Abstract

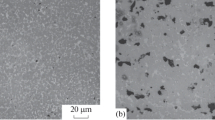

To determine the possibility of maintaining the maximum possible carbon content in TiC carbide, a powder additionally doped with chromium carbide, molybdenum, and carbon was produced by plasma spraying of the cermets of the TiC–NiCr system. To reduce the effect of gases from the air atmosphere, plasma spraying was carried out using a standard plasmatron, supplemented with a special nozzle. The analysis of the oxygen, nitrogen, and carbon content in the powder manufacturing stages and in the coatings was carried out. The content of O and N is reduced in the sintering step for spraying a powder with respect to the content in the starting components, but increases again during spraying. In the coating, the quantitative distribution of the carbide phases was determined by their size. A change in the phase composition and dimensions of the crystal lattices of the phases in the powder for deposition and coatings was determined. The share of the main hardening TiC phase in the coating decreased by 9.7% with respect to the initial mixture, but taking into account the newly formed carbide phases with the participation of chromium and molybdenum, the proportion of all the carbide phases in the coating increased by 12.7%. The microhardness of the plasma coating at loads of 200 and 20 g on the indenter was 14.9 and 28.7 GPa, respectively. The reasons for the decrease in the actual microhardness of the cermet coating in relation to the theoretically possible one based on the volume fraction of the strengthening phases are analyzed.

Similar content being viewed by others

REFERENCES

Kear, B.H., Skandan, G., and Sadangi, R.K., Factors controlling decarburization in HVOF sprayed nano-WC/Co hard coatings, Scr. Mater., 2001, vol. 44, pp. 1703–1707.

Zhilyaev, V.A. and Patrakov, E.I., Influence of the method of production of TiC–Ni–Mo alloy on the features of formation of its composition and microstructure, Sov. Powder Metall. Met. Ceram., 1989, vol. 28, no. 8, pp. 626–632.

Kalita, V.I. and Komlev, D.I., Plazmennye pokrytiya s nanokristallicheskoi i amorfnoi strukturoi (Plasma Coatings with Nanocrystalline and Amorphous Structure), Moscow: Biblioteka, 2008.

Tret’yakov, V.I., Osnovy metallovedeniya i tekhnologii proizvodstva spechennykh tverdykh splavov (Fundamental Metal Science and Production Technology of Sintered Solid Alloys), Moscow: Metallurgiya, 1976.

Tsidulko, A.G., Rusanov, V.M., Bobrov, G.V., Doku-kina, I.A., Timofeeva, I.I., and Shaposhnikova, T.I., Loss of carbon during plasma-spraying of clad carbide powders, 1992, vol. 31, no. 10, pp. 883–885.

Koroleva, E.B., Klinskaya, N.A., Rybalko, O.F., and Ugol’nikova, T.A., Plasma metallization of refractory carbide powders, Fiz. Khim. Obrab. Mater., 1986, no. 6, pp. 57–60.

Zhilyaev, V.A., Regularities of reactions of groups IV, V transition metal carbides with nickel, Russ. J. Non-Ferrous Met., 2015, vol. 56, no. 5, pp. 575–579.

Volkova, N.M., Dudorova, T.A., and Gurevich, Yu.G., Influence of hold time on carbide grain growth in TiC–Ni alloys, Sov. Powder Metall. Met. Ceram., 1989, vol. 28, no. 8, pp. 613–617.

Frage, N., Kaputkina, L.M., Prokoshkina, V.G., Kaputkin, D.E., and Sverdlova, N.R., Changes in the phase composition, structure, and hardness of “titanium carbide-high-carbon steel” cermets under heat treatment, Met. Sci. Heat Treat., 2007, vol. 49, nos. 3–4, pp. 167–171.

Barantseva, E.A., Mizonov, V.E., and Khokhlova, Yu.V., Protsessy smeshivaniya sypuchikh materialov: modelirovanie, optimizatsiya, raschet (Mixing of Loose Materials: Modeling, Optimization, and Calculation), Ivanovo: Ivanovsk. Gos. Energ. Univ., 2008.

Kiparisov, S.S., Levinskii, Yu.V., and Petrov, A.P., Karbid titana: poluchenie, svoistva, primenenie (Titanium Carbide: Production, Properties, and Use), Moscow: Metallurgiya, 1987.

Peng, Y., Miao, H., and Peng, Z., Development of TiCN-based cermets: Mechanical properties and wear mechanism, Int. J. Refract. Met. Hard Mater., 2013, vol. 39, pp. 78–89.

Yaldiza, C.E., Veinthal, R., Gregor, A., and Georgiadis, K., Mechanical properties of thin hard coatings on TiC-NiMo substrates, Est. J. Eng., 2009, vol. 15, no. 4, pp. 329–339. https://doi.org/10.3176/eng.2009.4.10

Qiao, Z., Räthel, J., Berger, L.M., and Herrmann, M., Investigation of binderless WC–TiC–Cr3C2 hard materials prepared by spark plasma sintering (SPS), Int. J. Refract. Met. Hard Mater., 2013, vol. 38, pp. 7–14.

Rödiger, O., Zur Kenntnis des Systems Wolframkarbid-Titankarbid-Chromkarbid, Metallurgie, 1953, vol. 7, pp. 967–969.

Zhang, Y., Zheng, Y., Zhong, J., Yuan, Q., and Wu, P., Effect of carbon content and cooling mode on the microstructure and properties of Ti(C,N)-based cermets, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, pp. 1009–1013.

Stoica, V., Ahmed, R., Itsukaichi, T., Tobe, S., and Escribano, M., Sliding wear evaluation of hot isostatically pressed (HIPed) thermal spray cermet coatings, Proc. 2003 Int. Thermal Spray Conf. “Advancing the Science and Applying the Technology,” May 5–8, 2003 Orlando, Florida, USA, Marple, B.R. and Moreau, C., Eds., Materials Park, OH: ASM Int., 2003, pp. 459–466.

Panov, V.S., Chuvilin, A.M., and Fal’kovskii, V.A., Tekhnologiya i svoistva spechennykh tverdykh splavov i izdelii iz nikh (Technology and Properties of Sintered Solid Alloys and Products Formed Thereof), Moscow: Mosk. Inst. Stali Splavov, 2004.

Podchernyaeva, I.A., Kisel’, V.M., Evdokimenko, Y.I., Lavrenko, V.A., and Pasichnyi, V.V., Investigation of a wear-and corrosion-resistant coating of the TiCN–Ni-alloy system, obtained by high-speed gas-flame spraying, Powder Metall. Met. Ceram., 1999, vol. 38, nos. 7–8, pp. 358–361.

ACKNOWLEDGMENTS

The work was supported by the Russian Foundation for Basic Research (project nos. 17-08-00059a and 18-08-00842). Plasma spraying experiments were supported by the state assignment no. 075-00746-19-00.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Muravev

Rights and permissions

About this article

Cite this article

Kalita, V.I., Radyuk, A.A., Komlev, D.I. et al. Cermet Plasma TiC–Cr3C2–NiCr–Mo–C Coatings. Inorg. Mater. Appl. Res. 10, 402–410 (2019). https://doi.org/10.1134/S2075113319020205

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113319020205