Abstract

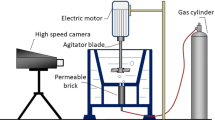

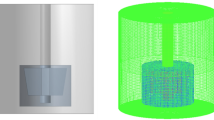

Gas–liquid flow and bubble coalescence and breakup behavior were studied in a top blown-rotary agitated reactor for steelmaking. Several important models of bubble coalescence and breakup mechanisms were considered and compared, and water model experiment was carried out to verify and optimize the mathematical models. The influence of different operating parameters including paddle arrangement, stirring speed and top blowing flow rate on the bubble size and distribution was revealed. The results show that the predicted bubble size and distribution present a good agreement with the experimental results using the improved Luo–Laakkonen combination model. As the position of the stirring paddle moves from the center to the side wall, the bubble distribution in the reactor becomes more uniform, and the bubble size gradually decreases. With the increase in the paddle rotation speed, the bubble size decreases. However, this effect begins to weaken when the paddle rotation speed exceeds 150 r/min. Increasing the top blowing flow rate will increase the bubble size in the reactor, but it has a weak effect on bubble dispersion. When the top blowing rate exceeds 2.0 m3/h, the bubble size in the bath is basically not less than 5 mm.

Similar content being viewed by others

References

M. He, N. Wang, M. Chen, M. Chen, C. Li, Powder Technol. 361 (2020) 455–461.

J.H. Ji, R.Q. Liang, J.C. He, ISIJ Int. 56 (2016) 794–802.

T. Tanaka, Y. Ogiso, M. Ueda, J. Lee, ISIJ Int. 50 (2010) 1071–1077.

K. Takahashi, K. Utagawa, H. Shibata, S.Y. Kitamura, N. Kikuchi, Y. Kishimoto, ISIJ Int. 52 (2012) 10–17.

Y. Nakai, I. Sumi, H. Matsuno, N. Kikuchi, Y. Kishimoto, ISIJ Int. 50 (2010) 403–410.

A. Aoyagi, Z. Mukuda, S. Takada, S. Oomiya, CAMP-ISIJ 7 (1994) 221.

X. Wang, S.G. Zheng, M.Y. Zhu, Ironmak. Steelmak. 47 (2020) 915–924.

Y. Hiraga, K. Gennai, Y. Nakasima, J. Harama, CAMP-ISIJ 9 (1996) 225.

H.J. Visser, R. Boom, ISIJ Int. 46 (2006) 1771–1777.

J. Yang, K. Okumura, M. Kuwabara, M. Sano, Metall. Mater. Trans. B 34 (2003) 619–629.

W. Wu, W. Wu, Y.B. Hu, L. Liu, Y.L. Ding, J. Iron Steel Res. Int. 15 (2008) No. 1, 15–18.

Y. Liu, M. Sano, T. Zhang, Q. Wang, J. He, ISIJ Int. 49 (2009) 17–23.

D. Cao, X.F. Wan, L. Zhao, G.B. Li, X.G. Zhang, X.W. Liao, Angang Technology (2018) No. 6, 16–20.

J.M. Su, Z.H. Dou, T.A. Zhang, Y. Liu, ISIJ Int. 60 (2020) 915–921.

J.M. Su, Z.H. Dou, T.A. Zhang, Y. Liu, J. Iron Steel Res. Int. 27 (2020) 1137–1144.

P. Shao, T.A. Zhang, Z. Zhang, Y. Liu, ISIJ Int. 54 (2014) 1507–1516.

J.H.. Ji, R.Q. Liang, J.C. He, ISIJ Int. 57 (2017) 453–462.

X. Guan, X. Li, N. Yang, M. Liu, Chem. Eng. J. 386 (2020) 121554.

H. Luo, H.F. Svendsen, AIChE J. 42 (1996) 1225–1233.

M.J. Prince, H.W. Blanch, AIChE J. 36 (1990) 1485–1499.

F. Lehr, M. Millies, D. Mewes, AIChE J. 48 (2002) 2426–2443.

M. Laakkonen, V. Alopaeus, J. Aittamaa, Chem. Eng. Sci. 61 (2006) 218–228.

T. Wang, J. Wang, Y. **, AIChE J. 52 (2006) 125–140.

M. Karimi, R. Andersson, AIChE J. 65 (2019) e16600.

Y. Liao, D. Lucas, Chem. Eng. Sci. 64 (2009) 3389–3406.

Y. Liao, D. Lucas, Chem. Eng. Sci. 65 (2010) 2851–2864.

N. Yang, Q. **ao, Chem. Eng. Sci. 170 (2017) 241–250.

M. An, X. Guan, N. Yang, Chem. Eng. Sci. 223 (2020) 115743.

D. Pfleger, S. Becker, Chem. Eng. Sci. 56 (2001) 1737–1747.

H.F. Svendsen, H.A. Jakobsen, R. Torvik, Chem. Eng. Sci. 47 (1992) 3297–3304.

W. Lou, M. Zhu, Metall. Mater. Trans. B 44 (2013) 1251–1263.

P. Chu, J. Finch, G. Bournival, S. Ata, C. Hamlett, R.J. Pugh, Adv. Colloid Interface Sci. 270 (2019) 108–122.

V.T. Nguyen, C.H. Song, B.U. Bae, D.J. Euh, Int. J. Multiphase Flow 54 (2013) 31–42.

W. Shi, X. Yang, M. Sommerfeld, J. Yang, X. Cai, G. Li, Y. Zong, Chem. Eng. J. 371 (2019) 470–485.

P. Ranganathan, S. Sivaraman, Chem. Eng. Sci. 66 (2011) 3108–3124.

E.K. Nauha, Z. Kálal, J.M. Ali, V. Alopaeus, Chem. Eng. J. 334 (2018) 2319–2334.

Z. Liu, F. Qi, B. Li, M. Jiang, Metall. Mater. Trans. B 46 (2015) 933–952.

L. Gemello, C. Plais, F. Augier, D.L. Marchisio, Chem. Eng. J. 372 (2019) 590–604.

Acknowledgements

The authors wish to express thanks to the National Natural Science Foundation of China (51604147 and 51774178) for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, P., Liu, Sx. & Miao, Xc. CFD-PBM simulation of bubble coalescence and breakup in top blown-rotary agitated reactor. J. Iron Steel Res. Int. 29, 223–236 (2022). https://doi.org/10.1007/s42243-021-00636-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00636-9