Abstract

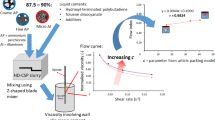

Hydroxyl-terminated polybutadiene (HTPB) is a reliable binder to build a strong polyurethane network for materials with more than 85 wt% of fillers, such as composite solid propellant (CSP), a fuel for space launch vehicles. However, a careful composition design is still challenging as high filler contents intricate the process, and it is responsible for both the perfection of a solid structure of CSP and the safety of the vehicle. The PU-based liquid contents (LC) CSP consists of HTPB, diisocyanate compound, amine compound, and plasticiser. The fillers include aluminium and ammonium perchlorate particles. The tendency of aluminium to agglomerate in PU-based LC and to be dispersed in the plasticiser, combined with the formation of a polyurethane network, causes time-dependency in viscosity of the CSP slurry. Thus, models to predict initial viscosity and minimum viscosity are highly demanded. In this work, particle packing models for both types of viscosity are proposed considering the wall slip phenomenon and the nature of the constituents. The models were tested on CSP slurry with 87.5–90 wt% fillers, including 15–20 wt% micro-aluminium. Based on viscosity measurements, high correlation levels (r = 0.7–0.99) were found in the correlation between particle packing parameters and the viscosities. This convinces the reliability of the models for predicting the initial and minimum viscosities of CSP. Moreover, phenomena revealed by a deep analysis of the start-up of shear flow, such as increasing shear modulus and residual stress with increasing particle packing parameters and the existence of positive and negative thixotropic behaviours, can be clearly explained by the models.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Lysien K, Stolarczyk A, Jarosz T (2021) Solid propellant formulations: a review of recent progress and utilized components. Materials 14:16657. https://doi.org/10.3390/ma14216657

Restasari A, Budi RS, Hartaya K (2018) Effects of ammonium perchlorate composition on high content aluminium propellant slurry. J Teknol Dirgant 15(2):105–114. https://doi.org/10.30536/j.jtd.2017.v0.a2509

Rodi V, Bajlovski M (2006) Influence of trimodal fraction mixture of ammonium-perchlorate on characteristics of composite rocket propellants. Sci Rev 56(2):38–44

Nair CPR, Prasad CHDV, Ninan KN (2013) Effect of process parameters on the viscosity of AP/Al/HTPB based solid propellant slurry. J Energy Chem Eng 1(1):1–9

Tüzün FN (2005) The effect of aluminum content variation on burning rate, pressure-propellant area ratio relationship, and other properties of hydroxyl terminated polybutadiene based composite propellants. J ASTM Int 2(4):1–15. https://doi.org/10.1520/JAI12936

Lempert DB, Manelis GB, Nechiporenko GN (2009) The ways for development of enviromentally safe solid composite propellants. Prog Propuls Phys 1:63–80. https://doi.org/10.1051/eucass/200901063

Babu KVS, Raju PK, Thomas CR, Hamed AS, Ninan KN (2017) Studies on composite solid propellant with tri-modal ammonium perchlorate containing an ultra fine fraction. Def Technol 3:239–245. https://doi.org/10.1016/j.dt.2017.06.001

Restasari A, Abdillah LH, Ardianingsih R, Sitompul HRD, Budi RS, Hartaya K, Wibowo HB (2021) Thixotropic behavior in defining particle packing density of highly filled AP/HTPB-based propellant. Symmetry 13:1767. https://doi.org/10.3390/sym13101767

Pinalia A, Prianto B, Setyaningsih H (2021) Preliminary results of DOA plasticizer effect on AP/HTPB composite propellant characteristics. AIP Conf Proc 0400:2366. https://doi.org/10.1063/5.0061303

Restasari A, Abdillah LH (2017) Pengaruh dioctyl adipate terhadap pot-life propelan berformula AP trimoda. In: Prosiding SIPTEKGAN XXI, pp 314–322

Yadav A, Pant CS, Das S (2020) Research advances in bonding agents for composite propellants. Propellants Explos Pyrotech 45(5):695–704. https://doi.org/10.1002/prep.201900329

Kakavas-Papaniaros PA (2020) On the distribution of particles in propellant solids. Acta Mech 231:3. https://doi.org/10.1007/s00707-019-02553-1

Abdillah LH, Winardi S, Sumarno S, Nurtono T (2018) Effect of mixing time to homogeneity of propellant slurry. IPTEK J Proc Ser 1:94–98. https://doi.org/10.12962/j23546026.y2018i1.3515

Restasari A, Budi RS, Hartaya K (2018) Pseudoplasticity of propellant slurry with varied aluminium content for castability development. J Phys Conf Ser 1005:012034. https://doi.org/10.1088/1742-6596/1005/1/012034

Teipel U, Forter-Barth U (2001) Rheology of nano-scaled aluminum suspensions. Propellants Explos Pyrotech 26(2):268–272

Iwasaki A, Matsumoto K, Ban R, Yoshihama S, Nakamura T, Habu H (2016) The continuous mixing process of composite solid propellant slurry by an artificial muscle actuator. Trans Japan Soc Aeronaut Sp Sci Aerosp Technol Japan 14(30):107–110. https://doi.org/10.2322/tastj.14.Pa_107

Li T, Xu J, Han J, He Y (2021) Effect of microstructure on micro-mechanical properties of composite solid propellant. Micromachines 12:1378. https://doi.org/10.3390/mi12111378

Hoffmann LFS, Bizarria FCP, Bizarria JWP (2020) Detection of liner surface defects in solid rocket motors using multilayer perceptron neural networks. Polym Test 88:106559. https://doi.org/10.1016/j.polymertesting.2020.106559

Coffelt C, Olsen D, Miller C, Zhou M (2022) Effect of void positioning on the detonation sensitivity of a heterogeneous energetic material. J Appl Phys 131:065101. https://doi.org/10.1063/5.0081188

Majcher A, Przybylski J, Figarski J (2017) A control system for stand for measuring the burn rate of solid rocket propellants using Crawford’s method. J Mach Constr Maint 3:67–73

Rueda MM, Auscher MC, Fulchiron M, Perie T, Martin G, Sonntag P, Cassagnau P (2017) Rheology and applications of highly filled polymers: a review of current understanding. Prog Polym Sci 66:22–53. https://doi.org/10.1016/j.progpolymsci.2016.12.007

Wilms P, Wieringa J, Blijdenstein T, Van Malssen K, Hinrichs J, Kohlus R (2020) Wall slip of highly concentrated non-brownian suspensions in pressure driven flows: a geometrical dependency put into a non-newtonian perspective. J Nonnewton Fluid Mech 282:104336. https://doi.org/10.1016/j.jnnfm.2020.104336

Wilms P, Wieringa J, Blijdenstein T, Van Malssen K, Hinrichs J, Kohlus R (2022) On the difficulty of determining the apparent wall slip of highly concentrated suspensions in pressure driven flows: the accuracy of indirect methods and best practice. J Nonnewton Fluid Mech 299:104694. https://doi.org/10.1016/j.jnnfm.2021.104694

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology. Elsevier Science Publishers BV, Amsterdam

Bertola V, Bertrand F, Tabuteau H, Bonn D, Coussot P (2003) Wall slip and yielding in pasty materials. J Rheol 47(5):1211–1226. https://doi.org/10.1122/1.1595098

Kalyon DM (2005) Apparent slip and viscoplasticity of concentrated suspensions. J Rheol 49(3):621–640. https://doi.org/10.1122/1.1879043

Lade R, Wasewar K, Sangtyani R, Kumar A, Shende D, Peshwe D (2018) Rheological and wall-slip behaviour of composite propellant suspension containing al-nanopowder. J Energ Mater 36(4):468–484. https://doi.org/10.1080/07370652.2018.1493056

Xu C, Fieß M, Willenbacher N (2017) Impact of wall slip on screen printing of front-side silver pastes for silicon solar cells. IEEE J Photovolt. https://doi.org/10.1109/JPHOTOV.2016.2626147

Gallier S (2009) A stochastic pocket model for aluminum agglomeration in solid propellants. Propellants Explos Pyrotech 34(2):97–105. https://doi.org/10.1002/prep.200700260

Shabana S, Sonawane SH, Ranganathan V, Pujjalwar PH, Pinjari DV, Bhanvase BA, Gogate PR, Ashokkumar M (2016) Improved synthesis of aluminium nanoparticles using ultrasound assisted approach and subsequent dispersion studies in di-octyl adipate. Ultrason Sonochem. https://doi.org/10.1016/j.ultsonch.2016.11.020

Oliveira JIS, Pires DC, Diniz MF, Siqueira JL, Mattos EC, Rezende LC, Lha K, Dutra RCL (2014) Determination of primary amine content in bonding agent used in composite solid propellants. Propellants Explos Pyrotech 39(4):1–7. https://doi.org/10.1002/prep.201300147

Santhosh G, Reshmi S, Nair CPR (2020) Rheokinetic characterization of polyurethane formation in a highly filled composite solid propellant. J Therm Anal Calorim 140:213–223. https://doi.org/10.1007/s10973-019-08793-6

Hutauruk J, Bura RO, Wibowo HB (2020) Karakterisasi ukuran dan bentuk amonium perklorat china, korea selatan dan indonesia serta potensi pengaruhnya terhadap karakteristik propelan. J Teknol Dirgant 18(1):53–62. https://doi.org/10.30536/j.jtd.2020.v18.a3346

Sitompul HR, Wibowo HB, Abdillah LH, Ardianingsih R, Restasari A (2021) Integrated quality analysis method of aluminum for composite propellant production. J Teknol Dirgant 19(2):177–192. https://doi.org/10.30536/j.jtd.2021.v19.a3655

Chen L-T, Chen C-Y, Chen H-N (2019) FCC or HCP: the stable close-packed lattice of crystallographically equivalent spherical micelles in block copolymer homopolymer blend. Polymer 169:131–137. https://doi.org/10.1016/j.polymer.2019.02.041

Furnas CC (1931) Grading aggregates I—mathematical relations for beds of broken solids of maximum density. Ind Eng Chem 23(9):1052–1058. https://doi.org/10.1021/ie50261a017

Ye X, Li Y, Ai Y, Nie Y (2018) Novel powder packing theory with bimodal particle size distribution-application in superalloy. Adv Powder Technol 29(9):2280–2287. https://doi.org/10.1016/j.apt.2018.06.012

Hoque E, Pant CS, Das S (2020) Study on friction sensitivity of passive and active binder-based composite solid propellants and correlation with burning rate. Def Sci J 70(2):159–165. https://doi.org/10.14429/dsj.70.14802

Brookfield Engineering Laboratories (2014) More solutions for sticky problems. Brookfield Engineering Laboratories Inc, Massachusetts

Brookfield Engineering Laboratories. BROOKFIELD DV3T Viscometer operating instructions manual No. M13-2100-A0415, vol 8139. Brookfield Engineering Laboratories Inc, Middleboro

Briggs JL, Steffe JF (1997) Using Brookfield data and the Mitschka method to evaluate power law foods. J Texture Stud 28:517–522. https://doi.org/10.1111/j.1745-4603.1997.tb00134.x

Haminiuk CWI, Maciel GM, Plata-Oviedo MSV, Quenehenn A, Scheer AP (2009) Study of the rheological parameters of honey using the mitschka method study of the rheological parameters of honey using the mitschka method. Int J Food Eng 5(3):1–9. https://doi.org/10.2202/1556-3758.1572

Masubuchi Y, Watanabe H (2014) Origin of stress overshoot under start-up shear in primitive chain network simulation. ACS Macro Lett 3:1183–1186. https://doi.org/10.1021/mz500627r

Kubo MTK, Rojas ML, Miano AC, Augusto PED (2019) Rheological properties of tomato products. In: Poretta S (ed) Tomato chemistry, industrial processing and product development. The Royal Society of Chemistry, Croydon

Osman MA, Atallah A, Schweizer T, Öttinger HC (2004) Particle–particle and particle-matrix interactions in calcite filled high-density polyethylene—steady shear. J Rheol 48(5):1167–1184. https://doi.org/10.1122/1.1784782

Obaid N, Kortschot MT, Sain M (2017) Understanding the stress relaxation behavior of polymers reinforced with short elastic fibers. Materials 10(472):1–15. https://doi.org/10.3390/ma10050472

Anneja A, Wilkes GL, Rightor EG (2003) A study of slabstock flexible polyurethane foams based on varied toluene diisocyanate isomer ratios. J Polym Sci Part B Polym Physics 41(3):258–268. https://doi.org/10.1002/polb.10363

Restasari A, Hamid N, Marpaung L, Rusnaenah A, Sukma A, Sukma R (2021) Structure relaxation disruption on temperature- dependence of polymerization of HTPB-based polyurethane. J Teknol Dirgant 19(2):193–200. https://doi.org/10.30536/j.jtd.2021.v19.a3654

Ardianingsih R, Kumoro AC (2019) Analisis viskositas slurry propelan untuk akurasi karakterisasi rheologi berbasis perekat hidroxy terminated polybutadiene dengan plasticizer dioctyl adipate. Teknik 40(3):154–160. https://doi.org/10.14710/teknik.v40i3.27209

Rodic V, Petric M (2004) The effect of additives on solid rocket propellant characteristics. Sci Tech Rev 54(3–4):9–14

Erisken C, Gocmez A, Yilmazer U, Pekel F, Ozkar S (1998) Modeling and rheology of htpb based composite solid propellants. Polym Compos 19(4):463–472. https://doi.org/10.1002/pc.10121

Lade R, Wasewar K, Sangtyani R, Kumar A, Shende D, Peshwe D (2019) Effect of aluminum nanoparticles on rheological behavior of HTPB-based composite rocket propellant. J Energ Mater 37(2):125–140. https://doi.org/10.1080/07370652.2018.1543737

Nitta K-H, Kuriyagawa M (2012) Reinforcement of plastomeric segmented polyurethane, In: Cavaco LI, Melo JA (ed) Polyurethane, properties, structure and applications. Nova Science Publishers Inc, New York

Yudin VE, Otaigbe JU, Svetlichnyi VM, Korytkova EN, Almjasheva OV, Gusarov VV (2008) Effects of nanofiller morphology and aspect ratio on the rheo-mechanical properties of polyimide nanocomposites. Express Polym Lett 2(7):485–493. https://doi.org/10.3144/expresspolymlett.2008.58

Bika DG, Gentzler M, Michaels, (2001) Mechanical properties of agglomerates. Powder Technol 117(1–2):98–112. https://doi.org/10.1016/S0032-5910(01)00318-7

Arabani M, Karami MV (2007) Geomechanical properties of lime stabilized clayey sands. Arab J Sci Eng 32(1B)

Tunnicliffe LB, Nelson K, Pan S, Curtis J, Herd CR (2020) Reinforcement of rubber by carbon black and lignin-coated nanocellulose fibrils. Rubber Chem Technol 93(4):633–651. https://doi.org/10.5254/RCT.20.79961

Wolff S, Wang MJ (1993) Carbon black reinforcement of elastomerss. In: Donnet J-B, Bansal RC, Wang M-J (eds) Carbon black, 2nd edn. Taylor and Francis, New York

Lawandy SN, Halim SF, Darwish NA (2009) Structure aggregation of carbon black in ethylene-propylene diene polymer. Express Polym Lett 3(3):152–158. https://doi.org/10.3144/expresspolymlett.2009.20

Kohjiya S, Katoh A, Suda T, Shimanuki J, Ikeda Y (2006) Visualization of carbon black networks in rubbery matrix by skeletonisation of 3D TEM image. Polymer 47:3298–3301. https://doi.org/10.1016/j.polymer.2006.03.008

Evdokimov IN, Losev AP (2011) Thixotropy in native petroleum emulsions. J Dispers Sci Technol 32(8):1206–1212. https://doi.org/10.1080/01932691.2010.505530

Li Y, Hou WG, Zhu WQ (2007) Thixotropic properties of aqueous suspensions containing cationic starch and aluminum magnesium hydrotalcite-like compound. J Colloid Interface Sci 313:305–314. https://doi.org/10.1016/j.jcis.2007.03.071

Gatos KG, Kameo K, Karger-Kocsis J (2007) On the friction and sliding wear of rubber/layered silicate nanocomposites. Express Polym Lett 1(1):27–31. https://doi.org/10.3144/expresspolymlett.2007.6

Mohammadi M, Shadizadeh SR, Manshad AK, Mohammadi AH (2020) Experimental study of the relationship between porosity and surface area of carbonate reservoir rocks. J Pet Explor Prod Technol 10:1817–1834. https://doi.org/10.1007/s13202-020-00838-z

Rubio-Hernández FJ (2018) Rheological behavior of fresh cement pastes. Fluids 3:106. https://doi.org/10.3390/fluids3040106

Cloitre M, Bonnecaze R (2017) A review on wall slip in high solid dispersions. Rheol Act 56(3):283–305. https://doi.org/10.1007/s00397-017-1002-7

Abdel-Hafez AA, Brodt MW, Carney JR, Lightstone JM (2011) Laser dispersion and ignition of metal fuel particles. Rev Sci Instrum 82:064101. https://doi.org/10.1063/1.3598341

Ramaswamy AL, Shin H, Armstrong RW, Lee CH, Sharma J (1996) Nanosecond and picosecond laser-induced cracking and ignition of single crystals of ammonium perchlorate. J Mater Sci 31:6035–6042. https://doi.org/10.1007/BF01152156

Medvedev VV, Forat EV, Tsipilev VP, Yakovlev AN (2017) The effect of aluminum particles dispersity on characteristics of ammonium perchlorate—aluminum composition laser ignition. J Phys Conf Ser 830:012146. https://doi.org/10.1088/1742-6596/755/1/011001

Catalano R, Slomberg D, Picard C, Hucher N, Vidal V, Saint-Antonin F, Hubaud JC, Rose J, Labille J (2021) In situ determination of engineered nanomaterial aggregation state in a cosmetic emulsion-toward safer-by-design products. Environ Sci Nano 8:3546–3559. https://doi.org/10.1039/d1en00345c

Acknowledgements

The authors thank the RISPRO-LPDP Competitive Research Program KEP-27/LPDP/2020 and National Agency for Research and Innovation (BRIN) for funding the research.

Funding

This research was funded by RISPRO-LPDP Competitive Research Program Batch-II with contract No. 082.01.06.3534.001.002.053A.524119 and Skep-27/LPDP/2020. It is also funded by Research Organization for Aeronautics and Space, National Agency for Research and Innovation (BRIN), with research funding No. B-4/III/PN/1/2022.

Author information

Authors and Affiliations

Contributions

Conceptualisation, methodology, and writing—original draft: AR; Investigation and validation: AR, LHA, RA, RSB, HRDS; Visualisation, writing—review and editing: AR, LHA, RA, BP, AP, K, EDA, HR; Funding acquisition, resources and project administration: HBW and KH; Supervision: HBW.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Restasari, A., Abdillah, L.H., Ardianingsih, R. et al. Particle packing models to determine time-dependent slip flow properties of highly filled polyurethane-based propellant. J Rubber Res 25, 157–170 (2022). https://doi.org/10.1007/s42464-022-00166-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-022-00166-3