Abstract

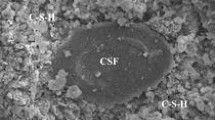

The compatibility of different families of superplasticizers with various types of cement and mineral admixtures is the prime criterion for selecting a suitable superplasticizer (SP) at an optimum dosage in a concrete mix. The comparative performance of polycarboxylate (PCE) and naphthalene (SNF)-based superplasticizers on the various properties of cement paste and concrete mix containing Type I and Type V cement and volcanic ash (VA) were investigated in this study. A difference in crystalline phase was observed with the addition of superplasticizer and volcanic ash to Type V cement, indicating the presence of Gismondine in the studied cases. Scanning electron microscopy analysis showed that the PCE-based superplasticizer produced a relatively compact microstructure with Type I cement than with Type V cement. In contrast, the SNF-based superplasticizer had a compact microstructure with Type V cement. In terms of microstructural modification, compressive strength, sorptivity, and hydration characteristics, the PCE-VA mixture performed better with Type I cement, whereas the SNF-VA mixture displayed better results for Type V cement. The study highlights the effects of different combinations of cement-SP-VA mixtures and the importance of examining these effects to select concrete mix with desired properties.

Similar content being viewed by others

References

Ghrici M, Kenai S, Meziane E (2006) Mechanical and durability properties of cement mortar with Algerian natural pozzolana. J Mater Sci 41:6965–6972

Hossain KMA, Lachemi M (2007) Strength, durability and micro-structural aspects of high performance volcanic ash concrete. Cem Concr Res 37:759–766

Rixom R, Mailvaganam N (1999) Chemical admixtures for concrete. E&FN Spon, London

Ramachandran VS (2002) Concrete admixtures handbook. Standard Publishers, New Delhi

Aïtcin PC (2019) High performance concrete. E& FN Spon, London

Plank J, Sakai E, Miao CW, Yu C, Hong JX (2015) Chemical admixtures-chemistry, applications and their impact on concrete microstructure and durability. Cem Concr Res 78:81–99

John E, Gettu R (2014) Effect of temperature on flow properties of superplasticized cement paste. ACI Mater J 111:67

Ghezal AF, Assaf GJ (2016) Time-dependent behavior of self consolidating concrete loaded at early age: influence of chemical admixtures. J Mater Civ Eng 28(1):04015066-1-104015066–11

Coppola L, Lorenzi S, Kara P, Garlati S (2017) Performance and compatibility of phosphonate-based superplasticizers for concrete. Buildings 7(62):1–10

Liu J, Yu C, Shu X, Ran Q, Yang Y (2019) Recent advance of chemical admixtures in concrete. Cem Concr Res 124:105834

Jayasree C, Gettu R (2008) Experimental study of the flow behaviour of superplasticized cement paste. Mater Struct 41:1581–1593

Saand A, Ali K, Kumar A, Bheel N (2021) Effect of metakaolin developed from natural material Soorh on fresh and hardened properties of self-compacting concrete. Innov Infrastruct Solut 6:166. https://doi.org/10.1007/s41062-021-00534-9

Tahwia AM, El-Far O, Amin M (2022) Characteristics of sustainable high strength concrete incorporating eco-friendly materials. Innov Infrastruct Solut 7:8. https://doi.org/10.1007/s41062-021-00609-7

Moubarak AMR, Elwardany H, El-hassan KA, El-Din Taher S (2021) Optimizing metakaolin and silica-fume in RC beams with/without strengthening. Innov Infrastruct Solut 6:117. https://doi.org/10.1007/s41062-020-00449-x

Al-Bahar S, Chakkamalayath J, Joseph A, Abdulsalam M, Al-Otaibi S, Al-Aibani A (2017) Effect of volcanic ash incorporation on the mechanical properties and the surface morphology of hydrated cement paste. ASCE J Mater Civ Eng 29(8):04017052-1–11

Al-Fadala S, Chakkamalayath J, Al-Bahar S, Al-Aibani A, Ahmed S (2017) Significance of performance based specifications in the qualification and characterization of blended cement using volcanic ash. Constr Build Mater 144:532–540

Hallal A, Kadri EH, Ezziane K, Kadri A, Khelafi H (2010) Combined effect of mineral admixtures with superplasticizers on the fluidity of the blended cement paste. Constr Build Mater 24:1418–1423

Jayasree C (2009) Study of cement-superplasticizer interaction and its implications for concrete performance. Doctoral thesis, Indian Institute of Technology Madras, India

Alonso MM, Palacios M, Puertas F (2013) Compatibility between polycarboxylate-based admixtures and blended-cement paste. Cem Concr Compos 35:151–162

Adjoudj M, Ezziane K, Kadri EH, Ngo T, Kaci A (2014) Evaluation of rheological parameters of mortar containing various amounts of mineral addition with polycarboxylate superplasticizer. Constr Build Mater 70:549–559

Colak A (2002) The long-term durability performance of gypsum–Portland cement–natural pozzolan blends. Cem Concr Res 32:109–115

Hossain KMA, Lachemi M (2010) Fresh, mechanical, and durability characteristics of self-consolidating concrete incorporating volcanic ash. J Mater Civ Eng 22(7):651–657

Kuwait cement company. https://kuwaitcement.com/index.php/products/?lang=enHuetal. Accessed 8 May 2022

Breilly D, Fadlallah S, Froidevaux V, Colas A, Allais F (2021) Origin and industrial applications of lignosulfonates with a focus on their use as superplasticizers in concrete. Constr Build Mater 301:124065

Jayasree C, Krishnan JM, Gettu R (2011) Influence of superplasticizer on the non-Newtonian characteristics of cement paste. Mater Struct 44:929–942

Roussel N (2006) Correlation between yield stress and slump: comparison between numerical simulations and concrete rheometers results. Mater Struct 39:501–509

Standard specification for Portland cement, ASTM C150-21. ASTM International, Pennsylvania (2021)

Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete, ASTM C618-19. ASTM International, Pennsylvania (2019)

Baltazar LG, Henriques FMA, Jorne F, Cidade MT (2014) Combined effect of superplasticizer, silica fume and temperature in the performance of natural hydraulic lime grouts. Constr Build Mater 50:584–597

Standard specification for chemical admixtures for concrete, ASTM C494-19. ASTM International, Pennsylvania (2019)

Standard practice for selecting proportions for normal, heavyweight, and mass concrete, ACI 211.1-91. American Concrete Institute, USA (2002)

Kantro DL (1980) Influence of water reducing admixtures on properties of cement paste—a miniature slump test. Cem Concr Agg 2:95–102

Standard practice for measuring hydration kinetics of hydraulic cementitious mixtures using isothermal calorimetry, ASTM C1679-17. ASTM International, Pennsylvania (2017)

Khayat KH, Yahia A (1998) Simple field tests to characterize fluidity and washout resistance of structural cement grout. Cem Concr Agg 20:145–156

Chakkamalayath J, Abdulsalam M, Al-Bahar S, Al-Fahad F (2015) Comparative performance of two commercially available superplasticizers on the flow behavior of cement paste incorporating mineral admixtures.In: Chang S, Al-Bahar S, Husain A, Zhao J (eds) Advances in civil engineering and building materials IV: selected papers from 4th international conference on civil engineering and building materials, 15–16 November 2014. CRC Press, pp 93–96

Palacios M, Puertas F, Bowen P, Houst YF (2009) Effect of PCs Superplasticizers on the rheological properties and hydration process of slag blended cement pastes. J Mater Sci 44:2714–2723

Swamy RN (1991) Mineral admixtures for high strength concrete. Indian Concr J 65:265–271

Pekmezci BY, Akyuz S (2004) Optimum usage of a natural pozzolan for the maximum compressive strength of concrete. Cem Concr Res 34:2175–2179

Li G, Tagnit-Hamou A, Aïtcin PC (2003) Improving cement-superplasticizer compatibility by using soluble alkalis as a chemical additive in concrete. In: Grieve G, Owens G (eds) Proceedings of 11th international congress on the chemistry of cement, South Africa, 11–16 May, Durban, South Africa, pp 655–665

Siler P, Kratky J, De Belie N (2012) Isothermal calorimetry and solution calorimetry to assess the effect of superplasticizers and mineral admixtures on cement hydration. J Therm Anal Calorion 107:313–320

Zhang Y, Sun W, Liu S (2002) Study on the hydration heat of binder paste in high performance concrete. Cem Concr Res 32:1483–1488

Roncero J, Valls S, Gettu R (2002) Study of the influence of superplasticizers on the hydration of cement paste using nuclear magnetic resonance and X-ray diffraction techniques. Cem Concr Res 22:103–108

Prince W, Espagne M, Aїtcin PC (2003) Ettringite formation: a crucial step in cement superplasticizer compatibility. Cem Concr Res 33:635–641

Ramachandran VS, Beaudoin JJ (2001) Handbook of analytical techniques in concrete science and technology. Noyes and William Andrew Publications, New York

Tzouvalas G, Papageorgiou A, Tsimas S, Papageorgio D (2005) Study of early hydration of cement pastes containing alternative calcium sulphate bearing materials. In: Proceeding of international conference on use of foamed concrete in construction, Dundee, UK, pp 41–51

Zhang X (2007) Quantitative microstructural characterization of concrete cured under realistic temperature conditions. Doctoral Thesis, Ecole Polytechnique Federale de Lausanne, Zwitzerland

Puertas F, Santos H, Palacios M, Martinez-Ramirez S (2005) Polycarboxylate superplasticizer admixtures: effects on hydration, microstructure and rheological behaviour in cement pastes. Adv Cem Res 17:77–89

Taylor HFW (1997) Cement chemistry. Thomas Telford, London

Jayasree C, Gettu R (2010) Correlating properties of superplasticized paste, mortar and concrete. Indian Concr J 84(7):7–18

Standard test method for measurement of rate of absorption of water by hydraulic cement concretes, ASTM C1585-20. ASTM International, Pennsylvania (2020)

Alexander MG, Magee BJ (1999) Durability performance of concrete containing condensed silica fume. Cem Concr Res 29:917–922

Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration, ASTM C1202-19. ASTM International, Pennsylvania (2019)

Standard test method for determining the apparent chloride diffusion coefficient of cementitious mixtures by bulk diffusion, ASTM C1556-11a. ASTM International, Pennsylvania (2016)

Standard test method for acid-soluble chloride in mortar and concrete, ASTM C1152-20. ASTM International, Pennsylvania (2020)

Standard test method for length change of hardened hydraulic-cement mortar and concrete, ASTM C157-17. ASTM International, Pennsylvania (2017)

Acknowledgements

Kuwait Institute for Scientific Research (KISR) had funded this project, EU085K. The authors wish to acknowledge the assistance received from Dr. Antony Joseph for the X-ray diffraction analysis. The authors also wish to acknowledge the Research Supporting staff of Concrete Technology and Material Testing Laboratory while performing the experiments.

Funding

This study was supported by Kuwait Institute for Scientific Research (Project No. EU085K).

Author information

Authors and Affiliations

Contributions

All authors contributed to the Experimental tests and analysis.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chakkamalayath, J., Abdulsalam, M. & Al-Bahar, S. Compatibility of superplasticizers with cement paste and concrete mixes containing Type I and Type V cement, and volcanic ash. Innov. Infrastruct. Solut. 7, 259 (2022). https://doi.org/10.1007/s41062-022-00855-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00855-3