Abstract

It is very difficult to realize sub-3 nm patterns using conventional lithography for next-generation high-performance nanosensing, photonic and computing devices. Here we propose a completely original and novel concept, termed self-shrinking dielectric mask (SDM), to fabricate sub-3 nm patterns. Instead of focusing the electron and ion beams or light to an extreme scale, the SDM method relies on a hard dielectric mask which shrinks the critical dimension of nanopatterns during the ion irradiation. Based on the SDM method, a linewidth as low as 2.1 nm was achieved along with a high aspect ratio in the sub-10 nm scale. In addition, numerous patterns with assorted shapes can be fabricated simultaneously using the SDM technique, exhibiting a much higher throughput than conventional ion beam lithography. Therefore, the SDM method can be widely applied in the fields which need extreme nanoscale fabrication.

Similar content being viewed by others

Introduction

Because of the rapid evolution of nanosensors, nanophotonics and semiconductor technology down to the sub-10 nm technology node, the research of sub-10 nm patterning has attracted much attention in recent years1,2,3,4,5,6. For instance, sub-10 nm electromagnetic hot spots with extreme near-field confinement are crucial to plasmonic applications6,7,8. Nanoscaled graphene, quantum point contacts and quantum dot devices for high level computing require precise sub-10 nm patterning9. Thus a variety of approaches including the helium and neon ion beam lithography10,11, electron beam lithography12,13,14,15,16, advanced scanning probe lithography17, nanoimprint lithography18,19 and extreme ultraviolet lithography (EUV)20,21,22, have been proposed in order to resolve the difficulties of the sub-10 nm patterning. Nonetheless, these methods all have their individual problems which are difficult to be overcome. For example, ion beam, electron beam and scanning probe lithography are capable of high-resolution patterning, but their throughput is typically low23,24,25,26,27. Although the high-voltage electron-beam lithography based on an aberration-corrected scanning transmission electron microscope (TEM) is a very promising approach to achieve the patterns down to 2 nm15,16, large-area patterning is not feasible currently using this method because a large sample cannot be put into the TEM holder. Nanoimprint lithography suffers from the surface sticking issue and poor mold condition19. As for the EUV lithography, although a short wavelength of 13.5 nm provides a high potential for nanopatterning, EUV lithography has not yet to be proven effective and needs further development due to the challenges from photoresist, mask, optical reflectivity and source power21,28,29. Consequently, quadruple patterning is under high consideration for the 7 nm technology node in semiconductor industry due to the delay of the EUV lithography. However, how far the quadruple patterning can go depends on the cost, overlay control and the cost-effectiveness of the extreme scaling37. However, the re-deposition effect cannot explain the whole phenomenon we have observed. For example, Fig. 2b,c clearly shows that the Al2O3 mask re-shapes from the wide V-shaped geometry to the straight nanogap with a high aspect ratio after the ion irradiation. It is not reasonable that re-deposition would form such a straight gap rather than a V-shaped geometry33,38,39. Furthermore, the spherical Al2O3 surface as shown in Fig. 4e is unlikely to be solely caused by the re-deposition effect. As a result, re-deposition is not the only mechanism involved in the self-shrinking mask and some other mechanisms should take place simultaneously. Another likelihood is the ion bombardment induced viscous flow and surface diffusion of the hard dielectric mask, which has been widely discussed in the previous studies37,40,41,42,43. Please be noticed that the nanopattern as shown in Figs 2 and 3 is quite uniform and straight, which cannot be solely explained by either the re-deposition or the ion-induced viscous flow and surface diffusion. The charging effect might be the possible reason for this high quality nanopattern. When the sample is exposed to the ions, the non-conductive dielectric mask will be charged by positive ions44. The charging effect might keep the sputtered or flowing dielectric mask from being severely distorted due to the repulsive force between the positively charged mask. As a result, the line array could stay straight and uniform as shown in in Figs 2 and 3. The TEM image and energy dispersive spectroscopy (EDS) map** of the nanogap cross section have been provided in the supplementary information. The EDS map** indicates that the edge of the Al2O3 mask was highly doped by Ga and so it can be deduced that the Al2O3 mask was charged during the ion irradiation. The TEM image shows that the Ga-doped Al2O3 was filled into the gaps, which might be attributed to the re-deposition or ion-induced viscous flow/surface diffusion. To sum up, the self-shrinking process may be a comprehensive manifestation of the above-mentioned mechanisms. It is noteworthy that the dielectric mask should be hard enough in order to prevent it from being milled out completely. If this happens, self-shrinking process will not occur. Therefore, Al2O3 was chosen as the mask in this study because of its extremely hard-wearing nature to ion milling.

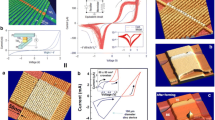

Another attractive point of SDM is its capability to fabricate a myriad of nanopatterns simultaneously as long as the initial patterns are within the exposure area of the ion source. In Fig. 5, its ability to fabricate a large area of a uniform sub-10 nm line array is shown. A large exposure area of 3570 μm2 irradiated by the Ga ions is illustrated in Fig. 5a. In fact, even a larger area can be achieved by SDM as long as the initial pattern is within the exposure region of the ion source. Figure 5b depicts the uniformly fabricated sub-10 nm line array after the ion irradiation and a small linewidth of only 5.1 nm is clearly manifested in Fig. 5c.

SEM images of a large area of uniform ~5 nm patterns fabricated by the SDM method.

(a) A large exposure area of ~3570 μm2 with the ion irradiation. (b) A magnified image from (a), revealing a uniform line array over a large area. (c) A magnified image from (b), revealing a narrow gap of only 5.1 nm in width.

Some particular methods had been proposed to define sub-10 nm patterns by focused ion beam, such as delineating patterns on a sample with a thick sacrificial metal layer using the lowest Ga ion beam current45, or utilizing helium or neon as the ion beam source10,11. However, these techniques are extremely time-consuming with a very low throughput to fabricate nanostructures within a large area, because of the low beam current (1.1pA) and the inefficient milling rate of helium and neon. For example, to fabricate a line array with a large area of 3570 μm2 (the same as that shown in Fig. 5a) with sequential line-by-line writing by focused Ga ion beam, it will take more than 610 hours using the lowest 1.1 pA beam current. Nevertheless, the minimum gap width is ~20 nm even using this lowest beam current. However, it takes only ~30 minutes (less than 20 minutes for the initial patterns and about 10 minutes for the ion irradiation) to fabricate a sub-10 nm (~5.1 nm) line array with a large area of 3570 μm2 using the SDM technique (Fig. 5). This result indicates that SDM is over 1000 times more rapid than the focused ion beam lithography and the feature size down to a few nanometer can be achieved at the same time.

In conclusion, we have proposed a novel concept to fabricate sub-3 nm patterns. Based on the self-shrinking mask instead of the focused beam approach, the SDM method can fabricate nanopatterns with the feature size of only a few nanometer, which is difficult to be fulfilled with the conventional lithography. We believe that the SDM technique opens a new door and im**es a great impact on the nanofabrication of sub-5 nm patterns in a variety of applications.

Methods

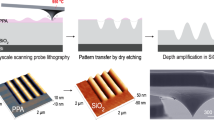

Preparation of the Al2O3 dielectric mask

The Al2O3 layer of a thickness of ~360 nm was deposited by atomic layer deposition at 200 °C (Savannah S100, Cambridge nanotech), using trimethylaluminum [TMA, Al(CH3)3] and H2O vapor as the precursors.

Initial patterns on the Al2O3 dielectric mask

A line array or other initial patterns on the Al2O3 dielectric mask can be prepared by conventional lithography techniques. In this study, we delineated the initial patterns on the Al2O3 mask by the focused Ga ion beam (FEI Helios Nanolab 600i dual beam system) with an accelerating voltage of 30 kV, a beam current of 2.5 nA, 1 μs dwell time and a dose of 2.4 nC/μm2 for each gap.

Ion irradiation

The samples with initial patterns on the Al2O3 mask was irradiated by Ga ions at 30 keV and a beam current of 2.5 nA (FEI Helios Nanolab 600i dual beam system). The samples were exposed to Ga ions with a field of view of 3570 μm2 for about 10 minutes to get sub-3 nm nanopatterns on the Al2O3 mask. In situ observation was carried out by the SEM equipped in the dual beam system.

Wet etching of the Al2O3 mask

Al2O3 was etched away in dilute HF solution. Then the sample was observed by the SEM equipped in FEI Helios 600i dual beam system.

Additional Information

How to cite this article: Yang, P.-S. et al. Novel Self-shrinking Mask for Sub-3 nm Pattern Fabrication. Sci. Rep. 6, 29625; doi: 10.1038/srep29625 (2016).

References

Scholder, O. et al. Helium focused ion beam fabricated plasmonic antennas with sub-5 nm gaps. Nanotechnology 24, 395301 (2013).

Wang, Y. et al. Ultrafast nonlinear control of progressively loaded, single plasmonic nanoantennas fabricated using helium ion milling. Nano letters 13, 5647–5653 (2013).

Tang, X., Francis, L., Dutu, C. A., Reckinger, N. & Raskin, J.-P. InNanotechnology (IEEE-NANO), 2013 13th IEEE Conference on 570–573 (IEEE, 2013).

Wang, X. et al. Room-temperature all-semiconducting sub-10-nm graphene nanoribbon field-effect transistors. Physical review letters 100, 206803 (2008).

Siegfried, T., Ekinci, Y., Solak, H., Martin, O. J. & Sigg, H. Fabrication of sub-10 nm gap arrays over large areas for plasmonic sensors. Applied Physics Letters 99, 263302 (2011).

Zhu, W., Banaee, M. G., Wang, D., Chu, Y. & Crozier, K. B. Lithographically fabricated optical antennas with gaps well below 10 nm. Small 7, 1761–1766 (2011).

Duan, H., Hu, H., Kumar, K., Shen, Z. & Yang, J. K. Direct and reliable patterning of plasmonic nanostructures with sub-10-nm gaps. ACS nano 5, 7593–7600 (2011).

Bisio, F. et al. Pushing the high-energy limit of plasmonics. ACS nano 8, 9239–9247 (2014).

Boden, S., Moktadir, Z., Bagnall, D., Mizuta, H. & Rutt, H. Focused helium ion beam milling and deposition. Microelectronic Engineering 88, 2452–2455 (2011).

Winston, D. et al. Neon Ion Beam Lithography (NIBL). Nano letters 11, 4343–4347 (2011).

Sidorkin, V. et al. Sub-10-nm nanolithography with a scanning helium beam. Journal of Vacuum Science & Technology B 27, L18–L20 (2009).

Hu, W., Sarveswaran, K., Lieberman, M. & Bernstein, G. H. Sub-10 nm electron beam lithography using cold development of poly(methylmethacrylate). Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures 22, 1711 (2004).

Vieu, C. et al. Electron beam lithography: resolution limits and applications. Applied Surface Science 164, 111–117 (2000).

Broers, A., Hoole, A. & Ryan, J. Electron beam lithography—Resolution limits. Microelectronic Engineering 32, 131–142 (1996).

Manfrinato, V. R. et al. Resolution limits of electron-beam lithography toward the atomic scale. Nano letters 13, 1555–1558 (2013).

Van Dorp, W. F., van Someren, B., Hagen, C. W., Kruit, P. & Crozier, P. A. Approaching the resolution limit of nanometer-scale electron beam-induced deposition. Nano letters 5, 1303–1307 (2005).

Garcia, R., Knoll, A. W. & Riedo, E. Advanced scanning probe lithography. Nat Nano 9, 577–587 (2014).

Austin, M. D. et al. Fabrication of 5 nm linewidth and 14 nm pitch features by nanoimprint lithography. Applied Physics Letters 84, 5299–5301 (2004).

Stephen Y. Chou, P. R. K., Wei, Zhang, Lingjie, Guo & Lei, Zhuang Sub-10 nm imprint lithography and applications. Journal of Vacuum Science & Technology B 15 (1997).

Wagner, C. & Harned, N. EUV lithography: Lithography gets extreme. Nature Photonics 4, 24–26 (2010).

Bakshi, V. EUV lithography, Vol. 178. (Spie Press Bellingham, 2009).

Bjorkholm, J. E. EUV lithography—the successor to optical lithography? Intel Technology Journal 3, 98 (1998).

Pease, R. F. Maskless lithography. Microelectronic Engineering 78–79, 381–392 (2005).

Reyntjens, S. & Puers, R. A review of focused ion beam applications in microsystem technology. Journal of Micromechanics and Microengineering 11, 287 (2001).

Tseng, A. A. Recent developments in micromilling using focused ion beam technology. Journal of Micromechanics and Microengineering 14, R15 (2004).

Kim, C.-S., Ahn, S.-H. & Jang, D.-Y. Review: Developments in micro/nanoscale fabrication by focused ion beams. Vacuum 86, 1014–1035 (2012).

Utke, I., Moshkalev, S. & Russell, P. Nanofabrication using focused ion and electron beams: principles and applications. (Oxford University Press, 2012).

Bakshi, V. EUV source technology. EUV lithography. SPIE: Bellingham, WA, (2009).

Hill, S. et al. In SPIE Advanced Lithography 692117-692117-692111 (International Society for Optics and Photonics, 2008).

Pan, D. Z., Liebmann, L., Bei, Y., **aoqing, X. & Yibo, L. In 2015 52nd ACM/EDAC/IEEE Design Automation Conference (DAC) 1–6 (2015).

Moon, H. S. et al. Atomic layer deposition assisted pattern multiplication of block copolymer lithography for 5 nm scale nanopatterning. Advanced Functional Materials 24, 4343–4348 (2014).

Philipp, G., Weimann, T., Hinze, P., Burghard, M. & Weis, J. Shadow evaporation method for fabrication of sub 10 nm gaps between metal electrodes. Microelectronic engineering 46, 157–160 (1999).

Giannuzzi, L. A. & Stevie, F. A. Introduction to focused ion beams: instrumentation, theory, techniques and practice. (Springer Science & Business Media, 2005).

Wang, Y. M. et al. High aspect ratio 10-nm-scale nanoaperture arrays with template-guided metal dewetting. Sci. Rep. 5, 10.1038/srep09654 (2015).

Melngailis, J. Focused ion beam technology and applications. Journal of Vacuum Science & Technology B 5, 469–495 (1987).

Hopman, W. C. et al. Focused ion beam scan routine, dwell time and dose optimizations for submicrometre period planar photonic crystal components and stamps in silicon. Nanotechnology 18, 195305 (2007).

Liu, N. W. et al. Fabrication of Anodic‐Alumina Films with Custom‐Designed Arrays of Nanochannels. Advanced Materials 17, 222–225 (2005).

Lugstein, A., Basnar, B., Smoliner, J. & Bertagnolli, E. FIB processing of silicon in the nanoscale regime. Applied Physics A 76, 545–548 (2003).

Kubena, R., Seliger, R. & Stevens, E. High resolution sputtering using a focused ion beam. Thin Solid Films 92, 165–169 (1982).

Makeev, M. A. & Barabási, A.-L. Ion-induced effective surface diffusion in ion sputtering. Applied physics letters 71, 2800–2802 (1997).

Facsko, S. et al. Formation of ordered nanoscale semiconductor dots by ion sputtering. Science 285, 1551–1553 (1999).

Mayer, T., Chason, E. & Howard, A. Roughening instability and ion‐induced viscous relaxation of SiO2 surfaces. Journal of applied physics 76, 1633–1643 (1994).

Vauth, S. & Mayr, S. Relevance of surface viscous flow, surface diffusion and ballistic effects in keV ion smoothing of amorphous surfaces. Physical Review B 75, 224107 (2007).

Kim, K. H., Akase, Z., Suzuki, T. & Shindo, D. Charging effects on SEM/SIM contrast of metal/insulator system in various metallic coating conditions. Materials transactions 51, 1080–1083 (2010).

Menard, L. D. & Ramsey, J. M. Fabrication of sub-5 nm nanochannels in insulating substrates using focused ion beam milling. Nano letters 11, 512–517 (2011).

Acknowledgements

We acknowledge the financial support by the Taiwan Semiconductor Manufacturing Company (tsmc) and Ministry of Science and Technology, Taiwan, under contract number 103-2622-E-002-031.

Author information

Authors and Affiliations

Contributions

M.-J.C. conceived the project. P.-H.Y. designed the experiments, prepared the materials and collected the data. P.-H.Y. and M.-J.C. wrote the manuscript. P.-H.Y., P.-H.C., C.R.K. and M.-J.C. discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yang, PS., Cheng, PH., Kao, C. et al. Novel Self-shrinking Mask for Sub-3 nm Pattern Fabrication. Sci Rep 6, 29625 (2016). https://doi.org/10.1038/srep29625

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep29625

- Springer Nature Limited