Abstract

The primary aim of the present study is to develop a micro-deformation method for measuring the quasi-static transmission error in gears. First, the micro-deformation method is introduced, based on which a transmission error measurement scheme is established. Following this, the measurement method is experimentally verified by measuring the quasi-static transmission error of spur gears. Strain data collected by a strain data acquisition system is processed to obtain the transmission error results. Finally, the credibility of the micro-deformation method is substantiated theoretically using material mechanics and transmission error results obtained from the magnetic gate detection method. This study contributes to the advancement of gear transmission research by proposing a novel approach to quantify pseudo-static gear transmission error.

Similar content being viewed by others

References

Abboud E, Grolet A, Mahé H et al (2021) Computation of dynamic transmission error for gear transmission systems using modal decomposition and Fourier series. Forsch Ingenieurwes 86(4):751–755

Anichowski B, Kahraman A, Talbot D (2017) Dynamic Transmission Error Measurements From Spur Gear Pairs Having Tooth Indexing Error. Asme International Design Engineering Technical Conferences & Computers & Information in Engineering Conference.

Benatar M, Handschuh MJ, Kahraman A et al (2019) Static and dynamic transmission error measurements of helical gear pairs with various tooth modifications. J Mech Des 141(10):1–11

Blankenship GW, Kahraman A (1995) Steady state forced response of a mechanical oscillator with combined parametric excitation and clearance type non-linearity. J Sound Vib 185(5):743–765

Bruzzone F, Maggi T, Marcellini C et al (2019) Proposal of a novel approach for 3D tooth contact analysis and calculation of the static transmission error in loaded gears. Proced Struct Integ 24:178–189

Cheng JH, Liang M, Fan FL (2012) experiment research and analysis of transmission error of gears. Advanced materials research. Trans Tech Publications Ltd 503:1074–1077

Chun X, Siyu C (2020) Experimental study of the effect of assembly error on the lightly loaded transmission error of spur gear with crown modification. J Low Freq Noise Vibration Act Cont 39(4):1039–1051

Dong GJ, Wang M (2014) Modeling of error analysis simulation of normal circular Arc Bevel gear transmission. Key engineering materials. Trans Tech Publications Ltd 589:606–610

Gregory RW, Harris SL, Munro RG (1963) A method of measuring transmission error in spur gears of 1: 1 ratio. J Sci Instrum 40(1):5

Guo CH, Yang WT, Liu ZF et al (2013) Tooth contact analysis and transmission error optimization for Klingelnberg spiral Bevel gear. Applied mechanics and materials. Trans Tech Publications Ltd 310:323–327

Hayashi, T. Hayashi (1981) Development of the dynamic measurement method of transmission error of a gear pair. Proceedings of the International Symposium on Gearing and Power Transmission, Tokyo, Japan.

Hotait MA, Kahraman A (2013) Experiments on the relationship between the dynamic transmission error and the dynamic stress factor of Spur gear Pairs. Mech Mach Theory 70:116–128

Houser DR, Blankenship GW (1989) Methods for measuring gear transmission error under load and at operating speeds. Sae Int off-Highway Power Congress Expo 98:1367–1374

Kang M, Kahraman A (2012) Measurement of vibratory motions of gears supported by compliant shafts. Mech Syst Signal Process 29:391–403

Dun Cai Lei, ** Yuan Tang, Jian Jie Tang (2014b), Gear Dynamic Transmission Error Testing 2013 International Conference on Applied Mechanics, Fluid and Solid Mechanic, 2904: 352–357.

Li KK, Bian YS, Liu BD (2014) Transmission error analysis of external gear drive based on form and position errors. Applied mechanics and materials. Trans Tech Publications Ltd 614:36–39

Liu C, Shi W, Curá FM et al (2020) A novel method to predict static transmission error for spur gear pair based on accuracy grade. J Central South Univ 27(11):3334–3349

Tamminana VK, Kahraman A, Vijayakar S (2007) A Study of the relationship between the dynamic factors and the dynamic transmission error of Spur gear Pairs. J Mech Des 129(1):75–84

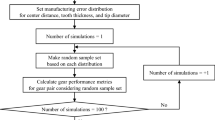

Tang JJ, Tang JY (2014) Transmission error calculation based on manufacturing errors and load. Advanced materials research. Trans Tech Publications Ltd 971:848–851

Wang YN, Sun ZL, Yin MA (2013) Considering thermal deformation in gear transmission error calculation. Applied mechanics and materials. Trans Tech Publications Ltd 281:211–215

Yu B, Kou H, Shi Z et al (2022) A virtual measurement method of the transmission error based on point clouds of the gear. Measure Sci Rev 22(2):92–99

Zhu **aolu, E Zhongkai, et al (1992) Analysis of load capacity of gears. Higher Education Press, Bei**g, Bei**g

Acknowledgements

This work was supported in part by the 2020 National Key Research and Development Program of China 2020YFB2008100, the National Natural Science Foundation of China under Project 52105061, the Natural Science Foundation of Jiangsu Province under Project BK20200424 and Project BK20200430, the Nan**g University of Aeronautics and Astronautics, Jiangsu Key Laboratory of Precision and Micro-manufacturing Technology, and the Sichuan Gas Turbine Establishment, Aero Engine Corporation of China. The authors would like to thank the anonymous reviewers for giving valuable suggestions to improve the quality of their work.

Funding

2020 National Key Research and Development Program of China (2020YFB2008100), National Natural Science Foundation of China (52105061), and the Natural Science Foundation of Jiangsu Province (BK20200424, BK20200430).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, H., Zhang, J., Pan, K. et al. Quasi-Static Transmission Error Measurement Using Micro-Deformation. Iran J Sci Technol Trans Mech Eng 48, 723–731 (2024). https://doi.org/10.1007/s40997-023-00678-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-023-00678-2