Abstract

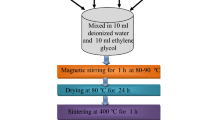

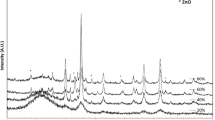

The co-precipitation technique is employed for preparing ZnO/CoFe2O4 composites. X-ray diffraction, Fourier Transform Infrared Spectroscopy (FTIR) and Rietveld refinement techniques is performed to investigate the composite structure obtained after annealing. The Rietveld refinement method gives information about crystalline phases present in the sample. Rietveld analysis of X-ray diffraction results reveals the presence of two phases where phase 1 is zinc oxide with hexagonal structure, whereas phase 2 is cobalt ferrite with cubic structure. XRD shows the size of crystallites for phase 1 is 43 nm, and for phase 2 is 38 nm. FTIR peaks centered at 440–515 cm−1 corresponds to M–O stretching vibrations. Dielectric properties such as ε′, ε″, Tanδ, conductivity, and electric modulus of the sample have been measured at temperature 30–300 °C and the frequency range is 1–107 Hz. Dielectric parameters show dependence on frequency and temperature as well as on concentration and temperature used for synthesis of samples. Synthesized sample at temperature 400 °C and concentration 1:1 shows highest value of ε′ i.e., above 1000. To study magnetic properties VSM characterization is used. High value of ε′, Tan δ and remarkable low value of conductivity (high resistivity), retentivity (0.01–2.17 emu/g) and coercivity (34.8–213 Oe) indicate its application in high frequency devices.

Similar content being viewed by others

References

R S Yadav, J Havlica, J Masilko, J Tkacz, I Kuvritka and J Vilcakova J. Mater. Sci. Mater. Electron. 27 5992 (2016)

R Nongjai, S Khan, K Asokan, H Ahmed and I Khan J. Appl. Phys. 112 84321 (2012)

S M Patange, S E Shirsath, B G Toksha, S S Jadhav and K M Jadhav J. Appl. Phys. 106 23914 (2009)

S S Bharambe, A Trimukhe and P Bhatia Mater. Today Proc. 23 373 (2020)

A S Priya, D Geetha and N Kavitha Vacuum 160 453 (2019)

D Tomar and P Jeevanandam J. Alloys Compd. 843 155815 (2020)

M Shakil, U Inayat, M I Arshad, G Nabi, N R Khalid and A Shah Ceram. Int. 46 7767 (2020)

A Hashhash and M Kaiser J. Electron. Mater 45 462 (2016)

K K Bharathi and C V Ramana J. Mater. Res. 26 584 (2011)

D R S Gangaswamy, S Bharadwaj, M C Varma, G Choudary and K H Rao J. Magn. Magn. Mater. 468 73 (2018)

S Rohilla, S Kumar, P Aghamkar, S Sunder and A Agarwal J. Magn. Magn. Mater. 323 897 (2011)

M I A Maksoud, A El-Ghandour, G S El-Sayyad, R A Fahim, A H El-Hanbaly and M Bekhit J. Inorg. Organomet. Polym. Mater. 30 3709 (2020)

P A Vinosha, A Manikandan, A S J Ceicilia, A Dinesh, G F Nirmala, A C Preetha, Y Slimani, M A Almessiere, A Baykal and B Xavier Ceram. Int. 47 10512 (2021)

D Chahar, S Taneja, P Thakur and A Thakur J. Alloys Compd. 843 155681 (2020)

Mubasher and M Mumtaz J. Alloys Compd. 866 158750 (2021)

A Gupta and S Rohilla Mater. Today Proc. 44 4282 (2021)

W Hong et al J. Colloid Interface Sci. 485 175 (2017)

L Khanna and N K Verma J. Magn. Magn. Mater. 336 1 (2013)

M Yuan, Y Su, W Deng and H Zhou Chem. Eng. J. 375 122091 (2019)

W Chen, Q Liu, X Zhu and M Fu Appl. Organomet. Chem. 32 4017 (2018)

K C B Naidu and W Madhuri J. Magn. Magn. Mater. 420 109 (2016)

M C Dimri, A Verma, S C Kashyap, D C Dube, O P Thakur and C Prakash Mater. Sci. Eng. B 133 42 (2006)

N Sivakumar, A Narayanasamy, C N Chinnasamy and B Jeyadevan J. Phys. Condens. Matter. 19 386201 (2007)

K W Wagner Ann. Phys 40 817 (1913)

N Singh, A Agarwal and S Sanghi Appl. Phys. 11 783 (2011)

H I Hsiang, C S Hsi, C Y Tsai and L T Mei Ceram. Int. 41 4140 (2015)

P Chand, S Vaish and P Kumar Phys. B Condens. Matter. 524 53 (2017)

T Slatineanu, A R Iordan et al J. Mater. Sci. Eng. B. 178 1040 (2013)

N Ponpandian, P Balaya and A Narayanasamy J. Phys. Condens. Matter 14 3221 (2002)

M S Hossain et al J. Adv. Dielectr. 8 1850030 (2018)

H B Duvuru et al Ceram. Int. 45 16512 (2019)

T W Mammo et al Phys. B Condens. Matter 581 411769 (2020)

A B Mugutkar, S K Gore, U B Tumberphale and R S Mane J. Magn. Magn. Mater. 502 166490 (2020)

Z Bitar, W Abdeen and R Awad Mater. Res. Innov. 24 104 (2020)

L W McKeen Film Properties of Plastics and Elastomers (Norwich: William Andrew) (2017)

S Choudhury, M Sinha, H Dutta, M K Mandal, S K Pradhan and A K Meikap Mater. Res. Bull. 60 446 (2014)

M Z Khan, I H Gul and H Anwar J. Magn. Magn. Mater. 424 382 (2017)

A Shanmugavani, R K Selvan, S Layek and C Sanjeeviraja J. Magn. Magn. Mater. 354 363 (2014)

S Jangra, S Sanghi, A Agarwal, M Rangi and K Kaswan Ceram. Int. 44 7683 (2018)

S Brahma, R N P Choudhary and A K Thakur Phys. B Condens. Matter 355 188 (2005)

L Chauhan, A K Shukla and K Sreenivas Ceram. Int. 41 8341 (2015)

A K Jonscher J. Phys. D. Appl. Phys. 32 57 (1999)

M A El Hiti J. Phys. D. Appl. Phys. 29 501 (1996)

H Böttger and V V Bryksinm Hop** Conduction in Solids (Berlin: Akademie-Verlag) (1985)

T Wen, Y Li, D Zhang et al J. Colloid Interface Sci. 497 14 (2017)

D S Mathew and R S Juang Chem. Eng. J. 129 51 (2007)

C Liu and Z J Zhang Chem. Mater. 13 2092 (2001)

N Biglari, A Nasiri, S Pakdel and M Nasiri J. Mater. Sci. Mater. Electron. 27 13113 (2016)

J Füzer, M Strečková, S Dobák, L Ďáková, P Kollár, M Fáberová and M Vojtko J. Alloys Compd. 753 219 (2018)

M M Hessien, M M Rashad, K El-Barawy and I A Ibrahim J. Magn. Magn. Mater. 320 1615 (2008)

E Mehran, S F Shayesteh and F Nasehnia J. Supercond. Nov. Magn. 29 1241 (2016)

A Kmita, J Żukrowski, J Kuciakowski, M Marciszko-Wiąckowska, A Żywczak, D Lachowicz and M Sikora Metall. Mater. Trans. A 52 1632 (2021)

N Boda, G Boda, K C B Naidu, M Srinivas, K M Batoo, D Ravinder and A P Reddy J. Magn. Magn. Mater. 473 228 (2019)

K C B Naidu and W Madhuri Bull. Mater. Sci. 40 417 (2017)

J J Lu, H Y Deng and H L Huang J. Magn. Magn. Mater. 209 37 (2000)

L A S De Oliveira, A Pentón-Madrigal, A P Guimarães and J P Sinnecker J. Magn. Magn. Mater. 401 890 (2016)

L Kumar, P Kumar, S K Srivastava and M Kar J. Supercond. Nov. Magn. 27 1677 (2014)

U Sarac, M C Baykul and Y Uguz J. Supercond. Nov. Magn 28 3105 (2015)

E C Snelling Soft Ferrites Properties and Applications Chapter 1 (1969)

M T Farid, I Ahmad, M Kanwal, G Murtaza, I Ali, M N Ashiq and S A Khan J. Magn. Magn. Mater. 422 337 (2017)

S Li, J Pan, F Gao, D Zeng, F Qin, C He, G Dodbiba and T Fujita J. Mater. Sci. Mater. Electron. 32 13511 (2021)

C Aziz and B Azhdar J. Magn. Magn. Mater. 542 168577 (2022)

R R Kanna, K Sakthipandi et al Ceram. Int. 46 13695 (2020)

G Rana, P Dhiman, A Kumar et al Chem. Eng. Res. Des. 175 182 (2021)

M T Farid, I Ahmad et al J. Electron Mater. 46 1826 (2017)

Acknowledgements

Authors Jyoti Saini and Rahul Patwa would like to acknowledge University grant commission, New Delhi, India for JRF. One of the authors Dr. Sunil Rohilla acknowledge the research grant received from IQAC, CRSU through Letter No. CRSU/IQAC/2023/216.

Author information

Authors and Affiliations

Contributions

JS: methodology, investigation, synthesis, writing—original draft. SR: supervision, characterization, conceptualization, formal analysis, writing—review and editing. RP: visualization, formal analysis, literature review. SS: data curation, validation.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saini, J., Rohilla, S., Patwa, R. et al. Studies of the co-precipitation method-synthesized ZnO/CoFe2O4 nanocomposites structural, dielectric and magnetic characteristics for high-frequency application. Indian J Phys (2024). https://doi.org/10.1007/s12648-024-03309-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12648-024-03309-x