Abstract

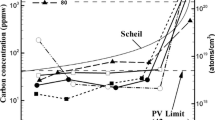

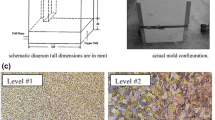

Currently, a large amount of recycled Si material is used in casting multicrystalline Si, which leads to an increase in impurities in the crystal. In this study, an innovative mechanical stirring device in the casting furnace is investigated, for forcing Si melt convection during the crystal directional growth. The qualification rate of Si ingot with the stirring is increased by 6.43% due to an increase of the minority carrier lifetime and a decrease of impurity clusters in the improved Si crystal, compared to that without the stirring. It was found that some impurities, such as carbon and oxygen, can achieve better segregation effect in cast multicrystalline Si, with the help of the stirrer. Also, the stirring action on Si melt can reduce the number of dislocation clusters in Si ingot, which is beneficial for improving the quality of the Si crystal.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Klugmann-Radziemska E, Kuczyńska-Łażewska A (2020) The use of recycled semiconductor material in crystalline silicon photovoltaic modules production - a life cycle assessment of environmental impacts. Sol Energ Mat Sol C 205:110259

Durairaj S, Kesavan V, Keerthivasan T, Kumar MA, Srinivasan M, Ramasamy P (2022) Investigation of orientation, surface morphology, impurity concentration and reflectivity of the multi-crystalline silicon wafers. Mater Chem Phys 282:125932

Trempa M, Kranert C, Reimann C, Friedrich J (2021) Impact of silicon feedstock contamination by gas phase diffusion on material quality of cast silicon ingots. J Cryst Growth 570:126224

Bellmann MP, Meese EA, Arnberg L (2010) Impurity segregation in directional solidified multi-crystalline silicon. J Cryst Growth 312(21):3091–3095

Hu Z, Li J, Tan Y, Jiang D, Li P (2022) Interaction of impurity distribution and groove at the micro-zone of solid/liquid interface in silicon. Mater Design 214:110384

Funke C, Schmid E, Gärtner G, Reißenweber S, Fütterer W, Poklad A, Raabe L, Pätzold O, Stelter M (2014) Impurities, inclusions, and dislocations in multicrystalline silicon grown from well-mixed and poorly mixed melts. J Cryst Growth 401:732–736

Popescu A, Vizman D (2017) Numerical study of the influence of forced melt convection on the impurities transport in a silicon directional solidification process. J Cryst Growth 474:55–60

Yu Q, Liu L, Li Z, Shao Y (2018) Parameter study of traveling magnetic field for control of melt convection in directional solidification of crystalline silicon ingots. Int J Heat Fluid FL 71:55–67

Li Z, Liu L, Liu X, Zhang Y, **ong J (2012) Effects of argon flow on melt convection and interface shape in a directional solidification process for an industrial-size solar silicon ingot. J Cryst Growth 360:87–91

Li Z, Liu L, Nan X, Kakimoto K (2012) Role of marangoni tension effects on the melt convection in directional solidification process for multi-crystalline silicon ingots. J Cryst Growth 346(1):40–44

Kumar MA, Srinivasan M, Ramasamy P (2019) Effect of crucible rotation on the distribution of carbon, oxygen and nitrogen impurities in multi-crystalline silicon grown by directional solidification process – a numerical simulation analysis. Mater Res Express 6:105912

Chen S, Zou G, He L, Mao W, Lei Q. A kind of ingot furnace for directionally solidifying and growing crystalline silicon, Chinese patent, CN 201920654622.4

Li Y, Liu L, Chen J (2021) Effect of mechanical stirring on silicon purification during Al-Si solvent refining. J Cryst Growth 553:125943

Dumitrica S, Vizman D, Garandet J-P, Popescu A (2012) Numerical studies on a type of mechanical stirring in directional solidification method of multicrystalline silicon for photovoltaic applications. J Cryst Growth 360:76–80

Lei Q, He L, Rao S, Tang C, Ming L, Xu Y, Mao W, Zhou C, Luo H, Li J, Zhou L (2012) Production of high performance multi-crystalline silicon ingot by using composite nucleant. J Cryst Growth 542:125666

Buchovska I, Liaskovskiy O, Vlasenko T, Beringov S, Kiessling FM (2017) Different nucleation approaches for production of high-performance multi-crystalline silicon ingots and solar cells. Sol Energ Mat Sol C 159:128–135

Chatelain M, Botton V, Albaric M, Pelletier D, Cariteau B, Abdo D, Borrelli M (2018) Mechanical stirring influence on solute segregation during plane front directional solidification. Int J Therm Sci 126:252–262

Li J, Prakash RR, Jiptner K, Chen J, Miyamura Y, Harada H, Kakimoto K, Ogura A, Sekiguchi T (2013) Butterfly-shaped distribution of SiNx precipitates in multi-crystalline Si for solar cells. J Cryst Growth 377:37–42

Dezfoli ARA, Hwang WS, Shukur AK, Augusto J, Huang YS, Tzeng S (2017) 3D numerical study of coupled crystallization and carbon segregation during multi-crystalline silicon ingot solidification. Mater Sci Semicond Process 59:76–86

Schwanke S, Trempa M, Reimann C, Kuczynski M, Schroll G, Sans J, Heitmann J, Friedrich J (2021) Influence of crucible properties and Si3N4-coating composition on the oxygen concentration in multi-crystalline silicon ingots. J Cryst Growth 568-569:126178

Liu L, Ma W, Qi X, Li Z, Zhang Y (2017) Global simulation of coupled oxygen and carbon transport in an industrial directional solidification furnace for crystalline silicon ingots: effect of crucible cover coating. Int J Heat Mass Transf 108:2355–2364

He L, Yuan S, Xu Y, Lei Q, Mao W, Luo H, He X, Li X, Wang L, Yang D, Qian Y (2021) Evaluation of large-scale recycled seed for cast monocrystalline silicon: defect multiplication mechanisms and feasibility. Sol Energ Mat Sol C 230:111266

Acknowledgements

The authors would like to thank the National Key Research and Development Program of China (No. 2020YFB1506501) and Jiangsu Key Lab of Silicon Based Electronic Materials for financial support.

Funding

This study was supported by the National Key Research and Development Program of China (No. 2020YFB1506501).

Author information

Authors and Affiliations

Contributions

Dongli Hu and **bing Zhang: Conceptualization, Methodology, Software, Investigation, Writing-original draft. Shuai Yuan: Methodology, Software, Investigation. Hongrong Chen: Resources, Writing - review & editing, Data curation. Huali Zhang: Validation, Formal analysis, Visualization, Software. Chen Wang: Investigation, Data curation.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

All authors are agreed.

Consent for Publication

There are no details on an individual reported in the manuscript.

Conflicts of Interest/Competing Interests

The authors declare that there is no conflict of interest regarding the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, D., Zhang, J., Yuan, S. et al. Improving Performance of Cast Silicon Ingot by Forcing Silicon Melt Convection with Mechanical Stirring. Silicon 15, 2737–2744 (2023). https://doi.org/10.1007/s12633-022-02217-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02217-1