Abstract

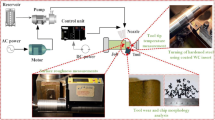

The impact of Minimum Quantity Lubrication (MQL) plays a pivotal role in the modern metal-cutting industry for sustainable manufacturing. Despite being one of the oldest machining processes, turning remains a crucial manufacturing technique with significant industrial relevance. But in the modern era, sustainability issues like economic, health, and socials hinder the machining processes. Hence, in this research work, liquid CO2-assisted Minimum Quantity Lubrication condition is employed at a variable flow rate in turning EN31 alloy steel. The effect of process parameters was thoroughly investigated to set the Liquid CO2-assisted MQL's flow rate so that the productivity and product quality remain intact. In addition, the microstructures were also studied by scanning electron microscopy (SEM) to image the material's surface after machining. The images can reveal details about the size, shape, and distribution of chips and the presence of defects or other surface features. Thus, the work figures out the proper flow rate for desired output and studies the behavior of responses. The study reveals that the 2.5 ml/min flow rate yields minimum surface roughness (Ra), minimum rake surface temperature rise (Trake) and maximum material removal rate (MRR).

Similar content being viewed by others

Data Availability

N/A.

Code Availability

N/A.

References

A. Das, S.K. Patel, B.B. Biswal et al., Performance evaluation of various cutting fluids using MQL technique in hard turning of AISI 4340 alloy steel. Measurement 150, 107079 (2020). https://doi.org/10.1016/j.measurement.2019.107079

A. Sharma, R. Kumar, Potential use of minimum quantity lubrication (MQL) in machining of biocompatible materials using environment friendly cutting fluids: an overview. Proceedings of the 2nd International Conference on Aspects of Materials Science and Engineering (ICAMSE 2021), vol 45 (Elsevier, 2021), p. 5315–5319. https://doi.org/10.1016/j.matpr.2021.01.904

V.S. Sharma, M. Dogra, N.M. Suri, Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 49, 435–453 (2009). https://doi.org/10.1016/j.ijmachtools.2008.12.010

A. Das, S.K. Patel, M. Arakha et al., Processing of hardened steel by MQL technique using nano cutting fluids. Mater. Manuf. Process. 36(3), 316–328 (2021). https://doi.org/10.1080/10426914.2020.1832688

Chetan, S. Ghosh, P.V. Rao, Specific cutting energy modelling for turning nickel-based nimonic 90 alloy under MQL condition. Int. J. Mech. Sci. 146–147, 25–38 (2018). https://doi.org/10.1016/j.ijmecsci.2018.07.033

Z. Said, M. Gupta, H. Hegab et al., A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 105, 2057–2086 (2019). https://doi.org/10.1007/s00170-019-04382-x

K. Weinert, I. Inasaki, J.W. Sutherland et al., Dry machining and minimum quantity lubrication. CIRP Ann. Manuf. Technol. 53(2), 511–537 (2004). https://doi.org/10.1016/S0007-8506(07)60027-4

Y. Su, L. Gong, B. Li et al., Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int. J. Adv. Manuf. Technol. 83(9–12), 2083–2089 (2015). https://doi.org/10.1007/s00170-015-7730-x

A. Filipovic, D.A. Stephenson, Minimum quantity lubrication (MQL) applications in automotive power-train machining. Mach. Sci. Technol. 10(1), 3–22 (2006). https://doi.org/10.1080/10910340500534258

J. Kouam, V. Songmene, M. Balazinski et al., Effects of minimum quantity lubricating (MQL) conditions on machining of 7075–T6 aluminium alloy. Int. J. Adv. Manuf. Technol. 79(5–8), 1325–1334 (2015). https://doi.org/10.1007/s00170-015-6940-6

N. Hanenkamp, S. Amon, D. Gross, Hybrid supply system for conventional and CO2/MQL-based cryogenic cooling. Proceedings of the 8th CIRP Conference on High Performance Cutting; 2018 June 25–27; Budapest, Hungary (Elsevier, 2018), p. 219–222. https://doi.org/10.1016/j.procir.2018.08.293

S. Misra, G. Paul, A.G. Barman, Investigation on the effects of nose radius and rake surface of cutting tool for machinability during sustainable turning of EN31 alloy steel, in Machines Mechanism and Robotics. (Springer, Cham, 2021), pp.919–927

S. Mondal, G. Paul, S.C. Mondal, Experimental investigation on the effect of process parameters for CNC turning of UNI Al 3055 alloy under MQCL based cooling technique, in Machines Mechanism and Robotics. (Springer, Cham, 2021), pp.643–651

K.A. Osman, H.O. Unver, U. Seker, Application of minimum quantity lubrication techniques in the machining process of titanium alloy for sustainability: a review. Int. J. Adv. Manuf. Technol. 100(9–12), 2311–2332 (2018). https://doi.org/10.1007/s00170-018-2813-0

X. Ji, X. Zhang, B. Li et al., Modeling the effects of minimum quantity lubrication on machining force, temperature, and residual stress. Mach. Sci. Technol. 18(4), 547–564 (2014). https://doi.org/10.1080/10910344.2014.955367

T. Jadam, S. Datta, M. Masanta, Influence of cutting tool material on machinability of Inconel 718 superalloy. Mach. Sci. Technol. 25(3), 349–397 (2021). https://doi.org/10.1080/10910344.2020.1815047

C. Saikaewa, P. Paengchita, A. Wisitsoraatb, Machining performances of TiN + AlCrN coated WC and Al2O3 + TiC inserts for turning of AISI 4140 steel under dry condition. J. Manuf. Process. 50, 412–420 (2020). https://doi.org/10.1016/j.jmapro.2019.12.057

D. Mari, D.R. Gonseth, A new look at carbide tool life. Wear 165(1), 9–17 (1993). https://doi.org/10.1016/0043-1648(93)90366-T

A.E. Diniz, H.A. MicaroniR, Evaluating the effect of coolant pressure and flow rate on tool wear and tool life in the steel turning operation. Int. J. Adv. Manuf. Technol. 50(9–12), 1125–1133 (2010). https://doi.org/10.1007/s00170-010-2570-1

K. Mondal, G. Paul, A.G. Barman, Effect of Tool geometry on chip morphology formed during CNC turning of a round shaped product, in Machines Mechanism and Robotics. (Springer, Cham, 2021), pp.571–579

H. Gurbuz, Y.E. Gonulacar, S. Baday, Effect of MQL flow rate on machinability of AISI 4140 steel. Mach. Sci. Technol. 24(5), 663–687 (2020). https://doi.org/10.1080/10910344.2020.1752234

N. Sudhakar, N. Jagadeesh, R. Kumar et al., Hot workability and corrosion behavior of EN31 grade steel. Proceedings of the 1st International Conference on Emerging Trends in Materials and Manufacturing Engineering, vol 5 (Elsevier, 2018), p. 6855–6861. https://doi.org/10.1016/j.matpr.2017.11.346

J. Rajaparthiban, M. Ravichandranb, B. Stalinc et al., Machining of EN31 steel using carbide insert—a statistical approach. Proceedings of the 2nd International Conference on Materials Manufacturing and Modelling (Elsevier, 2020), p. 2559–2564. https://doi.org/10.1016/j.matpr.2020.03.386

S.P. Sahoo, S. Datta, T. Roy et al., Machining performance of Ti6Al4V under dry environment, pressurized air supply and water-MQL: analysis of machining-induced vibration signals and captured thermographs. Sadhana 46(208), 1–22 (2021). https://doi.org/10.1007/s12046-021-01738-6

A. Sharma, R.C. Singh, R.M. Singari, Optimization of machining parameters during cryogenic turning of AISI D3 steel. Sadhana 45(124), 1–12 (2020). https://doi.org/10.1007/s12046-020-01368-4

D. Umbrelloa, Z. Pu, S. Carusoa et al., The effects of Cryogenic cooling on surface integrity in hard machining. Proceedings of the 1st CIRP Conference on Surface Integrity (CSI), vol 19 (Elsevier, 2011), p. 371–376. https://doi.org/10.1016/j.proeng.2011.11.127

A. Iturbe, E. Hormaetxe, A. Garay et al., Surface integrity analysis when machining Inconel 718 with conventional and cryogenic cooling. Proceedings of the 3rd CIRP Conference on Surface Integrity (CIRP CSI), vol 45 (Elsevier, 2016), p. 67–70. https://doi.org/10.1016/j.procir.2016.02.095

M. Mia, M.K. Gupta, D. Carou et al., Multi-objective Optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti–6Al–4V. J. Clean. Prod. 210, 121–133 (2019). https://doi.org/10.1016/j.jclepro.2018.10.334

D.V. Schroeder, Introduction to Thermal Physics (Addison Wesley Longman Publication, Boston, 2000), pp.1–37

S.C. Nalband, K. Pamidimukkala, R.K. Gunda et al., Effect of minimum quantity solid lubrication (MQSL) parameters on cutting force and temperature during turning of EN31 steel. Proceedings of the 1st International Conference & Exposition on Mechanical, Material and Manufacturing Technology (Elsevier, 2020), p. 3314–3319. https://doi.org/10.1016/j.matpr.2020.10.119

Funding

The first and third authors are gratefully acknowledge the funding received from the University of Engineering and Management Kolkata under the grand-in aided project.

Author information

Authors and Affiliations

Contributions

Authors have equally contributed in the paper. The first author has carried out the research work under the supervision of the second & third author.

Corresponding author

Ethics declarations

Conflict of interest

The Author declares no conflict of interest.

Ethical Approval

N/A.

Consent to Participate

Yes.

Consent for Publication

Yes.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Misra, S., Kumar, Y. & Paul, G. Study on Effects of Flow Rate of Coolant During CO2-Assisted MQL Turning of EN31 Steel. J. Inst. Eng. India Ser. C 105, 41–57 (2024). https://doi.org/10.1007/s40032-023-01011-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-023-01011-1