Abstract

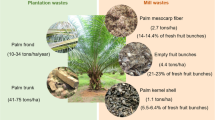

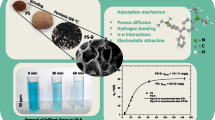

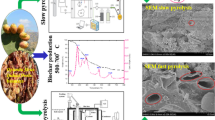

This study examines the effects of washing pretreatments on the chemical characteristics of biomass and the resultant biochar derived from empty fruit bunches (EFBs) of palm oil plantations. We optimized parameters such as washing duration, techniques, and water volume to improve biochar quality. Following the washing pretreatment, the EFBs were subjected to slow pyrolysis at 500 °C for 2 h under a nitrogen atmosphere. In-depth analyses employing techniques like X-ray fluorescence (XRF), X-ray diffraction (XRD), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA-DTG), and inductively coupled plasma mass spectrometry (ICP-MS) demonstrated profound changes in the EFB biomass and biochar structure and composition. Specifically, the sample L-EFB4, soaked in water for 72 h, showed a 67.08% reduction in ash content and a significant decrease in potassium content, enhancing the biochar’s potential applications. The fixed carbon content increased to 17.06 wt.% in the L-EFB3 sample, representing EFBs soaked for 30 min, indicating the effectiveness of targeted washing treatments in optimising biochar properties. Additionally, ICP-MS analysis of the EFB leachate provided insights into the elemental solubility, revealing high concentrations of potassium (72,871.9 ppb), demonstrating its solubility and the leaching process’ effectiveness. This analysis further corroborated the significant role of pretreatment in modifying the ash characteristics, which is crucial for optimizing the combustion behavior of the resultant biochar.

Graphical Abstract

Similar content being viewed by others

Data availability

All relevant data are within the paper and its Supporting Information files.

References

FAO FAO, (2022). Crops and livestock products [WWW Document]. URL https://www.fao.org/faostat/en/#data/QCL (accessed 29.02.24)

James Rubinsin N, Daud WRW, Kamarudin SK, et al (2021) Modelling and optimisation of oil palm biomass value chains and the environment–food–energy–water nexus in peninsular Malaysia. Biomass Bioenergy 144:. https://doi.org/10.1016/J.BIOMBIOE.2020.105912

Chia WY, Chong YY, Chew KW et al (2020) Outlook on biorefinery potential of palm oil mill effluent for resource recovery. J Environ Chem Eng 8:104519. https://doi.org/10.1016/J.JECE.2020.104519

Ahmad FB, Zhang Z, Doherty WOS, O’Hara IM (2019) The outlook of the production of advanced fuels and chemicals from integrated oil palm biomass biorefinery. Renew Sustain Energy Rev 109:386–411. https://doi.org/10.1016/J.RSER.2019.04.009

Kahar P, Rachmadona N, Pangestu R et al (2022) An integrated biorefinery strategy for the utilization of palm-oil wastes. Bioresour Technol 344:126266. https://doi.org/10.1016/j.biortech.2021.126266

Norrrahim MNF, Farid MAA, Lawal AA et al (2022) Emerging technologies for value-added use of oil palm biomass. Environmental Science: Advances 1:259–275. https://doi.org/10.1039/D2VA00029F

Loh SK (2017) The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers Manag 141:285–298. https://doi.org/10.1016/J.ENCONMAN.2016.08.081

Noerhidajat, Yunus R, Zurina, et al (2016) Effect of high pressurized sterilization on oil palm fruit digestion operation. Int Food Res J 23:129–134

Mohammad S, Baidurah S, Kobayashi T, et al (2021) Palm oil mill effluent treatment processes—a review. Processes 9:. https://doi.org/10.3390/PR9050739

Halim SA, Mohd NA, Razali NA (2022) A comparative assessment of biofuel products from rice husk and oil palm empty fruit bunch obtained from conventional and microwave pyrolysis. J Taiwan Inst Chem Eng 134:104305. https://doi.org/10.1016/J.JTICE.2022.104305

Handoko S, Nurhadi N, Mujiati S, Fitriani R (2021) Characterization of pyrolysis products of oil palm empty fruit bunch. IOP Conf Ser Earth Environ Sci 749:012041. https://doi.org/10.1088/1755-1315/749/1/012041

Weber K, Quicker P (2018) Properties of biochar. Fuel 217:240–261. https://doi.org/10.1016/J.FUEL.2017.12.054

Akinnawo OO, Nurhafizah MD, Abdullah N (2023) Pyrolysis kinetic study of the thermal degradation of pre-treated empty fruit bunches. Mater Today Prochttps://doi.org/10.1016/J.MATPR.2023.03.512

Abdullah N, Sulaiman F (2013) The properties of the washed empty fruit bunches of oil palm. J Phys Sci 24:117–137

Bhatnagar A, Singhal A, Tolvanen H et al (2022) Effect of pretreatment and biomass blending on bio-oil and biochar quality from two-step slow pyrolysis of rice straw. Waste Manag 138:298–307. https://doi.org/10.1016/J.WASMAN.2021.12.013

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86. https://doi.org/10.1016/J.PECS.2017.05.004

Abelha P, Leiser S, Pels JR, Cieplik MK (2022) Combustion properties of upgraded alternative biomasses by washing and steam explosion for complete coal replacement in coal-designed power plant applications. Energy 248:. https://doi.org/10.1016/J.ENERGY.2022.123546

Singhal A, Konttinen J, Joronen T (2021) Effect of different washing parameters on the fuel properties and elemental composition of wheat straw in water-washing pre-treatment. Part 2: Effect of washing temperature and solid-to-liquid ratio. Fuel 292:120209. https://doi.org/10.1016/J.FUEL.2021.120209

Akhlisah ZN, Yunus R, Abidin ZZ et al (2021) Pretreatment methods for an effective conversion of oil palm biomass into sugars and high-value chemicals. Biomass Bioenergy 144:105901. https://doi.org/10.1016/j.biombioe.2020.105901

Cen K, Zhang J, Ma Z, et al (2019) Investigation of the relevance between biomass pyrolysis polygeneration and washing pretreatment under different severities: water, dilute acid solution and aqueous phase bio-oil. Bioresour Technol 278:. https://doi.org/10.1016/j.biortech.2019.01.048

Cheng YS, Mutrakulcharoen P, Chuetor S, et al (2020) Recent situation and progress in biorefining process of lignocellulosic biomass: toward green economy. Appl Sci Eng Prog 13:. https://doi.org/10.14416/J.ASEP.2020.08.002

Singhal A, Goossens M, Konttinen J, Joronen T (2021) Effect of basic washing parameters on the chemical composition of empty fruit bunches during washing pretreatment: a detailed experimental, pilot, and kinetic study. Bioresour Technol 340:125734. https://doi.org/10.1016/j.biortech.2021.125734

Tan C, Saritpongteeraka K, Kungsanant S et al (2018) Low temperature hydrothermal treatment of palm fiber fuel for simultaneous potassium removal, enhanced oil recovery and biogas production. Fuel 234:1055–1063. https://doi.org/10.1016/J.FUEL.2018.07.137

Ariff M, Fuad HM, Faizal HM et al (2019) Experimental investigation on water washing and decomposition behaviour for empty fruit bunch. J Adv Res Fluid Mech Ther Sci J Homepage 59:207–219

Bandara YW, Gamage P, Gunarathne DS (2020) Hot water washing of rice husk for ash removal: the effect of washing temperature, washing time and particle size. Renew Energy 153:646–652. https://doi.org/10.1016/J.RENENE.2020.02.038

Gudka B, Jones JM, Lea-Langton AR et al (2016) A review of the mitigation of deposition and emission problems during biomass combustion through washing pre-treatment. J Energy Inst 89:159–171. https://doi.org/10.1016/J.JOEI.2015.02.007

Nurdiawati A, Novianti S, Zaini IN et al (2015) Production of low-potassium solid fuel from empty fruit bunches (EFB) by employing hydrothermal treatment and water washing process. J Japan Instit Energy 94:775–780. https://doi.org/10.3775/JIE.94.775

Anyaoha KE, Sakrabani R, Patchigolla K, Mouazen AM (2018) Critical evaluation of oil palm fresh fruit bunch solid wastes as soil amendments: prospects and challenges. Resour Conserv Recycl 136:399–409. https://doi.org/10.1016/J.RESCONREC.2018.04.022

Zhou S, Xue Y, Cai J et al (2021) An understanding for improved biomass pyrolysis: toward a systematic comparison of different acid pretreatments. Chem Eng J 411:128513. https://doi.org/10.1016/J.CEJ.2021.128513

Song D-Y, Lee J-W (2024) Valorization of biochar and lignin derived from the NaOH pretreatment of lignocellulosic biomass for applications as an adsorbent and antioxidant. Biomass Bioenergy 182:107103. https://doi.org/10.1016/j.biombioe.2024.107103

Sarkar D, Santiago IJ, Vermaas JV (2023) Atomistic origins of biomass recalcitrance in organosolv pretreatment. Chem Eng Sci 272:118587. https://doi.org/10.1016/J.CES.2023.118587

Lizasoain J, Trulea A, Gittinger J et al (2017) Corn stover for biogas production: effect of steam explosion pretreatment on the gas yields and on the biodegradation kinetics of the primary structural compounds. Bioresour Technol 244:949–956. https://doi.org/10.1016/J.BIORTECH.2017.08.042

Han J, Yu D, Wu J, et al (2022) Effects of torrefaction on ash-related issues during biomass combustion and co-combustion with coal. Part 3: ash slagging behavior. SSRN Electron J. https://doi.org/10.2139/SSRN.4193741

Abdullah N, Gerhauser H, Bridgwater AV (2007) Bio-oil from fast pyrolysis of oil palm empty fruit bunches. J Phys Sci 18:57–74

Adilah S, Nur S, Nurhayati A (2014) Slow pyrolysis of oil palm empty fruit bunches for biochar production and characterisation. J Phys Sci 25:97–112

Idris J, Shirai Y, Anduo Y et al (2015) Improved yield and higher heating value of biochar from oil palm biomass at low retention time under self-sustained carbonization. J Clean Prod 104:475–479. https://doi.org/10.1016/J.JCLEPRO.2015.05.023

Sembiring KC, Rinaldi N, Simanungkalit SP (2015) ScienceDirect bio-oil from fast pyrolysis of empty fruit bunch at various temperature. / Energy Procedia 65:162–169. https://doi.org/10.1016/j.egypro.2015.01.052

Hanafi NHM, Rozali S, Ibrahim S (2024) Empty fruit bunch derived biochar synthesized via microwave-metal-assisted pyrolysis and its potential as solid biofuel. Biomass Convers Biorefin 2024:1–18. https://doi.org/10.1007/S13399-023-05257-8

Safana AA, Abdullah N, Sulaiman F (2018) Bio-char and bio-oil mixture derived from the pyrolysis of mesocarp fibre for briquettes production. J Oil Palm Res 30:130–140. https://doi.org/10.21894/JOPR.2018.0007

Nelson ES, Iyuke S, Daramola MO, Okewale A (2023) Extraction and characterization of silica from empty palm fruit bunch (EPFB) ash. Processes 11:. https://doi.org/10.3390/PR11061684

Vinceković M, Šegota S, Jurić S, et al (2022) Development and characterization of a novel soil amendment based on biomass fly ash encapsulated in calcium alginate microspheres. International Journal of Molecular Sciences 2022, Vol 23, Page 9984 23:9984. https://doi.org/10.3390/IJMS23179984

Sohni S, Norulaini NAN, Hashim R et al (2018) Physicochemical characterization of Malaysian crop and agro-industrial biomass residues as renewable energy resources. Ind Crops Prod 111:642–650. https://doi.org/10.1016/J.INDCROP.2017.11.031

Novianti S, Nurdiawati A, Zaini IN et al (2015) Low-potassium fuel production from empty fruit bunches by hydrothermal treatment processing and water leaching. Energy Procedia 75:584–589. https://doi.org/10.1016/J.EGYPRO.2015.07.460

Singhal A, Goossens M, Fantozzi D, et al (2021) Step washing: a modified pretreatment approach for industrial applications to improve chemical composition of agricultural residues. Bioresour Technol 341:. https://doi.org/10.1016/J.BIORTECH.2021.125753

Lachman J, Baláš M, Lisý M, et al (2021) An overview of slagging and fouling indicators and their applicability to biomass fuels. Fuel Processing Technology 217:. https://doi.org/10.1016/J.FUPROC.2021.106804

Krerkkaiwan S, Boonbumrung D (2020) Production of high quality empty fruit bunch pellet by water washing and torrefaction. IOP Conf Ser Earth Environ Sci 463:012130. https://doi.org/10.1088/1755-1315/463/1/012130

Ibrahim A, Abdullah MF, Sam ST (2018) Hydrolysis empty fruit bunch (EFB) using green solvent. IOP Conf Ser Mater Sci Eng 429:. https://doi.org/10.1088/1757-899X/429/1/012059

Isahak WNRW, Hamzah N, Nordin NAM et al (2013) Dehydration studies of biomass resources for activated carbon production using bet and XRD techniques. Adv Mat Res 620:491–495. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/AMR.620.491

Kim SH, Lee CM, Kafle K (2013) Characterization of crystalline cellulose in biomass: basic principles, applications, and limitations of XRD, NMR, IR, Raman, and SFG. Korean J Chem Eng 30:2127–2141. https://doi.org/10.1007/S11814-013-0162-0

Santi LP, Kalbuadi DN, Goenadi DH (2019) Empty fruit bunches as potential source for biosilica fertilizer for oil palm. J Trop Biodivers Biotechnol 4:90. https://doi.org/10.22146/JTBB.38749

Uroić Štefanko A, Leszczynska D (2020) Impact of biomass source and pyrolysis parameters on physicochemical properties of biochar manufactured for innovative applications. Front Energy Res 8:. https://doi.org/10.3389/FENRG.2020.00138

Puri L, Hu Y, Naterer G (2024) Critical review of the role of ash content and composition in biomass pyrolysis. Frontiers in Fuels 2:. https://doi.org/10.3389/FFUEL.2024.1378361/PDF

Muzyka R, Misztal E, Hrabak J, et al (2023) Various biomass pyrolysis conditions influence the porosity and pore size distribution of biochar. Energy 263:. https://doi.org/10.1016/J.ENERGY.2022.126128

Grafmü J, Böhm A, Zhuang Y, et al (2022) Wood ash as an additive in biomass pyrolysis: effects on biochar yield, properties, and agricultural performance. ACS Sustain Chem Eng 10:2720–2729https://doi.org/10.1021/acssuschemeng.1c07694

Nizamuddin S, Jaya Kumar NS, Sahu JN et al (2015) Synthesis and characterization of hydrochars produced by hydrothermal carbonization of oil palm shell. Can J Chem Eng 93:1916–1921. https://doi.org/10.1002/CJCE.22293

Ahmad TY, Hirajima T, Kumagai S, Sasaki K (2010) Production of solid biofuel from agricultural wastes of the palm oil industry by hydrothermal treatment. Waste Biomass Valorization 1:395–405. https://doi.org/10.1007/S12649-010-9045-3/METRICS

Abdulrazzaq H, Jol H, Husni A, Abu-Bakr R (2014) Characterization and stabilisation of biochars obtained from empty fruit bunch, wood, and rice husk. bioresources.cnr.ncsu.edu 9:2888–2898

Li S, Chen G (2018) Thermogravimetric, thermochemical, and infrared spectral characterization of feedstocks and biochar derived at different pyrolysis temperatures. Waste Manage 78:198–207. https://doi.org/10.1016/J.WASMAN.2018.05.048

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/J.FUEL.2006.12.013

Acknowledgements

Appreciation is extended to the Energy Laboratory at the School of Physics, Universiti Sains Malaysia (USM), the Faculty of Science and Mathematics at Universiti Pendidikan Sultan Idris (UPSI), and the Department of Physical & Earth Sciences at Crawford University, Igbesa, Nigeria for their support.

Funding

The Ministry of Higher Education funded this study through the Fundamental Research Grant Scheme (FRGS), project code FRGS/1/2019STG05/USM/02/7, and the Petroleum Technology Development Fund (PTDF), Nigeria.

Author information

Authors and Affiliations

Contributions

M. D. Nurhafizah: conceptualization, writing—original draft, funding acquisition, and supervision. O. O. Akinnawo: data curation and investigation. N. Abdullah: methodology, resources, writing—review and editing. A. B. Suriani: Raman formal analysis.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights.

• Enhanced biochar quality: targeted washing pretreatments significantly improve the chemical properties of biochar from palm oil EFBs.

• Reduction in non-carbon elements: achieved a 67.08% reduction in ash and a 94.5% decrease in potassium levels, enhancing biochar utility.

• Increased energy recovery potential: optimized processes raised the high heating value of biochar from 20.98 to 25.39 MJ/kg.

• Comprehensive characterization: employed advanced techniques like XRF, XRD, and ICP-MS to analyze structural and compositional changes.

• Sustainable applications: demonstrated the biochar’s potential in soil amendment, pollution control, and energy production.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nurhafizah, M.D., Akinnawo, O.O., Abdullah, N. et al. Influence of washing parameters on biomass and biochar properties of empty fruit bunches from oil palm plantation. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05830-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05830-9