Abstract

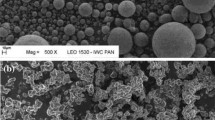

In this study, composite samples were produced using Ni, Co, and WC powders at different sintering temperatures by pack boronizing and powder metallurgy method. Prepared composites were boronized in commercial Ekabor®-2 powder between 1000 and 1400°C for 2 and 6 h using the pack boronizing method. Using the powder metallurgy method, all powders were sintered in the tube furnace under argon shroud at the same temperature range. Ultrasonic velocity, ultrasonic attenuation and Young’s modulus values were determined by using the pulse-echo method, which is one of the non-destructive testing methods. Transverse and longitudinal ultrasonic velocities and density were used to calculate the Young’s modulus of these samples. Ultrasonic properties such as ultrasonic velocity, ultrasonic attenuation and Young’s modulus and mechanical properties such as microhardness and density showed a linear relationship with the sintering temperature. SEM (scanning electron microscopy), EDX (energy dispersive X-ray spectroscopy) analysis was performed to characterize the properties of Ni–Co–WC ceramic composite samples. The relative effects of the surface images and microstructural changes of the samples prepared at different temperatures and different methods on the ultrasonic attenuation and velocity were investigated in Ni–Co–WC composite samples. As the sintering temperature increased, microhardness and density values of the composite samples also increased. The X-ray analyzes showed that the phases in the produced composites were successfully made in both methods. In addition, the experimental results of the composites obtained by the pack boronizing method increased linearly as the sintering temperature increased compared to the powder metallurgy method. The surface hardness of the material obtained in the boriding process increased approximately 4.5 times.

Similar content being viewed by others

REFERENCES

Kursawe, S., Pott, Ph., Sockel, H.G., et al., On the influence of binder content and binder composition on the mechanical properties of hard metals, Int. J. Refract. Met. Hard Mater., 2001, vol. 19, p. 335.

Genga, R.M., Cornish, L.A., and Akdoğan, G., Effect of Mo2C additions on the properties of SPS manufactured WC–TiC–Ni cemented carbides, Int. J. Refract. Met. Hard Mater., 2013, vol. 41, p. 12.

Guo, Z., **ong, J., Yang, M., et al., Effect of Mo2C on the microstructure and properties of WC–TiC–Ni cemented carbide, Int. J. Refract. Met. Hard Mater., 2008, vol. 26, p. 601.

Xu, P.Q., Dissimilar welding of WC–Co cemented carbide to Ni42Fe50.9C0.6Mn3.5Nb3 invar alloy by laser–tungsten inert gas hybrid welding, Mater. Des., 2011, vol. 32, p. 229.

Laptev, A.V., Ponomarev, S.S., and Ochkas, L.F., Structural features and properties of alloy 84%WC-16%Co, obtained by solid-phase and liquid-phase hot pressing JJ. Influence of the temperature at which the specimens are made on their physicomechanical properties, Powder Metall. Met. Ceram., 2001, vol. 40, nos. 1—2, pp. 77–83.

Carol, D.F., Sintering and microstructural development in WC/Co based alloys made with superfine WC powder, Int. J. Refract. Met. Hard Mater., 1999, vol. 17, pp. 123–132.

Kear, B.H. and McCandlish, L.E., Chemical processing and properties of nanostructured WC–Co materials, Nanostruct. Mater., 1993, vol. 3, pp. 19–30.

Gao, L. and Kear, B.H., Low temperature carburization of high surface area tungsten powders, Nanostruct. Mater., 1995, vol. 5, pp. 555–569.

Choi, K., Hwang, N.M., and Kim, D.Y., Effect of VC addition on microstructural evolution of WC–Co alloy: Mechanism of grain growth inhibition, Powder Metall., 2000, vol, 43, pp. 168–172.

Pereira, P., Vilhena, L.M., Sacramento, J., et al., Abrasive wear resistance of WC-based composites produced with Co or Ni-rich binders, Wear, 2021, vol. 482—483, p. 203924.

Manohar, G., Pandey, K.M., and Maity, S.R., Effect of sintering mechanisms on mechanical properties of AA7075/B4C composite fabricated by powder metallurgy techniques, Ceram. Int., 2021, vol. 47, pp. 15147–15154.

Zawrah, M.F., Synthesis and characterization of WC–Co nanocomposites by novel chemical method, Ceram. Int., 2007, vol. 33, pp. 155–161.

Özkan, V., Sarpün, İ.H., Erol, A., et al., Influence of mean grain size with ultrasonic velocity on micro-hardness of B4C–Fe–Ni composite, J. Alloys Compd., 2013, vol. 574, pp. 512–519.

Shang, W., Zhan, X., Wen, Y., et al., Deposition mechanism of electroless nickel plating of composite coatings on magnesium alloy, Chem. Eng. Sci., 2019, vol. 207, pp. 1299–1308.

Yönetken, A. and Erol, A., Investigation of mechanical properties of boronized composites produced by electroless Ni coating, J. Miner. Metal Mater. Eng., 2020, vol. 6, pp. 1–6.

Kayali, Y. and Yönetken, A., Investigation of wear behaviours of borided materials produced by the powder metallurgy method in different compositions, Prot. Met. Phys. Chem. Surf., 2021, vol. 57, pp. 771–778.

Kul, M., Danacı, I., Gezer, Ş., et al., Effect of boronizing composition on hardness of boronized AISI 1045 steel, Mater. Lett., 2020, vol. 279, p. 128510.

Hongsheng, C., Keqin, F., Ji, X., et al., Characterization and forming process of a functionally graded WC–Co/Ni composite, Int. J. Refract. Met. Hard Mater., 2012, vol. 35, p. 306.

Mohammadzadeh, H., Rezaie, H., Samim, H., et al., Synthesis of WCNi composite powders by thermochemical processing method based on co-precipitation, Mater. Chem. Phys., 2015, vol. 149–150, p. 145.

Fernandes, C.M., Senos, A.M.R., Vieira, M.T., et al., Mechanical characterization of composites prepared from WC powders coated with Ni rich binders, Int. J. Refract. Met. Hard Mater., 2008, vol. 26, p. 491.

Voitovich, V.B., Sverdel, V.V., Voitovich, R.F., et al., Oxidation of WC–Co, WC–Ni, and WC–Co–Ni hard metals in the temperature range 500–800°C, Int. J. Refract. Met. Hard Mater., 1996, vol. 14, p. 289.

Zhang, Q., Wul, M., and Wen, Z., Electroless nickel plating on hollow glass microspheres, Surf. Coat. Technol., 2005, vol. 192, p. 213.

Krishnaveni, K., Sankara, N., and Seshadri, S.K., Electrodeposited Ni–B coatings: Formation and evaluation of hardness and wear resistance, Mater. Chem. Phys., 2006, vol. 99, p. 300.

Shon, I.J., Jeong, I.K., Ko, I.Y., et al., Sintering behavior and mechanical properties of WC–10Co, WC–10Ni and WC–10Fe hard materials produced by high-frequency induction heated sintering, Ceram. Int., 2009, vol. 35, p. 339.

Guo, J., Fang, Z.Z., Fan, P., et al., Kinetics of the formation of metal binder gradient in WC–Co by carbon diffusion induced liquid migration, Acta Mater., 2011, vol. 59, p. 4719.

Wang, Y. and Xu, Z., Nanostructured Ni–WC–Co composite coatings fabricated by electrophoretic deposition, Surf. Coat. Technol., 2006, vol. 200, p. 3896.

Goeuriot, P. and Thevenot, F., Boron as sintering additive in cemented WC–Co (or Ni) alloys, Ceram. Int., 1987, vol. 13, p. 99.

Sinha, A.K., Boriding (boronizing), in ASM Int. Handbook, Vol. 4, Materials Park, OH, USA: Mater. Int. Soc., 1991, pp. 437–447.

Roumiana, S.P., Naruemon, S., and Veljko, S., The effect of boronizing on metallic alloys for automotive applications, J. Mater. Eng. Perform., 2008, vol. 17, pp. 340–345.

Kayalı, Y., Kutu Borlama yöntemiyle borlanmış hardox çeliklerinin yüzey özelliklerinin incelenmesi, 4th Int. Conf. Eng. Appl. Sci. (ICETAS), (Kiev, Ukraine, 2019), pp. 44–47.

Meric, C., Sahin, S., Backir, B., and Koksal, N.S., Investigation of the boronizing effect on the abrasive wear behavior in cast irons, Mater. Des., 2006, vol. 27, pp. 751–757.

Palanichamy, P., Mathew, M.D., Latha, S., et al., Assessing microstructural changes in alloy 625 using ultrasonic waves and correlation with tensile properties, Scr. Mater., 2001, vol. 45, pp. 1025–1030.

Martin, L.P. and Rosen, M., Correlation between surface area reduction and ultrasonic velocity in sintered zinc oxide powders, J. Am. Ceram. Soc., 1997, vol. 80, pp. 839–846.

Eren Gültekin, E., The effect of heating rate and sintering temperature on the elastic modulus of porcelain tiles, Ultrasonics, 2018, vol. 83, pp. 120–125.

Özkan Bilici, V., Yönetken, A., and Erol, A., Investigation of microstructure and ultrasonic velocity relationship of borided and non-borided Ti–Co–Cr composites, 4th Int. Conf. Eng. Appl. Sci. (ICETAS), (Kiev, Ukraine, 2019).

Kulkarni, N., Moudgil, B., and Bhardwaj, M., Ultrasonic characterization of green and sintered ceramics: I, Time domain, Am. Ceram. Soc. Bull., 1994, vol. 73, pp. 146–153.

Mason, W. and McSkimmin, H., Attenuation and scattering of high frequency sound waves in metals and glasses, J. Acoust. Soc. Am., 1947, vol. 19, no. 3, Melville, NY: Am. Inst. Phys. for Acoust. Soc. Am., pp. 464–473.

Ozer, A., The microstructures and mechanical properties of Al–15Si–2.5Cu–0.5Mg/(wt%) B4C composites produced through hot pressing technique and subjected to hot extrusion, Mater. Chem. Phys., 2016, vol. 183, pp. 288–296.

Yao, X., Zheng, Y.F., Liang, J.M., et al., Microstructures and tensile mechanical properties of an ultrafine grained AA6063–5 vol % SiC metal matrix nano composite synthesized by powder metallurgy, Mater. Sci. Eng., 2015, vol. A648, pp. 225–234.

Tosun, G. and Kurt, M., The density variation of metal matrix Al2O3 / Al–Mg composite depend on production parameters, Fırat Üni. Müh. Bil. Der., 2019, vol. 31, pp. 21–28.

Hunger, H.J. and Trute, G., Boronizing to produce wear-resistant surface layers, Heat Treat. Met., 1994, vol. 2, pp. 31–39.

Fichtl, W., Trausner, N., and Matuschka, A.G., Boronizing with Ekabor, Elektroschmelzwerk Kempten GmbH, 1987.

Er, Ü. and Par, B., The investigation on abrasive wear resistance of surface hardened AISI 1030 and AISI 1050 steels by boronizing, Eng. & Arch. Fac. Osmangazi Univ., 2004, vol. 27, no. 1.

Matik, U., The Influence of heat-treatment on hardness and structural characteristics of electroless Ni–B deposited ferrous powder metal compacts. Part C, GU J. Sci., 2017, vol. 5, pp. 223–230.

Dil, G., Gökşenli, A., Yüksel, B., et al., Analysis of the effect of heat treatment on corrosion resistance of electroless Ni–B/Ni–B–W dublex coating, BSEU J. Sci., 2020, vol. 7, pp. 911–922.

Guo, J., Hou, Y., Li, B., et al., Morphology-controlled synthesis of NiB nanoparticles by addition of hydrogen peroxide, Mater. Lett., 2017, vol. 200, pp. 90–93.

Tarragó, J.M., Roa, J.J., Valle, V., et al., Fracture and fatigue behavior of WC–Co and WC–CoNi cemented carbides, Int. J. Refract. Met. Hard Mater., 2015, vol. 49, p. 184.

Yaohong, X., Keqin, F., Hongsheng, C., et al., Fabrication and micro-structure of a multilayer functionally graded (WC–Co)–Ni composite, J. Alloys Compd., 2015, vol. 631, p. 77.

Musil, J., Kunc, F., Zeman, H., et al., Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings, Surf. Coat. Technol., 2002, vol. 154, p. 304.

Yuan, Z., Li, F., Zhang, P., et al., Mechanical properties study of particles reinforced aluminum matrix composites by micro-indentation experiments, Chin. J. Aeronaut., 2014, vol. 27, p. 397.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Yönetken, A., Bilici, V.Ö. Ultrasonic and Mechanical Characterization of Borided Ceramic–Metal Composite. Russ J Nondestruct Test 58, 779–789 (2022). https://doi.org/10.1134/S1061830922090091

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922090091