Abstract

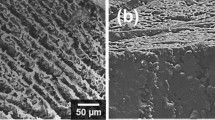

Nickel foams, consisting of 51 to 62 pct aligned, elongated pores surrounded by a network of Ni walls, were fabricated by reduction and sintering of directionally cast suspensions of nanometric NiO powders in water. Use of dispersant in the slurry considerably affected the foam morphology and microstructure at both the micro- and macro-scale, most likely by modifying ice solidification into dendrites (creating the aligned, elongated macro-pores) and NiO powder accumulation in the inter-dendritic space (creating the Ni walls with micro-pores). The mean width of the Ni walls, in foams solidified with and without dispersant, was 21 ± 5 and 75 ± 13 µm, respectively. Additionally, the foams with the dispersant showed less dense walls and rougher surfaces than those without the dispersant. Moreover, the fraction of closed pores present in the foam walls with the dispersant was higher than that of the samples without dispersant. We finally verified the potential energy application of the Ni foam produced in this study by carrying out a preliminary single-cell performance test with the Ni foam sample as the gas diffusion layer on the anode side of a polymer electrolyte membrane fuel cell.

Similar content being viewed by others

References

H.C. Shin and M. Liu: Adv. Funct. Mater., 2005, vol. 15, pp. 582–86.

L. Giani, G. Groppi, and E. Tronconi: Ind. Eng. Chem. Res., 2005, vol. 44, pp. 4993–5002.

K.C. Leong and L.W. **: Int. J. Heat Fluid Flow, 2006, vol. 27, pp. 144–53.

J. Adler: Int. J. Appl. Ceram. Technol., 2005, vol. 2, pp. 429–39.

L. Lefebvre, J. Banhart, and D.C. Dunand: Adv. Eng. Mater., 2008, vol. 28, pp. 769–74.

P. Colombo, D.C. Dunand, and V. Kumar: J. Mater. Res., 2013, vol. 28, pp. 2187–90.

V. Ganesh, V. Lakshminarayanan, and S. Pitchumani: Electrochem. Solid State Lett., 2005, vol. 8, p. A308–12.

H. Park, C. Ahn, H. Jo, M. Choi, D.S. Kim, D.K. Kim, S. Jeon, and H. Choe: Mater. Lett., 2014, vol. 129, pp. 174–77.

M. Gauthier, L.-P. Lefebvre, Y. Thomas, and M.N. Bureau: Mater. Manuf. Process., 2004, vol. 19, pp. 793–811.

V. Paserin, S. Marcuson, J. Shu, and D.S. Wilkinson: Adv. Eng. Mater., 2004, vol. 6, pp. 454–59.

Y. Boonyongmaneerat and D.C. Dunand: Adv. Eng. Mater., 2008, vol. 10, pp. 379–83.

S. Deville: Materials, 2010, vol. 3, pp. 1913–27.

E. Munch, J. Franco, S. Deville, P. Hunger, E. Saiz, and A.P. Tomsia: JOM, 2008, vol. 60, pp. 54–58.

J.L. Fife, J.C. Li, D.C. Dunand, and P.W. Voorhees: J. Mater. Res., 2009, vol. 24, pp. 117–24.

A.I.C. Ramos and D.C. Dunand: Metals, 2012, vol. 2, pp. 265–73.

R. Sepulveda, A.A. Plunk, and D.C. Dunand: Mater. Lett., 2015, vol. 142, pp. 56–59.

J. Jiang, G. Oberdorster, and P. Biswas: J. Nanopart. Res., 2009, vol. 11, pp. 77–89.

M.J. Rosen and J.T. Kunjappu: Surfactants and Interfacial Phenomena, 4th ed., Wiley, New Jersey, US, 2012.

B. Jankovic, B. Adnadevic, and S. Mentus: Chem. Eng. Sci., 2008, vol. 63, pp. 567–75.

G. Parravano: J. Am. Chem. Soc., 1952, vol. 74, pp. 1194–98.

J.A. Rodriguez, J.C. Hanson, A.I. Frenkel, J.Y. Kim, and M. Perez: J. Am. Chem. Soc., 2002, vol. 124, pp. 346–54.

J.T. Richardson, R. Scates, and M.V. Twigg: Appl. Catal. A, 2003, vol. 246, pp. 137–50.

T.A. Utigard, M. Wu, G. Plascencia, and T. Marin: Chem. Eng. Sci., 2005, vol. 60, pp. 2061–68.

Q. Jeangros, T.W. Hansen, J.B. Wagner, C.D. Damsgaard, R.E. Dunin-Borkowski, C. Hebert, J. Vanherle, and A. Hessler-Wyser: J. Mater. Sci., 2013, vol. 48, pp. 2893–2907.

S. Deville, E. Saiz, and A.P. Tomsia: Biomaterials, 2006, vol. 27, pp. 5480–89.

K. Nagashima and Y. Furukawa: J. Cryst. Growth, 1997, vol. 171, pp. 577–85.

G.W. Young, S.H. Davis, and K. Brattkus: J. Cryst. Growth, 1987, vol. 83, pp. 560–71.

S. Deville: Adv. Eng. Mater., 2008, vol. 10, pp. 155–69.

S. Deville, E. Saiz, and A.P. Tomsia: Acta Mater., 2007, vol. 53, pp. 1965–74.

W.L. Li, K. Lu, and J.Y. Walz: Int. Mater. Rev., 2012, vol. 57, pp. 37–60.

U.G.K. Wegst, M. Schecter, A.E. Donius, and P.M. Hunger: Philos. Trans. R. Soc. London Ser. A, 2009, vol. 368, pp. 2099–21.

D.H. Napper: Polymeric Stabilization of Colloidal Dispersions, vol. 18, Academic Press, London, 1983.

S. Padilla, R. Garcia-Carrodeguas, and M. Vallet-Regi: J. Eur. Ceram. Soc., 2004, vol. 24, pp. 2223–32.

S. Sanchez-Salcedo, J. Werner, and M. Vallet-Regi: Acta Biomater., 2008, vol. 4, pp. 913–22.

W.W. Mullins and R.F. Sekerka: J. Appl. Phys., 1964, vol. 35, pp. 444–51.

W.F. Gale and T.C. Totemeier: Smithells Metals Reference Book, 8th ed., Elsevier Butterworth-Heinemann, Alabama, US, 2013.

H. Choi, O.-H. Kim, M. Kim, H. Choe, Y.-H. Cho, Y.-H. Cho, and Y.-E. Sung: ACS Appl. Mater. Int., 2014, vol. 6, pp. 7665–71.

K.P. Dharmasena and H.N.G. Wadley: J. Mater. Res., 2002, vol. 17, pp. 625–631.

R.W. Revie and H.H. Uhlig: Uhlig’s Corrosion Handbook, 3rd ed., Wiley, New Jersey, US, 2011.

Acknowledgments

This study was supported by the Priority (2012-0006680) and Pioneer (2011-0001684) Research Centers Programs through NRF. HC also acknowledges supports from the International Research and Development Program (NRF-2013K1A3A1A39074064) and the Basic Science Research Program (2014R1A2A1A11052513). DCD also acknowledges support from the Institute for Sustainability and Energy at Northwestern University (ISEN). YS acknowledges the Institute for Basic Science (IBS) in Korea by the Project Code (IBS-R006-G1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 17, 2015.

Rights and permissions

About this article

Cite this article

Jo, H., Kim, M.J., Choi, H. et al. Morphological Study of Directionally Freeze-Cast Nickel Foams. Metallurgical and Materials Transactions E 3, 46–54 (2016). https://doi.org/10.1007/s40553-016-0068-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40553-016-0068-y