Abstract

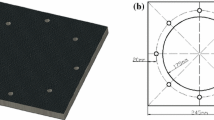

Silicon carbide ceramics are widely used for armor protection due to their high compressive strength, high hardness and low density. In the present study, an experimental technique based on the plate-impact technique is developed to measure the tensile strength of ceramic materials. As the strength of ceramics under dynamic loading is highly sensitive to the strain rate, the effort was made to maintain a constant strain rate loading at the failure location. Numerical simulations were used to design several geometries of wavy-machined flyer-plates, which generate a pulse-shaped compressive wave upon impact, with smoothed rising and falling times ranged from 0.65 to 1 \(\upmu\)s. Such shockless plate-impact experiments were performed on a SiC ceramic at impact velocities set between 200 and 450 m/s. Thanks to laser interferometry analysis, the target rear face velocity provides a measurement of the material spall strength at a given strain-rate loading. The strain rate in the failure zone was evaluated via elasto-plastic numerical simulations, using the pulse loading and spall strength determined experimentally. With an appropriate design of the flyer-plate, the plate-impact technique is found to properly allow a well-controlled strain-rate loading around 10\(^4\)-10\(^5\) s\(^{-1}\) with relatively long rising time to be reached. This work is expected to provide a suitable tool to investigate the high strain-rate behavior of ceramic materials.

Similar content being viewed by others

References

Sheldon DA (1998) Silicon carbide abrasive wheel, US Patent 5,711,774

She X, Huang AQ, Lucía O, Ozpineci B (2017) Review of silicon carbide power devices and their applications. IEEE Trans Ind Electron 64(10):8193–8205

Hotza D, Di Luccio M, Wilhelm M, Iwamoto Y, Bernard S, da Costa JCD (2020) Silicon carbide filters and porous membranes: a review of processing, properties, performance and application. J Membr Sci 610:118193

Helms HE (1983) Ceramic applications in turbine engines. Ceramics for high-performance applications III. Springer, Belin, pp 151–172

Kuhn M, Tierney D, Simmers M (2016) Silicon carbide for the modern warfighter. Am Ceram Soc Bull 96:8

Forquin P, Denoual C, Cottenot CE, Hild F (2003) Experiments and modelling of the compressive behaviour of two sic ceramics. Mech Mater 35(10):987–1002

Grady DE (1994) Shock-wave strength properties of boron carbide and silicon carbide. Le J Phys IV 4(C8):C8-385

Martin SR (2004) Experimental characterization of the effect of microstructure on the dynamic behavior of SiC. PhD thesis, Georgia Institute of Technology

Grady DE (1995) Dynamic properties of ceramic materials. Technical report, Sandia National Labs, Albuquerque, NM, USA

Wilkins ML, Cline CF, Honodel CA (1969) Fourth progress report of light armor program. California University, Livermore. Lawrence Radiation Lab, Technical report

Crouch IG, Franks GV, Tallon C, Thomas S, Naebe M (2017) Glasses and ceramics. The science of armour materials. Elsevier, Amsterdam, pp 331–393

Zinszner J-L, Forquin P, Rossiquet G (2015) Experimental and numerical analysis of the dynamic fragmentation in a SiC ceramic under impact. Int J Impact Eng 76:9–19

Deng H, Nemat-Nasser S (1992) Dynamic damage evolution in brittle solids. Mech Mater 14(2):83–103

Shockey DA, Curran DR, Seaman L, Rosenberg JT, Petersen CF (1974) Fragmentation of rock under dynamic loads. Int J Rock Mech Min Sci Geomech 11:303–317

Forquin P, Blasone M, Georges D, Dargaud M, Saletti D, Andò E (2020) The brittle’s codex chair. DYMAT Winter School 2020:180–185

Lambert DE, Ross CA (2000) Strain rate effects on dynamic fracture and strength. Int J Impact Eng 24(10):985–998

Gálvez F, Rodriguez J, Sánchez V (1997) Tensile strength measurements of ceramic materials at high rates of strain. Le J Phys IV 7(C3):C3-151

Ramesh KT (2008) High rates and impact experiments. Handb Exp Solid Mech 933:929–960

Forquin P, Riedel W, Weerheijm J (2013) Dynamic test devices for analyzing the tensile properties of concrete. Understanding the tensile properties of concrete. Elsevier, Amsterdam, pp 137–181

Forquin P (2017) Brittle materials at high-loading rates: an open area of research. Philos Trans A Math Phys Eng Sci 375(2085):20160436

Paris V, Frage N, Dariel MP, Zaretsky E (2010) The spall strength of silicon carbide and boron carbide ceramics processed by spark plasma sintering. Int J Impact Eng 37(11):1092–1099

Antoun T, Curran D, Razorenov S, Seaman L, Kanel GI, Utkin A (2003) Spall fracture. Spall fracture: shock wave and high pressure phenomena. Springer, New York

Schuler H, Mayrhofer C, Thoma K (2006) Spall experiments for the measurement of the tensile strength and fracture energy of concrete at high strain rates. Int J Impact Eng 32(10):1635–1650

Forquin P, Erzar B (2010) Dynamic fragmentation process in concrete under impact and spalling tests. Int J Fract 163(1–2):193–215

Erzar B, Forquin P (2010) An experimental method to determine the tensile strength of concrete at high rates of strain. Exp Mech 50(7):941–955

Forquin P, Lukić B (2018) On the processing of spalling experiments part i: identification of the dynamic tensile strength of concrete. J Dyn Behav Mater 4(1):34–55

Grady DE (1988) The spall strength of condensed matter. J Mech Phys Solids 36(3):353–384

Forquin P, Hild F (2010) A probabilistic damage model of the dynamic fragmentation process in brittle materials. Adv Appl Mech 44:1–72

Denoual C, Hild F (2000) A damage model for the dynamic fragmentation of brittle solids. Comput Methods Appl Mech Eng 183(3–4):247–258

Dandekar DP, Bartkowski PT (2001) Tensile strengths of silicon carbide (SiC) under shock loading. Technical report, Army Research Lab Aberdeen proving ground MD

Bartkowski P, Dandekar DP (1996) Spall strengths of sintered and hot pressed silicon carbide. In: AIP conference proceedings, vol 370, pp 535–538. American Institute of Physics

Dandekar DP, Bartkowski PT (2001) Chapter 10. Spall strengths of silicon carbides under shock loading. In: Meyers MA, Murr LE, Staudhammer KP (eds) Fundamental issues and applications of shock-wave and high strain-rate phenomena, pp 71–77

Forquin P, Zinszner J-L (2017) A pulse-sha** technique to investigate the behaviour of brittle materials subjected to plate-impact tests. Philos Trans R Soc A 375(2085):20160333

Forrestal MJ, Warren TL (2021) A conical striker bar to obtain constant true strain rate for Kolsky bar experiments. J Dyn Behav Mater 7:161–164

LaLone BM, Gupta YM (2009) Elastic limit of x-cut quartz under shockless and shock wave compression: Loading rate dependence. J Appl Phys 106(5):053526

Davis JP, Deeney C, Knudson MD, Lemke RW, Pointon TD, Bliss DE (2005) Magnetically driven isentropic compression to multimegabar pressures using shaped current pulses on the z accelerator. Phys Plasmas 12(5):056310

Erzar B, Buzaud E (2012) Shockless spalling damage of alumina ceramic. Eur Phys J Special Topics 206:05

Zinszner J-L, Erzar B, Forquin P (2017) Strain rate sensitivity of the tensile strength of two silicon carbides: experimental evidence and micromechanical modelling. Philos Trans R Soc A 375:20160167

Yep S, Belof J, Orlikowski D, Nguyen J (2013) Fabrication and application of high impedance graded density impactors in light gas gun experiments. Rev Sci Instrum 84:103909

Martin LP, Patterson JR, Orlikowski D, Nguyen JH (2007) Application of tape-cast graded impedance impactors for light-gas gun experiments. J Appl Phys 102(2):023507

Hall AC, Battaile CC, Webb EB, Wise JL, Urrea DA, McCloskey JF, Roemer TJ, Beatty DE (2008)Graded-density thermal spray coatings for light gas gun flyer plates. Technical report, Sandia National Lab (SNL-NM), Albuquerque, NM, USA

Cotton M, Chapman D, Winter R, Harris E, Eakins D (2015) Tailored ramp wave generation in gas gun experiments. In: EPJ Web of Conferences, vol 94, p 01065. EDP Sciences

Forquin P (2016) Procede et dispositif pour mesurer la resistance des materiaux solides par impact de plaques sans choc, October 11 . Patent UGA, INPI, N\(^\circ\)1000369617

Novikov SA, Divnov II, Ivanov AG (1966) Investigation of the fracture of steel, aluminum and copper during explosive loading. Fiz Metallov Metalloved 21(4):608–615

https://www.ceramicsrefractories.saint-gobain.com/hexoloy/why-use-hexoloy-sic-material. Saint-Gobain website

Plassard F, Mespoulet J, Héreil PL (2011) Analysis of a single stage compressed gas launcher behaviour: from breech opening to sabot separation. In: 8th European LS-DYNA Users Conference, Strasbourg, 05

Strand OT, Goosman DR, Martinez C, Whitworth TL, Kuhlow WW (2006) Compact system for high-speed velocimetry using heterodyne techniques. Rev Sci Instrum 77:083108–083108

Kettenbeil C, Mello M, Bischann M, Ravichandran G (2018) Heterodyne transverse velocimetry for pressure-shear plate impact experiments. J Appl Phys 123:125902

Acknowledgements

The authors would like to acknowledge the helpful clarifications obtained from Dr. J.L. Zinszner regarding the interferometry system and data post-processing. For their assistance in preparing the plate-impact experiments, the authors would like to thank W. Kaczmarek, E. Pollier, Dr. L. Zingg and L. Debove. The authors are thankful to Saint-Gobain Research Provence for providing the silicon carbide samples. This research was performed in the framework of the Brittle’s CODEX chair, supported by the UGA (Univ. Grenoble Alpes) Foundation and sponsored by the Saint-Gobain and Lafarge-Holcim companies. These sponsors are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dargaud, M., Forquin, P. A Shockless Plate-Impact Spalling Technique, Based on Wavy-Machined Flyer-Plates, to Evaluate the Strain-Rate Sensitivity of Ceramic Tensile Strength. J. dynamic behavior mater. 8, 73–88 (2022). https://doi.org/10.1007/s40870-021-00317-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-021-00317-4