Abstract

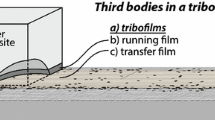

The abrasive wear performance of vinyl ester resins modified with various volume fractions (5, 10, 15, 20 and 30%) of graphite powder has been measured. Using a conveyor belt driven testing machine developed locally, it has been possible to realistically simulate the effect of three-body abrasive wear upon these graphite modified polymer samples. A comparison of the calculated dimensionless wear rates obtained for these surfaces reveals that the effect of the graphite powder depends strongly upon the volume fraction of particles in the resin matrix. It appears that, for intermediate volume fractions, the presence of graphite powder in the resin matrix reduces the abrasive wear of the polymer surface. Scanning electron microscopy has been used to probe the mechanisms of abrasive wear of the pure resin and graphite modified surfaces. It appears that the embedded graphite particles can act as a lubricant during the abrasion process thus reducing the wear rate. The effect of increasing graphite powder volume fraction upon the abrasive wear mechanism is discussed.

Similar content being viewed by others

References

K. Kato, in Proceedings of Austrib'98-Tribology at Work, Brisbane, December 1998, p. 123.

N. AxÉn and I. M. Hutchings, Mater. Sci. and Technol. 12 (1996) 757.

M. Cirino, R. B. Pipes and K. Friedrich, J. Mater. Sci. 22 (1987) 2481.

K. Friedrich, “Friction and Wear of Polymer Composites” (Elsevier, Amsterdam, 1986) p. 233.

M. Cirino, K. Friedrich and R. B. Pipes, Composites 19 (1988) 383.

Idem., Wear 121 (1988) 127.

I. M. Hutchings, Powder Technology 76 (1993) 3.

J. H. Tylczak and A. Oregon, “Friction, Lubrication and Wear Technology” (ASM Handbook, 18, ASM International, 1992) p. 184.

A. M. HÄger and M. Davies, in “Advances in Composite Tribology-Composite Materials Series 8,” edited by K. Friedrich (Elsevier, Amsterdam, 1993) p. 107.

A. W. Roberts and S. J. Wiche, Tribology International 26 (1993) 345.

A. A. Cenna, J. Doyle, N. W. Page, A. Beehag and P. C. Dastoor, Wear 240 (2000) 207.

K. Friedrich, in “Friction and Wear of Polymer Composites” (Elsevier, Amsterdam, 1986) p. 2.

A. G. Evans and D. B. Marshall, in “Fundamentals of Friction and Wear of Materials,” edited by D. A. Rigney (ASM International, 1981) p. 439.

A. G. Evans, in “The Science of Ceramic Machining and Surface Finishing II,” edited by B. J. Hockey and R.W. Rice (NBS Sp. Pub. 562, Washington, 1979) p. 1.

R. I. Trezona, D. N. Allsopp and I. M. Hutchings, Wear 225-229 (1999) 205.

K. Friedrich and M. Cyffka, ibid. 103 (1985) 333.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cenna, A.A., Dastoor, P., Beehag, A. et al. Effects of graphite particle addition upon the abrasive wear of polymer surfaces. Journal of Materials Science 36, 891–900 (2001). https://doi.org/10.1023/A:1004890832700

Issue Date:

DOI: https://doi.org/10.1023/A:1004890832700