Abstract

A novel α-tocopherol-producing bacteria strain was isolated and identified as Bacillus tequilensis QH1 (QH1). The effects of QH1 strain inoculation alone (QH), combined with cell wall degradation enzyme (QC), or Lactiplantibacillus plantarum subsp. plantarum YM3 and cell wall degradation enzyme (QLC) as the additives on the fermentation characteristics, structural carbohydrates, and α-tocopherol content of rice straw and corn stover silages were investigated, and without additives as the control (CON), in 4 replicates. After silages were kept in a laboratory cabinet (26–34 ℃) and the dark for 42 d, experimental silos (polyethylene plastic bags) were opened for analysis. The results exhibited that the control and additives-treated rice straw and corn stover were ensiled well, indicated by high lactic acid content and little butyric acid content. The QH and QC degraded structural carbohydrates, demonstrated by lower (P < 0.001) neutral detergent fiber (NDF) and acid detergent fiber (ADF) than the control, but did not enhance lactic acid fermentation, evidenced by lower (P < 0.001) lactic acid content in QH-treated silages compared with the control silages. The effect of QLC on degrading structural carbohydrates was influenced by material factors, evidenced by no role in decreasing the contents of NDF and ADF in rice straw silage and a good role in decreasing the contents of NDF and ADF in corn stover silage. However, the water-soluble carbohydrate (WSC) contents in both rice straw and corn stover silages were increased (P < 0.001) by QLC compared with the control. The control and additives-treated silages had much higher (P < 0.001) α-tocopherol content and lower (P < 0.001) chlorophyll content compared with the material before ensiling. Compared with the control, higher α-tocopherol content was found in QH-treated rice straw (P = 0.071) and corn stover silages (P < 0.05), and QLC-treated corn stover silage (P < 0.05). Therefore, the QH1 strain had the potential to be applied in rice straw silage production, and QLC was recommended to be applied in corn stover silage production.

Graphical Abstract

Similar content being viewed by others

Introduction

Rice and corn are widely planted in the world. The rice straw and corn stover were used as the material for silage-making for the livestock due to their high production [1, 2]. However, the rice straw and corn stover have a low nutrient value since they contain high concentrations of structural carbohydrates and few crude proteins [3,4,5]. To degrade the structural carbohydrates and provide water-soluble carbohydrates (WSC) for the fermentation of lactic acid bacteria (LAB), the cell wall degradation enzyme and LAB inoculation were used in silage-making [6, 7]. Additionally, the cell wall degradation enzyme can degrade structural carbohydrates as sugar to provide a carbon source not only for LAB inoculation, but also for other bacteria. Lindqvist et al. found that the combination of cell wall degradation enzymes and LAB inoculation increased the α-tocopherol content in some mixed forage silage relative to the raw material, maybe deriving from other bacteria [8].

The α-tocopherol is one of the fat-soluble vitamins in plants and is the most potent form of vitamin E, accounting for almost all vitamin E activity in living tissues, which has a certain effect on the prevention and treatment of various types of uterine diseases caused by hormone and nutritional imbalances [9]. Pagan et al. showed that natural vitamin E is more effective than synthetic vitamin E in preventing physiological disease in animals, so it is both physiologically and economically worthwhile to preserve natural vitamin E levels in silage close to the initial levels of fresh material [10]. Some plants are preserved as silage for the cattle, which is a bacteria-driven fermented feed. Studies reported that the α-tocopherol lost during making forage as silage, especially large α-tocopherol loss during wilting before ensiling varied between 20 and 35% of initial content and increased with prolonged wilting [9]. However, there was an inconsistent result of increased α-tocopherol in wheat and barley silage relative to the fresh forage material [11]. Studies have found that increased α-tocopherol might be derived from the degradation of chlorophyll [12]. Nevertheless, most of the forage is rich in chlorophyll, and there were few cases of ensiling increasing α-tocopherol content [8, 13]. On the other hand, Lindqvist et al. reported that a small loss or increase of α-tocopherol occurred in mixed forage silage treated with LAB and cell wall degrading enzymes relative to the material before ensiling and the reason was attributed to some α-tocopherol-producing bacteria on the forage [8]. Our previous study demonstrated that some bacteria had negative correlations with the α-tocopherol loss, and better survived in propionic acid and Lactiplantibacillus plantarum-treated silages relative to the control and other treated silages, due to high abundances of these bacteria [14]. To date, some bacteria such as Desulfotomaculum nigrificans were demonstrated to produce α-tocopherol but it could degrade protein [15]. It could not be used as inoculation for silage-making. Therefore, the great expectation was to explore new α-tocopherol-producing bacteria strains to improve either fermentation quality or α-tocopherol content.

Recently, we isolated a novel bacterial strain, which was identified as the Bacillus tequilensis QH1 (QH1) strain from silage and could produce α-tocopherol. Additionally, the rice straw and corn stover lack chlorophyll after harvesting the grain, and become yellow, and their α-tocopherol contents were lowered due to decomposition during wilting or delaying harvest [9, 16, 17]. Rice straw and corn stover might be good materials to investigate whether the α-tocopherols are derived from chlorophyll or strains. To date, there was little information on Bacillus tequilensis in rice straw silage. Therefore, in this study, the purpose was to clarify the characteristics of QH1 strain and verify the effects of QH1 strain addition alone (QH), combined with cell wall degradation enzymes (QC), or L. plantarum YM3 and cell wall degradation enzyme (QLC) on the fermentation quality, structural carbohydrates degradation, and α-tocopherol content of rice straw and corn stover silage.

Materials and methods

The screen and identification for QH1 strain

Ten grams of silage were blended with 90 mL of sterilized normal saline (8.50 g/L NaCl). The solutions were serially diluted with sterilized distilled water (from 10–1 to 10–7) and surface-plated on RCM agar medium (Qingdao Hope Bio-Technology Co., Ltd, Qingdao, China). Forty-eight strains were isolated from silages randomly. The ability to produce α-tocopherol in MB medium was used as the screening criteria (Additional file 1: Fig. S1). The formula of MB was based on Radhika et al. [18] and was revised as follows (per liter of distilled water): 0.66 g K2HPO4·3H2O, 1.0 g NH4Cl, 2.0 g CaSO4, 4.0 g MgSO4, 5.0 g sodium citrate (dihydrate), 46 mL sodium lactate (60%), 1.50 g yeast extract, 0.75 g (NH4)2SO4·FeSO4·6H2O, 0.05 g C2H3NaO2S. Consequently, one strain with the strongest α-tocopherol production capacity was screened and named QH1.

Extraction of genomic DNA and species identification of QH1 strain were followed by the procedures reported by Liu et al. [19]. Briefly, genomic DNA was extracted by a TIANamp Bacterial DNA kit (Tiangen Biotech Co., Ltd, Bei**g, China) following the manufacturer’s instructions. The 16S rDNA coding region was amplified using polymerase chain reaction (PCR). The PCR primers used for amplifying the 16S rDNA sequence were 25F (5’-AACTGAAGAGTTTGATCCTGGCTC-3′) and 1492R (5′-TACGGCTACCTTGTTACGACT-3′). The PCR products were purified using DNA purification systems (Promega, Madison, WI) and analyzed for 16S rDNA using a 3730xl DNA Analyzer (ABI Applied Biosystems, San Francisco, CA, USA). The 16S rDNA sequences were aligned with 16S rDNA sequences from GenBank to identify organisms by BLAST analysis. Then, nucleotide substitution rates were calculated, and phylogenetic trees were constructed using the neighbor-joining method [20]. The nucleotide sequence (Additional file 1: Fig. S2) for the 16S rRNA gene of the QH1 strain was attached to theAdditional file.

Morphological and physiological tests for QH1 strain

The QH1 strain was stored at − 80 °C and used after culturing in RCM medium (Difco Laboratories, Detroit, MI) at 30 °C for 36 h. Gram stain results were determined in three replicates according to the methods described by Endo and Okada [21]. Growth of the QH1 strain at different temperatures was observed in the RCM medium after incubation at 5, 10, 20, 30, 37, 40, 45, 50, and 55 °C for 2 d. Growth of the QH1 strain at different pH values (3.5, 4.0, 4.5, 5.0, 6.0, 7.0, 8.0, 8.5, 9.0, 10.0, pH adjusted with 0.1% HCl or NaOH) was observed in RCM medium after incubation at 37 °C for 2 days. QH1 strain was examined in three replicates for physiological and biochemical tests. Growth at different pH and temperatures were determined according to Bergey’s Manual of Systematic Bacteriology [22]. We use “well growth”, “normal growth”, “weak growth” and “no growth” to describe the performance of QH1 strain under different conditions. We measured the turbidity of the QH1 strain solution with a spectrophotometer and evaluated the growth situation according to the OD600 value. OD value (> 0.3) was identified as “well growth”; OD value (0.1–0.3) was identified as “normal growth”; OD value (0.05–0.1) was identified as “weak growth”; OD value (< 0.05) was identified as “no growth.”The growth ability of the QH1 strain was reflected by the turbidity and the OD value. Sugar fermentation patterns were examined using the sugar listed in API 50 CHL (bioMérieux, l’Etoile, France) and the RCM medium without carbon sources. The result was read after 24 h and verified after 48 h. Fermentation of the carbohydrate medium was indicated by a blue color, except for esculin (dark brown). The ability of the QH1 strain to produce cell wall degradation enzymes was analyzed in a carboxymethylcellulose medium and the cellobiohydrolase activity in the rice straw was measured according to the method reported by our previous study [23].

Silage preparation

The rice and corn were cultivated in 3 different fields (4 plots per field and 100 m2 per plot) at Jiangsu Academy of Agricultural Sciences and Baima practice teaching base of Nan**g Agricultural University, respectively. On September 20, 2021, 50 kg of whole plant rice was harvested from random 3 plots in each field and was mixed well. The rice straw was obtained after being wilted for 12 h on a sunny day to remove the grain and water. After the corn ears were removed on August 20, 2021, the corn stover gradually became yellow. On September 20, 2021, 50 kg of corn stover was harvested from random 3 plots in each field and was mixed well. Rice straw and corn stover were chopped into 1- to 2-cm-long pieces by a forage chopper (Sh-2000, Shanghai Donxe Industrial Co., Ltd., Shanghai, China).

Cell wall degradation enzymes, hemicellulase (50 U/mg) and cellulase (20 U/mg) mixture (1:1, m/m), derived from Trichoderma reesei, were purchased from a company (Shanghai Yuanye Biotechnology Co., Ltd., Wuxi, China). A LAB strain, identified as L. plantarum using its 16S rDNA sequence (GenBank Accession No. 2417264), was stockpiled at -80 ℃ and was employed after culturing in de Man Rogosa and Sharp (MRS) broth at 37 ℃ for 14 h (approximately 1 × 1010 cfu/mL). The QH1 strain was statically cultured in the RCM medium at 37 ℃ for 36 h (approximately 1 × 1010 cfu/mL) before use. The QH1 strain alone, QH1 combined with the cell wall degradation enzyme, or the mixture of L. plantarum and the cell wall degradation enzyme as the 3 additive treatments (QH, QC, and QLC).

Silage making

The experiment design was as follows: 3 Fields × 2 Straw materials (rice straw and corn stover) × [The control and 3 additive treatments (QH, QC, and QLC)] × 4 replicates. In detail, exactly 96 silos were used in this experiment. Experimental silos (polyethylene plastic bags, 60 cm length × 25 cm wide) were used in this experiment. The 1200 g of rice straw and corn stover were ensiled with 250 mL and 200 mL of distilled water as control, respectively. Using 1 mL QH1 strain suspension, the combination of 1 mL QH1 strain suspension and 1.2 g cell wall degradation enzymes, the combination of 1 mL QH1 strain suspension, 1 mL L. plantarum suspension (approximately 1 × 1010 cfu/mL) strain suspension and 1.2 g cell wall degradation enzymes treated 1200 g of rice straw and corn stover as the QH-, QC- and QLC- treated rice straw and corn stover groups, separately. These treated rice straw and corn stover groups were added with the same volume of distilled water as the control. After being mixed well, treated rice straw and corn stover groups and the control groups were filled in the silo. The silo was sealed using the vacuum package machine (DZD-400, Aomitai Technology Co., Ltd., Nan**g, China) to ensure an anaerobic environment. Experimental silos were stored in a laboratory cabinet (26–34 °C) to keep them in the dark for 42 d. In the rice straw or corn stover group, random 4 silos per additive group and the control were used for microbial and chemical analyses across fields factor. The data collected from the 32 silo samples were used for statistical analyses to evaluate the main effect of additives and straw materials (n = 4) across fields factor.

Chemical and microbial analyses of raw material and silage

Rice straw and corn stover samples (10 g) were immersed in 140 mL of distilled water at 4 °C for 18 h, and the filtrate was used to measure pH using a glass electrode pH meter (PHS-3C, CSDIHO Co., Ltd, Shanghai, China). According to the procedures described by Playne and McDonald [24], buffer capacity (BC) was determined. Rice straw and corn stover samples (10 g) were immersed in 90 mL of sterilized saline with a concentration of 0.85%, shaking at 120 rpm to 37 °C for 1 h, and absorbed 1 mL of liquid for serial dilution with sterile water (10–1–10–7). Take 0.1 mL of the diluted liquid, and spread it evenly in the medium, placing it in a constant temperature incubator to cultivate and measure the number of aerobic bacteria, yeast, mold, and lactic acid bacteria. The counts of LAB, aerobic bacteria, yeasts, and molds were measured by the same method reported by Zong et al. [14]. Rice straw and corn stover samples (50 g) were placed in the oven to determine dry matter (DM) content for 3 d at 65 °C. The dried samples were ground and passed through a 1 mm screen with laboratory knife mills (FW100, Taisite Instrument Co., Ltd., Tian**, China) to determine crude protein (CP), WSC, neutral detergent fiber (NDF), acid detergent fiber (ADF), and acid detergent lignin (ADL) content. Total N (TN) was determined by Kjeldahl procedure [25] and CP content was calculated by multiplying TN by 6.25. The WSC content was analyzed by colorimetric after-reaction with an anthrone reagent [26]. Amylase-treated NDF, ADF, and ADL contents were determined according to the procedures described by Soest et al. [27], heat-stable amylase and sodium sulfite were used in the NDF procedure and the results of NDF, ADF and ADL were expressed on DM basis. Rice straw and corn stover samples (10 g) were placed in a 50-mL tube and stored at -80 ℃ to determine α-tocopherol content.

After ensiling for 42 days, the silo was opened and silage was mixed well. Silage samples (10 g) were placed in a 50 mL centrifuge tube and stored at − 80 °C to determine α-tocopherol content. Silage samples (10 g) were immersed in 60 mL of distilled water at 4 °C for 18 h, the filtrate was used to measure pH, organic acids, and ammonia-N. Organic acids were determined by high-performance liquid chromatography (Agilent 1260; Agilent Technologies, Germany), and the chromatographic column was a Carbomix® H-NP5 column (mobile phase: 2.5 mmol/L H2SO4; flow rate: 0.5 mL/min; temperature: 55 °C). The ammonia-N content was determined by the phenol-hypochlorite reaction described by Broderick and Kang [28]. The analytical methods for nutrient and microbial composition are the same as those for rice straw and corn stover before ensiling.

Analysis of α-tocopherol and chlorophyll

The α-tocopherol production of the QH1 strain produced in the RCM and MB medium was determined according to the methods described by Liu et al. with some modifications and was used as the screening criteria [29]. Briefly, taking 0.4 mL of the bacterial liquid, centrifuged at 4 °C and 10,000 rpm for 2 min. The supernatant (0.35 mL) was treated with anhydrous ethanol and n-heptane (v/v = 6:10, 1.6 mL) and was centrifuged at 4 °C and 1500 rpm for 10 min. Then, 0.35 mL of the supernatant was treated with 0.147% C20H13N4NaO6S2 (m/v, 0.05 mL) ethanol reagent and 0.04% FeCl3 ethanol solution (m/v, 0.025 mL) for reacting 5 min. The reacted mixture was added to 6.23% phosphate ethanol solution (v/v, 0.5 mL) was added to obtain the reaction solution and the α-tocopherol absorbance value was detected at 560 nm. Rice straw, corn stover, and silage samples were frozen in liquid nitrogen and were grounded with a laboratory grinder (FW100, Tester Instrument Co., Ltd., Tian**, China). The α-tocopherol extractions in rice straw, corn stover, and silages were obtained according to the method described by Lindqvist et al. [8]. The content of α-tocopherol was determined by the same method reported by Liu et al. using high-performance liquid chromatography (Agilent 1260; Agilent Technologies, Germany) [30]. Chlorophyll content in rice straw, corn stover, and silage samples was determined according to the method reported by Kalaji et al. [31]. Pigment concentrations were calculated from the absorbance of the extract at 663 and 645 nm using the formula:

Statistical analyses

All statistical analyses were performed using the Statistical Packages for Social Science (IBM SPSS 22.0 for Windows). Two-way analysis of variance (ANOVA, General Linear Models) (2 Straw materials (rice straw and corn stover) × [The control and 3 additive treatments (QH, QC, and QLC)] × 4 replicates) was performed by analyzing fermentation parameters, and microbial and chemical compositions, α-tocopherol to evaluate the main effect of additive across the field factor. The means (n = 4) of additives and the control were then compared for significance using Tukey’s test at P < 0.05. Trends were discussed at 0.05 ≤ P ≤ 0.10.

Results

Identification, physiological, and biochemical characteristics analysis of the QH1 strain

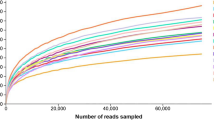

As shown in Fig. 1, blasted in Genbank, the 16S rDNA sequence of the QH1 strain was 100% similar to B. tequilensis and was assigned to B. tequilensis in the phylogenetic diagram. As shown in Tables 1 and 2, the QH1 strain was Gram-positive bacilli and can grow at 50 °C, low pH 4.5, and could ferment most sugar. Amazingly, the QH1 strain could produce α-tocopherol in the RCM medium. The α-tocopherol production of the QH1 strain increased during 48 h cultivation. The OD600 of the QH1 strain increased during 36 h cultivation but decreased from 36 to 48 h (Fig. 2). Additionally, the QH1 strain had a good ability to secrete cell wall degradation enzymes and its highest cellobiohydrolase activity was cultured for 72 h according to Fig. 3.

Chemical and microbial characteristics of rice straw and corn stover before ensiling

The chemical and microbial characteristics of rice straw and corn stover before ensiling are shown in Table 3. Notably, the WSC contents of rice straw and corn stover were higher than 100 g/kg DM while their CP contents were lower than 70 g/kg DM. Chlorophyll contents of both rice straw and corn stover were lower than 0.4 ug/kg DM. Corn stover had higher α-tocopherol content relative to rice straw.

Fermentation characteristics of rice straw and corn stover silage

As shown in Additional file 2: Table S1, there were interactions of additives and materials in pH, contents of lactic acid, acetic acid, propionic acid, butyric acid, and ammonia-N, the ratio of lactic acid to acetic acid (LA/AA), numbers of lactic acid bacteria, aerobic bacteria and yeasts (P < 0.001), and had non-significant effects on ethanol (P > 0.05).

Compared with the control silage, QH-treated rice straw and corn stover silages had lower (P < 0.001) lactic acid content, while there was no difference (P > 0.05) in the lactic acid content among the control, QC-, and QLC-treated silage. The QH-, QC-, and QLC-treated rice straw silage had lower (P < 0.001) acetic acid content and higher (P < 0.001) LA/AA than the control, while only the QH- treated corn stover silage had higher (P = 0.048) LA/AA than the control silage. Compared with the control silage, all additives-treated silages had lower (P < 0.001) propionic acid content. The butyric acid content was little in all silages, which was below 0.5 g/kg DM. No difference in the ammonia-N content between the control and additives-treated silages, while all rice straw silages had higher (P < 0.001) ammonia-N than the corn stover silages. In corn stover silages, QH-, QC-, and QLC-treated had more (P < 0.001) LAB than the control silage. Only QC-, and QLC-treated corn stover silages had fewer (P < 0.05) aerobic bacteria than the control (P < 0.05). QH-treated corn stover silages had more (P < 0.001) yeasts than the control silage while QC-treated corn stover silages had fewer (P < 0.05) yeasts than the control. The mold number in all silages was below 3.60 lg cfu/g FM.

Chemical characteristics of rice straw and corn stover silage

As shown in Additional file 2: Table S2, the interaction of additives and materials had significant effects on DM, DM loss, CP, WSC, NDF, ADF, and ADL (P < 0.001). In the rice straw silage groups, QC- and QLC-treated rice straw silages had higher (P < 0.05) contents of DM and CP than the QH-treated silage and the control silage. The QH-, QC-, and QLC-treated corn stover silages had higher (P < 0.05) CP than the control silage. The QH-, QC-, and QLC-treated rice straw silages had lower (P < 0.001) DM loss and higher (P < 0.05) WSC content than the control silage, and QH- and QC-treated corn stover silages had lower (P < 0.001) DM loss than the control silage. Only QC- and QLC-treated corn stover silage had higher (P < 0.001) WSC content than the control silage. QH- and QC-treated rice straw silages and QH- and QC-treated corn stover silages had lower (P < 0.001) NDF and ADF than the control silage. Especially, QH-treated silage had the lowest (P < 0.05) ADL in the rice straw and corn stover silages.

α-Tocopherol and chlorophyll content in rice straw and corn stover silage

As shown in Figs. 4 and 5, the interaction of additives and materials had significant effects on the α-tocopherol, and chlorophyll, increasing the rate of α-tocopherol, and decreasing rate of chlorophyll (P < 0.001). Generally, the α-tocopherol content of corn stover silages was higher (P < 0.001) than rice straw silages, and their α-tocopherol content was higher (P < 0.05) than rice straw and corn stover before ensiling.

Effect of additives on α-tocopherol content of rice straw and corn stover silages. Bars with different letters indicated a significant difference among the treatments at P < 0.05, n = 4. CON, rice straw or corn stover ensiled without additives; QH, rice straw or corn stover ensiled with QH1 strain; QC, rice straw or corn stover ensiled with QH1 strain combined with cell wall degradation enzyme; QLC, rice straw or corn stover ensiled with QH1 strain combined with L. plantarum YM3 and cell wall degradation enzyme; A, additive; M, materials; A × M, additive × material. The increasing rate of α-tocopherol was calculated by the formula: increasing rate of α-tocopherol = (α-tocopherol content of ensiled rice or corn stover – α-tocopherol content of rice or corn stover)/α-tocopherol content rice straw or corn stover × 100%

Effect of additives on chlorophyll content of rice straw and corn stover silages. Bars with different letters (a, b) indicated the significant difference among the treatments at P < 0.05, n = 4. CON, rice straw or corn stover ensiled without additives; QH, rice straw or corn stover ensiled with QH1 strain; QC, rice straw or corn stover ensiled with QH1 strain combined with cell wall degradation enzyme; QLC, rice straw or corn stover ensiled with QH1 strain combined with L. plantarum YM3 and cell wall degradation enzyme; A, additive; M, materials; A × M, additive × material. The decreasing rate of chlorophyll was calculated by the formula: decreasing rate of chlorophyll = (chlorophyll content of ensiled rice or corn stover – chlorophyll content of rice or corn stover)/chlorophyll content of rice straw or corn stover × 100%

The QH-treated (P < 0.001) rice straw silages had higher α-tocopherol content than QC-treated (P < 0.001) and the control silage (P = 0.071). QH-treated (P < 0.001) corn stover silages had higher (P < 0.05) α-tocopherol content than the control silage (P < 0.05). The QLC-treated corn stover silage had the highest α-tocopherol content (P < 0.05) which was followed by the QH-treated corn stover silage. Accordingly, QLC-treated corn stover silages had the highest (P < 0.001) increase rate of α-tocopherol, while the QC-treated (P < 0.001) silages of corn stover silages had the lowest increase rate of α-tocopherol.

Contrary to the changes of α-tocopherol, the chlorophyll content of corn stover silages was lower (P < 0.001) than rice straw silages and their chlorophyll contents were decreased compared with rice straw and corn stover before ensiling. The QH- and QC-treated rice straw silages had higher (P < 0.05) chlorophyll content relative to the control silage. In corn stover silage, the control group had the biggest (P < 0.001) decrease rate of chlorophyll. In rice straw silage, the QC group had the smallest (P < 0.05) decrease rate of chlorophyll.

Discussion

In this study, the QH1 strain was identified as Bacillus tequilensis, which belonged to the Bacillus genera. Bacillus is a facultative anaerobic bacterial. Some species of Bacillus genera have the advantages of non-pathogenicity, high-temperature resistance, fast growth rate, and antibacterial ability and are the dominant population in soil and plant microecology [32, 33]. The QH1 strain was the first reported Bacillus that could produce α-tocopherol, which could utilize most sugar, as indicated by a wide spectrum of sugar utilization. Additionally, the QH1 strain tolerated a high temperature of 50 ℃ and grew at pH from 4.5 to 9.0, but did not grow below 10 ℃ and pH 4.0. This indicated that the QH1 strain belonged to mesophiles and was of acidic endurance. Furthermore, the QH1 strain had the potential to degrade lignocellulose into sugar to promote fermentation due to secreting cell wall degrading enzymes. The above characteristics of the QH1 strain might approach the requirement of making agricultural straw as silage in wide growth temperature, pH range, and utilization of various fermentation substrates.

Quality silage depends on the high production of lactic acid, which decreases the pH value of silage and inhibits other harmful microorganisms from degrading nutrients, e.g., degrading protein into ammonia-N [34]. In this study, rice straw and corn stover had good quality after ensiling, demonstrated by lactic acid content higher than 100 g/kg DM, low pH, and butyric acid content. This was because they had high WSC content (above 100 g/kg DM), sufficient LAB (> 5 lg cfu/g DM), and low BC. Lower lactic acid content was found in the QH-treated rice straw and corn stover silages relative to the control silage. Furthermore, although cell wall degradation enzyme combined with QH1 strain was added to degrade structural carbohydrates, demonstrated by lower contents of NDF, ADF, and ADL and higher WSC content than the control, QC did not promote lactic acid fermentation versus the control. These results reflected that the QH1 strain did not have a strong ability to ferment WSC into lactic acid. Similarly, the result of lower lactic acid content in cellulase-producing Bacillus strain-treated alfalfa silage was reported by Li et al. [35]. Interestingly, in the rice straw silage group, compared with the control silage, higher LA/AA and lower acetic acid content in QH-, QC-, and QLC-treated silages indicated that the QH1 strain could restrain the heterolactic fermentation, and strong heterolactic fermentation was in the control silage. However, this inhibition for heterolactic fermentation was not shown in corn stover. This was because of material factors. Similarly, material factors played a role in the ammonia-N content. Ammonia-N content in silage is an important item. The key value, 100 g/kg N, is used to evaluate protein degradation and more than this value indicates protein degradation seriously [34]. High ammonia-N content (> 100 g/kg N) in rice straw silages relative to corn stover silages stated that protein was degraded. It could be caused by enterobacteria rather than clostridia due to trace butyric acid (< 0.1 g/kg DM) in silages. Clostridia often had strong activity in silage with low contents of DM and lactic acid and high pH [36]. Enterobacteria could degrade protein and be active at pH above 4.00, demonstrated by more aerobic bacteria in rice straw than in corn stover silage in this study. Consequently, rice straw silages had a bigger DM loss tendency relative to corn stover silage averaged across the additives.

In this study, QH and QC had good effects on decreasing the contents of NDF, ADF, and ADL of rice straw and corn stover silages compared with the control. This was because of the roles of QH1 strain, secreting cell wall degrading enzymes (32.6 IU/mL of cellobiohydrolase activity), and the addition of commercial cell degrading enzymes. Dar et al. reported that cellulase secretion activity of B. tequilensis could be up to 44.02 IU/mL [37]. In contrast, the QLC did not decrease NDF, ADF, and ADL in rice straw silage compared with the control, and QLC had a good effect on decreasing the above items than the control in the corn stover silage group. This was because of material factors. Jalilvand et al. reported that cell wall degrading enzymes had specificity on the substrate [38]. Interestingly, in the rice straw silage group, higher contents of WSC, NDF, and ADL in QLC-treated silage than control. This was consistent with the views that the most digestible fraction of the structural carbohydrates was degraded by the combination of LAB and cell wall degrading enzymes; consequently, the more undigestible residue was left [39, 40]. The higher contents of lactic acid and WSC in QC- and QLC-treated silages than in the QH-treated rice straw and corn stover silages agreed with the views that saccharification of structural carbohydrates and lactic acid fermentation was enhanced by the addition of commercial cell wall degrading enzymes and LAB [41, 42]. On the other hand, the low contents of WSC content, lactic acid, NDF, ADF, and ADL in QH-treated rice straw and corn stover silages indicated that the QH1 strain might consume the WSC to produce other metabolite substances, not only lactic acid. Notably, the structural carbohydrate degradation difference between QC- and QH-treated silages was caused by the competition of bacterial and fungal cell wall degrading enzymes on the substrate and lactic acid. Lactic acid adjusted the pH of silage, and activities of cell wall degrading enzymes were influenced by pH [40].

As shown in Fig. 4, the α-tocopherol content of rice straw and corn stover silage was higher than the material before ensiling, which agreed with a part of the outcomes of rice straw silage reported by Baba and Yoshino [16]. However, this could not be explained by the previous standpoint, α-tocopherol was derived from chlorophyll degradation [11]. This was because rice straw and corn stover materials or their silages contained few chlorophylls in this study. Indeed, in the rice straw material, the α-tocopherol content was higher than chlorophyll by over 19,000 times. This indicated that rice straw and corn stover might have the α-tocopherol-producing bacteria. In both rice straw and corn stover silage, the increase rate of α-tocopherol in QH-treated silage was higher than in the control silage. This confirmed that α-tocopherol-producing QH1 strain could be applied in making silage affirmatively. Interestingly, the highest and lowest increase rate of α-tocopherol were in QLC- and QC- treated corn stover silages, respectively. The former could be explained by the synergistic effect of QH1 strain and L. plantarum in corn stover rather than in rice straw silage due to the low ammonia-N. Dar et al. found that the NH4Cl was a significant factor that influenced the activity of the B. tequilensis strain [37]. The latter could be caused by the high lactic acid production (122 g/kg DM) and low pH (3.78) in QC-treated corn stover silage. Our previous study confirmed that α-tocopherol could be degraded at low pH and high lactic acid concentration [30].

Conclusions

A novel α-tocopherol-producing bacteria was identified as B. tequilensis QH1. Additives-treated and the control rice straw and corn stover silages were preserved well and α-tocopherol was increased relative to the material before ensiling. The addition of QH1 strain increased the α-tocopherol content and maximally degraded the structural carbohydrates in rice straw and corn stover silage. The QLC maximally increased the contents of the α-tocopherol and decreased the structural carbohydrates of corn stover silage. Therefore, the QH1 strain had the potential to be applied in rice straw silage production, and QLC was recommended to be applied in corn stover silage production.

Availability of data and materials

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- ADF:

-

Acid detergent fiber expressed inclusive of residual ash

- ADL:

-

Acid detergent lignin inclusive of residual ash

- NDF:

-

Neutral detergent fiber assayed with a heat-stable amylase and expressed inclusive of residual ash

- cfu:

-

Colony-forming units

- CON:

-

Rice straw or corn stover ensiled without additives

- CP:

-

Crude protein

- DM:

-

Dry matter

- DM loss:

-

Dry matter loss

- FM:

-

Fresh matter

- LAB:

-

Lactic acid bacteria

- mEq:

-

Milligram equivalent

- N:

-

Nitrogen

- TN:

-

Total nitrogen

- QH:

-

Rice straw or corn stover ensiled with QH1 strain

- QC:

-

Rice straw or corn stover ensiled with QH1 strain combined with cell wall degradation enzyme

- QLC:

-

Rice straw or corn stover ensiled with QH1 strain combined with L. plantarum YM3 and cell wall degradation enzyme

- WSC:

-

Water-soluble carbohydrate

- SEM:

-

Standard error of the means

References

Dong C, Cai Q, Wang C, Harada J, KaS N, Yixin S. QTL analysis for traits associated with feeding value of straw in rice (Oryza sativa L.). Rice Sci. 2008;15:6. https://doi.org/10.1016/S1672-6308(08)60042-6.

Wang J, Yang ZP. Effects of different additives on silage qualities of corn stalks. Anim Husb Feed Sci. 2009;1:17–9. https://doi.org/10.19578/j.cnki.ahfs.2009.z3.006.

Feng Y, Zhao X, Guo Y, Yang G, Ren G. Changes in the material characteristics of maize straw during the pretreatment process of methanation. Biomed Res Int. 2012;2012:325426. https://doi.org/10.1155/2012/325426.

Soest P. Rice straw, the role of silica and treatments to improve quality. Anim Feed Sci Technol. 2006;130:137–71. https://doi.org/10.1016/j.anifeedsci.2006.01.023.

Sun L, Yin Q, Gentu G, Xue Y, Hou M, Liu L, Jia Y. Feeding forage mixtures of alfalfa hay and maize stover optimizes growth performance and carcass characteristics of lambs. Anim Sci J. 2018;89:359–66. https://doi.org/10.1111/asj.12928.

Eun JS, Beauchemin KA, Hong SH, Bauer MW. Exogenous enzymes added to untreated or ammoniated rice straw: effects on in vitro fermentation characteristics and degradability. Anim Feed Sci Technol. 2006;131:87–102. https://doi.org/10.1016/j.anifeedsci.2006.01.026.7.

Ni K, Wang Y, Pang H, Cai Y. Effect of cellulase and lactic acid bacteria on fermentation quality and chemical composition of wheat straw silage. Am J of Plant Sci. 2014;5:13. https://doi.org/10.4236/ajps.2014.513201.

Lindqvist H, Nadeau E, Jensen SK. Alpha-tocopherol and β-carotene in legume-grass mixtures as influenced by wilting, ensiling and type of silage additive. Grass Forage Sci. 2011;69:119–28. https://doi.org/10.1111/j.1365-2494.2011.00827.x.

Kalač P. Carotenoids, ergosterol and tocopherols in fresh and preserved herbage and their transfer to bovine milk fat and adipose tissues: a review. J Agrobiol. 2012;29:1–13. https://doi.org/10.2478/v10146-012-0001-7.

Pagan JD, Kane E, Nash D. Form and source of tocopherol affects vitamin E status in Thoroughbred horses. Pferdeheilkunde. 2005;21:101–2. https://doi.org/10.21836/pem20050743.

Sato S, Uegaki R, Kawamura J-y, Kimura T. Enhancement of α-tocopherol by ensiling in barley (Hordeum vulgare) and wheat (Triticum aestivum). Grassl Sci. 2018;64(4):245–51. https://doi.org/10.1111/grs.12204.

Rise M, Cojocaru M, Gottlieb HE, Goldschmidt EE. Accumulation of α-tocopherol in senescing organs as related to chlorophyll degradation. Plant Physiol. 1989;89:1028–30. https://doi.org/10.1104/pp.89.4.1028.

Jia T, Sun Z, Gao R, Yu Z. Lactic acid bacterial inoculant effects on the vitamin content of alfalfa and Chinese leymus silage. Asian-Austral J Anim Sciences. 2019;32:1873–81. https://doi.org/10.5713/ajas.19.0135.

Zong C, Wu Q, Wu A, Chen S, Dong D, Zhao J, Shao T, Liu Q. Exploring the diversity mechanism of fatty acids and the loss mechanisms of polyunsaturated fatty acids and fat-soluble vitamins in alfalfa silage using different additives. Anim Feed Sci Technol. 2021;280:115044. https://doi.org/10.1016/j.anifeedsci.2021.115044.

Cinquina CL. Isolation of tocopherol from Desulfotomaculum nigrificans. J Bacteriol. 1968;95:2436–8. https://doi.org/10.1128/JB.95.6.2436-2438.1968.

Baba M, Yoshino K. Silage fermentation quality by the harvest of straight rice straw crop preparation method and β-carotene and α-tocopherol. Bull Saitama Prefect Agric Forest Res Center. 2007;10:61–3.

Ca K. β-carotene and α-tocopherol contents of forage rice plant (Oryza sativa L.) and silage making for fattening beef cattle. Jpn J Grassl Sci. 2007;53:167–71. https://doi.org/10.14941/grass.53.167.

Radhika V, Subramanian S, Natarajan KA. Bioremediation of zinc using Desulfotomaculum nigrificans: bioprecipitation and characterization studies. Water Res. 2006;40:3628–36. https://doi.org/10.1016/j.watres.2006.06.013.

Liu QH, Yang FY, Zhang JG, Shao T. Characteristics of Lactobacillus parafarraginis ZH1 and its role in improving the aerobic stability of silages. J Appl Microbiol. 2014;117:405–16. https://doi.org/10.1111/jam.12530.

Saitou N, Nei M. The neighbor-joining method: a new method for reconstructing phylogenetic trees. Mol Biol Evol. 1987;4:406. https://doi.org/10.1093/oxfordjournals.molbev.a040454.

Endo A, Okada S. Lactobacillus satsumensis sp. Nov., isolated from mashes of shochu, a traditional Japanese distilled spirit made from fermented rice and other starchy materials. Int J Syst Evol Micr. 2005;55:83. https://doi.org/10.1099/ijs.0.63248-0.

Boone DR, Garrity GM, Castenholz RW, Brenner DJ, Krieg NR, Staley JT. Bergey’s manual of systematic bacteriology: the Firmicutes, vol. 3. 2nd ed. New York: Springer; 2001. p. 21–128. https://doi.org/10.1007/978-0-387-21609-6.

Liu Q, Li J, Zhao J, Wu J, Shao T. Enhancement of lignocellulosic degradation in high-moisture alfalfa via anaerobic bioprocess of engineered Lactococcus lactis with the function of secreting cellulase. Biotechnol Biofuels. 2019;12:88. https://doi.org/10.1186/s13068-019-1429-4.

Playne MJ, McDonald P. The buffering constituents of herbage and of silage. J Sci Food Agric. 1966;17:264–8. https://doi.org/10.1002/jsfa.2740170609.

Krishnamoorthy U, Muscato TV, Sniffen CJ. Nitrogen fractions in selected feed stuffs. J Dairy Sci. 1982;65:217–25. https://doi.org/10.3168/jds.S0022-0302(82)82180-2.

Liu QH, Dong ZH, Shao T. Effect of additives on fatty acid profile of high moisture alfalfa silage during ensiling and after exposure to air. Anim Feed Sci Technol. 2018;236:29–38. https://doi.org/10.1016/j.anifeedsci.2017.11.022.

Soest P, Robertson JB, Lewis BA. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci. 1991;74:3583–97. https://doi.org/10.3168/jds.S0022-0302(91)78551-2.

Broderick GA, Kang JH. Automated simultaneous determination of ammonia and total amino acids in ruminal fluid and in vitro media. J Dairy Sci. 1980;63:64–75. https://doi.org/10.3168/jds.S0022-0302(80)82888-8.

Liu S, Lai M, Lin Z. Spectrophotometric determination of vitamin E and its significance. Acta Nutrimenta Sinica. 1987;9:12. https://doi.org/10.13325/j.cnki.acta.nutr.sin.1987.04.012.

Liu QH, Shao T, Bai YF. The effect of fibrolytic enzyme, Lactobacillus plantarum and two food antioxidants on the fermentation quality, alpha-tocopherol and beta-carotene of high moisture napier grass silage ensiled at different temperatures. Anim Feed Sci Technol. 2016;221:1–11. https://doi.org/10.1016/j.anifeedsci.2016.08.020.

Kalaji HM, Dąbrowski P, Cetner MD, Samborska IA, Łukasik I, Brestic M, Zivcak M, Tomasz H, Mojski J, Kociel H, Panchal BM. A comparison between different chlorophyll content meters under nutrient deficiency conditions. J Plant Nutr. 2017;40:1024–34. https://doi.org/10.1080/01904167.2016.1263323.

Pradhan AK, Pradhan N, Mall G, Panda HT, Sukla LB, Panda PK, Mishra BK. Application of lipopeptide biosurfactant isolated from a halophile: Bacillus tequilensis CH for inhibition of biofilm. Appl Biochem Biotech. 2013;71:1362–75. https://doi.org/10.1007/s12010-013-0428-3.

Ye J, N C, J Z, H Y, Wu J. Research application progress on the Bacillus sp. in plant pathogenic fungi biocontrol. Agric Sci Technol. 2013;14:695–8.

McDonald P, Henderson AR, Heron S. The Biochemistry of Silage. 1991.

Dx Li, Ni KK, Zhang YC, Ling YL, Yang FY. Influence of lactic acid bacteria, cellulase, cellulase-producing Bacillus pumilus and their combinations on alfalfa silage quality. J Integr Agr. 2018;17:2768–82.

Kung L, Shaver RD, Grant RJ, Schmidt RJ. Silage review: interpretation of chemical, microbial, and organoleptic components of silages. J Dairy Sci. 2018;101:4020–33. https://doi.org/10.3168/jds.2017-13909.

Dar MA, Pawar KD, Chintalchere JM, Pandit RS. Statistical optimization of lignocellulosic waste containing culture medium for enhanced production of cellulase by Bacillus tequilensis G9. Waste Disposal Sustain Energy. 2019;1:213–6. https://doi.org/10.1007/s42768-019-00016-w.

Jalilvand G, Odongob NE, Lópezd S, Naserianc A, Valizadehc R, Eftekhar Shahrodic F, Kebreabb E, France J. Effects of different levels of an enzyme mixture on in vitro gas production parameters of contrasting forages. Anim Feed Sci Technol. 2008;146:289–301. https://doi.org/10.1016/j.anifeedsci.2008.01.007.

Dolezal P, Biro D. The effect of urea additive on the fermentation process of ensilaged sugar beet pulp. Acta Fytotech Zootech. 2002;5:43–6.

Muck RE, Nadeau EMG, McAllister TA, Contreras-Govea FE, Santos MC, Kung JL. Silage review: recent advances and future uses of silage additives. J Dairy Sci. 2018;101(5):3980–4000. https://doi.org/10.3168/jds.2017-13839.

Mohapatra S, Padhy S, Mohapatra PKDT, H N. Enhanced reducing sugar production by saccharification of lignocellulosic biomass, pennisetum species through cellulase from a newly isolated aspergillus fumigatus. Bioresour Technol. 2018;253:262–72. https://doi.org/10.1016/j.biortech.2018.01.023.

Xu D, Ding Z, Bai J, Ke W, Zhang Y, Li F, Guo X. Evaluation of the effect of feruloyl esterase-producing Lactobacillus plantarum and cellulase pretreatments on lignocellulosic degradation and cellulose conversion of co-ensiled corn stalk and potato pulp. Bioresour Technol. 2020;310:123476. https://doi.org/10.1016/j.biortech.2020.123476.

Acknowledgements

This work was supported by the Key research and development projects of Hainan province (ZDYF2022XDNY153), the National Natural Science Foundation of China (31971765), and the Natural Science Foundation of Chongqing city (cstc2019jcyj-msxmX0066).

Funding

This work was supported by the Key research and development projects of Hainan province (ZDYF2022XDNY153), the National Natural Science Foundation of China (31971765), and the Natural Science Foundation of Chongqing city (cstc2019jcyj-msxmX0066).

Author information

Authors and Affiliations

Contributions

Professor Qinhua Liu and Tao Shao designed the experiment. Dr. Qifeng Wu, Yu **ao, and Cheng Zong experimented using the methods in the related references. Dr. Qifeng Wu wrote the manuscript. All authors edited and reviewed the manuscript. Dr. Qinhua Liu, as the corresponding author, submitted this paper. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors listed have read the complete manuscript and have approved submission of the paper.

Competing interests

No conflicts of interest declared by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Fig. S1.

Color change of QH1 strain in MB medium after culturing for 48 h. Fig. S2 The 16S rRNA sequence of the QH1 strain.

Additional file 2: Table S1.

Effects of additives on the fermentation characteristics of rice straw and corn stover silages. Table S2. Effects of additives on the chemical compositions of rice straw and corn stover silages.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Wu, Q., **ao, Y., Shao, T. et al. Effects of additives containing a novel strain on the fermentation characteristics, structural carbohydrates, and α-tocopherol content of rice straw and corn stover silages. Chem. Biol. Technol. Agric. 10, 21 (2023). https://doi.org/10.1186/s40538-023-00382-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40538-023-00382-y