Abstract

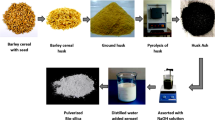

High-toughness epoxy biocomposites are made in the current work employing coconut rachilla fibre and biosilica particles recovered from finger millet husk (FMH) for lightweight and affordable technological applications. The purpose of this study is to determine the impact of FMH biosilica particles added at various concentrations on the mechanical and wear properties, as well as the thermal and hydrophobic behaviour, of epoxy composites made from coconut rachilla fibre. The combination of 3 vol.% FMH biosilica particle with surface-treated palmyra sprout fibre as a reinforcing material has the highest tensile strength, impact strength, flexural strength, and hardness with 155 MPa, 6.17 J, 183 MPa, and 92 D-shore, respectively. The coconut rachilla fibre and FMH biosilica-generated epoxy composite have the lowest specific wear rate and coefficient of friction (COF) of 0.006 mm3/Nm and 0.42, respectively, with the addition of 5 vol% FMH biosilica particles. These composites also exhibit excellent thermal properties having maximum first decomposition temperature of 342 °C and glass transition temperature of 102 °C. Additionally, these composites keep their hydrophobic properties indefinitely, and the ERB3 composite has the lowest contact angle at 81°. These epoxy composites having improved mechanical, thermal, and wear properties may be helpful in a range of engineering applications that can use for high load bearing capacity and biodegradability, such as sporting goods, automobiles, home furnishings, food packaging, transport, and aircraft.

Similar content being viewed by others

Data availability

All data within manuscript.

References

Arun Prakash VR, Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Ramesh B et al (2018) Drilling of pultruded and liquid composite moulded glass/epoxy thick composites: Experimental and statistical investigation. Measurement 114:109–121

Elsheikh AH et al (2022) Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Cleaner Eng Technol:100450

Arun Prakash VR, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos Part A Appl Sci Manuf 118:317–326

Vincent VA et al (2020) Strength characterization of caryota urens fibre and aluminium 2024-T3 foil multistacking sequenced SiC-toughened epoxy structural composite. Biomass Convers Biorefin:1–11

Chockalingam S, Gopalarama Subramaniyan G, Bisen A, Kaliappan S, Sekar S, Patil PP, Anil Kumar TCh, Ramesh B, Venkatesan S (2022) Optimization of abrasive wear characteristics of polyethylene/acrylate copolymer nanocomposites. Adv Mater Sci Eng 2022, Article ID 6110591. https://doi.org/10.1155/2022/6110591

Ferreira DP, Cruz J, Fangueiro R (2019) Surface modification of natural fibers in polymer composites. In: Green composites for automotive applications. Woodhead Publishing, pp 3–41

Pankaj, Jawalkar CS, Kant S (2022) Critical review on chemical treatment of natural fibers to enhance mechanical properties of bio composites. Silicon 14:5103–5124. https://doi.org/10.1007/s12633-021-01194-1

Arun Prakash VR, Viswanathan R (2019) Fabrication and characterization of silanized echinoidea fillers and kenaf fibre-reinforced Azadirachta-indica blended epoxy multi-hybrid biocomposite. Int J Plast Technol 23(2):207–217

Singh H, Chatterjee A (2020) Potential of alkali treated cornhusk film as reinforcement for epoxy laminate composites. Cellulose 27:2555–2567. https://doi.org/10.1007/s10570-019-02917-9

Singh H, Chatterjee A (2021) Effect of filler loading and orientation on alkali-treated cornhusk film reinforced epoxy laminate composites. Indian J Fibre Text Res 46:275–286

Giri Jayant P, Kaustubh NK, Prasad AH (2013) Modeling and optimization of assembly of transmission system through ergonomic consideration: an overview

Murugan MA et al (2020) Low velocity impact and mechanical behaviour of shot blasted SiC wire-mesh and silane-treated aloevera/hemp/flax-reinforced SiC whisker modified epoxy resin composites. Silicon 12:1847–1856

Arun Prakash VR, Xavier JF, Ramesh G, Maridurai T, Siva Kumar K, Blessing Sam Raj R (2020) Mechanical, thermal and fatigue behaviour of surface-treated novel Caryota urens fibre–reinforced epoxy composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-00938-0

Akter R, Neher B, Gafur MA, Hossain R, Ahmed F (2021) Study of the physical and mechanical properties of coconut spathe fiber reinforced obsolete polymer composites. Mater Sci Appl 12(5):223–238

Agrawal N, Aggarwal M, Roy D, Mukhopadhyay K, Bhattacharya AR (2018) Micro-fibrillar fiber of bicomponent polymer blends: Traditional paradigm with modern approach. Adv Mater Proc 3(7):433–442

Alshahrani H, Arun Prakash VR (2022) Mechanical, fatigue and DMA behaviour of high content cellulosic corn husk fibre and orange peel biochar epoxy biocomposite: A greener material for cleaner production. J Clean Prod:133931https://doi.org/10.1016/j.jclepro.2022.133931

Neopolean P, Karuppasamy K (2022) Characterization of silane treated opuntia short fibre and bagasse biosilica toughened epoxy resin composite. Silicon. https://doi.org/10.1007/s12633-021-01634-y

Poomathi S, Roji SSS (2022) Experimental investigations on Palmyra sprout fiber and biosilica-toughened epoxy bio composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02867-6

Jayabalakrishnan D, Prabhu P, Mohamed Iqbal S, Mugendiran V, Ravi S, Arun Prakash VR (2021) Mechanical, dielectric, and hydrophobicity behavior of coconut shell biochar toughened Caryota urens natural fiber reinforced epoxy composite. Polym Compos 43(1):493–502

Gairola S, Sinha S, Singh I (2022) Novel millet husk crop-residue based thermoplastic composites: Waste to value creation. Ind Crops Prod 182:114891

Shubhra QTH, Moshiul Alam AKM, Adul Quaiyyum M (2013) Mechanical properties of polypropylene composites: A review. J Thermoplast Compos Mater 26(3):362–391

Rajadurai A (2017) Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin. Defence Technology 13(1):40–46

Merizgui T et al (2021) High content silver/zinc oxide nanoparticle and cobalt nanowire in Caryota urens fibreepoxy composites for enhanced microwave shielding. J Magn Magn Mater 536:168118

Arun Prakash VR, Rajadurai A (2016) Mechanical, thermal and dielectric characterization of Iron oxide particles dispersed glass fiber epoxy Resin hybrid composite. Digest J Nanomater Biostruct 11(2):373–380

Prabhu P, Jayabalakrishnan D, Balaji V et al (2022) Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-02177-3

Balaji N, Kumar JVSP, Ramesh G et al (2022) Investigation on DMA, fatigue and creep behaviour of rice husk ash biosilica-prickly pear short fibre-reinforced epoxy resin composite. Silicon. https://doi.org/10.1007/s12633-022-01981-4

Mohan Prasad M, Sutharsan SM, Ganesan K et al (2022) Role of sugarcane bagasse biogenic silica on cellulosic Opuntia dillenii fibre-reinforced epoxy resin biocomposite: mechanical, thermal and laminar shear strength properties. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-02154-w

Suganya G, Senthil kumar S, Jayabalakrishnan D et al (2022) Mechanical, thermal, and fatigue behavior of aloe vera fiber/pistachio shell powder toughened epoxy resin composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02787-5

Alshahrani H, Arun Prakash VR (2022) Thermal, mechanical and barrier properties of rice husk ash biosilica toughened epoxy biocomposite coating for structural application. Prog Org Coat 172:107080

Syakur A, Heri S (2017) Determination of hydrophobic contact angle of epoxy resin compound silicon rubber and silica. In: IOP Conference Series: Materials Science and Engineering, vol. 190, no. 1. IOP Publishing

Yorseng K et al (2020) Influence of accelerated weathering on the mechanical, fracture morphology, thermal stability, contact angle, and water absorption properties of natural fiber fabric-based epoxy hybrid composites. Polymers 12(10):2254

Author information

Authors and Affiliations

Contributions

P. Sivamurugan: research

R. Selvam: research, testing and drafting

M. Pandian: research

Mohd.ShaikhulAshraf: research and drafting

Inavolu Srinivasa Chakrapani: research

A. Thanikasalam: testing and drafting

P. Roshith: research and characterization

K. Ramesh: research and finance

B. Ramesh: research

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sivamurugan, P., Selvam, R., Pandian, M. et al. Extraction of novel biosilica from finger millet husk and its coconut rachilla-reinforced epoxy biocomposite: mechanical, thermal, and hydrophobic behaviour. Biomass Conv. Bioref. 14, 14251–14259 (2024). https://doi.org/10.1007/s13399-022-03342-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03342-y