Abstract

Background

Rhizomucor miehei (RM) lipase is a regioselective lipase widely used in food, pharmaceutical and biofuel industries. However, the high cost and low purity of the commercial RM lipase limit its industrial applications. Therefore, it is necessary to develop cost-effective strategies for large-scale preparation of this lipase. The present study explored the high-level expression of RM lipase using superfolder green fluorescent protein (sfGFP)-mediated Escherichia coli secretion system.

Results

The sfGFP(−15) mutant was fused to the C-terminus of RM lipase to mediate its secretion expression. The yield of the fusion protein reached approximately 5.1 g/L with high-density fermentation in 5-L fermentors. Unlike conventional secretion expression methods, only a small portion of the target protein was secreted into the cell culture while majority of the fusion protein was still remained in the cytoplasm. However, in contrast to intracellular expression, the target protein in the cytoplasm could be transported efficiently to the supernatant through a simple washing step with equal volume of phosphate saline (PBS), without causing cell disruption. Hence, the approach facilitated the downstream purification step of the recombinant RM lipase. Moreover, contamination or decline of the engineered strain and degradation or deactivation of the target enzyme can be detected efficiently because they exhibited bright green fluorescence. Next, the target protein was immobilized with anion-exchange and macropore resins. Diethylaminoethyl sepharose (DEAE), a weak-basic anion-exchange resin, exhibited the highest bind capacity but inhibited the activity of RM lipase dramatically. On the contrary, RM lipase fixed with macropore resin D101 demonstrated the highest specific activity. Although immobilization with D101 didn’t improve the activity of the enzyme, the thermostability of the immobilized enzyme elevated significantly. The immobilized RM lipase retained approximately 90% of its activity after 3-h incubation at 80 °C. Therefore, D101 was chosen as the supporting material of the target protein.

Conclusion

The present study established a highly efficient strategy for large-scale preparation of RM lipase. This innovative technique not only provides high-purity RM lipase at a low cost but also has great potential as a platform for the preparation of lipases in the future.

Similar content being viewed by others

Background

Lipases (glycerol ester hydrolases E.C. 3.1.1.3) catalyze hydrolysis as well as esterification reactions and is one of the most widely used enzymes in biocatalysis being identified [1, 2]. In terms of regioselectivity, there are three types of lipases: sn-1,3-selective (hydrolyze the ester bonds of triglycerides at positions R1 or R3), sn-2-selective (hydrolyze the ester bonds of triglycerides at position R2) and non-selective. Lipases derived from R. miehei (RM lipase) is a regioselective lipase which can only catalyze 1, 3-diglceride or 1-monoglyceride. It can catalyze the hydrolysis of triacylglycerols (TAGs) into glycerol and fatty acids, synthesize esters from various alcohols and fatty acids and undergo transesterification and aminolysis reactions [3]. Therefore, it is widely used in chemical synthesis [4, 5], degradation of biological waste oil [6], food [16]. We reported a novel E. coli secretion expression system mediated by sfGFP previously [17]. It indicated that sfGFP motif guided the secretion of various proteins fused at its C-terminus. It proposed that the β-barrel structure and negative charges distributed on the surface of the molecules facilitated the secretion of the target protein fused with it. Therefore, serial of sfGFP bearing various net negative charges were generated. Among them, sfGFP mutant bearing 15 net negative charges, sfGFP(-15) demonstrated the highest efficiency. In the present study, we discovered that RM lipase can be expressed with this E. coli secretion system efficiently. Interestingly, RM lipase was secreted efficiently with the target protein fused to either N- or C-terminus of sfGFP(-15), which suggested that sfGFP secretion system works with a mechanism different from the conventional signal peptides. The recombinant protein was further immobilized with resins and used to convert TAG to diacylglycerol (DAG).

The secretion expression of RM lipase levitated the cellular toxicity of the protein and simplified the downstream purification, hence, increased the yield of the target protein and reduced the overall cost of the protein preparation. More importantly, the whole procedure can be monitored by naked eyes because sfGFP(-15) endows the engineering strains and the enzyme obvious green colour (Fig. 1). Therefore, the contamination or decline of the engineering strain can be detected by naked eyes easily. The fermentation progress can be monitored through measuring the fluorescence intensity of the cell culture. The activity of the fixed enzyme can be estimated by the colour change of the resins.

Materials and Methods

Strains, Plasmids, Media and Reagents

E. coli DH5α for gene cloning were stored in our lab. E. coli BL21, BL21 (DE3), BL21 (DE3) pLysS, BL21 CodonPlus (DE3) were purchased from TransGen Biotechnology (China). E. coli C41, C43 and Rossetta (DE3) were purchased from Biyotime (China). Plasmid pET23a-sfGFP(−15) was stored in our lab. Luria–Bertani (LB) were prepared as described in the Manual of Molecular Cloning [18]. The substrate 4-nitrophenyl palmitate (p-NPP) was purchased from Macklin (USA) and 4-Nitrophenol was purchased from Macklin (USA). Dibutyl phthalate (DBP), bis(2-ethylhexyl) phthalate (DEHP), dicyclohexyl phthalate (DCHP) were purchased from ANPEL-Trace Standard Technical Services (Shanghai, China). Isopropyl cyclohexane-3-ene carboxylate (CHCI) and methyl cyclohex-3-ene-1-carboxylate (CHCM) were purchased from Haohong Scientific Co. Ltd (Shanghai, China). XAD-22 resin was purchased from ROHM (USA). D101, D201, AB-8 and D301 resins were purchased from Anhui Sanxing (China). DEAE resin was purchased from Ruidahenghui (China). DAG standard was purchased from Yuanye Biotechnology (China). All other chemicals were analytical reagents.

Expression and Recovering of RM Lipase Fused with sfGFP(−15)

The ORF encoding RM lipase was synthesized by Sangon (China) and cloned into pET23a vector through TLTC method to generate expression vectors pET23a-RM, pET23a-sfGFP(−15)-RM and pET-RM-sfGFP(−15) [19]. To facilitate the purification, a 6×His tag was fused to the N-termini of the fusion proteins. The recombinant plasmids were verified by Sanger sequencing, followed by transforming into E. coli BL21 (DE3). To induce the expression of the target genes, the transformants were incubated at 37 °C to OD600 of 0.6–0.8, and then induced with 0.5 mM of Isopropyl-β-D-thiogalactopyranoside (IPTG) at 18 °C for 24 h. To recover the recombinant protein, the cells were collected by centrifugation at 5000 rpm for 10 min, followed by incubating with 1 mL of PBS at 4 °C, overnight.

Purification of RM-sfGFP(−15) with Ni-affinity Chromatography

Cells were collected and resuspended in lysis buffer (50 mM Tris-HCl; 200 mM NaCl; 50 mM NaH2PO4; 25 mM Imidazole; 10% Glycerol, pH 8.0) with lysozyme to a final concentration of 1 mg/mL. Samples were ultrasonicated to break the cells. The crude cell lysate was collected after centrifugation at 13,000 rpm for 10 min. The sample was then centrifugated at 13,000 rpm for 10 min, and the supernatant was applied to Ni-NTA beads for affinity purification. The column was washed twice with 2 column volume of wash buffer (50 mM Tris-HCl; 200 mM NaCl; 50 mM NaH2PO4; 40 mM Imidazole, pH 8.0). One column volume of elution buffer (50 mM Tris-HCl; 200 mM NaCl; 50 mM NaH2PO4; 200 mM Imidazole, pH 8.0) was used to recover the target protein. The sample was then collected and dialyzed with a Millipore 10-kDa cut-off membrane at 4 °C to remove ions and salts, followed by resuspending with storage buffer (50 mM Tris-HCl, pH 7.5).

Evaluation of the Concentration of the Target Protein

To determining the concentration of RM lipase fused with sfGFP(−15) in the cells directly, the fusion protein was purified and the concentration was evaluated with Bradford method [20]. Meanwhile, the fluorescence intensity of serial diluted fusion protein was measured with spectrum photometer at wavelength of 488 nm and a standard curve was plot.

Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis (SDS-PAGE)

Protein samples were separated via SDS-PAGE using 10 ~ 15% (w/v) polyacrylamide gel, followed by staining with Coomassie Brilliant Blue G250.

Analysis of the Enzymatic Activity of RM Lipase

To investigate the activity of the recombinant RM lipase, p-NPP was used as the substrate. In a standard assay, the reaction mixture contained 40 µL of p-NPP (12.5 mM), 940 µL of Tris-HCl buffer (50 mM, pH 8.0) and 20 µL of diluted enzyme solution. The mixture was incubated at 40 ℃ for 5 min and the reaction was terminated with 60 µL of 20% Trichloroacetic Acid. Subsequently, 300 µL of 0.5 M NaOH was added and the sample was centrifuged at 1000 g for 1 min, followed by measuring the absorbances at 405 nm. All experiments were conducted in triplicate and 4-Nitrophenol was used to plot the standard curve. One unit (U) of lipase activity was defined as the amount of enzyme that released 1 µmol of p-NP from p-NPP per min under the assay conditions.

To analyze the substrate spectrum of RM lipase with or without sfGFP(−15), several commonly used esters, including CHCM, CHCI, DBP, DEHP, and DCHP were tested. To set the reactions, 50 µL of CHCM or CHCI (1 M), 28 µL of DBP (70mM, dissolved in acetonitrile), 40 µL DEHP (50 mM), 20 µL of DCHP (100 mM) was used. All the substrates were dissolved in acetonitrile. Equal molar of RM lipase with or without sfGFP(−15) (approximately 7 nmol) was added the reaction mixture to a final volume of 1 mL. The mixture was incubated at 37 ℃ for 40 min, followed by adding 200 µL of acetonitrile to terminate the reaction. The samples were centrifuged at 10,000×g for 1 min, followed by HPLC to analyze the decrease of the substrates.

A Prominence Ultra-Fast Liquid Chromatograph (Shimadzu) equipped with an GL Sciences InertSustain C18 column (4.6 × 250 mm, 5 μm). To analyze CHCM and CHCI, the mobile phase was 10 mM Na2HPO4 (pH 3.0) and acetonitrile at a flow rate of 1.0 mL/min. The elution condition was 0–15 min with 20–75% (v/v) methanol linear gradient and 15–25 min with 75 − 20% methanol linear gradient. The effluent was monitored at a wavelength of 205 nm. To analyze DBP, DEHP, and DCHP, the mobile phase was 40% acetonitrile and methanol/acetonitrile solution (6:4 in volume) at a flow rate of 1.3 mL/min. The elution program is set to increase the volume fraction of mobile phase B from 0 to 40% (v/v) within the first 0–21 min, from 40 to 60% (v/v) within 21–45 min, from 60 to 80% (v/v) within 45–50 min, from 80 to 100% (v/v) within 50–67 min, and from 100 to 0% (v/v) within 67–68 min. The effluent was monitored at a wavelength of 242 nm. All experiments were conducted in triplicate and the substrates were used to plot the standard curve.

High-density Fermentation of the Recombinant RM Lipase

Fed-batch fermentation was performed as previously described [21]. The recombinant E. coli strain was inoculated into individual flasks containing 100 mL of LB supplemented with 100 µg/mL of Ampicillin, and the cultures were incubated at 200 rpm, 37 °C until OD600 reached 0.6. The cell culture was then transferred into 5-L fermenters (BG-4, Baoxing, China) containing 2 L of LB medium (Tryptone 10%, yeast extract 5%, NaCl 10%, pH7.0). During the early stage of the fermentation, the culture was maintained at 37 °C, pH 6.5-7.0 using NaOH. The cell culture was agitated at 300 rpm to maintain 30% dissolved oxygen (DO). After approximately 18 to 24 h, medium (280.5 g/L glucose, 96.2 g/L NH4Cl)was added to the cell growth continuously, with DO kept above 20%. When OD600 increased to approximately 30–40, the temperature of the cell culture was adjusted to 28 °C and the expression of the target gene was induced with IPTG. DO of the cell culture was kept at 20 to 30% with agitation of 600 rpm. This condition was maintained until the end of the fermentation.

Immobilization of the Recombinant RM Lipase

The resins were rinsed with 95% of ethanol for 24 h and washed with dH2O twice, followed by rinsing with 5% (v/v) HCl for 2 h and washed with dH2O until pH back to 7.0. Five mil-liter of the enzyme (5 mg/mL) was added to 0.2 g resin. The mixture was incubated at 4 ℃ overnight to fix the enzyme. The immobilized enzyme was collected by centrifuging at 5000×g for 1 min, followed by washing with the washing buffer twice. Subsequently, the immobilized enzyme was lyophilized for 8 h to remove water and stored at 4℃ for further use. To improve the activity of the fixed enzyme with KCl, equal volume of the enzyme was added to 2.5 mL 25% (w/v) of KCl (supplemented with 0.2% (w/v) of sorbitol and 0.2% (w/v) of sucrose) to a final concentration of 2.5 mg/mL, followed by adding 0.2 g resin.

Recovering and Reusage of the Immobilized RM Lipase

Approximately 1.5 mg of the immobilized RM lipase was added to the reaction mixture contained 400 µL of p-NPP (12.5 mM), 9.6 mL of Tris-HCl buffer (50 mM, pH 8.0). The mixture was incubated at 40 ℃ for 5 min. Subsequently, the immobilized enzyme was recovered though filtration with a vacuum filtration device using filter paper and applied for the next round of reaction.

Characterization of the Immobilized RM Lipase

To determine the optimum temperature of the immobilized RM lipase, the enzymatic activity was measured at the gradient temperatures with an interval of 5 °C in phosphate buffer (50 mM, pH8.0). The optimum pH was determined by measuring the enzymatic activities in the following buffer: pH 6.0–8.0 (phosphate buffer, 50 mM) and pH 9.0–10.0 (Tris-HCl buffer, 50 mM). To evaluate the thermostability of the immobilized RM lipase, the enzyme was incubated in phosphate buffer (50 mM, pH 8.0) at 70 ℃, 75 ℃ and 80 ℃ for 0–3 h, followed by measuring the residual activity at 40℃. All the assays were performed in triplicate.

Glycerolysis of TAG in the Solvent-free System Using RM-sfGFP(−15) IM

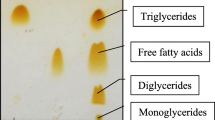

The enzymatic glycerolysis reaction was carried out as previously reported [22]. The reaction mixture consisted of glycerol and soybean oil at a molar ratio of 5:1, followed by adding 0.5 g of immobilized lipase. The sample was incubated at 50 °C for 3 h. The reaction was stirred using a magnetic stirrer at 180 rpm. Thin-layer chromatography (TLC) with Silica TLC gel 60F10-20 cm from Haiyang Chemical Co., Ltd. (Qingdao, China) was performed to monitor the progress of the reaction. The solvent system contained Hexane, Anhydrous ether, Formic acid at a ratio of 80:20:2 (v/v/v). Iodine was used to stain the gel.

Fluorescence-activated Cell Sorting (FACS) Assay to Evaluate the Intensity of Green Fluorescence of RM Lipase-sfGFP(−15)

To monitor the expression of the GFP fusion protein during the high-density fermentation with FACS, 5 mL of cell culture was collected every 3 h. Cells from each sample were sorted with Flow Cytometer (Beckman Coulter, USA). The intensity of the green florescence was measured with the FITC channel, 525/460 nm band pass.

To test whether the cells maintained intact after the GFP fusion protein was washing off with PBS buffer, the cells were sorted with Flow Cytometer (Beckman Coulter, USA) before and after washing. The intensity of the green florescence was measured with the FITC channel, 525/460 nm band pass.

Results

Construction of the Recombinant Strains for the sfGFP(−15)-mediated Secretion Expression of RM Lipase

To achieve secretion expression of RM lipase, its ORF (Genbank Accession No. AKA60076.1) including the propeptide coding sequence was cloned into pET23a-sfGFP(−15) (Fig. 2A) and transformed to E. coli BL21 (DE3), followed by spreading on LB plates supplemented with ampicillin and incubating at 37 °C overnight. The colonies displayed obvious green fluorescence under blue light due to leaking expression of the fusion protein (Fig. 2B). The green colonies were inoculated into shake flasks for the expression of the target protein. The cell culture displayed bright green fluorescence. The result of SDS-PAGE indicated a single band consistent with the predicted molecular weight of the target protein was detected in the supernatant (Fig. 3B, C). On the contrary, no obvious band was detected in the supernatant of the cell culture with RM lipase expressed using intracellular expression vector pET23a-RM (Fig. 3A). Although only a small portion of the target protein was secreted, the target protein remained in the cells was translocated into the supernatant after incubated in PBS at 4 °C overnight (Fig. 3B, C). On the other hand, the intracellularly expressed RM lipase was remained in the cells after washing (Fig. 3A). Consistent with the result of SDS-PAGE, the fluorescence was transfer to the washing buffer after incubated with PBS (Fig. 3B, C). These results proved that sfGFP(−15) mediated the secretion expression of RM lipase successfully. It worth noting that the secretion expression was achieved with sfGFP(−15) fused to either N- or C-terminal of RM lipase, which implied that sfGFP(−15) mediated secretion through a mechanism different from conventional signal peptides.

The previous reports indicated that RM lipase is synthesized as a precursor that includes a 70-amino acid propeptide before the 269 amino-acid residues of the mature enzyme. This propeptide is important for the correct folding of RM lipase [23,24,25]. In the present study, the specific activity of RM lipase was 8016.9 U/g while the specific activities of RM-sfGFP(−15) and sfGFP(−15)-RM were 4153.7 U/g and 2453.3 U/g, respectively. As the molecular weight of RM lipase and the fusion protein were approximately 36.8 kDa and 64.5 kDa, the specific activity of RM lipase was 295.6 U/µmol and 258.6 U/µmol for RM-sfGFP(−15), 157.3 U/µmol for sfGFP(−15)-RM. This result suggested that sfGFP(−15) affected the activity of RM lipase slightly, but inhibited the propeptide to exert its function dramatically. Therefore, sfGFP(−15) fused to the C-terminus of RM lipase (RM-sfGFP(−15) ) was used for the further study.

Schematic illustrating the structure of the proteins. (A) the structure of the fusion protein. The ORF of the mature lipase is blue and the propeptide is light blue. The ORF of sfGFP(−15) is green. (B) the colonies of E. coli BL21(DE3) bearing pET23a-RM (left) and pET23a-RM-sfGFP(−15) (right) on LB plates supplemented with Ampicillin

SDS-PAGE to analyze the sfGFP(−15)-mediated secretion expression of RM lipase. (A) the recombinant expression of RM lipase in E. coli; (B) the recombinant expression of RM lipase with sfGFP(−15) fused to its N-terminus; (C) the recombinant expression of RM lipase with sfGFP(−15) fused to its C-terminus. M. protein molecular weight marker (the size of each band was indicated on the left). S stands for the supernatant and C stands for the cells

The Effect of sfGFP(−15) Tag to the Activity of RM Lipase to Various Esters

The activity of RM lipase and RM- sfGFP(−15) to commonly used chemical materials, such as CHCM, CHCI, DBP, DEHP, and DCHP were tested. The result indicated all of them can be catalyzed by both RM lipase and RM-sfGFP(−15). RM lipase demonstrated 2.0 and 1.5-fold higher activity to plasticizers, DBP, DEHP, and DCHP than RM-sfGFP(−15). On the contrary, RM-sfGFP(−15) showed slightly higher activity to drug precursors, such as CHCM and CHCI (Supplementary Table 1). This result indicated the effects of sfGFP(−15) to RM lipase vary with each chemical.

Optimization of the Secretion Expression of RM Lipase

Because sfGFP has absorbance at 488 nm, we plot a standard curve using the concentration of RM-sfGFP against the fluorescence intensity of the RM-sfGFP at 488 nm (Supplementary Fig. 1). Consequently, the concentration of the recombinant protein can be quantitively analyzed through measuring OD488 of the cell culture directly, which facilitated the expression condition optimization. The secretion expression of RM lipase with different E. coli expression strains were investigated and the result indicated the highest yield was obtained with E. coli BL21(DE3) (Fig. 4A). Therefore, it was chosen as the host for further studies. Next, the induction condition was optimized. The highest fluorescence intensity was obtained after 15 h of induction using IPTG of 0.1 mM (Fig. 4B), with a yield of the target protein reached 0.168 g/L.

High-density Fermentation to Generate RM-sfGFP(−15)

The RM lipase was also prepared with high-density fermentation. The color change of the cells during the whole process of the fermentation was visible (Fig. 5A). The green fluorescence intensity of the cell culture increased gradually during the first 18-h cell growth phase and reached maximum after 3 h of induction (Fig. 5B). The results of SDS-PAGE and FACS confirmed this result (Fig. 5C and D, Supplementary Fig. 2).

The 5-L high-density fermentation of RM-sfGFP(−15). (A) the color change of the cell culture during the fermentation; (B) cell density and the fluorescent intensity of the target protein during the fermentation; (C) SDS-PAGE to analyze the expression of the target protein during the fermentation (the target protein is indicated with a black arrow). Three samples were collected at each time point and standard deviations are indicated. M. protein molecular weight marker (the size of each band was indicated on the left); (D) FACS to analyze the fluorescent intensity of the cells during the fermentation

After the fermentation, the cells were collected and RM-sfGFP(−15) was washed off from the cells. The yield of the target protein was approximately 5.1 mg/mL. The result of FACS indicated the shape of the cells remained contact after washing with PBS while the fluorescence intensity decreased dramatically (Fig. 6A and B), which suggested that the target protein was released to the buffer without causing cell disruption. The result of SDS-PAGE also indicated that most of the target protein was translocated into PBS after washing (Fig. 6C). Therefore, the target protein was separated from the endogenous proteins through centrifugation and the supernatant was utilized for immobilization directly.

FACS and SDS-PAGE to analyze the of fluorescent intensity of the cells. (A) cells collected before washing with PBS overnight; (B) cells collected after washing with PBS overnight. (C) SDS-PAGE of the cells from A (lane 1) and B (lane 2). M. protein molecular weight marker (the size of each band was indicated on the left)

The Immobilization of RM-sfGFP(−15)

RM-sfGFP(−15) was immobilized with three types of resins, including nonpolar macroporous, polar macroporous, and anion-exchange resins (Table 1). All of the resins were able to fix RM-sfGFP(−15).The fluorescence intensity of the enzyme solution decreased obviously after immobilization and the resins were stained to bright green (Fig. 7A). Since the surface of RM-sfGFP(−15) molecules were covered with negative charges, it is reasonable that anion-exchange resins, such as DEAE and D301 showed the highest immobilization capacity. Interestingly, DEAE demonstrated above 5-fold higher binding capacity to RM-sfGFP(−15) in comparison with D301 resin. Approximately 364.5 mg of the target protein was immobilized by 1 g of DEAE resin. On the contrary, D201 resin demonstrated the lowest immobilization efficiency, with only 46.8 mg of the target protein was fixed (Table 1). The enzyme activity of RM-sfGFP(−15) was inhibited to different degree after immobilization (Table 1). The enzyme activity of RM-sfGFP(−15) decreased dramatically after fixed with DEAE resin, which was only approximately 2248.1 U/g (Table 1). On the other hand, RM-sfGFP(−15) remained approximately 80% activity after fixed with D101 resin, which was 3626.2 U/g.

It is reported that KCl improves the activity of immobilized RM lipase [26]. The result of the present study indicated KCl improved 20.6% of the activity of RM-sfGFP(−15) immobilized with D101. On the contrary, KCl affected the binding of RM-sfGFP(−15) to DEAE resin significantly and most of the target protein failed binding to DEAE resin in the presence of KCl. Therefore, D101 resin was chosen as the supporting material for the immobilization of RM-sfGFP(−15). The immobilized enzyme was named as RM-sfGFP(−15) IM.

The results are presented as the means ± SDs of three independent experiments.

The Features of RM-sfGFP(−15) IM

The optimal pH of RM-sfGFP(−15) IM was pH 7.5, which was consistent with the free enzyme (Fig. 8A). However, the optimal temperature of RM-sfGFP(−15) IM was 60 ℃, which was much higher than the free enzyme (Fig. 8B). In addition, the thermostability of RM-sfGFP(−15) improved significantly after immobilization. The fixed enzyme retained above 90% of its activity after incubation at 80 ℃ for 3 h. On the contrary, the free enzyme lost half activity under this condition (Fig. 8C).

The characteristics of RM-sfGFP(−15) IM in comparison with the free RM-sfGFP(−15). (A) the optimum pH of free and immobilized RM-sfGFP(−15); (B) the optimum temperature of free and immobilized RM-sfGFP(−15); (C) The thermostability of free and immobilized RM-sfGFP(−15). Each reaction was performed in triplicate and standard deviations are indicated

The immobilized enzyme can be reused for the catalytic reaction and save the cost in industry. Therefore, the reusability of RM-sfGFP(−15) IM was investigated. The conversion efficiency of RM-sfGFP(−15) IM decreased slightly and remained approximately 91.3% activity at the second round of reaction. And then the conversion efficiency decreased gradually with the repetitive use. After 6 repeats, only 43.5% of the initial activity was preserved (Fig. 9). During the whole progress, the RM-sfGFP(−15) IM remained green color. The stability of the immobilized enzyme was tested after stored at 4 ℃ for 5 months. The result indicated that the immobilized enzyme remained approximately 71.2% of its activity.

Conversion of TAG to DAG with RM-sfGFP(−15) IM

Previous reports applied RM lipase to synthesize DAG by glycerolysis of soybean oil in a solvent-free system [27, 28]. The present study indicated that RM-sfGFP(−15) IM was able to catalyze this reaction. DAG was generated at 3-h reaction at 50 °C (Fig. 10).

Discussion

It reported that sfGFP and its mutants promoted the secretion expression of the foreign proteins [17]. The fusion protein was translocated from cytoplasm to the inner membrane, subsequently transporting to the outer membrane, and eventually the extracellular medium. Later, Zhang et al., applied this sfGFP mediated secretion system to gram-positive microbes and achieved secretary expression of phospholipase D in Bacillus subtilis successfully [29]. However, the mechanism remains unclarified. The previous study indicated that enhanced green fluorescence protein (eGFP) fused to the 218 C-terminal amino acids of α-hemolysin (HlyAc) was unable to be secreted by the type I secretion system and stalled the secretion of HlyAc, presumably because folded protein blocked the translocation [16]. The present study indicated sfGFP(−15) promotes the secretion of the target proteins fused to either N- or C-terminus. Therefore, we deduced that sfGFP and its mutants mediated the secretion through a noncanonical mechanism. Moreover, majority of the fusion protein was still retained in the cells and was separated from the cells through washing with PBS, which is also different from the conventional secretion expression. The previous study demonstrated the net negative charges of sfGFP mutants play important role in promoting the secretion expression of the fusion proteins. Consistent with this theory, RM lipase with a relatively low pI (approximately 4.82) demonstrated higher secretion efficiency than Thermomyces lanuginosus (TL) lipase (pI 5.23 ), which can also be expressed with this system efficiently, but cannot be washed off from the cells efficiently (data not shown). Another reason why RM lipase can be secreted efficiently may relate with the catalytic activity of RM lipase. This lipase may disturb the phospholipid bilayer of the cells and improve the translocation of the proteins from inner membrane to periplasm. Therefore, it is perspective to achieve successful expression of more lipases, phospholipases, esterase etc. with this system.

In most cases, RM lipase requires immobilization before used as industrial biocatalyst [3]. The binding of lipases on suitable supports allows the re-use of the biocatalysts and save the cost of the enzymes. Moreover, immobilization improves the enzyme activity, selectivity and decreases inhibition occasionally. RM lipase is an interfacial enzyme performs its function at the interface of drops of insoluble substrates (oils or fats). These lipases display low activity on water soluble, monomeric substrates in homogenous aqueous solution. As the substrate concentration increases and exceeds its critical micelle concentration, the activity increases dramatically. This phenomenon is called interfacial activation [30,31,32]. According to the structures of lipases, the interfacial activation mechanism was clarified. There is a short polypeptide chain called lid (or flap) exists in a lipase. In the closed form, it isolates the active center from the surrounding hydrophilic environment. When the lid moves to an open form, a large hydrophobic pocket and the active center is exposed to the environment, which becomes strongly adsorbed on any hydrophobic surface [33,34,35,36]. According to this theory, the well-defined hydrophobic support surfaces may resemble the hydrophobic drops of insoluble natural lipase substrates. Therefore, hydrophobic supports were considered as good support for RM lipase [37]. The lipase is adsorbed on strongly hydrophobic solid surfaces and exhibits a dramatic enhanced esterase activity in the absence of additional hydrophobic interfaces. Moreover, these supports promote highly selective adsorption of lipases, at very low ionic strength, from impure protein extracts. In this study, we chose 6 resins with different properties as the supporting material. The result indicated the fusion protein was fixed with DEAE resin at a high capacity and the binding was very stable. It is reasonable since RM lipase-sfGFP(−15) carries high net negative charges. However, the enzyme activity was significantly jeopardized after the binding. The clue lays in fact that the DEAE is a cellular-based hydrophilic material, which fails to provide a hydrophobic surface. The support of the RM IM from Novozyme is Duolite ES 562, a weak anion-exchange resin based on phenol–formaldehyde copolymers [9]. In the present study, the weak anion-exchange polystyrene resin D301 also showed a high loading capacity and activity. However, D101 and D201 resins also derived from polystyrene demonstrated an even better binding capacity. Although the activity of RM lipase was inhibited slightly after fixed, the thermostability of the fixed enzyme improved obviously. Moreover, these resins are cheap (approximately 10 dollar/kg) and the whole procedure is straightforward. Therefore, preparing immobilized RM lipase with polystyrene-based resins is feasible. It is reported that octyl–glyoxyl agarose is an ideal support for lipase because the enzyme can be immobilized on this support stability through interfacial interaction [38,39,40]. It is a good candidate and worths further study.

The commercial liquid RM and immobilized RM was prepared with A. oryzae, a Generally Recognized as Safe (GRAS) strain [41]. However, the yield of RM lipase still needs to be improved. In 2022, Li et al. increased the yield of recombinant RM lipase to 550.0 U/mL through morphology control and optimization of the fermentation process [42] Another problem with this system is the extracellular proteins of A. oryzae are abundant. Therefore, the enzyme product contains many A. oryzae endogenous proteins, which affects the industrial application of the enzyme. Lipase can also be prepared with Pichia pastoris, which is also GRAS [43, 44]. Moreover, the strong secretary expression capacity of P. pastoris lead to a high purity of the product. However, the yield of RM lipase with this system is also less than 1 g/L [12, 45]. Furthermore, the fermentation period of P. pastoris is more than a week, which is much longer than E. coli and hence, increase the cost of the recombinant RM lipase. The method in the present study overcame the low secretion efficiency of E. coli recombinant expression system [46]. The yield of the target protein reached 5.1 g/L and the pure enzyme can be washed off from cells without complex extraction process. Considering the high activity of RM, the low-cost RM-sfGFP(−15) prepared in the present study is an excellent source for biodiesel conversion. It can also be applied in pharmaceutical industry because its high activity and the protein can be removed easily during the downstream product-purification process [47, 48]. In addition, the membrane filtration in oil processing industry can also remove RM-sfGFP(−15) completely. However, we don’t recommend to add RM-sfGFP(−15) in food directly because E. coli generates endotoxin [49]. Although most cells retained contact during the PBS-washing step. Cells disrupted during fermentation and downstream preparation can still release endotoxin and contaminate the enzyme. Therefore, the enzyme needs to be purified before applied in food industry, which increased the cost of the product dramatically.

In summary, large-scale preparation of RM lipase with a visually accessible, cost-effective way was achieved in this study. Moreover, this sfGFP-mediated secretion expression system also demonstrated great potential in industrial preparation of other lipases.

Data Availability

No datasets were generated or analysed during the current study.

References

Stergiou P-Y, Foukis A, Filippou M, Koukouritaki M, Parapouli M, Theodorou LG, Hatziloukas E, Afendra A, Pandey A, Papamichael EM. Advances in lipase-catalyzed esterification reactions. Biotechnol Adv. 2013;31:1846–59.

Paiva AL, Balcão VM, Malcata FX. Kinetics and mechanisms of reactions catalyzed by immobilized lipases*. Enzyme Microb Technol. 2000;27:187–204.

Rodrigues RC, Fernandez-Lafuente R. Lipase from Rhizomucor miehei as an industrial biocatalyst in chemical process. J Mol Catal B: Enzymatic. 2010;64:1–22.

Skrobo B, Deska J. On the lipase-catalyzed resolution of functionalized biaryls. Tetrahedron: Asymmetry. 2013;24:1052–6.

da Silva MR, de Mattos MC, de Oliveira MdCF TLG, Ricardo NMPS, de Gonzalo G, Lavandera I, Gotor-Fernández V, Gotor V. Asymmetric chemoenzymatic synthesis of N-acetyl-α-amino esters based on lipase-catalyzed kinetic resolutions through interesterification reactions. Tetrahedron. 2014;70:2264–71.

Monteiro RRC, Arana-Peña S, da Rocha TN, Miranda LP, Berenguer-Murcia Á, Tardioli PW, dos Santos JCS, Fernandez-Lafuente R. Liquid lipase preparations designed for industrial production of biodiesel. Is it really an optimal solution? Renewable Energy. 2021;164:1566–87.

Huang Z, Guo Z, **e D, Cao Z, Chen L, Wang H, Jiang L, Shen Q. Rhizomucor miehei lipase-catalysed synthesis of cocoa butter equivalent from palm mid-fraction and stearic acid: characteristics and feasibility as cocoa butter alternative. Food Chem. 2021;343:128407.

Zou X, Huang J, ** Q, Guo Z, Liu Y, Cheong L, Xu X, Wang X. Lipid composition analysis of milk fats from different mammalian species: potential for use as human milk fat substitutes. J Agric Food Chem. 2013;61:7070–80.

Zou XQ, Huang JH, ** QZ, Liu YF, Tao GJ, Cheong LZ, Wang XG. Preparation of human milk fat substitutes from palm stearin with arachidonic and docosahexaenoic acid: combination of enzymatic and physical methods. J Agric Food Chem. 2012;60:9415–23.

Calero J, Verdugo C, Luna D, Sancho ED, Luna C, Posadillo A, Bautista FM, Romero AA. Selective ethanolysis of sunflower oil with Lipozyme RM IM, an immobilized Rhizomucor miehei lipase, to obtain a biodiesel-like biofuel, which avoids glycerol production through the monoglyceride formation. New Biotechnol. 2014;31:596–601.

Rodrigues RC, Fernandez-Lafuente R. Lipase from Rhizomucor miehei as a biocatalyst in fats and oils modification. J Mol Catal B: Enzymatic. 2010;66:15–32.

Huang J, **a J, Yang Z, Guan F, Cui D, Guan G, Jiang W, Li Y. Improved production of a recombinant Rhizomucor miehei lipase expressed in Pichia pastoris and its application for conversion of microalgae oil to biodiesel. Biotechnol Biofuels. 2014;7:111.

He D, Luo W, Wang Z, Lv P, Yuan Z. Combined use of GAP and AOX1 promoters and optimization of culture conditions to enhance expression of Rhizomucor miehei lipase. J Ind Microbiol Biotechnol. 2015;42:1175–82.

Sena RO, Carneiro C, Moura MVH, Brêda GC, Pinto MCC, Fé LXSGM, Fernandez-Lafuente R, Manoel EA, Almeida RV, Freire DMG, Cipolatti EP. Application of Rhizomucor miehei lipase-displaying Pichia pastoris whole cell for biodiesel production using agro-industrial residuals as substrate. Int J Biol Macromol. 2021;189:734–43.

Luo W, He D, Fu J, lv P, Qi W, Alam MA, Wang Z, Huang S. Effect of Propeptide Variation on properties of Rhizomucor miehei lipase. J Biobased Mater Bioenergy. 2018;12:330–8.

Burdette LA, Leach SA, Wong HT, Tullman-Ercek D. Develo** Gram-negative bacteria for the secretion of heterologous proteins. Microb Cell Fact. 2018;17:196.

Zhang Z, Tang R, Zhu D, Wang W, Yi L, Ma L. Non-peptide guided auto-secretion of recombinant proteins by super-folder green fluorescent protein in Escherichia coli. Sci Rep. 2017;7:6990.

Sambrook JF, Fritsch EF, Maniatis T. Molecular Cloning: A Laboratory Manual. 2001.

Yu F, Li X, Wang F, Liu Y, Zhai C, Li W, Ma L, Chen W. TLTC, a T5 exonuclease-mediated low-temperature DNA cloning method. Front Bioeng Biotechnol. 2023;11:1167534.

Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem. 1976;72:248–54.

Sohoni SV, Nelapati D, Sathe S, Javadekar-Subhedar V, Gaikaiwari RP, Wangikar PP. Optimization of high cell density fermentation process for recombinant nitrilase production in E. Coli. Bioresour Technol. 2015;188:202–8.

Noureddini H, Harmeier SE. Enzymatic glycerolysis of soybean oil. J Am Oil Chem Soc. 1998;75:1359–65.

Boel E, Huge-Jensen B, Christensen M, Thim L, Fiil NP. Rhizomucor miehei triglyceride lipase is synthesized as a precursor. Lipids. 1988;23:701–6.

Wang J, Wang D, Wang B, Mei Z-h, Liu J, Yu H-w. Enhanced activity of Rhizomucor miehei lipase by directed evolution with simultaneous evolution of the propeptide. Appl Microbiol Biotechnol. 2012;96:443–50.

Wang Z, Lv P, Luo W, Yuan Z, He D. Expression in < i > Pichia pastoris and characterization of < i > Rhizomucor miehei lipases containing a new propeptide region. J Gen Appl Microbiol. 2016;62:25–30.

Su F, Li G, Zhang H, Yan Y. Enhanced performance of Rhizopus oryzae lipase immobilized on hydrophobic carriers and its application in Biorefinery of Rapeseed Oil Deodorizer Distillate. Bioenergy Res. 2014;7:935–45.

Noureddini H, Harkey DW, Gutsman MR. A continuous process for the glycerolysis of soybean oil. J Am Oil Chem Soc. 2004;81:203–7.

Fregolente PBL, Fregolente LV, Pinto GMF, Batistella BC, Wolf-Maciel MR, Filho RM. Monoglycerides and Diglycerides Synthesis in a solvent-free system by Lipase-Catalyzed Glycerolysis. Appl Biochem Biotechnol. 2008;146:165–72.

Zhang H, Li X, Liu Q, Sun J, Secundo F, Mao X. Construction of a Super-folder fluorescent protein-guided secretory expression system for the production of phospholipase D in Bacillus subtilis. J Agric Food Chem. 2021;69:6842–9.

Brzozowski AM, Derewenda U, Derewenda ZS, Dodson GG, Lawson DM, Turkenburg JP, Bjorkling F, Huge-Jensen B, Patkar SA, Thim L. A model for interfacial activation in lipases from the structure of a fungal lipase-inhibitor complex. Nature. 1991;351:491–4.

Verger R. Interfacial activation’ of lipases: facts and artifacts. Trends Biotechnol. 1997;15:32–8.

Reis P, Holmberg K, Watzke H, Leser ME, Miller R. Lipases at interfaces: a review. Adv Colloid Interface Sci. 2009;147–148:237–50.

Grochulski P, Li Y, Schrag JD, Bouthillier F, Smith P, Harrison D, Rubin B, Cygler M. Insights into interfacial activation from an open structure of Candida rugosa lipase. J Biol Chem. 1993;268:12843–7.

Zisis T, Freddolino PL, Turunen P, van Teeseling MC, Rowan AE, Blank KG. Interfacial activation of Candida Antarctica Lipase B: combined evidence from Experiment and Simulation. Biochemistry. 2015;54:5969–79.

Ericsson DJ, Kasrayan A, Johansson P, Bergfors T, Sandström AG, Bäckvall J-E, Mowbray SL. X-ray structure of Candida Antarctica Lipase A shows a novel lid structure and a likely Mode of Interfacial activation. J Mol Biol. 2008;376:109–19.

Skjold-Jørgensen J, Vind J, Moroz OV, Blagova E, Bhatia VK, Svendsen A, Wilson KS, Bjerrum MJ. Controlled lid-opening in Thermomyces lanuginosus lipase– An engineered switch for studying lipase function. Biochim et Biophys Acta (BBA) - Proteins Proteom. 2017;1865:20–7.

Fernandez-Lafuente R, Armisén P, Sabuquillo P, Fernández-Lorente G, Guisán M. Immobilization of lipases by selective adsorption on hydrophobic supports. Chem Phys Lipids. 1998;93:185–97.

Arana-Peña S, Mendez-Sanchez C, Rios NS, Ortiz C, Gonçalves LRB, Fernandez-Lafuente R. New applications of glyoxyl-octyl agarose in lipases co-immobilization: strategies to reuse the most stable lipase. Int J Biol Macromol. 2019;131:989–97.

Rueda N, dos Santos JCS, Torres R, Ortiz C, Barbosa O, Fernandez-Lafuente R. Chapter Four - Immobilization of Lipases on Heterofunctional Octyl–Glyoxyl Agarose Supports: Improved Stability and Prevention of the Enzyme Desorption. In Methods in Enzymology. Volume 571. Edited by Kumar CV: Academic Press; 2016: 73–85.

Arana-Peña S, Rios NS, Mendez-Sanchez C, Lokha Y, Carballares D, Gonçalves LRB, Fernandez-Lafuente R. Coimmobilization of different lipases: simple layer by layer enzyme spatial ordering. Int J Biol Macromol. 2020;145:856–64.

Frisvad JC, Møller LLH, Larsen TO, Kumar R, Arnau J. Safety of the fungal workhorses of industrial biotechnology: update on the mycotoxin and secondary metabolite potential of aspergillus Niger, aspergillus oryzae, and Trichoderma reesei. Appl Microbiol Biotechnol. 2018;102:9481–515.

Li C, Xu D, **ong Z, Yang Y, Tian G, Wu X, Wang Y, Zhuang Y, Chu J, Tian X. Optimization of the Fermentative production of Rhizomucor miehei lipase in aspergillus oryzae by Controlling morphology. Bioeng (Basel) 2022, 9.

Valero F. Heterologous expression systems for lipases: a review. Methods Mol Biol. 2012;861:161–78.

Valero F. Recent advances in Pichia pastoris as host for heterologous expression system for lipases: a review. Methods Mol Biol. 2018;1835:205–16.

Huang J, Zhao Q, Chen L, Zhang C, Bu W, Zhang X, Zhang K, Yang Z. Improved production of recombinant Rhizomucor miehei lipase by coexpressing protein folding chaperones in Pichia pastoris, which triggered ER stress. Bioengineered. 2020;11:375–85.

Baneyx F. Recombinant protein expression in Escherichia coli. Curr Opin Biotechnol. 1999;10:411–21.

Serdakowski London A, Kerins B, Tschantz WR, Eisfeld J, Mackay K. Endotoxin removal and prevention for pre-clinical biologics production. Biotechnol J. 2012;7:1509–16.

Magalhães PO, Lopes AM, Mazzola PG, Rangel-Yagui C, Penna TC, Pessoa A Jr. Methods of endotoxin removal from biological preparations: a review. J Pharm Pharm Sci. 2007;10:388–404.

Swartz JR. Advances in Escherichia coli production of therapeutic proteins. Curr Opin Biotechnol. 2001;12:195–201.

Acknowledgements

Not applicable.

Funding

This work was supported by National Key R&D Program of China (No. 2021YFC2100400). Hubei Technological innovation talents program(2023DJC123).

Author information

Authors and Affiliations

Contributions

M.J. and C.Z. designed and supervised the experiments and data analysis. X.S. andexpressed and purified all related proteins. J.Y. and Z.L. performed the high-density fermentation experiments. J.Z. helped with statistical analysis of the data. F.W. and Y.L. contributed in experiments in the detection of cell fluorescence intensity by flow cytometry. C.Z. wrote the paper with inputs from the other authors. L.M. conceived and managed the project.

Corresponding authors

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Yang, M., Su, X., Yang, J. et al. A Whole-Process Visible Strategy for the Preparation of Rhizomucor miehei Lipase with Escherichia coli Secretion Expression System and the Immobilization. Microb Cell Fact 23, 155 (2024). https://doi.org/10.1186/s12934-024-02432-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-024-02432-y