Abstract

The generation of spent aroma plant/process waste is increasing due to the growth of the essential oil industries due to the demand for essential oils. This study aims to convert such spent aroma plant waste, i.e., spent Lemongrass and Tagetes minuta, into bio-oil and biochar using slow pyrolysis. In this work, pyrolysis is conducted at different temperatures (350–500 ℃) at a heating rate of 10 ℃/min in a nitrogen atmosphere with a 50 mL/min flow rate. The maximum bio-oil yield obtained for Lemongrass was 37.3 wt% with a biochar yield of 31.6 wt% at 400 ℃; however, in the case of Tagetes minuta, the maximum bio-oil yield (39 wt%) was observed at 450 ℃ with 27.3 wt% of biochar yield. GC-MS analysis of bio-oil indicated its phenolic-rich nature along with other functionalities, i.e., carbonyls, furans, N-containing, and other types. Maximum phenolics observed with 60.27 area% for Lemongrass and 62.75 area% for Tagetes minuta at 450 ℃. Finally, to understand the breaking patterns of the biomass framework, flash pyrolysis through the analytical instrument, Py-GC/MS, was carried out at a high heating rate of 20 ℃/ms.

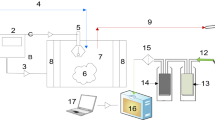

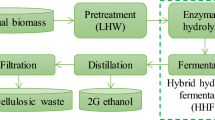

Graphical abstract

Similar content being viewed by others

Data availability

All data related to this work is provided here.

References

Saravanakumar A, Vijayakumar P, Hoang AT et al (2023) Thermochemical conversion of large-size woody biomass for carbon neutrality: principles, applications, and issues. Bioresour Technol 370:128562

Saha A, Basak BB (2020) Scope of value addition and utilization of residual biomass from medicinal and aromatic plants. Ind Crops Prod 145:111979. https://doi.org/10.1016/j.indcrop.2019.111979

Zheljazkov VD, Stewart CN, Joyce B et al (2018) Dual Utilization of Medicinal and Aromatic Crops as Bioenergy Feedstocks. J Agric Food Chem 66:8744–8752. https://doi.org/10.1021/acs.jafc.7b04594

Singh M, Pandey N, Mishra BB (2020) A divergent approach for the synthesis of (hydroxymethyl)furfural (HMF) from spent aromatic biomass-derived (chloromethyl)furfural (CMF) as a renewable feedstock. RSC Adv 10:45081–45089. https://doi.org/10.1039/d0ra09310f

Olofsson J, Börjesson P (2018) Residual biomass as resource–life-cycle environmental impact of wastes in circular resource systems. J Clean Prod 196:997–1006. https://doi.org/10.1016/j.jclepro.2018.06.115

Aguilar MM, Duret X, Ghislain T et al (2020) A simple process for the production of fuel additives using residual lignocellulosic biomass. Fuel 264:116702

Babu BV (2008) Biomass pyrolysis: a state-of‐the‐art review. Biofuels Bioprod Biorefining Innov a Sustain Econ 2:393–414

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Velvizhi G, Goswami C, Shetti NP et al (2022) Valorisation of lignocellulosic biomass to value-added products: paving the pathway towards low-carbon footprint. Fuel 313:122678

Dhyani V, Bhaskar T (2019) Pyrolysis of biomass. In: Biomass, biofuels, biochemicals: biofuels: alternative feedstocks and conversion processes for the production of liquid and gaseous biofuels. 217–244

Krishnaa BB, Biswasa B, Kumara J et al (2016) Slow pyrolysis of Jatropha seed de-oiled cake and estimation of kinetic parameters. J Energy Environ Sustain 1:34–39. https://doi.org/10.47469/jees.2016.v01.100004

Anuar Sharuddin SD, Abnisa F, Wan Daud WMA, Aroua MK (2016) A review on pyrolysis of plastic wastes. Energy Convers Manag 115:308–326. https://doi.org/10.1016/j.enconman.2016.02.037

Haque ANMA, Remadevi R, Naebe M (2018) Lemongrass (Cymbopogon): a review on its structure, properties, applications and recent developments. Cellulose 25:5455–5477. https://doi.org/10.1007/s10570-018-1965-2

Deshmukh Y, Yadav V, Nigam N et al (2015) Quality of bio-oil by pyrolysis of distilled spent of Cymbopogon flexuosus. J Anal Appl Pyrol 115:43–50

Shetty LJ, Sakr FM, Al-Obaidy K et al (2015) A brief review on medicinal plant Tagetes erecta Linn. J Appl Pharm Sci 5:091–095. https://doi.org/10.7324/JAPS.2015.510.S16

Salehi B, Valussi M, Flaviana Bezerra Morais-Braga M et al (2018) Tagetes spp. essential oils and other extracts. Chemical characterization and biological activity

Madhu P, Stephen Livingston T, Manickam IN (2017) Fixed bed pyrolysis of lemongrass (Cymbopogon flexuosus): bio-oil production and characterization. Energy sources, Part A recover. Util Environ Eff 39:1359–1368. https://doi.org/10.1080/15567036.2017.1328623

Kaur R, Kumar A, Biswas B et al (2022) Investigations into pyrolytic behaviour of spent citronella waste: slow and flash pyrolysis study. Bioresour Technol 366:128202

Biswas B, Singh R, Kumar J et al (2016) Slow pyrolysis of prot, alkali and dealkaline lignins for production of chemicals. Bioresour Technol 213:319–326. https://doi.org/10.1016/j.biortech.2016.01.131

Abu MS, Ahmed A, Je DM et al (2020) Bioresource technology pyrolysis of solid waste residues from lemon myrtle essential oils extraction for bio-oil production. 1–5. https://doi.org/10.1016/j.biortech.2020.123913

Grafmüller J, Böhm A, Zhuang Y et al (2022) Wood ash as an additive in biomass pyrolysis: effects on biochar yield, properties, and agricultural performance. ACS Sustain Chem Eng 10:2720–2729

Aniza R, Chen W-H, Kwon EE et al (2024) Lignocellulosic biofuel properties and reactivity analyzed by thermogravimetric analysis (TGA) toward zero carbon scheme-a critical review. Energy Convers Manag X 100538

Mishra RK, Mohanty K (2018) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol 251:63–74. https://doi.org/10.1016/j.biortech.2017.12.029

Sevilla M, Fuertes AB (2009) The production of carbon materials by hydrothermal carbonization of cellulose. Carbon N Y 47:2281–2289

Braun JL, Holtman KM, Kadla JF (2005) Lignin-based carbon fibers: oxidative thermostabilization of kraft lignin. Carbon N Y 43:385–394

Kumar A, Biswas B, Kaur R et al (2021) Predicting the decomposition mechanism of Loktak biomass using Py-GC/MS. Environ Technol Innov 23:101735. https://doi.org/10.1016/j.eti.2021.101735

Gao N, Li A, Quan C et al (2013) TG-FTIR and Py-GC/MS analysis on pyrolysis and combustion of pine sawdust. J Anal Appl Pyrol 100:26–32. https://doi.org/10.1016/j.jaap.2012.11.009

Liu Y, He Z, Shankle M, Tewolde H (2016) Compositional features of cotton plant biomass fractions characterized by attenuated total reflection Fourier transform infrared spectroscopy. Ind Crops Prod 79:283–286

Scholze B, Meier D (2001) Characterization of the water-insoluble fraction from pyrolysis oil (pyrolytic lignin). Part I. PY-GC/MS, FTIR, and functional groups. J Anal Appl Pyrol 60:41–54. https://doi.org/10.1016/S0165-2370(00)00110-8

Adapa PK, Schonenau LG, Canam T, Dumonceaux T (2011) Quantitative analysis of lignocellulosic components of non-treated and steam exploded barley, canola, oat and wheat straw using Fourier transform infrared spectroscopy. J Agric Sci Technol 177

Shen DK, Gu S, Bridgwater AV (2010) Study on the pyrolytic behaviour of Xylan-based hemicellulose using TG-FTIR and Py-GC-FTIR. J Anal Appl Pyrol 87:199–206. https://doi.org/10.1016/j.jaap.2009.12.001

Zhao S, Liu M, Zhao L, Zhu L (2018) Influence of interactions among three biomass components on the pyrolysis behavior. Ind Eng Chem Res 57:5241–5249

Wu Y, Gui Q, Zhang H et al (2023) Effect of biomass components’ interaction on the pyrolysis reaction kinetics and small-molecule product release characteristics. J Anal Appl Pyrol 173:106039

Farobie O, Amrullah A, Bayu A et al (2022) In-depth study of bio-oil and biochar production from macroalgae Sargassum sp. via slow pyrolysis. RSC Adv 12:9567–9578. https://doi.org/10.1039/d2ra00702a

Shen D, **ao R, Gu S, Luo K (2011) The pyrolytic behavior of cellulose in lignocellulosic biomass: a review. RSC Adv 1:1641–1660. https://doi.org/10.1039/c1ra00534k

Hoang AT, Ong HC, Fattah IMR et al (2021) Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process Technol 223:106997

Zhou X, Li W, Mabon R, Broadbelt LJ (2018) A mechanistic model of fast pyrolysis of hemicellulose. Energy Environ Sci 11:1240–1260. https://doi.org/10.1039/c7ee03208k

Lu X, Gu X (2022) A review on lignin pyrolysis: pyrolytic behavior, mechanism, and relevant upgrading for improving process efficiency. BioMed Central

Yu J, Paterson N, Blamey J, Millan M (2017) Cellulose, xylan and lignin interactions during pyrolysis of lignocellulosic biomass. Fuel 191:140–149

Abnisa F, Arami-Niya A, Daud WMAW, Sahu JN (2013) Characterization of bio-oil and bio-char from pyrolysis of palm oil wastes. BioEnergy Res 6:830–840

Lazzari E, Schena T, Marcelo MCA et al (2018) Classification of biomass through their pyrolytic bio-oil composition using FTIR and PCA analysis. Ind Crops Prod 111:856–864. https://doi.org/10.1016/j.indcrop.2017.11.005

Mullen CA, Strahan GD, Boateng AA (2009) Characterization of various fast-pyrolysis bio-oils by NMR spectroscopy. Energy Fuels 23:2707–2718

Xu J, Liu J, Ling P et al (2020) Raman spectroscopy of biochar from the pyrolysis of three typical Chinese biomasses: a novel method for rapidly evaluating the biochar property. Energy 202:117644. https://doi.org/10.1016/j.energy.2020.117644

Ghani WAWAK, Mohd A, da Silva G et al (2013) Biochar production from waste rubber-wood-sawdust and its potential use in C sequestration: chemical and physical characterization. Ind Crops Prod 44:18–24

Griffin GJ, Ward LP, Madapusi S et al (2022) A study of chemical pre-treatment and pyrolysis operating conditions to enhance biochar production from rice straw. J Anal Appl Pyrol 163:105455

Aktar S, Hossain MA, Rathnayake N et al (2022) Effects of temperature and carrier gas on physico-chemical properties of biochar derived from biosolids. J Anal Appl Pyrol 164:105542. https://doi.org/10.1016/j.jaap.2022.105542

Zhao B, Nartey OD (2014) Characterization and evaluation of biochars derived from agricultural waste biomass from Gansu, China. World Congr Adv Civil Environ Mater Res 1–17

Kumar A, Goyal V, Sarki N et al (2020) Biocarbon supported nanoscale ruthenium oxide-based catalyst for clean hydrogenation of arenes and heteroarenes. ACS Sustain Chem Eng 8:15740–15754

Xu J, Liu J, Ling P et al (2020) Raman spectroscopy of biochar from the pyrolysis of three typical Chinese biomasses: a novel method for rapidly evaluating the biochar property. Energy 202:117644

Pandey SD, Mendonça FG, Rodrigues MN et al (2021) Structural and elemental analysis of biochars in the search of a synthetic path to mimetize anthropic Amazon soils. J Environ Manage 279:111685

Kumar A, Saini K, Bhaskar T (2020) Advances in design strategies for preparation of biochar based catalytic system for production of high value chemicals. Bioresour Technol 299:122564

Ma X, Zhou B, Budai A et al (2016) Study of biochar properties by scanning electron microscope–energy dispersive X-ray spectroscopy (SEM-EDX). Commun Soil Sci Plant Anal 47:593–601

Ma X, Zhou B, Budai A et al (2016) Study of biochar properties by scanning electron microscope–energy dispersive X-ray spectroscopy (SEM-EDX). Commun Soil Sci Plant Anal 47:593–601. https://doi.org/10.1080/00103624.2016.1146742

Bilias F, Kalderis D, Richardson C et al (2022) Biochar application as a soil potassium management strategy: a review. Sci Total Environ 159782

Saini K, Biswas B, Kumar A et al (2021) Screening of sugarcane bagasse-derived biochar for phenol adsorption: optimization study using response surface methodology. Int J Environ Sci Technol 1–14

Bolan N, Hoang SA, Beiyuan J et al (2022) Multifunctional applications of biochar beyond carbon storage. Int Mater Rev 67:150–200

He M, Xu Z, Hou D et al (2022) Waste-derived biochar for water pollution control and sustainable development. Nat Rev Earth Environ 1–17

Acknowledgements

The authors would like to acknowledge the director of CSIR-IIP for his constant support and encouragement. A special thanks to the analytical division of the Indian Institute of Petroleum for assistance with characterization. Ramandeep Kaur, grateful to UGC, Delhi, for providing a Senior Research Fellowship.

Funding

This research received no specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Ramandeep Kaur: investigation, formal analysis, data curation, writing—original draft. Valiveti Tarun Kumar: formal analysis, writing. Bhavya B. Krishna: writing—review and editing, supervision. Thallada Bhaskar: supervision, conceptualization.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

•Pyrolysis of spent Lemongrass (LG) and Tagetes minuta (TM) optimized.

•Maximum bio-oil yield from Spent LG and TM was 37.3 and 39 wt.%, respectively.

•Slow pyrolysis oil contained a maximum of phenolics at 450℃.

•Derived biochar was amorphous and porous with high total carbon content.

•Py-GC/MS study assisted in understanding the breaking pathway.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaur, R., Kumar, V.T., Krishna, B.B. et al. Comprehensive pyrolysis investigation of Lemongrass and Tagetes minuta residual biomass: bio-oil composition and biochar physicochemical properties. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05764-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05764-2