Abstract

Flower-like palladium nanoclusters (FPNCs) are electrodeposited onto graphene electrode that are prepared by chemical vapor deposition (CVD). The CVD graphene layer is transferred onto a poly(ethylene naphthalate) (PEN) film to provide a mechanical stability and flexibility. The surface of the CVD graphene is functionalized with diaminonaphthalene (DAN) to form flower shapes. Palladium nanoparticles act as templates to mediate the formation of FPNCs, which increase in size with reaction time. The population of FPNCs can be controlled by adjusting the DAN concentration as functionalization solution. These FPNCs_CG electrodes are sensitive to hydrogen gas at room temperature. The sensitivity and response time as a function of the FPNCs population are investigated, resulted in improved performance with increasing population. Furthermore, the minimum detectable level (MDL) of hydrogen is 0.1 ppm, which is at least 2 orders of magnitude lower than that of chemical sensors based on other Pd-based hybrid materials.

Similar content being viewed by others

Introduction

Hydrogen (H2) gas is used extensively in many industrial processes and is an essential fuel source in clean-energy transportations and power generation applications1,2. However, it is highly flammable and explosive at volume concentrations higher than ca. 4%. Therefore, hydrogen sensors that have high sensitivity, rapid response and reversibility are required to detect and/or monitor minute hydrogen leakages in industrial applications3,4. In general, commercial hydrogen sensors composed of metal oxide (SnO2) films meet these demand but require an operating temperature of over 200 °C, which increases the overall power consumption of the sensing device5,6,7.

Palladium (Pd) is an attractive candidate to replace metal oxides, because H2 molecules are selectively adsorbed onto the surface of Pd by dissociation into hydrogen atoms (H2→2H) and diffused into the interstitial sites of Pd structure. As a result, the phase of Pd transfer a solid solution of Pd/H (α-phase) and a palladium hydride (β-phase), resulted in resistance changes at room temperature. However, materials based on Pd is susceptible to structural changes (such as vacancy and dislocation), which are increased during the phase transition of Pd (α to β) that occurs at hydrogen concentration higher than 2%, causing have been known to collapse during the sensing reaction due to an irreversible phase change8,9,10,11,12,13,14.

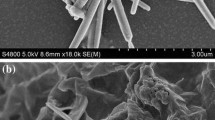

The shape control of metal nanostructure is important factor to enhance the activity and stability15. Numerous research have studied to improve the performance by change the nano-sized morphology such as nanocube30,31. Furthermore, Fourier Transform InfraRed (FTIR) spectra (Fig. 2b) of CG displays the linear line, due to the atomic scale32,33. The presence of DAN on the treated graphene surface is confirmed by peaks at 1362–1293 cm−1, corresponding to C-N stretching vibrations of primary amino groups and at 3414 and 3322–3227 cm−1, corresponding to asymmetric and symmetric N-H stretching of aromatic primary amino groups, respectively34,35. According to the FT-IR of FPNCs_CG, the DAN does not remain after electrodeposition (Fig. S3). Then, Pd is directly deposited onto the DAN-treated and -untreated graphene surface as working electrode with a Pd precursor contained sulfuric acid electrolyte in a three-electrode system. In case of DAN-untreated graphene, Pd2+ ions react with numerous functional group on the graphene surface induced by moisture, oxygen and fabrication process, resulted in evenly spread hexagonal pyramid structure (Fig. 3a–c)36. Conversely, partial negative charges on the nitrogen atoms of DAN preferentially combine with Pd2+ ions than the other functional groups. Pd nanoparticles (NPs) are then deposited on the graphene surface. With increasing electrodeposition time, flower-like palladium nanoclusters (FPNCs) are formed from these Pd NPs as nucleation sites (Fig. 3d–f). FPNCs formation mechanism can be explained as following reason37,38. Sulfate ions (SO42−) in sulfuric acid theoretically prohibit the growth of Pd at the adsorption sites. Furthermore, this effect is maximized on the Pd (111) plane, which is preferred adsorption plane for SO42− ions. To confirm the influence of sulfate ions, sulfuric acid as electrolyte is prepared with various concentration (0.01 and 0.1 M) as shown in Fig. S1. Smooth structure is observed at high concentration of H2SO4, due to the uniformly hindrance of the growth of (111) plane on the Pd surface. Adversely, low concentration induce to the partial hindrance, resulted in more sharp structure. This result indicate that Pd is predominantly composed of (111) plane and the growth of Pd can be controlled by sulfate ions concentration.

FE-SEM micrographs of FPNC_CG surfaces with various populations of FPNCs are shown in Fig. 4a–c. The population of FPNCs increase with increasing DAN concentration from 0.01 to 0.1 M, suggesting that the degree of modification is proportional to the number of Pd NPs as nuclei. In addition, the FPNCs are approximately ca. 300 nm in size and compose of numerous needles of hexagonal pyramids (Fig. 4d) with ca. 80 nm in length (Fig. 4e). The HR-TEM images in Fig. 4f shows that the FPNCs are highly crystallized, as indicated by well-defined fringe patterns. The corresponding FFT diffractogram shows a six-fold symmetry of diffraction spots indicative of hexagonal faces bound by the (111) plane, as described above. In addition, the interplanar spacing calculated from the FFT analysis of the micrograph is ca. 0.22 nm, which is consistent with the atomic spacing of (111) face-centered-cubic (fcc) Pd44,45,46.

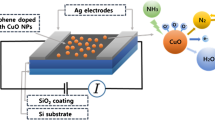

The FPNCs_CG based sensors also exhibited high selectivity for H2 gas compared to nitrogen dioxide (NO2) and ammonia (NH3) gas (Fig. S5). When the pristine CG was exposed to NO2 gas, the resistance decreased (Fig. S5a). On the other hands, the resistance upon exposure to NH3 gas shows increasing tendency (Fig. S5b). This is because NO2 and NH3 gases is electron acceptors and electron donor gas, resulted in change the hole concentration of graphene (p-type)47,48,49,50. According to the deposition of FPNCs, the resistance toward both gases increased, due to the reduced carrier mobility by the scattering effect of Pd. Furthermore, Sensitivity and MDL of NO2 and NH3 were lower than that of hydrogen gas, due to the different sensing mechanism of hydrogen (phase transition), indicating that FPNCs_CG based sensor show the high selectivity51.

The resistance of the FPNCs_CG electrode depended on the bend radius of the film-substrate assembly. Therefore, the resistance of the FPNCs_CG as a function of bend radius, shown in Fig. 8a, is used to evaluate the mechanical stability of FPNCs_CG sensors on PEN substrates43,52,53,54. No significant change in resistance is observed down to a bend radius of ca. 10 mm. Figure 8b shows the change in sensor response after repeated bending and relaxing. The response decreases by only 2% after 100 bending cycles. Furthermore, the morphology of the FPNCs is maintained without collapse even after 100 cycles of H2 exposure (Fig. 8c,d). This demonstrates the excellent mechanical flexibility and durability of the FPNCs_CG sensor electodes and shows that these film may be useful in wearable sensors55,56,57,58.

Conclusion

In conclusion, flower-like palladium nanoclusters (FPNCs) are electrodeposited on CVD graphene (FPNCs_CG) electrode. The shape and population of FPNCs can be controlled by modifying the graphene surface with DAN. The phenyl groups of DAN interact with the graphene surface via π-π interactions. The amino groups of DAN bind with Pd2+ ions to form Pd nanoparticles that act as nucleation sites. These sites and the hindering effects of sulfate ions, resulted in the growth of FPNCs on the graphene surface. Transferring the CVD graphene film onto PEN substrates provide sensor films with excellent flexibility and desirable mechanical properties. The FPNCs_CG electrode are used as the signal-transducing element in hydrogen gas sensors at room temperature. The sensitivity and response time of these sensors improve with increasing FPNCs population. In particularly, the FPNCs_CG_H electrode has a minimum detectable level (MDL) of 0.1 ppm H2. This report describes an effective method for the fabrication of flower-like metal-graphene composites with population control for various flexible electrochemical applications.

Methods

Materials

1,5-diaminonaphthalene (DAN), palladium (II) chloride (PdCl2) and sulfuric acid (H2SO4) were purchased from Aldrich Chemical Co. and used as received.

Fabrication of CG on the flexible film

Graphene was synthesized by chemical vapor deposition (CVD) on copper (Cu) foil in a CH4/H2 atmosphere in a furnace chamber. The Cu foil was placed in the furnace chamber and H2 gas was introduced at a flow rate of 8 sccm and a pressure of 147 mTorr for 30 min to stabilize the gas flow. The furnace was then heated at 40 °C/min to 1000 °C and held for 30 min. CH4 gas was introduced at 20 sccm and 560 mTorr and the chamber was cooled to 200 °C after 30 min. After the surface of the graphene was coated using PMMA solution, the Cu foil and associated impurities were removed using a copper etchant and 0.01 M sulfuric acid (H2SO4), respectively. Finally, the graphene was transferred to a flexible polyethylene naphthalate (PEN) film and dipped into the acetone solution at 60 °C for 2 hr to remove the PMMA.

Synthesis of FPNCs_CG electrode

Electrolyte for the electrodeposition of FPNCs was prepared by dissolving 0.1 M PdCl2 into 100 mL of 0.05 M H2SO4. Prior to electrodeposition, as-prepared CVD graphene piece (1.5 cm × 1.5 cm) was immersed in a methanolic solution containing a certain concentration (0.01, 0.1 and 1 M) of DAN (1,5-diaminonaphthalene) for 30 min. The concentration of DAN was used as the variable in controlling the population of deposited FPNCs. The electrodeposition process was conducted with a three-electrode system: the DAN-treated CVD graphene was used as the working electrode with a Ag/AgCl reference electrode and a Pt foil counter electrode. Pd was deposited by applying a constant potential of −0.1 V for 10 min. Then, the gold electrode was deposited on the FPNCs_CG by thermal evaporation.

Characterization of FPNCs_CG

Field Emission Scanning Electron Microscope (FE-SEM) images were obtained using a JEOL 6700 instrument. JEOL JEM-200CX and JEOL JEM-3010 instruments were used for Transmission Electron Microscopy (TEM) and High-Resolution Transmission Electron Microscopy (HR-TEM), respectively. Samples were dispersed in ethanol and cast onto perforated carbon grids. X-ray Photoemission Spectroscopy (XPS) and X-Ray Diffraction (XRD) experiments performed on a JPS-9000MS (JEOL, Mg Kα X-ray source) and M18XHF-SRA (Rigaku, SmartLab, λ = 1.5418 Å) instruments, respectively. RAMAN spectra were recorded on an FRA 1106/S FT-Raman (Bruker) spectrometer and excited with a 514-nm Ar laser. Samples for RAMAN spectroscopy were prepared on silicon-oxide-treated silicon wafers. The electrical properties and sensing performance of the FPNC_CG films were investigated using a current-source meter (Keithley 2400). I–V characteristics were determined using a WBCS 3000 potentiostat (WonA Tech). Fourier-Transform InfraRed (FT-IR) spectra were acquired using a Frontier FT-IR spectrometer (Perkin Elmer Inc.).

Electrical measurements of FPNCs_CG sensor

Resistance changes in the FPNC_CG films were monitored with a source meter connected to a computer. The FPNC_CG sensors were placed in a vacuum chamber within a vapor inlet/outlet pressure of 100 Torr. Hydrogen (H2) gas at various concentrations (0.1–100 ppm) was introduced into the chamber using a mass flow controller (MFC, KNH Instruments). The real-time resistance was measured at a constant applied current of 10−4 A. After exposure, the H2 gas was removed by blowing across the FPNC_CG film with compressed air (N2). This process was repeated several times. H2 gas/N2 air mixtures were supplied at various flow rates of 1–5 sccm and 2–8 slm using a MFC controller.

Additional Information

How to cite this article: Shin, D. H. et al. Flower-like Palladium Nanoclusters Decorated Graphene Electrodes for Ultrasensitive and Flexible Hydrogen Gas Sensing. Sci. Rep. 5, 12294; doi: 10.1038/srep12294 (2015).

References

Lubitz, W & Tumas, W. Hydrogen: an Overview. Chem. Rev. 107, 3900–3903 (2007).

Grochala, W. First There was Hydrogen. Nat. Chem. 7, 264–265 (2015).

Korotcentkov, G., Han, S. D. & Stetter, J. R. Review of Electrochemical Hydrogen Sensors. Chem. Rev. 109, 1402–1433 (2009).

Hubert, T., Brett, L. B., Black, G. & Banach . Hydrogen Sensors – A review. Sens. Actuators. B 157, 329–352 (2011).

Yang, D. J. et al. Ultrasensitive and Highly Selective Gas Sensors Based on Electrospun SnO2 Nanofibers Modified by Pd Loading. Adv. Funct. Mater. 20, 4258–4264 (2010).

Wang, B. et al. Fabrication of a SnO2 Nanowire Gas Sensor and Sensor Performance for Hydrogen. J. Phys. Chem. C 112, 6643–6647 (2008).

Gu, H., Wang, Z. & Hu, Y. Hydrogen Gas Sensors Based on Semiconductor Oxide Nanostructure. Sensors 12, 5517–5550 (2012).

Kolmakov, A. et al. Enhanced Gas Sensing by Individual SnO2 Nanowires and Nanobelts Functionalized with Pd Catalyst Particles. Nano Lett. 5, 667–673 (2005).

Baldi, A., Narayan, T. C., Koh, A. L. & Dionne, K. A. In situ Detection of Hydrogen-Induced Phase Transitions in Individual Palladium Nanocrystals. Nat. Mater. 13, 1143–1148 (2014).

Yang, F. et al. Smaller is Faster and more Sensitive: The Effect of Wire Size on the Detection of Hydrogen by Single Palladium Nanowires. ACS Nano 4, 5233–5244 (2010).

Zeng, X. Q. et al. Hydrogen Gas Sensing with Networks of Ultrasmall Palladium Nanowires Formed on Filtration Membrane. Nano Lett. 11, 262–268 (2011).

Tittl, A. et al. Palladium-Based Plasmonic Perfect Absorver in the Visible Wavelength Range and Its Application to Hydrogen Sensing. Nano Lett. 11, 4366–4369 (2011).

Yang, F., Taggart, D. K. & Penner, R. M. Fast, Sensitive Hydrogen Gas Detection Using Single Palladium Nanowires That Resist Fracture. Nano Lett. 9, 2177–2182 (2009).

Ding, D. & Chen, Z. A. Pyrolytic, Carbon-Stabilized, Nanoporous Pd Film for Wide-Range H2 Sensing. Adv. Mater. 19, 1996–1999 (2007).

Kim, Y. et al. Star-Shaped Pd@Pt Core-Shell Catalysts Supported on Reduced Graphene Oxide with Superior Electrocatalytic Performance. J. Mater. Chem. A 2, 6976–6986 (2014).

**e, X. et al. Large-Scale Synthesis of Palladium Concave Nanocubes with High-Index Facets for Sustainable Enhanced Catalytic Performance. Sci. Rep. 5, 8515 (2014).

**ong, Y. et al. Synthesis and Mechanism Study of Palladium Nanobars and Nanorods. J. Am. Chem. Soc. 129, 3665–3675 (2007).

**ong, Y., Cai, H., Yin, Y. & **a, Y. Synthesis and Characterization of Fivefold Twinned Nanorods and Right Bipyramids of Palladium. Chem. Phys. Lett. 440, 273–278 (2007).

Campbell, M. G. et al. Synthesis and Structure of Solution-Stable One-Dimensional Palladium Wires. Nat. Chem. 3, 949–953 (2011).

Lim, B., **ong, Y. & **a, Y. A Water-Based Synthesis of Octahedral, Decahedral and Icosahedral Pd Nanocrystals. Angew. Chem. Int. Ed. 46, 9279–9282 (2007).

**ing, Y. et al. Kinetically Controlled Synthesis of Triangular and Hexagonal Nanoplates of Palladium and Their SPR/SERS Properties. J. Am. Chem. Soc. 127, 17118–17127 (2005).

Kim, S. -W., Kim, M., Lee, W. Y. & Hyeon, T. Fabrication of Hollow Palladium Spheres and Their Successful Application to the Recycleable Heterogeneous Catalyst for Suzuki Coupling Reactions. J. Am. Chem. Soc. 124, 7642–7643 (2002).

Zhang, Y., Zhang, L. & Zhou, C. Review of Chemical Vapor Deposition of Graphene and Related Applications. Acc. Chem. Res. 46, 2329–2339 (2013).

Kwon, O. S. et al. Large-Scale Graphene Micropattern Nano-biohybrids: High-Performance Transducers for FET-type Flexible Fluidic HIV Immunoassays. Adv. Mater. 25, 4177–4185 (2013).

Hwangbo, Y. et al. Fracture Characteristics of Monolayer CVD-Graphene. Sci. Rep. 4, 4439 (2014).

Chung, M. G. et al. Flexible Hydrogen Sensors using Graphene with Palladium Nanoparticle Decoration. Sens. Actuators, B 169, 387–392 (2012).

Wu, W. et al. Wafer-Scale Synthesis of Graphene by Chemical Vapor Deposition and Its Application in Hydrogen Sensing. Sens. Actuators, B 150, 296–300 (2010).

Zhu, Y. et al. Graphene and Graphene Oxide: Synthesis, Properties and Applications. Adv. Mater. 22, 3906–3924 (2010).

Choi, H. et al. Flexible and Transparent Gas Molecule Sensor Intergrated with Sensing and Heating Graphene Layers. Small 18, 3685–3691 (2014).

Lee, J., Novoselov, K, S. & Shin, H S. Interaction Between Metal and Graphene: Dependence on the Layer Number of Graphene. ACS Nano 5, 608–612 (2010).

Dong, X. et al. Do** Single-Layer Graphene with Aromatic Molecules. Small 5, 1422–1426 (2009).

Radic, S. et al. Competitive Binding of Natural Amphiphiles with Graphene Derivatives. Sci. Rep. 3, 2273 (2013).

Liu, W. et al. Synthesis of High-Quality Monolayer and Bilayer Graphene on Copper using Chemical Vapor Deposition. Carbon 49, 4122–4130 (2011).

Li, X. G., Huang, M. R. & Li, S. X. Facile Synthesis of Poly(1,8-diaminonaphthalene) Microparticles with a Very High Silver-Ion Adsorbability by a Chemical Oxidative Polymerization. Acta Mate. 52, 5363–5374 (2004).

Pham, M. C., Oulahyane, M., Mostefai, M. & Chehimi, M. M. Multiple Internal Reflection FT-IR Spectroscopy (MIRFTIRS) Study of the Electrochemical Synthesis and the Redox Process of Poly(1,5-diaminonaphthalene). Synth. Met. 93, 89–96 (1998).

Hong, S. K., Song, S. M., Sul, O. & Cho, B. J. Carboxylic Group as the Origin of Electrical Performance Degradation during the Transfer Process of CVD Growth Graphene. J. Electrochem. Soc. 159, K107–K109 (2012).

Hsieh, T. L. et al. A Highly Efficient Dye-Sensitized Solar Cell with a Platinum Nanoflowers Counter Electrode. J. Mater. Chem. 22, 5550–5559 (2012).

Lei, Y. et al. Synthesis of Pt-Pd Core-Shell Nanostructures by Atomic Layer Deposition: Application in Propane Oxidative Dehydrogenation to Propylene. Chem. Mater. 24, 3525–3533 (2012).

Ponrouch, A. et al. Highly Porous and Preferentially Oriented {100} Platinum Nanowires and Thin Films. Adv. Funct. Mater. 22, 4172–4181 (2012).

Dus, R., Nowakowski, R. & Nowicka, E. Chemical and structural components of work function changes in the process of palladium hydride formation within thin Pd film. Journal of Alloys and Compounds 404-406, 284–287 (2005).

Grammatikopoulos, P., Cassidy, C., Singh, V. & Sowwan, M. Caolescence-Induced Crystallisation Wave in Pd Nanoparticles. Sci. Rep. 4, 5779 (2014).

Murata, Y. et al. Orientation-Dependent Work Function of Graphene on Pd(111). Appl. Phys. Lett. 97, 143114–143116 (2010).

Arco, L. G. D. et al. Highly Flexible and Transparent Graphene Films by Chemical Vapor Deposition ofr Organic Photovoltaics. ACS Nano 4, 2865–2873 (2010).

Sundaram, R. S. et al. Electrochemical Modification of Graphene. Adv. Mater. 20, 3050–3053 (2008).

Pandey, P. A., Wilson, N. R. & Convington, J. A. Pd-doped reduced graphene oxide sensing films for H2 detection. Sens. Actuators, B 183, 478–487 (2013).

Lange, U., Hirsh, T., Mirsky, V. M. & Wolfbeis, O. S. Hydrogen Sensor Based on a Graphene – Palladium Nanocomposites. Electrochim. Acta. 56, 3707–3712 (2011).

Gautam, M. & Jayatissa, A. H. Ammonia Gas Sensing Behavior of Graphene Surface Decorated with Gold Nanoparticles. Solid-State Electron. 78, 159–165 (2012).

Hu, N. et al. Ultrafast and Sensitive Room Temperature NH3 Gas Sensors Based on Chemically Reduced Graphene Oxide. Nanotechnol. 25 25502–25510 (2014).

Jeong, H. Y. et al. Flexible Room-Temperature NO2 Gas Sensors Based on Carbon Nanotubes/Reduced Graphene Hybrid Films. Appl. Phys. Lett. 96, 213105 (2010).

Su, P. -G. & Shieh, H. -C. Flexible NO2 Sensors Fabricated by Layer-By-Layer Covalent Anchoring and in situ Reduction of Graphene Oxide. Sens. Actuators, B 190, 865–872 (2014).

Cho, B. et al. Graphene-based Gas Sensor: Metal Decoration Effect and Application to a Flexible Device. J. Mater. Chem. C. 2 5280–5285 (2014).

An, J. H. et al. High-Performance Flexible Graphene Aptasensor for Mercury Detection in Mussels. ACS Nano 7, 10563–10571 (2013).

Kwon, O. S. et al. Flexible FET-Type VEGF Aptasensor Based on Nitrogen-Doped Graphene Converted from Conducting Polymer. ACS Nano 6, 1486–1493 (2012).

Kwon, O. S. et al. Ultrasensitive and Selective Recognition of Peptide Hormone Using Close-Packed Arrays of hPTHR-Conjugated Polymer Nanoparticles. ACS Nano 6, 5549–5558 (2012).

Garg, R., Dutta, N. K. & Choudhury, N. R. Work Function Engineering of Graphene. Nanomaterials 4, 267–300 (2014).

Park, S. J. et al. Ultrasensitive Flexible Graphene Based Field-Effect Transistor (FET)-Type Bioelectronic Nose. Nano. Lett. 12, 5082–5090 (2012).

Johnson, J. L., Behnam, A., Pearton, S. J. & Ural, A. Hydrogen Sensing Using Pd-Functionalized Multi-Layer Graphene Nanoribbon Networks. Adv. Mater. 22, 4877–4880 (2010).

Chung, M. G. et al. Flexible Hydrogen Sensors using Graphene with Palladium Nanoparticle Decoration. Sens. Actuators, B 169, 387–392 (2012).

Acknowledgements

This research was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MEST) (Grant no. 2011-0017125).

Author information

Authors and Affiliations

Contributions

D.H.S. designed the experiments and wrote the manuscript, J.S.L., J.J. and J.H.A. performed experiments and data collection, S.G.K. and K.H.C analyzed the materials and measured performance, J.J. planned and supervised the project; All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Shin, D., Lee, J., Jun, J. et al. Flower-like Palladium Nanoclusters Decorated Graphene Electrodes for Ultrasensitive and Flexible Hydrogen Gas Sensing. Sci Rep 5, 12294 (2015). https://doi.org/10.1038/srep12294

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep12294

- Springer Nature Limited

This article is cited by

-

Charge transport variation from Bloch–Grüneisen to Mott variable range hop** and transport change due to hydrogenation in Palladium thin films

Scientific Reports (2021)

-

Large Suspended Monolayer and Bilayer Graphene Membranes with Diameter up to 750 µm

Scientific Reports (2020)

-

Facile synthesis of palladium-decorated three-dimensional conducting polymer nanofilm for highly sensitive H2 gas sensor

Journal of Materials Science (2020)

-

Coral-Like Palladium Structures Produced by Electrochemical Deposition on Polypyrrole Surface

Journal of Inorganic and Organometallic Polymers and Materials (2020)

-

Chemically deposited palladium nanoparticles on graphene for hydrogen sensor applications

Scientific Reports (2019)