Abstract

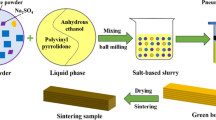

In this paper, the high-strength water-soluble Na2SO4–NaCl composite salt cores (NNCSC) strengthened by alumina powder using additive manufacturing 3D direct printing (3DP) method were reported, which can be used to manufacture the aluminum alloy castings with hollow-composite structures. The effects of polyvinyl pyrrolidone (PVP) concentration, alumina powder content, and sintering time on the performance of NNCSC were investigated. The microstructure and strengthening mechanism were analyzed and discussed. It was found that NNCSC green body exhibited good formability and bending strength at a PVP concentration of 10 wt%. When the alumina content was 40 wt% and sintered at 628 °C for 20 min, NNCSC possessed excellent comprehensive performance, and the bending strength, open porosity, sintering shrinkage, and water solubility rate were 53.09 MPa, 1.45%, 9.64% and 104.35 g/(min·m2), respectively, wherein the bending strength was increased by 215.6%. Microscopic analysis results showed that the NaCl phase in NNCSC samples was refined with the increase of alumina content, and the phase constitution altered as sintering time increased, resulting in a considerable improvement in the strength properties. Finally, the NNCSC components with slender-complex structures and corresponding aluminum alloy castings were obtained under the optimized process.

Similar content being viewed by others

References

F. Czerwinski, M. Mir, W. Kasprzak, Application of cores and binders in metalcasting. Int. J. Cast. Metal. Res. 28, 129–139 (2015). https://doi.org/10.1179/1743133614y.0000000140

X. Dong, H. Yang, X. Zhu, S. Ji, High strength and ductility aluminium alloy processed by high pressure die casting. J. Alloy. Compd. 773, 86–96 (2019). https://doi.org/10.1016/j.jallcom.2018.09.260

Z.Q. Hu, Injection parameters optimization and artificial aging of automotive die cast aluminum alloy. Mater. Manuf. Process. 31, 787–793 (2016). https://doi.org/10.1080/10426914.2015.1004706

S. Tu, F.C. Liu, G.J. Li, W.M. Jiang, X.W. Liu, Z.T. Fan, Fabrication and characterization of high-strength water-soluble composite salt core for zinc alloy die castings. Int. J. Adv. Manuf. Tech. 95, 505–512 (2018). https://doi.org/10.1007/s00170-017-1208-y

G.H. Cho, J. Li, E.H. Kim, Y.G. Jung, Preparation of a ceramic core with high strength using an inorganic precursor and the gel-casting method. Surf. Coat. Tech. 284, 396–399 (2015). https://doi.org/10.1016/j.surfcoat.2015.09.062

B.J. Stauder, H. Kerber, P. Schumacher, Foundry sand core property assessment by 3-point bending test evaluation. J. Mater. Process. Tech. 237, 188–196 (2016). https://doi.org/10.1016/j.jmatprotec.2016.06.010

L. Yang, S.Y. Tang, G.J. Li, F.C. Liu, X.W. Liu, W.M. Jiang, Z.T. Fan, Performance characteristics of collapsible CaO–SiO2 based ceramic core material via layered extrusion forming. Ceram. Int. 45, 7681–7689 (2019). https://doi.org/10.1016/j.ceramint.2019.01.068

F.C. Liu, S. Tu, X.L. Gong, G.J. Li, W.M. Jiang, X.W. Liu, Z.T. Fan, Comparative study on performance and microstructure of composite water-soluble salt core material for manufacturing hollow zinc alloy castings. Mater. Chem. Phys. 252, 123257 (2020). https://doi.org/10.1016/j.matchemphys.2020.123257

F.C. Liu, P. Jiang, Y. Huang, W.M. Jiang, X.W. Liu, Z.T. Fan, A water-soluble magnesium sulfate bonded sand core material for manufacturing hollow composite castings. Compos. Struct. 201, 553–560 (2018). https://doi.org/10.1016/j.compstruct.2018.06.084

W.G. Jiang, J.S. Dong, L.H. Lou, M. Liu, Z.Q. Hu, Preparation and properties of a novel water soluble core material. J. Mater. Sci. Technol. 26, 270–275 (2010). https://doi.org/10.1016/s1005-0302(10)60045-x

C. Cantas, B. Baksan, Effects of composition on the physical properties of water-soluble salt cores. Int. J. Metalcast. 15, 839–851 (2021). https://doi.org/10.1007/s40962-020-00511-5

X. Gong, W. Jiang, F. Liu, Z. Yang, F. Guan, Z. Fan, Effects of glass fiber size and content on microstructures and properties of KNO3-based water-soluble salt core for high pressure die casting. Int. J. Metalcast. 15, 520–529 (2021). https://doi.org/10.1007/s40962-020-00480-9

R.H. Huang, B.P. Zhang, Study on the composition and properties of salt cores for zinc alloy die casting. Int. J. Metalcast. 11, 440–447 (2017). https://doi.org/10.1007/s40962-016-0086-7

K. Oikawa, K. Sakakibara, Y. Yamada, K. Anzai, High-temperature mechanical properties of NaCl–Na2CO3 salt-mixture removable cores for aluminum die-casting. Mater. Trans. 60, 19–24 (2019). https://doi.org/10.2320/matertrans.MG201804

E. Adamkova, P. Jelinek, J. Beno, F. Mikgovsky, water-soluble cores-verifing development trends. Mater. Technol. 49, 61–67 (2015)

Z. **ao, L.T. Harper, A.R. Kennedy, N.A. Warrior, A water-soluble core material for manufacturing hollow composite sections. Compos. Struct. 182, 380–390 (2017). https://doi.org/10.1016/j.compstruct.2017.09.058

N. Kleger, M. Cihova, K. Masania, A.R. Studart, J.F. Loffler, 3D printing of salt as a template for magnesium with structured porosity. Adv. Mater. 31, 1903783 (2019). https://doi.org/10.1002/adma.201903783

J. Yaokawa, D. Miura, K. Anzai, Y. Yamada, H. Yoshi, Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater. Trans. 48, 1034–1041 (2007). https://doi.org/10.2320/matertrans.48.1034

X.Y. Liu, W.H. Liu, X.T. Wang, L. Song, F.H. **n, Y.M. Li, Composition optimization and strengthening mechanism of high-strength composite water-soluble salt core for foundry. Int. J. Metalcast. 16, 1809–1816 (2022). https://doi.org/10.1007/s40962-021-00725-1

X.L. Gong, X.J. **ao, X.W. Liu, Z.T. Fan, Fabrication of high-strength salt cores for manufacturing hollow aluminum alloy die castings. Mater. Manuf. Process. 38, 188–196 (2023). https://doi.org/10.1080/10426914.2022.2072887

A. Nommeots-Nomm, P.D. Lee, J.R. Jones, Direct ink writing of highly bioactive glasses. J. Eur. Ceram. Soc. 38, 837–844 (2018). https://doi.org/10.1016/j.jeurceramsoc.2017.08.006

W.J. Costakis, L.M. Rueschhoff, A.I. Diaz-Cano, J.P. Youngblood, R.W. Trice, Additive manufacturing of boron carbide via continuous filament direct ink writing of aqueous ceramic suspensions. J. Eur. Ceram. Soc. 36, 3249–3256 (2016). https://doi.org/10.1016/j.jeurceramsoc.2016.06.002

Q. Fu, E. Saiz, A.P. Tomsia, Direct ink writing of highly porous and strong glass scaffolds for load-bearing bone defects repair and regeneration. Acta Biomater. 7, 3547–3554 (2011). https://doi.org/10.1016/j.actbio.2011.06.030

X.L. Gong, X.W. Liu, Z. Chen, Z.Y. Yang, W.M. Jiang, Z.T. Fan, 3D printing of high-strength water-soluble salt cores via material extrusion. Int. J. Adv. Manuf. 118, 2993–3003 (2022). https://doi.org/10.1007/s00170-021-08131-x

Z. Chen, S. Fan, L. Peng, Y. Wang, X. Gong, X. Liu, Z. Fan, Fabrication and characterization of high-strength water-soluble composite salt cores via layered extrusion forming. Int. J. Adv. Manuf. 17, 988–997 (2023). https://doi.org/10.1007/s40962-022-00816-7

H. Shao, D. Zhao, T. Lin, J. He, J. Wu, 3D gel-printing of zirconia ceramic parts. Ceram. Int. 43, 13938–13942 (2017). https://doi.org/10.1016/j.ceramint.2017.07.124

S. Tang, Z. Fan, H. Zhao, L. Yang, F. Liu, X. Liu, Layered extrusion forming—A simple and green method for additive manufacturing ceramic core. Int. J. Adv. Manuf. Tech. 96, 3809–3819 (2018). https://doi.org/10.1007/s00170-018-1712-8

F.J. Martínez-Vázquez, A. Pajares, P. Miranda, A simple graphite-based support material for robocasting of ceramic parts. J. Eur. Ceram. Soc. 38, 2247–2250 (2018). https://doi.org/10.1016/j.jeurceramsoc.2017.10.016

G.V. Franks, C. Tallon, A.R. Studart, M.L. Sesso, S. Leo, Colloidal processing: enabling complex shaped ceramics with unique multiscale structures. J. Am. Ceram. Soc. 100, 458–490 (2017). https://doi.org/10.1111/jace.14705

H.J. Zhang, S.L. Sun, H.J. Liu, Z. Zhu, Y.L. Wang, Characteristic and mechanism of nugget performance evolution with rotation speed for high-rotation-speed friction stir welded 6061 aluminum alloy. J. Manuf. Process. 60, 544–552 (2020). https://doi.org/10.1016/j.jmapro.2020.10.081

P. Emadi, B. Andilab, C. Ravindran, Processing and properties of magnesium-based composites reinforced with low levels of Al2O3. Int. J. Metalcast. 16, 1680–1692 (2022). https://doi.org/10.1007/s40962-021-00738-w

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 52205361 and 52275334); and the Project was funded by China Postdoctoral Science Foundation (No. 2022M721229).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

**ao, X., Gong, X., Zhao, J. et al. Preparation of Alumina Powder-Reinforced High-Strength Salt Cores Produced via 3D Direct Printing for Aluminum Alloy Casting. Inter Metalcast (2023). https://doi.org/10.1007/s40962-023-01168-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01168-6