Abstract

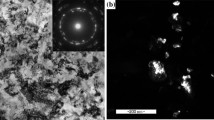

This paper discusses the formation of ultrafine-grained (UFG) structure and nanosized second-phase precipitates in commercially pure Grade 4 titanium subjected to severe plastic deformation by high pressure torsion at room temperature with subsequent heat treatment. It was found that the combined processing of Grade 4 titanium provides very high tensile strength (σB ≈ 1500 MPa), which significantly exceeds the previous results for this material. Analysis of the strengthening mechanisms showed that the superstrength of commercially pure titanium is due to several factors: UFG structure formation, dispersion strengthening from second-phase nanoparticles, high dislocation density, and grain boundary segregation. The contribution of these strengthening mechanisms is evaluated and compared with experimental data.

Similar content being viewed by others

Notes

Additional study of the grain boundary strengthening of UFG titanium will be performed taking into account similar works.

REFERENCES

Brunette, D.M., Tengvall, P., Textor, M., and Thomson, P., Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications, Berlin: Springer, 2001.

Froes, F.H. and Qian, M., Titanium in Medical and Dental Applications, UK: Woodhead Publishing, 2018.

Kolobov, Y.R., Nanotechnologies for the Formation of Medical Implants Based on Titanium Alloys with Bioactive Coatings, Nanotechnol. Russ., 2009, vol. 4, pp. 758–775. https://doi.org/10.1134/s1995078009110020

Valiev, R.Z., Zhilyaev, A.P., and Langdon, T.G., Bulk Nanostructured Materials: Fundamentals and Applications, Hoboken, New Jersey: TMS-Wiley, 2014. https://doi.org/10.1002/9781118742679

Ivanov, M.B., Kolobov, Y.R., and Golosov, E.V., Mechanical Properties of Mass-Produced Nanostructured Titanium, Nanotechnol. Russ., 2011, vol. 6, pp. 370–378. https://doi.org/10.1134/s1995078011030074

Kardashev, B.K., Narykova, M.V., Betekhtin, V.I., and Kadomtsev, A.G., Evolution of Elastic Properties of Ti and Its Alloys due to Severe Plastic Deformation, Phys. Mesomech., 2020, vol. 23, no. 3, pp. 193–198. https://doi.org/10.1134/S1029959920030029

Valiev, R.Z., Enikeev, N.A., Murashkin, M.Y., Aleksandrov, S.E., and Goldshtein, R.V., Superstrength of Ultrafine-Grained Aluminum Alloys Produced by Severe Plastic Deformation, Dokl. Phys., 2010, vol. 55, no. 6, pp. 267–270. https://doi.org/10.1134/s1028335810060054

Abramova, M.M., Enikeev, N.A., Valiev, R.Z., Etienne, A., Radiguet, B., Ivanisenko, Y., and Sauvage, X., Grain Boundary Segregation Induced Strengthening of an Ultrafine-Grained Austenitic Stainless Steel, Mater. Lett., 2014, vol. 136, pp. 349–352. https://doi.org/10.1016/j.matlet.2014.07.188

Sabirov, I., Murashkin, M.Y., and Valiev, R.Z., Nanostructured Aluminium Alloys Produced by Severe Plastic Deformation: New Horizons in Development, Mater. Sci. Eng. A, 2013, vol. 560, pp. 1–24. https://doi.org/10.1016/j.msea.2012.09.020

Wang, H.C., Shuro, I., and Umemoto, M., Annealing Behavior of Nano-Crystalline Austenitic SUS316L Produced by HPT, Mater. Sci. Eng. A, 2012, vol. 556, pp. 906–910. https://doi.org/10.1016/j.msea.2012.07.089

Rezyapova, L.R., Valiev, R.R., Sitdikov, V.D., and Valiev, R.Z., Study of Second Phase Precipitates in Nanostructured Commercially Pure Titanium, Lett. Mater., 2021, vol. 11, no. 3, pp. 345–350. https://doi.org/10.22226/2410-3535-2021-3-345-350

Sitdikov, V.D., Islamgaliev, R.K., Nikitina, M.A., Sitdikova, G.F., Wei, K.X., Alexandrov, I.V., and Wei, W., Analysis of Precipitates in Ultrafine-Grained Metallic Materials, Philos. Mag., 2018. https://doi.org/10.1080/14786435.2018.1529443

Sitdikov, V.D., Murashkin, M.Yu., and Valiev, R.Z., New X-Ray Technique to Characterize Nanoscale Precipitates in Aged Aluminum Alloys, J. Mater. Eng. Perform., 2017. https://doi.org/10.1007/s11665-017-2915-0

Rietveld, H.M., A Profile Refinement Method for Nuclear and Magnetic Structures, J. Appl. Cryst., 1969, vol. 2, pp. 65–71. https://doi.org/10.1107/s0021889869006558

Popa, N.C., The (hkl) Dependence of Diffraction-Line Broadening Caused by Strain and Size of All Laue Groups in Rietveld Refinement, J. Appl. Cryst., 1998, vol. 31, pp. 176–180. https://doi.org/10.1107/s0021889897009795

Griffiths, M., Winegar, J.E., Mecke, J.E., and Holt, R.A., Determination of Dislocation Densities in Hexagonal Closed-Packed Metals Using X-Ray Diffraction and Transmission Electron Microscopy, Adv. X-Ray Anal., 1992, vol. 35, pp. 593–599.

Jamison, J.S., Crystal Structures of Titanium, Zirconium, and Hafnium at High Pressures, Science, 1963, vol. 140, no. 3562, pp. 72–73. https://doi.org/10.1126/science.140.3562.72

Usikov, M.P. and Zilbershtein, V.A., The Orientation Relationship between the α- and ω-Phases of Titanium and Zirconium, Phys. Stat. Solid. A, 1973, vol. 19, pp. 53–58. https://doi.org/10.1002/pssa.2210190103

Singh, A.K., Mohan, M., and Divakar, C., Step-Loading Technique for Tungsten Carbide Opposed Anvil High-Pressure Setup, Rev. Sci. Instrum., 1983, vol. 54, pp. 1407–1409.

Wang, Y.B., Zhao, Y.H., Lian, Q., Liao, X.Z., Valiev, R.Z., Ringer, S.P., Zhu, Y.T., and Lavernia, E.J., Grain Size and Reversible Beta-to-Omega Phase Transformation in a Ti Alloy, Scripta Mater., 2010, vol. 63(6), pp. 613–616. https://doi.org/10.1016/j.scriptamat.2010.05.045

Bolmaro, R.E., Sordi, V.R., and Ferrante, M., High-Pressure Torsion of Ti: Synchrotron Characterization of Phase Volume Fraction and Domain Sizes, IOP Conf. Ser. Mater. Sci. Eng., 2014. https://doi.org/10.1088/1757-899x/63/1/012147

Straumal, B.B., Gornakova, A.S., and Mazilkin, A.A., Phase Transformations in Ti-Fe Alloys Induced by High-Pressure Torsion, Adv. Eng. Mater., 2015, vol. 17, no. 12, pp. 1835–1841. https://doi.org/10.1002/adem.201500143

Zhilyaev, A.P., Popov, V.A., Sharafutdinov, A.R., and Danilenko, V.N., Shear Induced ω-Phase in Titanium, Lett. Mater., 2011, vol. 1, pp. 203–207.

Kriegel, M.J., Kilmametov, A.R., Rudolph, M., Straumal, B.B., Gornakova, A.S., Stöcker, H., Ivanisenko, Y., Fabrichnaya, O., Hahn, H., and Rafaja, D., Transformation Pathway upon Heating of Ti–Fe Alloys Deformed by High-Pressure Torsion, Adv. Eng. Mater., 2018. https://doi.org/10.1002/adem.201700933

Errandonea, D., Meng, Y., Somayazulu, M., and Häusermann, D., Pressure-Induced α → ω Transition in Titanium Metal: A Systematic Study of the Effects of Uniaxial Stress, Physica B. Condens. Matter, 2005, vol. 355, pp. 116–125. https://doi.org/10.1016/j.physb.2004.10.030

Dey, G.K., Tewari, R., Banerjee, S., Jyoti, G., Gupta, S.C., Joshi, K.D., and Sikka, S.K., Formation of a Shock Deformation Induced ω Phase in Zr20Nb Alloy, Acta Mater., 2004, vol. 52(18), pp. 5243–5254. https://doi.org/10.1016/j.actamat.2004.07.008

Ahuja, R., Wills, J.M., Johansson, B., and Eriksson, O., Crystal Structures of Ti, Zr, and Hf under Compression: Theory, Phys. Rev. B, 1993, vol. 48(22), pp. 16269–16279. https://doi.org/10.1103/physrevb.48.16269

Valiev, R.Z., Nanostructural Design of Superstrong Metallic Materials by Severe Plastic Deformation Processing, Microstructures, 2023, vol. 3(1), p. 2023004. http://dx.doi.org/10.20517/microstructures.2022.25

Goldshtein, M.I., Litvinov, V.S., and Bronfin, B.M., Metallophysics of High-Strength Alloys, Moscow: Metallurgiya, 1986.

Popov, A.A., Pyshmintsev, I.Yu., Demakov, S.L., Illarionov, A.G., Lowe, T.C., Sergeyeva, A.V., and Valiev, R.Z., Structural and Mechanical Properties of Nanocrystalline Titanium Processed by Severe Plastic Deformation, Scripta Mater., 1997, vol. 37, pp. 1089–1094.

Kozlov, E.V., Glezer, A.M., Koneva, N.A., Popova, N.A., and Kurzina, I.A., Fundamentals of Plastic Deformation of Nanostructured Materials, Moscow: FIZMATLIT, 2016.

Langdon, T.G., Twenty-Five Years of Ultrafine-Grained Materials: Achieving Exceptional Properties through Grain Refinement, Acta Mater., 2013, vol. 61, no. 19, pp. 7035–7059. https://doi.org/10.1016/j.actamat.2013.08.018

Luo, P., Hu, Q., and Wu, X., Quantitatively Analyzing Strength Contribution Versus Grain Boundary Scale Relation in Pure Titanium Subjected to Severe Plastic Deformation, Metall. Mater. Trans. A, 2016, vol. 47, pp. 1922–1928. https://doi.org/10.1007/s11661-016-3391-0

Luo, P., McDonald, D.T., Xu, W., Palanisamy, S., Dargusch, M.S., and **a, K., A Modified Hall–Petch Relationship in Ultrafine-Grained Titanium Recycled from Chips by Equal Channel Angular Pressing, Scripta Mater., 2012, vol. 66, pp. 785–788. https://doi.org/10.1016/j.scriptamat.2012.02.008

Conrad, H., Effect of Interstitial Solutes on the Strength and Ductility of Titanium, Progr. Mater. Sci., 1981, vol. 26, pp. 123–403. https://doi.org/10.1016/0079-6425(81)90001-3

Scattergood, R.O., Koch, C.C., Murty, K.L., and Brenner, D., Strengthening Mechanisms in Nanocrystalline Alloys, Mater. Sci. Eng. A, 2008, vol. 493, no. 1–2, pp. 3–11. https://doi.org/10.1016/j.msea.2007.04.132

Kamat, S.V., Hirth, J.P., and Mehrabian, R., Mechanical Properties of Particulate-Reinforced Aluminum-Matrix Composites, Acta Metallurg., 1989, vol. 37, no. 9, pp. 2395–2402. https://doi.org/10.1016/0001-6160(89)90037-0

Bobylev, S.V., Enikeev, N.A., Sheinerman, A.G., and Valiev, R.Z., Strength Enhancement Induced by Grain Boundary Solute Segregations in Ultrafine-Grained Alloys, Int. J. Plasticity, 2019, vol. 123, pp. 133–144. https://doi.org/10.1016/j.ijplas.2019.07.013

Semenova, I., Salimgareeva, G., Da Costa, G., Lefebvre, W., and Valiev, R., Enhanced Strength and Ductility of Ultrafine-Grained Ti Processed by Severe Plastic Deformation, Adv. Eng. Mater., 2010, vol. 12, pp. 803–807. https://doi.org/10.1002/adem.201000059

Salishchev, G.A., Galeev, R.M., Malysheva, S.P., Zherebtsov, S.V., Mironov, S.Yu., Valiakhmetov, O.R., and Ivanisenko, E.I., Formation of Submicrocrystalline Structure in Titanium and Titanium Alloys and Their Mechanical Properties, Met. Sci. Heat Treat., 2006, vol. 48, pp. 63–69. https://doi.org/10.1007/s11041-006-0045-7

Sharkeev, Y.P., Eroshenko, A.Y., Danilov, V.I., Tolmachev, A.I., Uvarkin, P.V., and Abzaev, Yu.A., Microstructure and Mechanical Properties of Nanostructured and Ultrafine-Grained Titanium and the Zirconium Formed by the Method of Severe Plastic Deformation, Russ. Phys. J., 2014, vol. 56, pp. 1156–1162. https://doi.org/10.1007/s11182-014-0156-3

Funding

The work was carried out with financial support from the Russian Foundation for Basic Research (Grant No. 20-03-00614A) and under the government statement of work for laboratories (Order MN-8/1356 of 20.09.2021).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Usmanov, E.I., Rezyapova, L.R. & Valiev, R.Z. High-Strength State and Strengthening Mechanisms of Ultrafine-Grained Titanium. Phys Mesomech 26, 483–494 (2023). https://doi.org/10.1134/S1029959923050016

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959923050016