Abstract

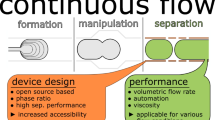

Double emulsions have great potential application in many fields. Although many companies and research institutions have developed various strategies for forming double emulsions, production and stability are not straightforward. Meanwhile, none of the well-organized simple device and scalable technique was available to form highly monodispersed double emulsions. Herein, we present a one-step strategy to produce highly monodisperse double emulsion via assembled micro-cross device. This device has a lot of advantages, such as easy assembly/disassembly and high repeatability. High-throughput is also easily achievable for its high-pressure capacity. Moreover, we systematically studied the effects of the three flow rates on the size and structure of the double emulsions. A mathematical model has been developed to predict the inner and outer droplets size of the double emulsion. We prepared the flame-retardant microcapsules with a dimethyl methylphosphonate (DMMP) inner core and an ultraviolet-curable polysiloxane shell. We hope that this assembled micro-cross device can be employed extensively in the area of microfluidics.

Similar content being viewed by others

References

Naik J et al (2012) Development of sustained release micro/nanoparticles using different solvent emulsification technique: A review. Int J Pharm Bio Sci. 3(4):573–590

Ding SK et al (2019) Double emulsions prepared by two-step emulsification: History, state-of-the-art and perspective. J Controlled Release 295:31–49

Clegg PS, Tavacoli JW, Wilde PJ (2016) One-step production of multiple emulsions: microfluidic, polymer-stabilized and particle-stabilized approaches. Soft Matter 12(4):998–1008

Chu LY et al (2007) Controllable monodisperse multiple emulsions. Angew Chem Int Ed Engl 46(47):8970–8974

Gallarate M et al (1999) On the stability of ascorbic acid in emulsified systems for topical and cosmetic use. Int J Pharm 188(2):233–241

Liu L et al (2010) Smart thermo-triggered squirting capsules for nanoparticle delivery. Soft Matter 6(16):3759–3763

Shum HC et al (2009) Double Emulsion Droplets as Microreactors for Synthesis of Mesoporous Hydroxyapatite. Chem Mater 21(22):5548–5555

Griffiths AD, Tawfik DS (2006) Miniaturising the laboratory in emulsion droplets. Trends Biotechnol 24(9):395–402

Engl W et al (2008) A droplet-based high-throughput tubular platform to extract rate constants of slow chemical reactions. Chem Eng Sci 63(6):1692–1695

Garti N (1997) Progress in stabilization and transport phenomena of double emulsions in food applications. LWT Food Sci Technol. 30(3):222–235

McClements DJ, Li Y (2010) Structured emulsion-based delivery systems: Controlling the digestion and release of lipophilic food components. Adv Coll Interface Sci 159(2):213–228

Shum HC et al (2011) Multicompartment Polymersomes from Double Emulsions. Angew Chem Int Ed 50(7):1648–1651

Yu Y et al (2019) Microfluidic generation of microsprings with ionic liquid encapsulation for flexible electronics. 2019:6906275

Yu YR et al (2018) Design of capillary microfluidics for spinning cell-laden microfibers. Nat Protoc 13(11):2557–2579

Adams LLA et al (2012) Single step emulsification for the generation of multi-component double emulsions. Soft Matter 8(41):10719–10724

Garti N (1998) A new approach to improved stability and controlled release in double emulsions, by the use of graft-comb polymeric amphiphiles. Acta Polym 49(10–11):606–616

Wang WT et al (2015) One-step microfluidic production of gas-in-water-in-oil multi-cores double emulsions. Chem Eng J 263:412–418

Williams M et al (2014) Preparation of Double Emulsions using Hybrid Polymer/Silica Particles: New Pickering Emulsifiers with Adjustable Surface Wettability. Acs Applied Materials Interfaces 6(23):20919–20927

Utada AS et al (2005) Monodisperse double emulsions generated from a microcapillary device. Science 308(5721):537–541

Zarzar LD et al (2015) Dynamically reconfigurable complex emulsions via tunable interfacial tensions. Nature 518(7540):520–524

Nie ZH et al (2005) Polymer particles with various shapes and morphologies produced in continuous microfluidic reactors. J Am Chem Soc 127(22):8058–8063

Chen CH et al (2009) Janus Particles Templated from Double Emulsion Droplets Generated Using Mcrofluidics. Langmuir 25(8):4320–4323

Okushima S et al (2004) Controlled production of monodisperse double emulsions by two-step droplet breakup in microfluidic devices. Langmuir 20(23):9905–9908

Nabavi SA et al (2015) Double emulsion production in glass capillary microfluidic device: Parametric investigation of droplet generation behaviour. Chem Eng Sci 130:183–196

Abate AR, Thiele J, Weitz DA (2011) One-step formation of multiple emulsions in microfluidics. Lab Chip 11(2):253–258

Wang WT et al (2014) One-step microfluidic approach for controllable production of gas-in-water-in-oil (G/W/O) double emulsions and hollow hydrogel microspheres. RSC Adv 4(32):16444–16448

Chang ZQ et al (2009) Co-axial capillaries microfluidic device for synthesizing size- and morphology-controlled polymer core-polymer shell particles. Lab Chip 9(20):3007–3011

Bauer WAC et al (2010) Hydrophilic PDMS microchannels for high-throughput formation of oil-in-water microdroplets and water-in-oil-in-water double emulsions. Lab Chip 10(14):1814–1819

Huang SH et al (2006) A monolithically three-dimensional flow-focusing device for formation of single/double emulsions in closed/open microfluidic systems. J Micromech Microeng 16(11):2336–2344

Wu P et al (2014) A 3D easily-assembled Micro-Cross for droplet generation. Lab Chip 14(4):795–798

Wu T et al (2017) Monodisperse droplets by im**ing flow-focusing. Microfluid Nanofluid 21(8)

Chen J et al (2018) Capillary-based integrated digital PCR in picoliter droplets. Lab Chip 18(3):412–421

Nisisako T, Torii T, Higuchi T (2002) Droplet formation in a microchannel network. Lab Chip 2(1):24–26

Deng NN et al (2011) Simple and cheap microfluidic devices for the preparation of monodisperse emulsions. Lab Chip 11(23):3963–3969

Feng FF, Qian LJ (2014) The Flame Retardant Behaviors and Synergistic Effect of Expandable Graphite and Dimethyl Methylphosphonate in Rigid Polyurethane Foams. Polym Compos 35(2):301–309

**ang HF et al (2007) Dimethyl methylphosphonate (DMMP) as an efficient flame retardant additive for the lithium-ion battery electrolytes. J Power Sources 173(1):562–564

Bouvet N et al (2016) A comparison of the gas-phase fire retardant action of DMMP and Br-2 in co-flow diffusion flame extinguishment. Combust Flame 169:340–348

Bouvet N et al (2016) Experimental and numerical investigation of the gas-phase effectiveness of phosphorus compounds. Fire Mater 40(5):683–696

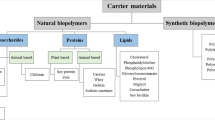

Estevinho BN et al (2017) Microencapsulation of Gulosibacter molinativorax ON4(T) cells by a spray-drying process using different biopolymers. J Hazard Mater 338:85–92

Zhang B, Jiang YJ, Han J (2017) The core-double-shell microcapsules flame retardant: Synthesis and its application for polyvinyl chloride composites. J Phys Chem Solids 111:391–402

Acknowledgements

This work is supported by the National Natural Science Foundation of China (NSFC No.31670866, 31970754).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Electronic supplementary material

ESM 1

(DOCX 194 kb)

Rights and permissions

About this article

Cite this article

Zhu, J., Chen, J., Luo, Z. et al. One-step microdevices for synthesizing morphology-controlled ultraviolet-curable polysiloxane shell particles. J Flow Chem 10, 627–635 (2020). https://doi.org/10.1007/s41981-020-00106-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-020-00106-5