Abstract

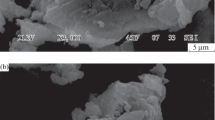

The kinetics of voluminal reduction of chromium ore fines containing coal (COFCC) by microwave heating was studied. When the molar ratio of carbon to oxygen was 0.84 and that of CaO to SiO2 was 0.39 in COFCC, the temperature-rising rate of COFCC by microwave heating was 62.5 °C/min, 68.75 °C/min, 70.59 °C/min, and 72.22 °C/min at 1000 °C, 1100 °C , 1200 °C , and 1300 °C , respectively. The results show that the voluminal reduction of COFCC by microwave heating at solid-solid phase is first order reaction, with the apparent activation energy of 51.480 kJ/mol. The limiting step of reaction rate for the overall reaction is the mass transfer of CO in the reduced product layer between dielectric particles of chromium ore and coal.

Similar content being viewed by others

References

WEI **a. Chrome Industry Development Present Situation at Home and Abroad [J]. Yunnan Metallurgy, 1995, (2): 1 (in Chinese).

WANG Wei-de. Summarized Introduction of Chromite Mining and Chromimium-Iron Alloy Production [J]. Mining Engineering, 2003, 1(6): 10 (in Chinese).

CEN Yong-quan, ZHANG Guo-fu. Development of Stainless Steel Smelting Technique [J]. Shanghai Metals, 1999, 21(3): 12 (in Chinese).

ZHU De-qing, LI Jian, FAN **ao-hui, et al. Method Overview About Chromite Ore Fines Agglomeration [J]. Sintering and Pelletizing, 2004, 29(2): 27 (in Chinese).

Niayesh M J. Chromite Ore Solid-State Reduction [J]. Ferro-Alloys, 1994, 25(3): 49 (in Chinese).

ZHANG You-**, LI Zheng-bang, XUE Zheng-liang. Application Technology of Chromite Ore Fines for Producing Stainless Steel Master Alloy [J]. Special Steel, 2003, 24(1): 29 (in Chinese).

LIU Chuan-xian, BAI Zheng-hua, ZHANG Zhe-ru. Handbook of Thermodynamic Data for Minerals and Compounds [M]. Bei**g: Science Press, 1985 (in Chinese).

Lin Q, Liu R, Chen N. Kinetics of Direct Reduction of Chrome Iron Ore [J]. Journal of Thermal Analysis and Calorimetry, 1999, 58(2): 317.

XU Rong-jun, NI Rui-ming, ZHANG Sheng-bi, et al. Reduction Kinetics of Chromite Pellet With Carbon [J]. Journal of Iron and Steel Research, 1995, 7(5): 1 (in Chinese).

ZHANG Li-juan, ZOU Zong-shu, LIU Ai-hua, et al. Kinetics of Chromite Smelting Reduction [J]. Journal of Northeastern University (Natural Science), 1996, 17(3): 252 (in Chinese).

WANG Yu-qing. Several Important Links of Smelting HC FeCr With Only India Chrome Ore Fines Totally [J]. Ferro-Alloys, 2001, 32(6): 13 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China and Baoshan Iron and Steel Co Ltd of China (50474083)

Rights and permissions

About this article

Cite this article

Chen, J., Wang, Sb., Zhang, M. et al. Kinetics of Voluminal Reduction of Chromium Ore Fines Containing Coal by Microwave Heating. J. Iron Steel Res. Int. 15, 10–15 (2008). https://doi.org/10.1016/S1006-706X(08)60258-7

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60258-7