Abstract

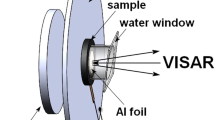

Carbon fiber composite cylinders were fabricated using the filament winding technique, and the cylinders were loaded internally with a high-energy explosive material. As the high-energy explosive material detonated, the transient deformation and failure of the composite cylinder were investigated both experimentally and numerically. For the experimental study, a high-speed video camera running at 5 million frames per second was used to capture the deformation and failure of the composite cylinder. A Photonic Doppler Velocimetry (PDV) system was also used to measure the radial velocity of the outer wall of the cylinder while the internal detonation progressed. Separately, Split Hopkinson Pressure Bar (SHPB) tests were conducted to check the strain-rate effect on the failure strength of the carbon fiber material. Finally, a multiscale approach was used to model the dynamic deformation and failure of the composite cylinder. The multiscale technique considers the failure of composites in terms of the constituent materials like fiber and matrix materials. The numerically predicted deformation and failure agreed well with the experimentally observed and measured results.

Similar content being viewed by others

Data availability

The data will be available by request after completion of the project.

References

Alaei D, Kwon YW, Ramezani A (2019) Fluid-structure interaction on concentric composite cylinders containing fluids in the annulus. Multiscale Multidisciplinary Model Exp Des 2: 185–197

Allison GE, Schriempf JT (1960) Explosively loaded metallic cylinders. II. J Appl Phys 31:846–851

Ashkenazi E (1965) Problems of the anisotropy of strength. Polym Mech 1(2):60–70

Beard AW, Palazotto AN (2006) Composite material for high-speed projectile outer casing. AIAA Scitech Forum, 6–10 January, AIAA 2020 – 0974.

Blom AW, Stickler PB, Gürdal Z (2010) Optimization of a composite cylinder under bending by tailoring stiffness properties in circumferential direction. Compos Part B: Eng 41(2):157–165

Daniel IM (2007) Failure of composite materials. Strain 43(1):4–12

Dattelbaum D, Coe J (2016) The dynamic loading response of carbon-fiber-filled polymer composites. In: Silberschmidt V (ed) in Dynamic deformation damage and fracture in Composite materials and structures. Woodhead Publishing, Boston, MA, USA, pp 225–275

Davies P, Choqueuse D, Bigourdan B, Chauchot P (2016) Composite cylinders for deep sea applications: an overview. J Pressure Vessel Technol 138(6): 060904

Dolan D (2020) Extreme measurements with photonic doppler velocimetry (PDV). Rev Sci Instrum 91(5):051501

Du N, **ong W, Wang T, Zhang X-F, Chen H-H, Meng-ting Tan M-T (2021) Study on energy release characteristics of reactive material casings under explosive loading. Def Technol 17(5):1791–1803

Franklin HG (1968) Classic theories of failure of anisotropic materials. Fibre Sci Technol 1(2):137–150

Gama BA, Lopatnikov SL, Gillespie JW Jr (2004) Hopkinson Bar experimental technique: a critical review. Appl Mech Rev 57(4):223–250

Gol’denblat I, Kopnov V (1965) Strength of glass-reinforced plastics in the complex stress state. Polym Mech 1(2):54–59

Gray G III, Blumenthal WR (2000) Split-Hopkinson pressure bar testing of soft materials. ASM Handb 8:488–496

Hashin Z (1980) Failure criteria for unidirectional fiber composites. J Appl Mech 47:329–334

Hashin Z, Rotem A (1973) A fatigue failure criterion for fiber reinforced materials. J Compos Mater 7(4):448–464

Hernández-Moreno H, Douchin B, Collombet F, Choqueuse D, Davies P (2008) Influence of winding pattern on the mechanical behavior of filament wound composite cylinders under external pressure. Compos Sci Technol 68:3–4

Hinton M, Kaddour A, Soden P (2002) A comparison of the predictive capabilities of current failure theories for composite laminates, judged against experimental evidence. Compos Sci Technol 62(12):1725–1797

Hur S-H, Son H-J, Kweon J-H, Choi J-H (2008) Postbuckling of composite cylinders under external hydrostatic pressure. Compos Struct 86:1–3

Kaddour A, Hinton M, Smith P, Li S (2013) The background to the third worldwide failure exercise. J Compos Mater 47:20–21

Kwon YW (2021) Revisiting failure of brittle materials. J Press Vessel Technol 143(6):064503

Kwon YW, Darcy J (2018a) Failure criteria for fibrous composites based on multiscale modeling. Multiscale Multidisciplinary Model Exp Des 1(1): 3–17

Kwon YW, Darcy J (2018b) Further discussion on newly developed failure criteria for fibrous composites. Multiscale Multidisciplinary Model Exp Des 1(4): 307–316

Kwon YW, Sugimoto S (2020) Numerical study of implosion of shell structures. Multiscale Multidisciplinary Model Exp Des 3(4):313–336

Kwon YW, Diaz-Colon C, Defisher S (2022) Failure criteria for brittle notched specimens. J Press Vessel Technol 144(5):051506

Kwon YW, Markoff EK, DeFisher S (2024) Unified failure criterion based on stress and stress gradient conditions. Materials 17(3):569

Lee E, Finger M, Collins W (1973) W JWL equation of state coefficients for high explosives, Lawrence Livermore National Lab.(LLNL), Livermore, CA (United States), Tech. Rep., 1973

Lindholm U, Yeakley L L (1968) High strain-rate testing: tension and compression. Exp Mech 8(1):1–9

Macapagal VP, Kwon YW, Didoszak JM (2024) Cylindrical single-wall and double-wall structures with or without internal water subjected to underwater shock loading. Heliyon e26930. https://doi.org/10.1016/j.heliyon.2024.e269302024

Mercier P, Benier J, Azzolina A, Lagrange J, Partouche D (2006) Photonic Doppler velocimetry in shock physics experiments. Journal de Phys. IV (Proc.) 134: 805–812

Nelson SM, O’Toole BJ (2018) Computational analysis of blast loaded composite cylinders. Int J Impact Eng 119:26–39

Noor AK, Burton WS, Peters JM (1991) Assessment of computational models for multilayered composite cylinders. Int J Solids Struct 27(10):1269–1286

Puck A, Schürmann H (2004) Failure analysis of FRP laminates by means of physically based phenomenological models in failure criteria in fibre-reinforced-polymer composites. Elsevier, pp. 832–876

Roy AK, Tsai SW (1988) Design of thick composite cylinders. J Press Vessel Technol 110(3):255–262

Siromani D, Awerbuch J, Tan T-M (2014) Finite element modeling of the crushing behavior of thin-walled CFRP tubes under axial compression. Compos Part B: Eng 64:50–58

Strand OT, Berzins LV, Goosman DR, Kuhlow WW, Sargis PD, Whitworth TL (2005) Velocimetry using heterodyne techniques. In: 26th international congress on high-speed photography and photonics, SPIE, vol. 5580, pp. 593–599

Sun C, Quinn B, Tao J, Oplinger D (1996) Comparative evaluation of failure analysis methods for composite laminates, DOT/FAA/AR-95/109, Purdue University, School of Aeronautics and Astronautics, May

Tan D, Sun C, Wang Y (2003) Acceleration and viscoplastic deformation of spherical and cylindrical casings under explosive loading. Propellants Explosives Pyrotechnics 28(1): 43–47

Tennyson RC (1975) Buckling of laminated composite cylinders: a review. Composites 6(1): 17–24

Tsai SW, Pagano NJ (1968) Invariant properties of composite materials. Air Force Materials Lab Wright-Patterson AFB, Tech. Report

Tsai SW, Wu EM (1971) A general theory of strength for anisotropic materials. J Compos Mater 5(1):58–80

Yao WJ, Wang XM, Li WB, Gu XH (2009) Effect of carbon fiber composite material casing on blast power of explosive charge. Adv Mater Res 79–82: 461–464

Zhou Y, Wang Y, Jeelani S, **a Y (2007) Experimental study on tensile behavior of carbon fiber and carbon fiber reinforced aluminum at different strain rate. Appl Compos Mater 14:17–31

Acknowledgements

This work was financially sponsored by the US Office of Naval Research.

Author information

Authors and Affiliations

Contributions

YW Kwon conceptualized, funded, directed, supervised, and wrote the paper.S DeFisher designed and conducted the experiment, performed the numerical study, and collected both experimental and numerical data.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

The authors confirm there is no conflict of interest with this research.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

DeFisher, S., Kwon, Y.W. Experimental and numerical studies of failure of a composite casing for a high-energy explosive. Multiscale and Multidiscip. Model. Exp. and Des. (2024). https://doi.org/10.1007/s41939-024-00508-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41939-024-00508-1