Abstract

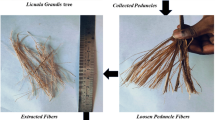

Natural fiber-polymer composites are rapidly becoming popular in a wide range of applications because they offer an environmentally friendly and cost-effective alternative to traditional petroleum-derived materials. On the other hand, a significant quantity of organic waste and residue from agro-industrial and agricultural activities is still being underutilized and is disposed of as landfill. In this study, Cymbopogon nardus popularly known as citronella grass left residue from the agro-industry was characterized for the first time. Scanning electron and optical microscopy were used to typify the surface topography of fiber bundles from the residues of Cymbopogon nardus shoot waste (CNS). Functional groups of isolated lignocellulosic CNS fibers were evaluated by Fourier transform infrared spectroscopy, thermal degradation by thermal gravimetric analysis, and crystallinity by X-ray diffraction. In addition, lignocellulosic fiber strength, Young’s modulus, and strain at break were evaluated using single fiber tensile testing. Weibull statistical parameters were used to examine the dispersed experimental findings. The low density (1305 kg/m3), high crystallinity (81.4%), higher thermal stability (326 °C), and strong tensile strength (435.9 MPa) make it suitable for composite reinforcement. This detailed analysis suggests how organic waste residues might be used as a novel sustainable ecological material for reinforcement in polymeric composites in the future.

Similar content being viewed by others

Data availability

The data associated with this article shall be made available on request.

References

Horue M, Rivero Berti I, Cacicedo ML, Castro GR (2021) Microbial production and recovery of hybrid biopolymers from wastes for industrial applications—a review. Bioresour Technol 340:125671

Sol FGT, Saavedra RAC (2019) Green composite materials from biopolymers reinforced with agroforestry waste. J Polym Environ 27:2651–2673. https://doi.org/10.1007/s10924-019-01561-5

Binoj JS, Raj RE, Indran S (2018) Characterization of industrial discarded fruit wastes (Tamarindus indica L.) as potential alternate for man-made vitreous fiber in polymer composites. Process Saf Environ Prot 116:527–534. https://doi.org/10.1016/j.psep.2018.02.019

Raja S, Ravichandran M, Isaac RSR, Abilash N (2019) A review: sources of silica from agro waste and its extraction methods. J Adv Res Dyn Control Syst 11:765–772

Sundaram RS, Rajamoni R, Suyambulingam I, Isaac R (2021) Comprehensive characterization of industrially discarded cymbopogon flexuosus stem fiber reinforced unsaturated polyester composites: effect of fiber length and weight fraction. J Nat Fibers 1–16. https://doi.org/10.1080/15440478.2021.1944435

Moshi AAM, Ravindran D, Bharathi SRS et al (2020) Characterization of a new cellulosic natural fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 142:212–221. https://doi.org/10.1016/j.ijbiomac.2019.09.094

Divya D, Jenish I, Raja S (2022) Comprehensive characterization of Furcraea selloa K. Koch peduncle fiber-reinforced polyester composites—effect of fiber length and weight ratio. Adv Mater Sci Eng 2022:1–10. https://doi.org/10.1155/2022/8099500

Indran S, Raj RE (2015) Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohydr Polym 117:392–399. https://doi.org/10.1016/j.carbpol.2014.09.072

Indran S, Raj RE, Daniel BSS, Saravanakumar SS (2016) Cellulose powder treatment on Cissus quadrangularis stem fiber-reinforcement in unsaturated polyester matrix composites. J Reinf Plast Compos 35:212–227. https://doi.org/10.1177/0731684415611756

Muthu chozha rajan B, Indran S, Divya D, et al (2020) Mechanical and thermal properties of Chloris barbata flower fiber/epoxy composites: effect of alkali treatment and fiber weight fraction. J Nat Fibers 00:1–14. https://doi.org/10.1080/15440478.2020.1848703

Saputra NA, Wibisono HS, Darmawan S, Pari G (2020) Chemical composition of Cymbopogon nardus essential oil and its broad spectrum benefit. IOP Conf Ser Earth Environ Sci 415. https://doi.org/10.1088/1755-1315/415/1/012017

Kakaraparthi PS, Srinivas KVNS, Kumar JK et al (2014) Variation in the essential oil content and composition of Citronella (Cymbopogon winterianus Jowitt.) in relation to time of harvest and weather conditions. Ind Crops Prod 61:240–248. https://doi.org/10.1016/j.indcrop.2014.06.044

Raja S, Rajesh R, Indran S et al (2021) Characterization of industrial discarded novel Cymbopogon flexuosus stem fiber: a potential replacement for synthetic fiber. J Ind Text. https://doi.org/10.1177/15280837211007507

Manimaran P, Saravanan SP, Sanjay MR et al (2019) Characterization of new cellulosic fiber: Dracaena reflexa as a reinforcement for polymer composite structures. J Mater Res Technol 8:1952–1963. https://doi.org/10.1016/j.jmrt.2018.12.015

Sumesh KR, Kavimani V, Rajeshkumar G, et al (2020) Mechanical, water absorption and wear characteristics of novel polymeric composites: impact of hybrid natural fibers and oil cake filler addition. J Ind Text 1–28. https://doi.org/10.1177/1528083720971344

Binoj JS, Edwin Raj R, Daniel BSS (2018) Comprehensive characterization of industrially discarded fruit fiber, Tamarindus indica L. as a potential eco-friendly bio-reinforcement for polymer composite. J Clean Prod 116:527–534. https://doi.org/10.1016/j.jclepro.2016.09.179

Indran S, Dhas R, Raj E et al (2018) Comprehensive characterization of natural Cissus quadrangularis stem fiber composites as an alternate for conventional FRP composites. Bionic Eng 15:914–923

Ganapathy T, Sathiskumar R, Senthamaraikannan P et al (2019) Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int J Biol Macromol 138:573–581. https://doi.org/10.1016/j.ijbiomac.2019.07.136

Divya D, Suyambulingam I, Sanjay MR, Siengchin S (2022) Suitability examination of novel cellulosic plant fiber from Furcraea selloa K. Koch peduncle for a potential polymeric composite reinforcement. Polym Compos 1–21. https://doi.org/10.1002/pc.26683

Senthamaraikannan P, Saravanakumar SS, Arthanarieswaran VP (2016) Physicochemical properties of new cellulosic fibers from bark of Acacia planifrons. Polym Anal Charact 21:207–213. https://doi.org/10.1080/1023666X.2016.1133138

Narayanasamy P, Balasundar P, Senthil S et al (2020) Characterization of a novel natural cellulosic fiber from Calotropis gigantea fruit bunch for ecofriendly polymer composites. Int J Biol Macromol 150:793–801. https://doi.org/10.1016/j.ijbiomac.2020.02.134

Manimaran P, Senthamaraikannan P, Sanjay MR et al (2018) Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr Polym 181:650–658. https://doi.org/10.1016/j.carbpol.2017.11.099

Balaji AN, Nagarajan KJ (2017) Characterization of alkali treated and untreated new cellulosic fiber from Saharan aloe vera cactus leaves. Carbohydr Polym 174:200–208. https://doi.org/10.1016/j.carbpol.2017.06.065

Sonia A, Priya Dasan K (2013) Chemical, morphology and thermal evaluation of cellulose microfibers obtained from Hibiscus sabdariffa. Carbohydr Polym 92:668–674. https://doi.org/10.1016/j.carbpol.2012.09.015

Iyyadurai J, Gandhi VCS, Suyambulingam I, Rajeshkumar G (2021) Sustainable development of Cissus quadrangularis stem fiber/epoxy composite on abrasive wear rate. J Nat Fibers 00:1–13. https://doi.org/10.1080/15440478.2021.1982819

Saravanan PMSP, Mohammad MRS, Suchart J, Vincenzo S (2020) New lignocellulosic Aristida adscensionis fibers as novel reinforcement for composite materials: extraction, characterization and Weibull distribution analysis. J Polym Environ 28:803–811. https://doi.org/10.1007/s10924-019-01640-7

Segal CJJ, Conrad M (1958) Empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Scherrer P (1918) Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen, Math Klasse 98–100

Sakji N, Jabli M, Khoffi F et al (2016) Physico-chemical characteristics of a seed fiber arised from Pergularia tomentosa L. fibers Polym 17:2095–2104. https://doi.org/10.1007/s12221-016-6461-4

Manimaran P, Prithiviraj M, Saravanakumar SS et al (2018) Physicochemical, tensile, and thermal characterization of new natural cellulosic fibers from the stems of Sida cordifolia. J Nat Fibers 15:860–869. https://doi.org/10.1080/15440478.2017.1376301

Arthanarieswaran VP, Kumaravel A, Saravanakumar SS (2015) Characterization of new natural cellulosic fiber from Acacia leucophloea bark. Polym Anal Charact 20:367–376. https://doi.org/10.1080/1023666X.2015.1018737

Belouadah Z, Ati A, Rokbi M (2015) Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohydr Polym 134:429–437. https://doi.org/10.1016/j.carbpol.2015.08.024

Babu BG, Princewinston D, Saravanakumar SS et al (2022) Investigation on the physicochemical and mechanical properties of novel alkali-treated Phaseolus vulgaris fibers. J Nat Fibers 19:770–781. https://doi.org/10.1080/15440478.2020.1761930

Porras A, Maranon A, Ashcroft IA (2015) Characterization of a novel natural cellulose fabric from Manicaria saccifera palm as possible reinforcement of composite materials. Compos Part B Eng 74:66–73. https://doi.org/10.1016/j.compositesb.2014.12.033

Boumediri AH, Bezazi A (2019) Extraction and characterization of vascular bundle and fiber strand from date palm rachis as potential bio-reinforcement in composite. Carbohydr Polym 222:1–32. https://doi.org/10.1016/j.carbpol.2019.114997

Senthamaraikannan P, Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis. L Carbohydr Polym 186:332–343. https://doi.org/10.1016/j.carbpol.2018.01.072

Marcel AA, Ravindran D, Bharathi SRS et al (2020) Characterization of natural cellulosic fiber extracted from Grewia damine flowering plant’s stem. Int J Biol Macromol 164:1246–1255. https://doi.org/10.1016/j.ijbiomac.2020.07.225

Lim CJ, Arumugam M, Lim CK, Ee GCL (2020) Mercerizing extraction and physicochemical characterizations of lignocellulosic fiber from the leaf waste of Mikania micrantha Kunth ex H.B.K. J Nat Fibers 17:726–737. https://doi.org/10.1080/15440478.2018.1527742

Rajeshkumar G, Devnani GL, Maran JP et al (2021) Characterization of novel natural cellulosic fibers from purple bauhinia for potential reinforcement in polymer composites. Cellulose 28:5373–5385. https://doi.org/10.1007/s10570-021-03919-2

Dalmis R, Köktaş S, Seki Y, Kılınç AÇ (2020) Characterization of a new natural cellulose based fiber from Hierochloe Odarata. Cellulose 27:127–139. https://doi.org/10.1007/s10570-019-02779-1

Gedik G (2021) Extraction of new natural cellulosic fiber from Trachelospermum jasminoides (star jasmine) and its characterization for textile and composite uses. Cellulose 28:6899–6915. https://doi.org/10.1007/s10570-021-03952-1

Sanjay MR, Siengchin S, Parameswaranpillai J et al (2019) A comprehensive review of techniques for natural fibers as reinforcement in composites: preparation, processing and characterization. Carbohydr Polym 207:108–121. https://doi.org/10.1016/j.carbpol.2018.11.083

Madhu P, Sanjay MR, Pradeep S et al (2019) Characterization of cellulosic fibre from Phoenix pusilla leaves as potential reinforcement for polymeric composites. J Mater Res Technol 8:2597–2604. https://doi.org/10.1016/j.jmrt.2019.03.006

Kathirselvam M, Kumaravel A, Arthanarieswaran VP, Saravanakumar SS (2019) Characterization of cellulose fibers in Thespesia populnea barks: influence of alkali treatment. Carbohydr Polym 217:178–189. https://doi.org/10.1016/j.carbpol.2019.04.063

Maache M, Bezazi A, Amroune S et al (2017) Characterization of a novel natural cellulosic fiber from Juncus effusus L. Carbohydr Polym 171:163–172. https://doi.org/10.1016/j.carbpol.2017.04.096

Manimekalai G, Kavitha S, Divya D et al (2021) Characterization of enzyme treated cellulosic stem fiber from Cissus quadrangularis plant: an exploratory investigation. Curr Res Green Sustain Chem 4:100162. https://doi.org/10.1016/j.crgsc.2021.100162

Somasundaram R, Rajamoni R, Suyambulingam I et al (2022) Utilization of discarded Cymbopogon flexuosus root waste as a novel lignocellulosic fiber for lightweight polymer composite application. Polym Compos 43:2838–2853. https://doi.org/10.1002/pc.26580

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Rocky BP, Thompson AJ (2021) Characterization of the crystallographic properties of bamboo plants, natural and viscose fibers by X-ray diffraction method. J Text Inst 112:1295–1303. https://doi.org/10.1080/00405000.2020.1813407

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Saravana Kumaar A, Senthilkumar A, Sornakumar T et al (2019) Physicochemical properties of new cellulosic fiber extracted from Carica papaya bark. J Nat Fibers 16:175–184. https://doi.org/10.1080/15440478.2017.1410514

Gandhi VCS, Jenish I, Indran S, Rajan DY (2022) Mechanical and thermal analysis of Cissus quadrangularis stem fiber/epoxy composite with micro-red mud filler composite for structural application. Trans Indian Inst Met 75:737–747. https://doi.org/10.1007/s12666-021-02478-1

Arul Marcel Moshi A, Ravindran D, Sundara Bharathi SR et al (2020) Characterization of surface-modified natural cellulosic fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 156:997–1006. https://doi.org/10.1016/j.ijbiomac.2020.04.117

Acknowledgements

The authors are thankful to National Institute of Technology Mizoram for providing the necessary support to carry out the research work.

Author information

Authors and Affiliations

Contributions

DM: investigation, validation, formal analysis, methodology, writing — original draft. AKP: conceptualization, validation, visualization, supervision, writing — review and editing. MTR: conceptualization, validation, methodology, supervision. SN: conceptualization, validation, formal analysis, writing — original draft.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors gave their consent to publish the work.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Malathi, D., Pulikkal, A.K., Ramesan, M.T. et al. Bio-fiber recovery from industrially discarded shoot waste (Cymbopogon nardus): a comprehensive study for reinforcement in sustainable composites. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04038-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04038-7