Abstract

Photocatalytic CO2 reduction reaction has been developed as an effective strategy to convert CO2 into reusable chemicals. However, the reduction products of this reaction are often of low utilization value. Herein, we effectively connect photocatalytic CO2 reduction and amino carbonylation reactions in series to reconvert inexpensive photoreduction product CO into value-added and easily isolated fine chemicals. In this tandem transformation system, we synthesize an efficient photocatalyst, NNU-55-Ni, which is transformed into nanosheets (NNU-55-Ni-NS) in situ to improve the photocatalytic CO2-to-CO activity significantly. After that, CO serving as reactant is further reconverted into organic molecules through the coupled carbonylation reactions. Especially in the carbonylation reaction of diethyltoluamide synthesis, CO conversion reaches up to 85%. Meanwhile, this tandem transformation also provides a simple and low-cost method for the 13C isotopically labeled organic molecules. This work represents an important and feasible pathway for the subsequent separation and application of CO2 photoreduction product.

Similar content being viewed by others

Introduction

Since the onset of the industrial revolution, the anthropic excessive emission of carbon dioxide (CO2) has resulted in serious environmental problems (e.g., the greenhouse effect)1,2,3,4. In order to effectively reduce the atmospheric concentration of CO2, the safe, green and sustainable photocatalytic CO2 reduction reaction (CO2RR) technology is currently regarded as one of the most promising solutions, due to the direct photoreduction of CO2 into value-added carbon-based chemicals with renewable solar energy5,28 and 29).

Characterization and photophysical properties study of nanosheets

To prove our speculation, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were employed to observe the morphology and size changes of the NNU-55-Ni catalysts before and after the photocatalytic process (Supplementary Figs. 30 and 31). Obviously, TEM and SEM characterizations showed that after the photocatalytic reaction, bulk NNU-55-Ni was exfoliated into ultrathin 2D nanosheets (NS = nanosheet) (Fig. 4a, d). And we have also effectively measured the size change of the catalyst before and after the photocatalytic reaction through atomic force microscopy in order to evaluate the degree of exfoliation. It showed that the thickness of the catalyst structure was sharply reduced from 96 nm (ca. 100 layers) (Fig. 4b) to 4.9 nm (~5 layers) (Fig. 4e) after undergoing the reaction, which closed to a 20-fold reduction, clearly proving an effective exfoliation process from 3D structure to 2D ultrathin NS structure (i.e., NNU-55-Ni-NS) (Fig. 4c, f). After peeling off process, the NNU-55-Ni-NS not only has a larger accessible specific surface area and more catalytically active metal sites, but also has excellent electron transfer and mass transport properties, in accordance to other 2D NSs demonstrated in previous important works43,44. To further verify the excellent electron transport performance of NNU-55-Ni-NS and study the quenching mechanism of the photocatalytic process, PL quenching experiments (Supplementary Note 7) and fluorescence excited-state lifetimes were tested. The PL spectra were performed under the condition of photocatalytic reaction without TEOA, the PL intensity of [Ru(bpy)3]Cl2 (Ex = 400 nm) followed linear Stern-Volmer behavior and decreased significantly as the increased catalyst concentration (Fig. 4g, Supplementary Fig. 32), which means that the photogenerated electrons could be transferred from [Ru(bpy)3]Cl2 to NNU-55-Ni-NS effectively. However, in the photocatalytic system without catalyst, the fluorescence intensity of PS cannot be quenched (Supplementary Fig. 33). Moreover, this charge transfer mode was also confirmed by the UV-Vis absorption spectrum experiment of [Ru(bpy)3]Cl2 (Supplementary Figs. 34 and 35). These experiment results indicated that in the process of photocatalytic CO2RR, the photogenerated electrons are mainly transferred from the light-excited [Ru(bpy)3]Cl2 to NNU-55-Ni-NS forming PS+, rather than get electrons firstly from TEOA to the excited PS*. Therefore, the photocatalytic process in our reaction system experienced an oxidative quenching mechanism. In addition, [Ru(bpy)3]Cl2 presented different photoluminescence lifetimes in reaction solutions involving different sizes of the catalysts. As shown in Fig. 4h, in the pure [Ru(bpy)3]2+ solution, the single excited emission followed the exponential first-order decay function, with a lifetime of 211 ns. For [Ru(bpy)3]2+ solution containing NNU-55-Ni-NS, however, we could clearly observe a decay of triplet metal-to-ligand charge transfer (3MLCT) excited state. Obviously, by fitting the fluorescence decay curves, the photoluminescence lifetime of photosensitizer decreased from 211 ns to 183 ns after adding catalyst (the difference value is ca. 28 ns) (Supplementary Table 6), indicating that the photoexcited electrons from photosensitizer were quickly transferred to the catalyst. Moreover, this charge transfer effect was more obvious and effective between photosensitizer and NNU-55-Ni-NS than between photosensitizer and bulky catalyst (Fig. 4h and Supplementary Table 6). In conclusion, the results of time-resolved PL decay spectroscopy experiment and PL quenching experiment could also prove that a significant charge transfer effect occurred between photosensitizer and NNU-55-Ni-NS catalyst and inhibited the recombination of photoexcited electrons and holes in the reaction system. Accordingly, the formation of NNU-55-Ni-NS with larger specific surface area and more exposed active metal sites is the main reason for the effective improvement of CO2 photoreduction activity45. But for NNU-55-Co with the relatively higher coordination binding energy, the exfoliation process did not occur under the identical photocatalytic reaction condition. Therefore, it finally displayed the poor photocatalytic CO2RR Performance due to the low specific surface area and less active metal sites. In addition, the stability of chemical composition and metal oxidation state of catalysts was confirmed by the nearly unchanged XRD (Supplementary Figs. 36 and 37), XPS (Supplementary Fig. 38a, b) and FTIR (Supplementary Fig. 39a, b) spectra before and after the photocatalytic reaction.

a–c TEM and AFM images of the bulky NNU-55-Ni. The height profile along the white line represents the thickness of the bulky NNU-55-Ni. d–f After the bulky NNU-55-Ni was in situ exfoliated into NNU-55-Ni-NS, leading to a change in TEM, AFM, and height profile. g The steady-state fluorescent spectra of [Ru(bpy)3]Cl2 upon the addition of increasing amounts of NNU-55-Ni-NS. h Time‐resolved fluorescence decay spectra of [Ru(bpy)3]Cl2 in the presence of different catalysts.

DFT theoretical calculation

At the same time, DFT calculations were employed to further study the catalytic difference on CO2 photoreduction performance of NNU-55-Co and NNU-55-Ni. We have studied the free energy pathway for reducing CO2 to CO through free energy diagrams on the catalytically active site of NNU-55-M, and the HER occurs as a competitive process (Supplementary Fig. 40). Four consecutive reaction steps of CO2RR on the metal catalytically active site have been considered, and the formation of *COOH is the rate-limiting step among them (Supplementary Figs. 41a, b). It is difficult to break the Co-O coordination bond due to having strong binding energy (−0.45 eV) between CO2 molecular and Co2+ ion, so the saturated hexa-coordination sites cannot serve as catalytically active sites for CO2 reduction process or HER. Gibbs free energy calculations disclosed that the COOH* intermediate formation step of the catalytically tetrahedral active Co2+sites had a free energy activation barrier (ΔG) of 1.453 eV, which was much larger than that of photocatalytic HER. So the NNU-55-Co catalyst is more active for HER rather than CO2RR, which agrees with those obtained experimentally. For the isomorphic NNU-55-Ni, because it undergoes an in situ exfoliation process during photocatalytic CO2RR to destroy Ni-O coordination bond, the resultant NNU-55-Ni-NS exposes more planar four-coordinated active Ni2+ sites. On this site, the ΔG for *COOH intermediate formation is only 0.272 eV and the ΔG for HER is 0.667 eV (Fig. 5a, b). For the other type of Ni2+ active site with tetrahedral configuration, the ΔG of *COOH intermediate and HER are 0.890 eV and 0.425 eV, respectively. Therefore, the planer Ni sites are identified as the active sites for CO2RR based on thermodynamics analysis and the NNU-55-Ni present superior catalytic performance for photocatalytic reduction of CO2 to CO as observed experimentally (Fig. 5c).

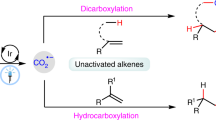

An idea for designing tandem reaction system

In the currently reported works for photocatalytic CO2RR, the final reductive products are rarely further transformed or utilized. Although NNU-55-Ni in this work can exhibit high photocatalytic selectivity, activity and durability for CO2-to-CO conversion, we hope that the reductive product CO with lower use value can be further converted into fine organic chemicals with high use value and mature separation technology (e.g., drug molecules, chemical raw materials, etc.) through tandem catalytic reactions46. It may be a feasible strategy for the future industrial application of CO2 photoreduction reaction technology47. More significantly, such a tandem conversion reaction pathway is also equivalent to realize the direct conversion from cheap CO2 to value-added carbon-based products. At the same time, the corresponding tandem catalytic reaction can also elude the potential dangers caused by the direct use of large doses of toxic CO reactants48. With this idea in mind, we chose to effectively connect the NNU-55-Ni-catalyzed CO2 photoreduction reaction with the aminocarbonylation by coupling organic reaction in series. The aminocarbonylation process generally follows a pathway starting with oxidative addition of palladium (0) center to Ar-X and insertion of CO to the organopalladium complex to form the corresponding carbonyl palladium complex, and then following by transmetallation and reductive elimination to afford the amide product49,50 (Fig. 5c). Therefore, by this cascade reaction, not only the low-value and low-concentration CO can be reconverted into important amide drug molecules or commercial products, but these resulting products already have matured industrial separation technology for practical application. Moreover, NNU-55-Ni-catalyzed CO2 photoreduction reaction can provide a sustainable, safe and green CO generation pathway for the aminocarbonylation. Thus, this kind of tandem reaction can effectively realize a strategy of killing two birds with one stone (Fig. 6).

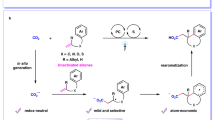

a Schematic illustration of the synthesis procedure of DEET via tandem reaction and actual CO utilization. b Select optimization conditions of the carbonylation reaction. c The recycle experiments of tandem reaction were conducted. d GC-MS shows the different mass charge ratios (m/z) when 12CO2 (blue) and 13CO2 (red) as the source of CO by the tandem reaction to synthesize DEET. Further details about high-resolution mass spectrometry are provided in Supplementary Fig. 47.

The synthesis of DEET and 13C isotope-labeled experiment by using the tandem reaction

Connecting two devices of different catalytic reaction regimes in series effectively is extremely important to successfully implementing of the tandem reaction. As shown in Fig. 7, the tandem reaction apparatus was built by connecting two independent chambers with good airtightness (Fig. 7a and Supplementary Fig. 42). The right chamber for photocatalytic CO2RR is utilized to produce continuous CO in a safe and green way, and then CO as a reactant can freely diffuse into the left chamber to undergo aminocarbonylation reactions and finally facilitate the synthesis of amide products (Supplementary Fig. 43). Through this tandem reaction device, we first tried to effectively connect the photocatalytic CO2RR (NNU-55-Ni as a catalyst) and the aminocarbonylation reaction of aryl iodide in series. Among the tandem reaction, the photocatalytic CO2RR was performed on the above optimal reaction conditions to obtain the highest CO yield (85.3 μmol), while the aminocarbonylation reaction of aryl iodide was carried out in 1,4-dioxane with Et3N as the organic base and tetrakis (triphenylphosphine) palladium-(0) catalyst. The reductive product CO from CO2 photoreduction reaction could be reconverted into the diethyltoluamide (DEET) (Supplementary Note 8 and 9), which is one of commercial pesticides to prevent some diseases of transmitted by mosquito vector, completing the chain conversion of CO2 to CO to DEET (Figs. 6a and 7b). In other words, such a reaction pathway also realized the direct conversion of low-value CO2 to high-value DEET. In addition, hydrogen as the byproduct of photocatalytic CO2RR almost had no effect on the palladium-catalyzed aminocarbonylation. After 16 h of tandem reaction, the conversion of CO to DEET reached as high as 85%. It is worth noting that the final DEET was effectively separated and the isolated product mass was about 15.2 mg (Supplementary Table 7). To further verify the sustainability of the tandem reaction, we tested three consecutive cycles of the photocatalytic CO2RR and the results showed that the tandem aminocarbonylation reaction still maintained a high CO conversion as demonstrated in Fig. 6c. Meanwhile, we attempted higher-scale experiments to obtain a higher yield of the target product. As shown in Supplementary Fig. 44, as the number of rounds of the photocatalytic cycle increased, the carbonylation reaction proceeded and the target amide compound (DEET) was accumulated continually (Supplementary Fig. 45), as demonstrated the deepen color of the reaction solution (Supplementary Fig. 44a). And the final purely organic product (DEET) yield could reach 84.4 mg (Supplementary Fig. 44b). Consequently, the tandem reaction successfully verified our initial purpose that reconverting the photocatalytic CO2RR product (CO) with low-value and low-concentration into value-added and easily isolated fine organic chemical. Furthermore, we also successfully synthesized isotopically labeled organic products through an isotope (13CO2) tracing experiment. During the tandem catalytic reaction, the injected isotope 13CO2 atmosphere was reduced to 13CO through photocatalytic CO2RR, and then 13CO as reactant undergone the tandem aminocarbonylation reaction to form isotope-labeled amide compounds (Supplementary Fig. 46). After that, the successful synthesis of 13C isotope-labeled DEET was confirmed by GC-MS (Fig. 6d) and high-resolution mass spectrometry characterization (Supplementary Fig. 47a, b). Therefore, this cascade reaction represents an effective method to use 13CO2 as a source of isotopically labeled amide molecules, suggesting a great promise in the research of carbon isotope labeling chemistry.

The substrate scope extension experiments in the tandem reaction

In order to evaluate the effectiveness of tandem reactions, we also explored the catalytic activity of other substrates with different functional substitutes under the same reaction conditions (Fig. 6b and Supplementary Table 7). When aniline and benzylamine were used as reactants, the CO conversions for amide formation were low (40 and 49%) (Supplementary Notes 10 and 11). The conversion of CO was then significantly improved by applying n-butylamine as the coupling partner (70%) (Supplementary Note 12). The reason of the relatively higher yield could be attributed to the relatively strong nucleophilicity of alkyl primary amine than its aromatic analog. Further examination demonstrated that aryl iodides with electron-donating group (-OMe) and electron-withdrawing group (-CN) as substitutes underwent the cascade reaction conditions smoothly51, providing the amides in 72% (Fig. 7c) and 67% yields (Supplementary Notes 13 and 14).

We then carried out more of the tandem reactions by using 4-iodoanisole and different amines as the coupling partners. A conversion of 78% on the basis of CO-to-d (Fig. 7d) was detected when amantadine was employed as the amino source (Supplementary Note 15). Amines with steric hindrance52, such as L-Alanyl methyl ester and D-Proline methyl ester, were viable partners to this tandem photocatalytic reductive-aminocarbonylation system (Supplementary Notes 16 and 17), with CO conversions of 58 and 51% observed (Figs. 7e, f). The cascade reaction strategy was also applied to synthesize Boscalid (Fig. 7g), a fungicide active against a broad range of fungal pathogens, with good CO conversion (74%) detected, though a hetero aryl iodide53—iodopyridine derivative and a relative more structural complicated aniline were required (Supplementary Note 18). These successful results have fully revealed the application prospect and universality of the direct transferring CO2 to important organic chemicals by connecting the photocatalytic CO2RR with palladium-catalyzed aminocarbonylation reaction (Fig. 7h and Supplementary Table 7).

The reaction type extension in the tandem reaction

To further confirm the synthetic utilities of this tandem catalytic system, we also tried to combined the photocatalytic CO2RR with other carbonylation reactions, such as carbonylative Suzuki coupling, phenoxycarbonylation and alkoxycarbonylation. When the carbonylative Suzuki coupling was applied in the follow-up chamber under the standard conditions (Condition A) with phenylboronic acid and 4-iodoanisole as the reaction partners, the corresponding biarylketone was detected, and the conversion of CO generated by photocatalytic CO2RR was 77% (Fig. 8b and Supplementary Note 19). However, the phenoxycarbonylation / alkoxycarbonylation reaction was found sluggish under the same conditions (Condition A). We suppose that the weaker nucleophilicity of oxygen should be responsible for that. Therefore, a modification of the reaction conditions for the carbonylation reaction chamber has been applied, and the tandem catalytic reaction are implemented (Condition B). For the alkoxycarbonylation reaction, when ethanol is used as the nucleophile, ester compounds could be formed through sequential transformation and the CO conversion could reach 59% (Fig. 8c and Supplementary Note 20). Furthermore, conducting the reaction by replacing the nucleophile with phenol, led to the success of the phenoxycarbonylation with the CO conversion at 44% (Fig. 8d and Supplementary Note 21). To summarize, we successfully cascade photocatalytic CO2RR and different types of carbonylation reactions to completing the chain conversion of CO2 to CO to amide (Fig. 8a)/ketone (Fig. 8b)/ester (Figs. 8c, d) compounds involving the formation of C–N/C–C/C–O bond, which further expands and highlight the practical application of tandem reactions.

Discussion

In summary, we have designed and synthesized a stable MOF-based catalyst system for photocatalytic CO2RR, in which NNU-55-Ni exhibits high activity, selectivity and durability for CO2 to CO photochemical conversion. Since NNU-55-Ni was exfoliated in situ to form ultrathin 2D nanosheets during the photocatalytic reaction process, resulting in the larger active specific surface area, more active metal sites and much faster electron transfer rate, so the photocatalytic performance of CO2RR was significantly improved. More importantly, we successfully achieved the re-conversion from the photocatalytic low-value product CO to value-added and easily separated fine organic chemicals through connecting photocatalytic CO2RR and the aminocarbonylation reaction in series. Such a tandem reaction tactic showed very high conversion and the application potential in the synthesis fine chemicals. In the meantime, we also achieved 13C isotopic labeling of bioactive molecules in an environmentally friendly manner. This work not only realized the value enhancement and separation application of photocatalytic low-value reduction product, but also provided a feasible and promising pathway for the subsequent application of the photocatalytic CO2RR.

Methods

Synthesis of NNU-55-Co

A solid mixture of 5-Azabenzimidazole (5-AD) (0.017 mmol), Co (CH3COO)2·6H2O (0.14 mmol) was suspended in DMF-H2O (3:1, 4 ml) solution in a 10 ml vial. Then the pH value of the solution was adjusted by addition of nitric acid solution (50 μl). The sonication steps take ~30 min. After the solution became clear, the vial was heated at 120 °C for 7 days and then slowly cooled to room temperature. Purple crystals of NNU-55-Co was obtained, and the yield was 58% (base on 5-AD). The CCDC number of NNU-55-Co is 2081042.

Synthesis of NNU-55-Ni

NNU-55-Ni was prepared by a similar method except that Ni (CH3COO)2·6H2O was used instead of Co (CH3COO)2·6H2O. The yield of the NNU-55-Ni dark blue powder was 48% (base on 5-AD).

Calculational methods

All calculational methods are provided in Supplementary Note 3.

General procedure for photocatalytic CO2 reduction experiments

The photocatalytic CO2RR was carried out in a 25 ml quartz reactor at a temperature of 25 °C maintained by using a thermostatic water bath with as-prepared crystal. Catalyst (20 mg) and [Ru(bpy)3]Cl2·6H2O (0.013 mmol) were added into the mixed solution which contained acetonitrile (10 ml) and deionized water (100 μl). Then TEOA (23 mmol) was added into the reaction mixture solution. The reaction system was saturated by CO2 for 30 min with a cap at 1 atm CO2 partial pressure and then irradiated using a Xe lamp (λ ≥ 420 nm, 300 W). The typical test is 16 h. The gas products in the headspace of the reactor were measured using GC with an FID detector to analyze CO/CH4/CO2 and a TCD detector to analyze O2 and H2.

Photophysical experiments

PL quenching experiments and photoluminescence lifetime experiments are provided in Supplementary Note 7.

Tandem reaction experiments

For a better comparison, all organic measurements were carried out under equivalent experimental conditions. Achieving high gas density in the reaction volume, the relatively small volume of the chamber reactor (Schlenk tube) was selected (A chamber, 25 ml and B chamber, 10 ml). A chamber was used for photocatalytic CO2RR according to the protocol above. The reaction conditions in chamber B were changed according to different organic catalysis. Condition A: B chamber was loaded with aryl iodide (0.5 mmol), Pd(PPh3)4 (6 mol%), Et3N (139 μl, 1 mmol), and the corresponding amine or aryl boronic acid (1 mmol). Subsequently, anhydrous 1,4-dioxane (3 ml) was added to the reactor. Condition B: B chamber was loaded with aryl iodide (0.5 mmol), Pd(PPh3)4 (6 mol%), Et3N (139 μl, 1 mmol). Due to Phenoxy/alkoxy compounds act as both solvent and reactant, and the corresponding alcohol (3 ml) or phenol (3.2 g, 34.1 mmol) was added to the reactor. The two chambers were chained together by a short linker, all joints were in a closed state. Subsequently, only open the joint of B, and the B chamber was then flash frozen at 77 K (liquid N2 bath) and degassed by three freeze-pump-thaw cycles, and evacuated to an internal pressure of ~100 mTorr. Then warm to room temperature, A chamber was placed under photocatalytic conditions, the B chamber was placed in an oil bath. After photocatalytic reacting for a set amount of time, A joint was slowly opened and B chamber was stirred at 65 °C for 16 h in the oil bath. The reaction product was detected and quantified by mass spectrometry (5977B Agilent Technologies) and NMR analysis after purification by column chromatography on silica gel.

Data availability

The data that support the findings of this study are available within the paper and its Supplementary Information files or are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Sudarsanam, P. et al. Functionalised heterogeneous catalysts for sustainable biomass valorisation. Chem. Soc. Rev. 47, 8349–8402 (2018).

Wang, S. et al. Porous hypercrosslinked polymer-TiO2-graphene composite photocatalysts for visible-light-driven CO2 conversion. Nat. Commun. 10, 676 (2019).

Kou, M. et al. Photocatalytic CO2 conversion over single-atom MoN2 sites of covalent organic framework. Appl. Catal. B. 291, 120146 (2021).

Habisreutinger, S. N., Schmidt-Mende, L. & Stolarczyk, J. K. Photocatalytic reduction of CO2 on TiO2 and other semiconductors. Angew. Chem. Int. Ed. 52, 7372–7408 (2013).

Zhang, T. & Lin, W. Metal-organic frameworks for artificial photosynthesis and photocatalysis. Chem. Soc. Rev. 43, 5982–5993 (2014).

Kong, T., Jiang, Y. & **ong, Y. Photocatalytic CO2 conversion: what can we learn from conventional COx hydrogenation? Chem. Soc. Rev. 49, 6579–6591 (2020).

Wang, S., Guan, B. Y., Lu, Y. & Lou, X. W. D. Formation of hierarchical In2S3–CdIn2S4 heterostructured nanotubes for efficient and stable visible light CO2 reduction. J. Am. Chem. Soc. 139, 17305–17308 (2017).

Kim, D., Sakimoto, K. K., Hong, D. & Yang, P. Artificial photosynthesis for sustainable fuel and chemical production. Angew. Chem. Int. Ed. 54, 3259–3266 (2015).

Li, X. et al. Selective visible-light-driven photocatalytic CO2 reduction to CH4 mediated by atomically thin CuIn5S8 layers. Nat. Energy 4, 690–699 (2019).

Jiang, Z. et al. Filling metal-organic framework mesopores with TiO2 for CO2 photoreduction. Nature 586, 549–554 (2020).

Vu, N.-N., Kaliaguine, S. & Do, T.-O. Critical aspects and recent advances in structural engineering of photocatalysts for sunlight-driven photocatalytic reduction of CO2 into fuels. Adv. Funct. Mater. 29, 1901825 (2019).

Guo, Q. et al. Efficient and selective CO2 reduction integrated with organic synthesis by solar energy. Chem 5, 2605–2616 (2019).

Wu, Y. A. et al. Facet-dependent active sites of a single Cu2O particle photocatalyst for CO2 reduction to methanol. Nat. Energy 4, 957–968 (2019).

Yan, Z.-H. et al. Photo-generated dinuclear {Eu(II)}2 active sites for selective CO2 reduction in a photosensitizing metal-organic framework. Nat. Commun. 9, 3353 (2018).

Lan, G. et al. Photosensitizing metal-organic layers for efficient sunlight-driven carbon dioxide reduction. J. Am. Chem. Soc. 140, 12369–12373 (2018).

Guo, Z. et al. Selectivity control of CO versus HCOO− production in the visible light-driven catalytic reduction of CO2 with two cooperative metal sites. Nat. Catal. 2, 801–808 (2019).

Wang, S., Yao, W., Lin, J., Ding, Z. & Wang, X. Cobalt imidazolate metal-organic frameworks photosplit CO2 under mild reaction conditions. Angew. Chem. Int. Ed. 53, 1034–1038 (2014).

Takeda, H. et al. Highly efficient and robust photocatalytic systems for CO2 reduction consisting of a Cu(I) photosensitizer and Mn(I) catalysts. J. Am. Chem. Soc. 140, 17241–17254 (2018).

Lu, M. et al. Rational design of crystalline covalent organic frameworks for efficient CO2 photoreduction with H2O. Angew. Chem. Int. Ed. 58, 12392–12397 (2019).

Pan, Y.-X. et al. Photocatalytic CO2 reduction by carbon-coated indium-oxide nanobelts. J. Am. Chem. Soc. 139, 4123–4129 (2017).

Liang, L. et al. Efficient infrared light induced CO2 reduction with nearly 100% CO selectivity enabled by metallic CoN porous atomic layers. Nano. Energy 69, 104421 (2020).

Franke, R., Selent, D. & Börner, A. Applied hydroformylation. Chem. Rev. 112, 5675–5732 (2012).

**ang, Y. & Kruse, N. Tuning the catalytic CO hydrogenation to straight- and long-chain aldehydes/alcohols and olefins/paraffins. Nat. Commun. 7, 13058 (2016).

Ai, H.-J., Zhao, F., Geng, H.-Q. & Wu, X.-F. Palladium-catalyzed thiocarbonylation of alkenes toward linear thioesters. ACS Catal. 11, 3614–3619 (2021).

Peng, J.-B., Geng, H.-Q. & Wu, X.-F. The chemistry of CO: carbonylation. Chem 5, 526–552 (2019).

Lian, Z., Nielsen, D. U., Lindhardt, A. T., Daasbjerg, K. & Skrydstrup, T. Cooperative redox activation for carbon dioxide conversion. Nat. Commun. 7, 13782 (2016).

Ibrahim, M. B., Suleiman, R., Fettouhi, M. & El Ali, B. A palladium–bisoxazoline supported catalyst for selective synthesis of aryl esters and aryl amides via carbonylative coupling reactions. RSC Adv. 6, 78826–78837 (2016).

Chen, M. et al. Palladium-catalyzed enantioselective Heck carbonylation with a monodentate phosphoramidite ligand: asymmetric synthesis of (+)-Physostigmine, (+)-Physovenine, and (+)-Folicanthine. Angew. Chem. Int. Ed. 59, 12199–12205 (2020).

Friis, S. D., Taaning, R. H., Lindhardt, A. T. & Skrydstrup, T. Silacarboxylic acids as efficient carbon monoxide releasing molecules: Synthesis and application in palladium-catalyzed carbonylation reactions. J. Am. Chem. Soc. 133, 18114–18117 (2011).

Friis, S. D., Lindhardt, A. T. & Skrydstrup, T. The development and application of two-chamber reactors and carbon monoxide precursors for safe carbonylation reactions. Acc. Chem. Res. 49, 594–605 (2016).

Lang, X.-D., You, F., He, X., Yu, Y.-C. & He, L.-N. Rhodium(i)-catalyzed Pauson–Khand-type reaction using formic acid as a CO surrogate: an alternative approach for indirect CO2 utilization. Green. Chem. 21, 509–514 (2019).

Morimoto, T. & Kakiuchi, K. Evolution of carbonylation catalysis: no need for carbon monoxide. Angew. Chem. Int. Ed. 43, 5580–5588 (2004).

Nielsen, D. U., Hu, X.-M., Daasbjerg, K. & Skrydstrup, T. Chemically and electrochemically catalysed conversion of CO2 to CO with follow-up utilization to value-added chemicals. Nat. Catal. 1, 244–254 (2018).

Hermange, P. et al. Ex situ generation of stoichiometric and substoichiometric 12CO and 13CO and its efficient incorporation in palladium catalyzed aminocarbonylations. J. Am. Chem. Soc. 133, 6061–6071 (2011).

Ren, X. et al. Rhodium-complex-catalyzed hydroformylation of olefins with CO2 and hydrosilane. Angew. Chem. Int. Ed. 56, 310–313 (2017).

Gotico, P. et al. Visible-light-driven reduction of CO2 to CO and its subsequent valorization in carbonylation chemistry and 13C isotope labeling. ChemPhotoChem 2, 715–719 (2018).

Huang, J. et al. Electrochemical exfoliation of pillared-layer metal-organic framework to boost the oxygen evolution reaction. Angew. Chem. Int. Ed. 57, 4632–4636 (2018).

Wang, X.-K. et al. Monometallic catalytic models hosted in stable metal-organic frameworks for tunable CO2 photoreduction. ACS Catal. 9, 1726–1732 (2019).

Liu, J. et al. Metal-free efficient photocatalyst for stable visible water splitting via a two-electron pathway. Science 347, 970–974 (2015).

Jiang, J. et al. Van der waals heterostructures by single cobalt sites-anchored graphene and g-C3N4 nanosheets for photocatalytic syngas production with tunable CO/H2 ratio. Appl. Catal., B. 295, 120261 (2021).

Zheng, H.-L. et al. Photochemical in-situ exfoliation of metal-organic frameworks for enhanced visible-light-driven CO2 reduction. Angew. Chem. Int. Ed. 59, 23588–23592 (2020).

Peng, Y. et al. Metal-organic framework nanosheets as building blocks for molecular sieving membranes. Science 346, 1356–1359 (2014).

Cao, L. et al. Self-supporting metal-organic layers as single-site solid catalysts. Angew. Chem. Int. Ed. 55, 4962–4966 (2016).

Zhao, M. et al. Ultrathin 2D metal-organic framework nanosheets. Adv. Mater. 27, 7372–7378 (2015).

Ding, Y. et al. Controlled intercalation and chemical exfoliation of layered metal-organic frameworks using a chemically labile intercalating agent. J. Am. Chem. Soc. 139, 9136–9139 (2017).

He, X., Cao, Y., Lang, X.-D., Wang, N. & He, L.-N. Integrative photoreduction of CO2 with subsequent carbonylation: photocatalysis for reductive functionalization of CO2. ChemSusChem 11, 3382–3387 (2018).

Lescot, C. et al. Efficient fluoride-catalyzed conversion of CO2 to CO at room temperature. J. Am. Chem. Soc. 136, 6142–6147 (2014).

Nielsen, D. U., Lescot, C., Gøgsig, T. M., Lindhardt, A. T. & Skrydstrup, T. Pd-catalyzed carbonylative α-Arylation of aryl bromides: scope and mechanistic studies. Chem. Eur. J. 19, 17926–17938 (2013).

Minatti, A. & Muñiz, K. Intramolecular aminopalladation of alkenes as a key step to pyrrolidines and related heterocycles. Chem. Soc. Rev. 36, 1142–1152 (2007).

D’Souza, D. M. & Müller, T. J. J. Multi-component syntheses of heterocycles by transition-metal catalysis. Chem. Soc. Rev. 36, 1095–1108 (2007).

Nordeman, P., Odell, L. R. & Larhed, M. Aminocarbonylations employing Mo(CO)6 and a bridged two-vial system: allowing the use of Nitro group substituted aryl iodides and aryl bromides. J. Org. Chem. 77, 11393–11398 (2012).

Cunico, R. F. & Maity, B. C. Direct carbamoylation of aryl halides. Org. Lett. 4, 4357–4359 (2002).

Wu, X.-F., Neumann, H. & Beller, M. Synthesis of heterocycles via palladium-catalyzed carbonylations. Chem. Rev. 113, 1–35 (2013).

Acknowledgements

This work was financially supported by the Excellent Youth Foundation of Jiangsu Scientific Committee (BK20211593); NSFC (Nos. 92061101, 21871141, 21871142, 21901123 and 22071109); Natural Science Foundation of Jiangsu Province (No. BK20190694); the Natural Science Research of Jiangsu Higher Education Institutions of China (19KJB150011) and Project funded by China Postdoctoral Science Foundation (2019M651873).

Author information

Authors and Affiliations

Contributions

Y.-Q.L., J.L., and Y.-S.X. conceived and designed the idea. Y.-S.X. synthesized the MOF-based catalysts. Y.-S.X., L.Z., G.-K.G., and C.J. conducted the characterizations and designed the tandem catalytic reaction related experiments. Mz.T. assisted with the characterizations and collected the CO2RR related experimental data. Y.-Q.L., J.L., L.-G.X. and Y.-S.X. analyzed the data. L.-Z.D. assisted with dealing with the data of SCXRD. Y.-Q.L., J.L., L.-G.X. and Y.-S.X. discussed the result and prepared the manuscript. All the authors reviewed and contributed to this paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ally Aukauloo, Bhalchandra Bhanage and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

**a, YS., Tang, M., Zhang, L. et al. Tandem utilization of CO2 photoreduction products for the carbonylation of aryl iodides. Nat Commun 13, 2964 (2022). https://doi.org/10.1038/s41467-022-30676-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-30676-y

- Springer Nature Limited

This article is cited by

-

Ultrafast electron transfer at the In2O3/Nb2O5 S-scheme interface for CO2 photoreduction

Nature Communications (2024)

-

A triple tandem reaction for the upcycling of products from poorly selective CO2 photoreduction systems

Nature Synthesis (2024)

-

CO2 photocatalytic reduction with robust and stable metal–organic framework: a review

Materials for Renewable and Sustainable Energy (2024)

-

Advancements on metal oxide semiconductor photocatalysts in photo-electrochemical conversion of carbon dioxide into fuels and other useful products

Frontiers in Energy (2024)

-

Photocatalytic CO2 reduction

Nature Reviews Methods Primers (2023)