Abstract

Stabilization of the subgrade soil is a primary and significant phase in highway construction. In constructing a flexible pavement subgrade, soil investigation is an important parameter, as the load is transferred to it under a repetitive vehicle load. Subgrade soils with low strength of bearing are incapable of bearing heavy loads and are considered unsuitable for construction. The author proposed a solution for the weak subgrade of flexible pavements in this paper. This study aims to address weak subgrade issues by using fly ash reinforced with reinforcement. The California bearing ratio test (CBR) unsoaked was performed on the fly ash positioning with square and circular reinforcement patterns in the center of the loaded area. The test was performed using different reinforcement of diameters 1 and 2 and twisted 2 mm (1 mm diameter reinforcement overlap, then it was twisted over each other to make a 2 mm diameter twisted reinforcement). The CBR value for plain fly ash is found to be 14.64%, and the maximum CBR value for square and circular reinforcement is 34.89% and 24.23%, respectively. The percentage increase in the CBR value for square and circular reinforcement is to be 138.31% and 65.50%, respectively. The study found that the reinforcement spacing pattern affects the subgrade bearing capacity. As the reinforcement spacing decreases, the bearing capacity of the fly ash increases with the increment of reinforcement diameter. This study is important for subgrade soil strengthening since this fine reinforcement has increased the bearing capacity of poor soils.

Similar content being viewed by others

Introduction

In the socioeconomic development of a country, creating an adequate road network is crucial, especially in rural areas. India is striving to establish high and uniform technical and management standards and to facilitate policy development and planning at the national level to ensure the sustainable management of rural roads. Under a survey to identify core networks as part of the PMGSY (Pradhan Mantri Gram Sadak Yojana) program, approximately 1.67 lakh unconnected habitations are eligible for coverage under the program, according to the latest figures made available by the state governments. This includes building 3.71 lakh km of new network roads and restoration of 3.68 lakh km of roads [1]. Total construction of road length by year in India is given in Fig. 1a; India has a total of 5.89 million km and is one of the largest road networks in the world. This road network carries 64.5% of all goods across the country, and 90% of India’s total passenger traffic uses a highway network to travel. Road transport has progressively increased with improved connectivity between cities, villages, and towns over the years. The total length of national highways in India was 132,500 km as of 1 March 2019. Through a series of measures, the government is working on policies to draw substantial investor interest [1]. A total of 200,000 km of national roads is targeted to be completed by 2022. A comparison of recent targets with achieved road lengths is represented in Fig. 1b. However, the construction of an extensive network of roads involves heavy financial investments through conventional means and approaches. Engineers are constantly confronted with the maintenance and growth of low financial capital floor infrastructure. To meet construction requirements, the traditional design of pavement and construction practice requires high-quality material. Quality products are in short supply in many parts of the globe.

As these pavements will be vulnerable to damage, building concrete or asphalt on these surfaces is not practical. As the soil function is of a subgrade nature, the loads applied from the pavement to the underlying layer should be transmitted sufficiently. If used in weak soils, fly ash enhances the soil’s CBR value by the interlocking phenomenon of soil fly ash [2,3,4]. By consuming lime kiln dust (LKD) and class F fly ash, Mohammadinia et al. [5] stabilized the mechanical properties of recycled construction and demolition (C&D) aggregates as a feasible replacement for road bases/subbases. For light traffic road, the granular materials stabilized with 10% S (slag) and 5% FA (fly ash) + 5% S blends have been discovered as a viable, long-term option for stabilizing forthcoming road bases and subbases [6]. Replacement of poor subgrade soil and the load-carrying capacity was found to improve to a greater extent by stabilizing the fly ash with electroplating waste and other additives like cement [7, 8]. Industrial waste, such as rice husk powder, foundry sands, foundry slag, and cement kiln mud, has shown adequate strength and durability [9]. Recycled glass (RG) and spent coffee ground (CG) geopolymers are innovative cementitious materials that use industrial wastes as precursors, such as fly ash and ground granulated blast-furnace slag. Tests on the California bearing ratio (CBR) of the CG + RG geopolymers show that their CBR value is higher than that of naturally occurring subgrade materials [10, 11]. The benefit of recycled plastic waste from waste bottles is to enhance the bearing capacity of soft soil [12]. The use of reclaimed plastic (RP), recycled concrete aggregates (RCA), and crushed brick (CB) is blended with demolition aggregates to form a railway cap** substance. With up to 7% RP and 3% RP, the RCA was found to have a higher CBR value of 50% as proposed for cap** materials by local authorities [13, 14]. Improving the subbase or subgrade layer is also a popular field of study. The CBR value of peat soils stabilized with polypropylene fiber increased significantly from 15 to 22 times [15]. The CBR value of fly ash mixed with electroplating waste sludge and cement has been raised considerably, resulting in significantly reduced pavement construction costs [16]. Adams et al. [17], Rao and Nasr [18], Ingle and Bhosale [19], and Gowthaman et al. [20] have carried out pioneering CBR soil reinforcement studies. The results of a series of laboratory CBR tests on silty sand reinforced by randomly dispersed polypropylene fibers (soaked and unsoaked) showed substantial improvement. Zornberg and Gupta [21] and Perkins and Ismeik [22] analyzed the results of a full pavement test carried out with a CBR value of about 1 to 8% on several reinforced parts using geogrids from saturated silty clay soils. The test results showed that the multilayer reinforcement for subbase soils with CBRs of 3% or more minor was the highest. There were no significant variations between different integral geogrids of the single layer.

The higher tensile modulus geogrids showed a strong 3% or lower contribution to CBRs. The decrease in the rutting rate between reinforced and unreinforced parts increases as the subgrade CBR decreases for all geosynthetics. The road service life improvement factor increases for strongly approved roads, with lower CBR values and fewer structural flooring. Kumar et al. [23] studied silty sand reinforced engineering properties. Bergado et al. [24] carried out CBR studies on compacted sand overlapped soft weathered clay. Geotextiles with different rigidities between clay and sand improved the specimens. The findings have shown that the use of geotextiles in soil improves the potential for bearing. The load value increases in some strains by increasing the loading speed and geotextile rigidity (i.e., rise in CBR value). Gosavi et al. [25] findings of the soaked California bearing ratio study indicate a significant increase in the CBR performance of black cotton soil after usage of reinforcing. The benefit of black cotton soil rises from 42 to 55% if 1% of tissue and fiber glass is added at random. With the introduction of 2% of fibers, the rate of increase in the CBR value becomes smaller, and the total value of CBR tends to decline for different fibers.

The primary goal of this research is to evaluate the influence of reinforcement on subgrade soil and how different reinforcing patterns improve its strength. An attempt has been made to investigate an alternate subgrade reinforcing method. Several researchers looked at the effects of geotextiles, cement, lime, and other elements on the behavior of subgrade soils. However, only a limited examination of the reinforcing strength of soil subgrade with these fine reinforcement bars has been conducted. The goal of this study is to see how reinforcement affects the soil subgrade.

Methods/experimental

Aim of the study

The main objective of this research is to address a weak subgrade soil that is unsuitable for pavement construction. As a result, waste material, such as fly ash combined with reinforcement, will be used, which has potential uses in highway and geotechnical applications. The widespread use of fly ash will not only assist to maintain ecological balances, but it will also allow the industry to develop a low-cost material based on this waste for mass-scale applications.

Materials and design

Fly ash

The fly ash used in the analysis was taken from the Kasimpur thermal power plant in the vicinity of Aligarh in Uttar Pradesh as shown in Fig. 2. Fly ash is classified as low-compressibility silt (ML). Figure 3 and Table 1 demonstrate the physical properties of fly ash. Fly ash from electrostatic precipitator (ESP) is continuously collected in buffer hoppers near ESP by vacuum pumps. Dry fly ash is pneumatically transferred from buffer hoppers to storage silos, and then dry or hydro mixing dust conditioners can be unloaded to pneumatic tank trucks to discharge them into open bed trucks, Belt conveyors transport ash into the ash storage zone (ash mound). Basin ash is regularly accumulated in wet hoppers, ground to sand, and occasionally moved to one of six hydro bins to be decanted. The accumulated ash is dispatched through belt conveyors to the ash mound area or discharged to the truck by the conveyors. Dry fly ash from hoppers is picked up in plastic bags for this research.

Reinforcing

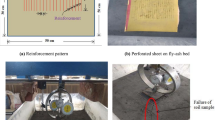

The reinforcement used in this study of diameters 1 and 2 and twisted 2 mm was made up of galvanized mild steel as sho wn in Fig. 4. Micropiles used as reinforcement and structural support are generally around 300 mm in diameter [30]. Authors have also to make sure that the reinforcement should not bend while placed in the CBR mold. The reinforcement of the required length was cut and made perfectly straight before pushing them into the CBR mold. The size reinforcement used in this work is 45 mm. The reinforcement was arranged in circular and square patterns located at the center of the CBR mold as shown in Fig. 5.

Calculation of reinforcement length

If pneumatic or vibratory rollers are used, the maximum lightweight lift thickness is almost infinite. Lift thickness is typically limited to 152.4 to 203.2 mm, as shown in Fig. 6. Proper positioning in lifts more significant than 152.4 mm to 203.2 mm poses a problem. Hence, the chosen lift thickness is 152.4 to 203.2 mm [31].

where x is the length of reinforcement.

Experimental methodology

The preparation and testing of specimens were performed according to IS: 2720 (part 16) to 1987 [32] for California bearing ratio test. The standard Proctor compaction test was performed using the equipment and procedures defined in IS: 2720 (part 7) to 1987 [33] equivalent (ASTM D 698-2000) [28] to achieve maximum dry density (MDD) and optimum moisture content (OMC) which sets a benchmark for a further test as the water to be added according to the OMC in the various CBR test. The OMC of the fly ash was 37% collected. Oven-dried and sieved through 5 kg of fly ash was taken, and water was added equivalent to OMC. The fly ash was thoroughly mixed so that water was uniformly mixed. The spacer disc was placed at the bottom of the mold; the first coat of wet mixing mixture is placed over it and uniformly compacted by 56 blows using a hammer of 2.6 kg with a free fall of 310 mm.

Similarly, the second and top layers (using a collar) were put again by 56 blows compacting each layer. The collar was removed instead with the aid of the steel cutting point, and excess content was shaved to the surface of the top of the mold. The filter paper was then placed on the base plate, and the mold was turned upside down so that the top of the specimen now turns backward on the penetration test. The specimens used for different positioning of reinforcement were inserted in the top layer of the CBR mold, and the corresponding test was carried out in the loading area of the plunger, as shown in Fig. 7.

The authors of this paper presented a solution for the reinforcement of subgrade soil. Effects of circular reinforcement on the strength of subgrade soil were also examined in this work; different types of circular arrangements were used within the center of the loaded area of the CBR mold in which the reinforcement is inserted in the prepared CBR mold, and other tests were performed by using these combinations such as the following: at the center, two reinforcements in the diametrically opposite position, four reinforcements in the diametrically opposite position, and four reinforcements in diametrically opposite position with one at the center as shown in Fig. 8. The load was applied through the CBR apparatus, and the results have been displayed in the graph in Fig. 9. The authors analyze the impact of the diameter of reinforcement on the strength parameters of fly ash. Different diameter reinforcements have been placed as described above in the center of the loaded area of CBR mold with various configurations.

Results and discussion

Effect of spacing of reinforcement on the strength of fly ash

The strength of the fly ash has been improved by reinforcing it with reinforcement. In this paper, the authors have tried various square combinations such as 30 mm × 30 mm square reinforcement at a spacing of 5 mm and 10 mm and 15 mm × 15 mm square reinforcement at a spacing of 5 mm as shown in Fig. 10.

For the present analysis, reinforcement of diameters 1, 2, and twisted 2 mm is used in these tests. Figure 10a shows the orientation of the reinforcement in a square pattern. Square reinforcement of 15 mm × 15 mm with a spacing of 5 mm is provided so that the whole square is divided into nine sub-squares with 5 mm sides, and reinforcement with a diameter of 1, 2, and twisted 2 mm is inserted at each node of every square. The load was introduced through the CBR apparatus. Figure 11 shows that the strength of fly ash with reinforcement can be substantially increased. CBR value for fly ash was found to be 14.64% in the absence of reinforcement. As shown in Fig. 10a following the reinforcement provision, the obtained CBR value is 18.58%, 23.94%, and 18.0% with a diameter of 1, 2, and twisted 2 mm, respectively, with CBR tests performed on fly ash using the reinforcement. There is a percentage increase in the CBR values, as seen in Table 2, due to fly ash mobilization with reinforcement. It has been observed from Fig. 12 that the CBR value of all three types of reinforcement, as provided by the square reinforcement, is continuously increasing. Figure 10b represents the reinforcement orientation in a square pattern. Square reinforcement of 30 mm × 30 mm with a spacing of 10 mm is used so that the whole square is divided into nine sub-squares of 10 mm sides, and reinforcement of diameters 1, 2, and twisted 2 mm is inserted at each node of every square. The load was applied via the CBR unit, and the effects were shown as a graph in Fig. 11.

By using a pattern as shown in Fig. 10b, the reinforcement will significantly increase the strength of fly ash as seen in Fig. 11. The CBR values for the reinforcement having diameters 1, 2, and twisted 2 mm are found to be 26.08%, 28.22%, and 18.68%, respectively.

Moreover, Fig. 11 shows that the strength of the fly ash can be significantly enhanced with reinforcement. After providing reinforcement, as shown in Fig. 10c, for diameters 1, 2, and twisted 2 mm reinforcement, the CBR values are found to be 30.41%, 34.89%, and 23.35%, respectively. There is a percentage increase in CBR, as shown in Table 2, which is due to the mobilization of fly ash.

From Fig. 11, it has been concluded that the CBR value is growing steadily in all three forms of reinforcement. However, it was observed that reducing the spacing between reinforcements improves subgrade strength substantially, and the optimum CBR value for both reinforcements of diameters 1 mm and 2 mm is found to be 5 mm as shown in Fig. 12.

Effect of the diameter of reinforcement on the strength of fly ash

The plunger is loaded into the CBR mold, and the subsequent test reading was noted. The CBR value for reinforcement of diameter 1 mm is found to be 16.64%, 19.90%, 21.89%, and 22.77% with one reinforcement inserted at the center, two reinforcements are inserted in diametrically opposite directions, four reinforcements are inserted in diametrically opposite directions, and four reinforcements are inserted in diametrically opposite directions with one at the center, respectively. The reinforcement is installed in the center of the loaded area of the CBR mold in a circular way.

For twisted reinforcement of a diameter of 2 mm, the obtained CBR value is 16.0%, 18.83%, 20.82%, and 23.26% with the same reinforcement pattern as shown in Fig. 8. The reinforcement is placed circularly in the center of the loaded area of the CBR mold.

The obtained CBR value for reinforcement of diameter 2 mm is 21.36%, 21.45%, 22.28%, and 24.23%, with the same reinforcement pattern as shown in Fig. 8. Reinforcement is placed in a circular pattern in the center of the loaded area of the CBR mold. In the case of circular reinforcement, the CBR value for the provision of the circular pattern increases in all three types of reinforcement arrangement. However, it was found that the increasing diameter significantly increases the subgrade strength as shown in Fig. 9, and the optimum CBR value for reinforcement of diameters 1 and 2 and twisted 2 mm is found when the reinforcement is placed at the circumference and center as shown in Fig. 13. There is a percentage increase in CBR, as seen in Table 2, due to fly ash mobilization.

Conclusions

The influence of reinforcement parameters such as diameter and spacing of reinforcing components was evaluated in an experimental investigation on unreinforced and reinforced soil samples. The following are some concluding observations:

-

The CBR value of fly ash was found to be 14.64%. The fly ash containing reinforcement of different geometries has shown good bearing strength characteristics. The use of reinforcement with varying spacing and diameter in the fly ash enhances the bearing strengths significantly.

-

The spacing pattern of the reinforcement has a considerable impact on the subgrade bearing capacity. The reinforcing spacing has an inverse relationship with the increase in bearing capacity, and the bearing capacity is increased as the diameter of reinforcement increases.

-

The bearing strengths of fly ash increase with reinforcement of diameters 1 mm and 2 mm to a great extent. When samples were placed with 5 mm spacing, the increment in CBR was a maximum of 107.71 and 138.31%, respectively.

-

The strength of subgrade soil in case of circular reinforcement increases up to 55.53, 58.87, and 56.50% for the reinforcement of diameters 1, 2, and twisted 2 mm, respectively.

-

This research is beneficial for strengthening subgrade soil as this fine reinforcement has boosted the bearing capacity of weak soils.

Availability of data and materials

Not applicable

Abbreviations

- CBR:

-

California bearing ratio

- MDD:

-

Maximum dry density

- OMC:

-

Optimum moisture content

- FA:

-

Fly ash

- ESP:

-

Electrostatic precipitator

- ML:

-

Low-compressibility silt

- PMGSY:

-

Pradhan Mantri Gram Sadak Yojana

- RP:

-

Reclaimed plastic

- RCA:

-

Recycled concrete aggregates

- CB:

-

Crushed brick

- S:

-

Slag

References

N. R. I. D. (2021) Agency, PRADHAN MANTRI GRAM SADAK YOJANA. India [Online]. http://omms.nic.in/#

Prabhakar J, Dendorkar N, Morchhale RK (2004) Influence of fly ash on strength behavior of typical soils. Constr Build Mater 18(4):263–267. https://doi.org/10.1016/j.conbuildmat.2003.11.003

Chandra S, Viladkar M, Nagrale P (2008) Mechanistic approach for fiber-reinforced. J Transport Eng Asce 134:15–23

Ghosh A, Dey U (2009) Bearing ratio of reinforced fly ash overlying soft soil and deformation modulus of fly ash. Geotext Geomembr 27:313–320. https://doi.org/10.1016/j.geotexmem.2008.12.002

Mohammadinia A, Arulrajah A, D’Amico A, Horpibulsuk S (2020) Alkali activation of lime kiln dust and fly ash blends for the stabilisation of demolition wastes. Road Mater Pavement Des 21(6):1514–1528. https://doi.org/10.1080/14680629.2018.1555095

Arulrajah A, Perera S, Wong YC, Maghool F, Horpibulsuk S (2021) Stabilization of PET plastic-demolition waste blends using fly ash and slag-based geopolymers in light traffic road bases/subbases. Constr Build Mater 284:122809. https://doi.org/10.1016/j.conbuildmat.2021.122809

Ahmad MS, Shah SS (2016) Load settlement behaviour of fly ash mixed with waste sludge and cement. Geotech Geol Eng 34(1):37–58. https://doi.org/10.1007/s10706-015-9927-z

Ahmad MS (2015) Long term assessment of strength and heavy metal concentration in cement-fly ash stabilized electroplating waste sludge. Malaysian J Civ Eng 27(1). https://doi.org/10.11113/mjce.v27.15905

Edil Tuncer B, Acosta Hector A, Benson Craig H (2006) Stabilizing soft fine-grained soils with fly ash. J Mater Civ Eng 18(2):283–294. https://doi.org/10.1061/(ASCE)0899-1561(2006)18:2(283)

Arulrajah A, Kua T-A, Horpibulsuk S, Mirzababaei M, Chinkulkijniwat A (2017) Recycled glass as a supplementary filler material in spent coffee grounds geopolymers. Constr Build Mater 151:18–27. https://doi.org/10.1016/j.conbuildmat.2017.06.050

Arulrajah A, Kua T-A, Suksiripattanapong C, Horpibulsuk S (2019) Stiffness and strength properties of spent coffee grounds-recycled glass geopolymers. Road Mater Pavement Des 20(3):623–638. https://doi.org/10.1080/14680629.2017.1408483

Babu GLS, Chouksey SK (2011) Stress-strain response of plastic waste mixed soil. Waste Manag 31(3):481–488. https://doi.org/10.1016/j.wasman.2010.09.018

Arulrajah A, Naeini M, Mohammadinia A, Horpibulsuk S, Leong M (2020) Recovered plastic and demolition waste blends as railway cap** materials. Transp Geotech 22:100320. https://doi.org/10.1016/j.trgeo.2020.100320

Naeini M, Mohammadinia A, Arulrajah A, Horpibulsuk S, Leong M (2019) Stiffness and strength characteristics of demolition waste, glass and plastics in railway cap** layers. Soils Found 59(6):2238–2253. https://doi.org/10.1016/j.sandf.2019.12.009

Huat B, Kalantari B, Prasad A (2010) Effect of polypropylene fibers on the California bearing ratio of air cured stabilized tropical peat soil. Am J Eng Appl Sci 3. https://doi.org/10.3844/ajeassp.2010.1.6

Ahmad MS, Salahuddin Shah S (2010) Load bearing strength of fly ash modified with cement and waste sludge. Int J Civ Eng 8(4):315–326

Adams C, Amofa N, Opoku-Boahen R (2014) Effect of geogrid reinforced subgrade on layer thickness design of low volume bituminous sealed road pavements. IRJES 3:59–67

Rao SVK, Nasr AMA (2012) Laboratory Study on the Relative Performance of Silty-Sand Soils Reinforced with Linen Fiber. Geotech Geol Eng 30(1):63–74. https://doi.org/10.1007/s10706-011-9449-2

Ingle GS, Bhosale SS (2017) Full-scale laboratory accelerated test on geotextile reinforced unpaved road. Int J Geosynthetics Ground Eng 3(4):33. https://doi.org/10.1007/s40891-017-0110-x

Gowthaman S, Nakashima K, Kawasaki S (2018) A state-of-the-art review on soil reinforcement technology using natural plant fiber materials: past findings, present trends and future directions. Materials (Basel) 11(4). https://doi.org/10.3390/ma11040553

Zornberg J, Gupta R (2010) Geosynthetics in pavements: North American contributions. In: 9th International Conference on Geosynthetics - Geosynthetics: advanced solutions for a challenging world, ICG 2010, pp 379–400

Perkins SW, Ismeik M (1997) A synthesis and evaluation of geosynthetic-reinforced base layers in flexible pavements- part I. 4(6):549–604. https://doi.org/10.1680/gein.4.0106

Kumar R, Kanaujia V, Chandra D (1999) Engineering behaviour of fibre-reinforced pond ash and silty sand. Geosynth Int 6:01/01. https://doi.org/10.1680/gein.6.0162

Bergado DT, Youwai S, Hai CN, Voottipruex P (2001) Interaction of nonwoven needle-punched geotextiles under axisymmetric loading conditions. Geotext Geomembr 19:299–328. https://doi.org/10.1016/S0266-1144(01)00010-3

Gosavi M, Patil KA, Mittal S, Saran S (2004) Improvement of properties of black cotton soil subgrade through synthetic reinforcement. J Inst Eng Civ Eng Div

Bureau of Indian Standards, “IS: 2720 (Part 3)-1980 Code of practice for determination of specific gravity,” New Delhi, 1980. [Online]. Available: https://doczz.net/doc/7243053/2720--part-3--section-ii-

Bureau of Indian Standards, “IS: 2720 (Part 4)-1985 Code of practice for grain size analysis.,” New Delhi, 1994. [Online]. Available: https://ia803007.us.archive.org/35/items/gov.in.is.2720.4.1985/is.2720.4.1985.pdf

American Society for Testing and Materials, “ASTM D-698 (2000), Standard test method for laboratory compaction characteristics of soil using standard effort,” America, 2000. [Online]. Available: https://infostore.saiglobal.com/en-gb/standards/astm-d-698-2000-151203_saig_astm_astm_2670400/

Bureau of Indian Standards, “IS: 1498-1970 Code of practice for Identification and classification of soil,” New Delhi, 1970. [Online]. Available: https://www.scribd.com/document/359132096/Is-1498-1970-Soil-Classification

Armour T, Groneck P, Keeley J, Sharma S (2000) Micropile design and construction guidelines: implementation manual. Federal Highway Administration, United States

Asphalt Institute, “Asphalt Pavement Thickness and Mix Design,” Lexington, 2020. [Online]. Available: https://www.asphaltinstitute.org/engineering/frequently-asked-questions-faqs/asphalt-pavement-thickness-and-mixdesign/

Bureau of Indian Standards, “IS: 2720 (Part 16)-1987 Code of practice for laboratory CBR test,” New Delhi, 1987. [Online]. Available: https://ia803004.us.archive.org/5/items/gov.in.is.2720.16.1987/is.2720.16.1987.pdf

Bureau of Indian Standards, “IS: 2720 (Part 7)-1987 Code for determination of water content dry density relation using light compaction,” New Delhi, 1980. [Online]. Available: https://civilengineer.co.in/wp-content/uploads/2017/03/IS-2720-PART-7-1980-INDIAN-STANDARD-METHODS-OF-TEST-FOR-SOILS-DETERMINATION-OF-WATERCONTENT-DRY-DENSITY-RELATION-USING-LIGHT-COMPACTION-SECOND-EDITION.pdf

Code availability

Not applicable

Funding

Not applicable

Author information

Authors and Affiliations

Contributions

Conceptualization: Prof. MSA, methodology, formal analysis, and investigation. SAA, writing — original draft preparation and writing — review and editing. Prof. MSA, funding acquisition, resources, Department of Civil Engineering, ZHCET, AMU, and supervision. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Ahmad, S.A., Ahmad, M.S. Experimental investigation to study the effect of reinforcement on strength behavior of fly ash. J. Eng. Appl. Sci. 69, 41 (2022). https://doi.org/10.1186/s44147-022-00096-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s44147-022-00096-2