Abstract

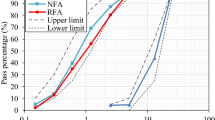

The 7-d compressive strength, 28-d compressive strength, 28-d uniaxial compressive strength, 28-d splitting tensile strength, 28-d flexural strength and stress–strain test of steel-polyvinyl alcohol fiber recycled coarse aggregate self-compacting concrete (SF–PVA–RCASCC) were carried out by orthogonal test method. It was shown that the incorporation of SF and PVA enhances the bearing capacity of the concrete. Six mechanical properties of SF–PVA–RCASCC, such as the 7-d compressive strength, were higher than those of the reference group, with the largest increases of 19.2%, 12.21%, 22.02%, 12.2%, 21.73% and 93.53%, respectively. The six mechanical properties of the SF–PVA–RCASCC were analyzed using a range analysis of variance, a factor-level analysis, and a correlation analysis of gray entropy. The optimal mixing ratio of SF–PVA–RCASCC is obtained, and the effect of the VS, VP and RR variation rules on the mechanical properties of SF–PVA–RCASCC is obtained. The established constitutive model of axial compression is highly accurate. The best mixture ratios for SF–PVA–RCASCC are 0.75vol% VS, 0.05vol% VP and 75 wt% RR. We performed nonlinear regression analysis on the six mechanical properties of SF–PVA–RCASC, and obtained regression equations with high accuracy. The results can provide a theoretical basis and technical support for the engineering application of SF–PVA–RCACSCC.

Similar content being viewed by others

References

Abed, M.; Fořt, J.; Rashid, K.: Multicriterial life cycle assessment of eco-efficient self-compacting concrete modified by waste perlite powder and/or recycled concrete aggregate. Constr. Build. Mater. 348, id. 128696 (2022)

Huda, S.; Shahria A.: Mechanical and freeze-thaw durability properties of recycled aggregate concrete made with recycled coarse aggregate. J. Mater. Civ. Eng. 27(10), id. 04015003 (2015)

Bogas, J.; De, B.; Ramos, D.: Freeze-thaw resistance of concrete produced with fine recycled concrete aggregates. J. Clean. Prod. 115, 294–306 (2016)

Okamura, H.; Ouchi, M.: Self-compacting concrete. J. Adv. Concr. Technol. 1(1), 5–15 (2003)

Zheng, C.; Li, S.; Hou, Y.; **, B.: Frost resistance of fiber-reinforced self-compacting recycled concrete. Rev. Adv. Mater. Sci. 61(1), 711–725 (2022)

Haido, J.; Tayeh, B.; Majeed, S.; Karpuzcu, M.: Effect of high temperature on the mechanical properties of basalt fibre self-compacting concrete as an overlay material. Constr. Build. Mater. 268, id. 121725 (2021)

Majeed, S.; Haido, J.; Atrushi, D.; Al-Kamaki, Y.; Dinkha, Y.; Saadullah, S., et al.: Properties of self-compacted concrete incorporating basalt fibers: experimental study and Gene Expression Programming (GEP) analysis. Comput. Concr. 28(5), 451–463 (2021)

Luo, D.; Wang, Y.; Niu, D.: Evaluation of the performance degradation of hybrid steel-polypropylene fiber reinforced concrete under freezing-thawing conditions. Adv. Civ. Eng. 2020, id. 8863047 (2020)

Wang, Y.;, Zhang, S.; Niu, D.; Fu, Q.: Quantitative evaluation of the characteristics of air voids and their relationship with the permeability and salt freeze-thaw resistance of hybrid steel-polypropylene fiber–reinforced concrete composites. Cem. Concrete Compos. 125, id. 104292 (2022)

Meng, K.; Xu, L.; Chi, Y.: Experimental investigation on the mechanical behavior of hybrid steel-polypropylene fiber reinforced concrete under conventional triaxial cyclic compression. Constr. Build. Mater. 291, id. 123262 (2021)

Tuyan, M.; Mardani-Aghabaglou, A.; Ramyar, K.: Freeze-thaw resistance, mechanical and transport properties of self-consolidating concrete incorporating coarse recycled concrete aggregate. Mater. Des. 53, 983–991 (2014)

Chen, Y.: A significance test in multi-level orthogonal designs with only one replicate. Chin. J. Appl. Probab. Stat. 27(5), 497–510 (2011)

Zheng, C.; Wang, J.; **, B.; Zhou, S.; Li, S.; Zhao, Y.: The influence of many factors on the development trend of the mechanical properties of self-compacting concrete. J. Funct. Mater. 52(12), 12022–12029 (2021)

**ao, J.; Du, J.: Complete stress-strain curve of concrete with different recycled coarse aggregates uniaxial compression. J. Build. Mater. 1, 111–115 (2008)

Pacheco, J.; Brito, J.; Chastre, C.; Evangelista. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 201, 110–120 (2019)

**ao, J.; Li, J.; Sun, Z.; Hao, X. Study on compressive strength of recyded aggregate concrete. J. Tongji Univ. (Natural Science), 12, 1558–1561 (2004)

Cordeiro, G.; Toledo, F.; Tavares, L.; Fairbairn, E.: Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cement Concr. Compos. 30(5), 410–418 (2008)

Guo, Z.: Strength and deformation of concrete-test basis and constitutive relation. pp. 35–38 (1997)

Bairagi, N.; Ravande, K.; Pareek, V.: Behaviour of concrete with different proportions of natural and recycled aggregates. Resour. Conserv. Recycl. 9, 109–126 (1993)

Günçan, N.: Using waste concrete as aggregate. Cem. Concr. Res. 25(7), 1385–1390 (1995)

**ao, J.; Li, J.; Zhang, C.: Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concrete Res. 35(6), 1187–1194 (2005)

Liu, H.; Ma, Y.; Ma, J.; Yang, W.; Che, J.: Frost resistance of desert sand concrete. Adv. Civ. Eng., 2021, id. 6620058 (2021)

**, B.; Zheng, C.; Hou, Y.; Wang, J.; Zhao, Y.; Li, S.: Orthogonal experimental study on the mechanical properties of polypropylene-steel fiber/recycled coarse aggregate concrete. J. Funct. Mater. 52(12), 12175–12183 (2021)

Funding

Thanks to the grant from the National Natural Science Foundation of China (Reference: 51968060). Engineering and Technology Research Center of Liupanshan Resources NYG2022022 Graduate Innovation Project of Ningxia University CXXM202239.

Author information

Authors and Affiliations

Contributions

Chuanlei Zheng was responsible for preliminary research and thesis writing. Yadi Zhao was responsible for implementing the experiment. Baohong ** provided technical guidance.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest in this matter.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, C., Zhao, Y. & **, B. Mechanical Properties of Steel-Polyvinyl Alcohol Fiber Recycled Coarse Aggregate Self-Compacting Concrete: Orthogonal Testing. Arab J Sci Eng 49, 5055–5068 (2024). https://doi.org/10.1007/s13369-023-08308-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08308-4