liquid chromatography during the final quality test because the test focused only on the main active pharmaceutical ingredient (API) and known impurities. In this study, we assessed the ability of a powder rheometer to analyze powder characteristics in detail to determine whether it can detect the influence of foreign APIs on powder flow. Aspirin, which was used as the host API, was combined with the guest APIs (acetaminophen from two manufacturers and albumin tannate) and subsequently subjected to shear and stability tests. The influence of known lubricants (magnesium stearate and leucine) on powder flow was also evaluated for standardized comparison. Using microscopic morphological analysis, the surface of the powder was observed to confirm physical interactions between the host and guest APIs. In most cases, the guest APIs were statistically detected due to characteristics such as their powder diameter, pre-milling, and cohesion properties. Furthermore, we evaluated the flowability of a formulation incorporating guest APIs for direct compression method along with additives such as microcrystalline cellulose, potato starch, and lactose. Even in the presence of several additives, the influence of the added guest APIs was successfully detected. In conclusion, powder rheometry is a promising method for ensuring stable product quality and reducing the risk of unforeseen cross-contamination by foreign APIs.

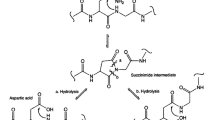

Graphical Abstract

Similar content being viewed by others

Data Availability

Data sets generated during the current study are available from the corresponding author on reasonable request.

References

ICH Harmonised Tripartite Guideline. Good Manufacturing Practice Guide For Active Pharmaceutical Ingredients Q7. https://www.pmda.go.jp/int-activities/int-harmony/ich/0047.html. Accessed 9 Jan 2024.

ICH Harmonised Tripartite Guideline. Pharmaceutical Development Q8 (R2) https://www.pmda.go.jp/int-activities/int-harmony/ich/0048.html. Accessed 9 Jan 2024.

Liu Y, Fernandez J, Pu Z, Zhang H, Cao L, Aguilar I, et al. Simultaneous monitoring and comparison of multiple product quality attributes for cell culture processes at different scales using a LC/MS/MS based Multi-attribute Method. J Pharm Sci. 2020;109(11):3319–29. https://doi.org/10.1016/j.xphs.2020.07.029.

Jallo LJ, Ghoroi C, Gurumurthy L, Patel U, Dave RN. Improvement of flow and bulk density of pharmaceutical powders using surface modification. Int J Pharm. 2012;423(2):213–25. https://doi.org/10.1016/j.ijpharm.2011.12.012.

Tran DT, Majerova D, Vesely M, Kulaviak L, Ruzicka MC, Zamostny P. On the mechanism of colloidal silica action to improve flow properties of pharmaceutical excipients. Int J Pharm. 2019;556:383–94. https://doi.org/10.1016/j.ijpharm.2018.11.066.

Macho O, Gabrisova L, Brokesova J, Svacinova P, Muzikova J, Galbava P, et al. Systematic study of Paracetamol powder mixtures and granules tabletability: key role of rheological properties and dynamic image analysis. Int J Pharm. 2021;608:14. https://doi.org/10.1016/j.ijpharm.2021.121110.

Pielenhofer J, Meiser SL, Gogoll K, Ciciliani AM, Denny M, Klak M, et al. Quality by Design (QbD) Approach for a Nanoparticulate Imiquimod Formulation as an investigational Medicinal product. Pharmaceutics. 2023;15(2). https://doi.org/10.3390/pharmaceutics15020514.

Wang YF, Snee RD, Meng W, Muzzio FJ. Predicting flow behavior of pharmaceutical blends using shear cell methodology: a quality by design approach. Powder Technol. 2016;294:22–9. https://doi.org/10.1016/j.powtec.2016.01.019.

Yamashita H, Sun CC. Material-sparing and expedited development of a tablet formulation of carbamazepine glutaric acid cocrystal- a QbD approach. Pharm Res. 2020;37(8):10. https://doi.org/10.1007/s11095-020-02855-3.

Takagaki K, Ito T, Arai H, Obata Y, Takayama K, Onuki Y. The usefulness of definitive screening design for a quality by design approach as demonstrated by a pharmaceutical study of orally disintegrating tablet. Chem Pharm Bull. 2019;67(10):1144–51. https://doi.org/10.1248/cpb.c19-00553.

Wax PM. Elixirs, diluents, and the passage of the 1938 federal food, drug and cosmetic act. Ann Intern Med. 1995;122(6):456–61. https://doi.org/10.7326/0003-4819-122-6-199503150-00009.

Ballentine C. Sulfanilamide Disaster. FDA Consumer magazine. U.S. Food and Drug Administration; 1981.

The Japanese Pharmacopoeia 18th edition. The Minister of Health, Labour and Welfare after hearing the opinion of the Pharmaceutical Affairs and Food Sanitation Council (PAFSC). https://www.pmda.go.jp/english/rs-sb-std/standards-development/jp/0029.html. Accessed 9 Jan 2024.

Tsuchiya M, Obara T, Mano N. Itraconazole contaminated with Rilmazafone in Japan: a retrospective analysis using the Japanese adverse drug Event Report Database. Drugs-Real World Outcomes. 2022;9(3):315–9. https://doi.org/10.1007/s40801-022-00306-6.

Izutsu K, Ando D, Morita T, Abe Y, Yoshida H. Generic drug shortage in Japan: GMP Noncompliance and Associated Quality issues. J Pharm Sci. 2023;112(7):1763–71. https://doi.org/10.1016/j.xphs.2023.03.006.

Dudhat SM, Kettler CN, Dave RH. To study cap** or lamination tendency of tablets through evaluation of Powder Rheological properties and Tablet Mechanical properties of directly compressible blends. AAPS PharmSciTech. 2017;18(4):1177–89. https://doi.org/10.1208/s12249-016-0576-1.

Hwang KM, Kim SY, Nguyen TT, Cho CH, Park ES. Use of roller compaction and fines recycling process in the preparation of erlotinib hydrochloride tablets. Eur J Pharm Sci. 2019;131:99–110. https://doi.org/10.1016/j.ejps.2019.01.036.

Kosugi A, Leong KH, Tsuji H, Hayashi Y, Kumada S, Okada K, et al. Characterization of powder- and Tablet properties of different direct compaction grades of Mannitol using a Kohonen Self-organizing map and a Lasso Regression Model. J Pharm Sci. 2020;109(8):2585–93. https://doi.org/10.1016/j.xphs.2020.05.010.

Osorio JG, Muzzio FJ. Effects of powder flow properties on capsule filling weight uniformity. Drug Dev Ind Pharm. 2013;39(9):1464–75. https://doi.org/10.3109/03639045.2012.728227.

Podczeck F, Newton JM. Powder and capsule filling properties of lubricated granulated cellulose powder. Eur J Pharm Biopharm. 2000;50(3):373–7. https://doi.org/10.1016/s0939-6411(00)00100-4.

Agarwal V, Siddiqui A, Ali H, Nazzal S. Dissolution and powder flow characterization of solid self-emulsified drug delivery system (SEDDS). Int J Pharm. 2009;366(1–2):44–52. https://doi.org/10.1016/j.ijpharm.2008.08.046.

Kinnunen H, Hebbink G, Peters H, Shur J, Price R. An investigation into the effect of fine lactose particles on the fluidization behaviour and aerosolization performance of carrier-based dry powder inhaler formulations. AAPS PharmSciTech. 2014;15(4):898–909. https://doi.org/10.1208/s12249-014-0119-6.

Zhao ZY, Wang GL, Huang ZW, Huang Y, Chen HP, Pan X, et al. Dry powder inhalers based on Chitosan-Mannitol Binary Carriers: Effect of the powder properties on the aerosolization performance. AAPS PharmSciTech. 2022;23(5):11. https://doi.org/10.1208/s12249-022-02287-9.

Cordts E, Steckel H. Capabilities and limitations of using powder rheology and permeability to predict dry powder inhaler performance. Eur J Pharm Biopharm. 2012;82(2):417–23. https://doi.org/10.1016/j.ejpb.2012.07.018.

Zhao ZY, Huang ZW, Zhang XJ, Huang Y, Cui YT, Ma C, et al. Low density, good flowability cyclodextrin-raffinose binary carrier for dry powder inhaler: anti-hygroscopicity and aerosolization performance enhancement. Expert Opin Drug Deliv. 2018;15(5):443–57. https://doi.org/10.1080/17425247.2018.1450865.

Hertel M, Schwarz E, Kobler M, Hauptstein S, Steckel H, Scherliess R. Powder flow analysis: a simple method to indicate the ideal amount of lactose fines in dry powder inhaler formulations. Int J Pharm. 2018;535(1–2):59–67. https://doi.org/10.1016/j.ijpharm.2017.10.052.

Sun Y, Qin L, Liu C, Su J, Zhang X, Yu D, et al. Exploring the influence of drug content on DPI powder properties and potential prediction of pulmonary drug deposition. Int J Pharm. 2020;575:10. https://doi.org/10.1016/j.ijpharm.2019.119000.

Liu TT, Tong SQ, Liao QQ, Cheng MS, Cun DM, Yang MS. Role of dispersion enhancer selection in the development of novel tratinterol hydrochloride dry powder inhalation formulations. Int J Pharm. 2023;635:8. https://doi.org/10.1016/j.ijpharm.2023.122702.

Lu XY, Chen L, Wu CY, Chan HK, Freeman T. The effects of relative humidity on the flowability and dispersion performance of Lactose mixtures. Materials. 2017;10(6):9. https://doi.org/10.3390/ma10060592.

Liu X, Drakontis C, Amin S. Designing high-performance colour cosmetics through optimization of powder flow characteristics. Int J Cosmet Sci. 2020;42(2):208–16. https://doi.org/10.1111/ics.12608.

Ajayi OM, Amin S. Flow and performance effects of talc alternatives on powder cosmetic formulations. Int J Cosmet Sci. 2021;43(5):588–600. https://doi.org/10.1111/ics.12733.

Chaudhari SP, Dave RH. To prepare and characterize microcrystalline cellulose granules using water and isopropyl alcohol as granulating agents and determine its end-point by thermal and rheological tools. Drug Dev Ind Pharm. 2015;41(5):744–52. https://doi.org/10.3109/03639045.2014.900080.

Tay JYS, Kok BWT, Liew CV, Heng PWS. Effects of particle surface roughness on In-Die Flow and Tableting Behavior of Lactose. J Pharm Sci. 2019;108(9):3011–9. https://doi.org/10.1016/j.xphs.2019.04.028.

Zhou Q, Armstrong B, Larson I, Stewart PJ, Morton DAV. Improving Powder Flow properties of a cohesive Lactose Monohydrate Powder by Intensive Mechanical Dry Coating. J Pharm Sci. 2010;99(2):969–81. https://doi.org/10.1002/jps.21885.

Jenike AW. Storage and flow of solids. University of Utah. Bulletin no. 123; 1964.

Mariano M. General aspects of powder rheology applied to pharmaceutical formulations. Drug Discov Today. 2024;29(5):103976. https://doi.org/10.1016/j.drudis.2024.103976.

Wei GG, Mangal S, Denman J, Gengenbach T, Bonar KL, Khan RI, et al. Effects of coating materials and processing conditions on flow enhancement of cohesive acetaminophen powders by high-shear processing with pharmaceutical lubricants. J Pharm Sci. 2017;106(10):3022–32. https://doi.org/10.1016/j.xphs.2017.05.020.

Shah RB, Tawakkul MA, Khan MA. Comparative evaluation of flow for pharmaceutical powders and granules. AAPS PharmSciTech. 2008;9(1):250–8. https://doi.org/10.1208/s12249-008-9046-8.

Lindberg NO, Pålsson M, Pihl AC, Freeman R, Freeman T, Zetzener H, et al. Flowability measurements of pharmaceutical powder mixtures with poor flow using five different techniques. Drug Dev Ind Pharm. 2004;30(7):785–91. https://doi.org/10.1081/ddc-120040343.

Shier AP, Kumar A, Mercer A, Majeed N, Doshi P, Blackwood DO, et al. Development of a predictive model for gravimetric powder feeding from an API-rich materials properties library. Int J Pharm. 2022;625:13. https://doi.org/10.1016/j.ijpharm.2022.122071.

Deng T, Garg V, Diaz LP, Markl D, Brown C, Florence A, et al. Comparative studies of powder flow predictions using milligrams of powder for identifying powder flow issues. Int J Pharm. 2022;628:11. https://doi.org/10.1016/j.ijpharm.2022.122309.

Navaneethan CV, Missaghi S, Fassihi R. Application of powder rheometer to determine powder flow properties and lubrication efficiency of pharmaceutical particulate systems. AAPS PharmSciTech. 2005;6(3):7.

Luukkonen P, Schæfer T, Podczeck F, Newton M, Hellén L, Yliruusi J. Characterization of microcrystalline cellulose and silicified microcrystalline cellulose wet masses using a powder rheometer. Eur J Pharm Sci. 2001;13(2):143–9. https://doi.org/10.1016/s0928-0987(00)00197-4.

Majerová D, Kulaviak L, Ruzicka M, Stepánek F, Zámostny P. Effect of colloidal silica on rheological properties of common pharmaceutical excipients. Eur J Pharm Biopharm. 2016;106:2–8. https://doi.org/10.1016/j.ejpb.2016.04.025.

Li JY, Ma SB, Sun Y, Song RX, Cai BL, Li H, et al. Predicting in vitro lung deposition behavior of combined dry powder inhaler via rheological properties. Eur J Pharm Biopharm. 2022;181:195–206. https://doi.org/10.1016/j.ejpb.2022.11.012.

Jüptner A, Scherliess R. Spray dried formulations for inhalation-meaningful characterisation of powder properties. Pharmaceutics. 2020;12(1):15. https://doi.org/10.3390/pharmaceutics12010014.

Yan ZL, Wilkinson SK, Stitt EH, Marigo M. Investigating mixing and segregation using discrete element modelling (DEM) in the Freeman FT4 rheometer. Int J Pharm. 2016;513(1–2):38–48. https://doi.org/10.1016/j.ijpharm.2016.08.065.

Suhaidi D, Dong YD, Wynne P, Hapgood KP, Morton DAV. Bulk flow optimisation of amorphous solid dispersion excipient powders through surface modification. Pharmaceutics. 2023;15(5):26. https://doi.org/10.3390/pharmaceutics15051447.

Narang AS, Sheverev V, Freeman T, Both D, Stepaniuk V, Delancy M, et al. Process analytical technology for high shear wet granulation: Wet mass consistency reported by in-line drag flow force sensor is consistent with powder rheology measured by At-Line FT4 powder Rheometer®. J Pharm Sci. 2016;105(1):182–7. https://doi.org/10.1016/j.xphs.2015.11.030.

Trivedi MR, Dave RH. To study physical compatibility between dibasic calcium phosphate and cohesive actives using powder rheometer and thermal methods. Drug Dev Ind Pharm. 2014;40(12):1585–96. https://doi.org/10.3109/03639045.2013.838576.

Huang YS, Medina-Gonzalez S, Straiton B, Keller J, Marashdeh Q, Gonzalez M, et al. Real-time monitoring of powder mass flowrates for plant-wide control of a continuous direct compaction tablet manufacturing process. J Pharm Sci. 2022;111(1):69–81. https://doi.org/10.1016/j.xphs.2021.06.005.

Ono T, Yonemochi E. Evaluation of the physical properties of dry surface-modified ibuprofen using a powder rheometer (FT4) and analysis of the influence of pharmaceutical additives on improvement of the powder flowability. Int J Pharm. 2020;579:10. https://doi.org/10.1016/j.ijpharm.2020.119165.

Wikstrom H, Remmelgas J, Solin S, Marucci M, Sandler N, Boissier C, et al. Powder flow from an intermediate bulk container - discharge predictions and experimental evaluation. Int J Pharm. 2021;597:12. https://doi.org/10.1016/j.ijpharm.2021.120309.

Acknowledgements

We thank Kei Ariyoshi, Keiji Yuge, Shinya Miyamoto, Ryutaro Nakashima, Ami Yamaguchi, Hiroto Ogata, Koushiro Hirai, Souta Imagawa, and Yuri Hattori, college students working in our laboratory, for providing assistance with the implementation of this study and the results.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

Conception or design of the work: Shuichi Setoguchi; Acquisition, analysis, or interpretation of data: Shuichi Setoguchi, Shotaro Goto, and Kazuhisa Matsunaga; Drafting the work or revising it critically for important intellectual content: Shuichi Setoguchi; Final approval of the version to be published: Shuichi Setoguchi, Shotaro Goto, and Kazuhisa Matsunaga; Agreement to be accountable for all aspects of the work: Shuichi Setoguchi, Shotaro Goto, and Kazuhisa Matsunaga.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(PDF 292 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Setoguchi, S., Goto, S. & Matsunaga, K. Potential of Powder Rheology for Detecting Unforeseen Cross-Contamination of Foreign Active Pharmaceutical Ingredients. AAPS PharmSciTech 25, 138 (2024). https://doi.org/10.1208/s12249-024-02856-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-024-02856-0