Abstract

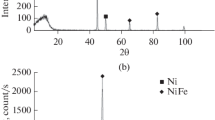

Pure Ni and its composites with different percentages of Ni–Cr nano-oxides were coated over carbon steel to assess the coating features and mechanical and corrosion behavior. A nano-oxide composite of Ni–Cr was first synthesized through chemical coprecipitation with uniform distribution constituents. Electrodeposition was employed to coat pure Ni and Ni–Ni–Cr) oxides (10, 20, 30, 40, and 50 g/L) on the steel sheets. Transmission electron microscope and field emission scanning electron microscope were adopted to examine the microstructure of powders and coatings, and X-ray diffraction analysis was employed to study the chemical composition. The microhardness, thickness, and wear resistance of the coatings were assessed, polarization and electrochemical impedance spectroscopy (EIS) tests were conducted to analyze the corrosion behavior, and the corresponding equivalent circuit was developed. Results showed flawless and crack-free coatings for all samples and uniform distribution of nano-oxides in the Ni matrix for the samples of 10–30 g/L. Agglomerated oxides were detected at high concentrations. Maximum microhardness (HV 661), thickness (116 µm), and wear resistance of coatings were found at 30 g/L. A three-loop equivalent circuit corresponded satisfactorily to all EIS data. The corrosion resistance increased with the nano-oxide concentration of up to 30 g/L but decreased at 40 g/L. The sample of 50 g/L showed the best corrosion resistance.

Similar content being viewed by others

References

W.L. Wu, R.F. Chen, Z.R. Yang, Z.Y. He, Y. Zhou, and F.Z. Lv, Corrosion resistance of 45 carbon steel enhanced by laser graphene-based coating, Diam. Relat. Mater., 116(2021), art. No. 108370.

A.Y. Ivannikov, V.I. Kalita, D.I. Komlev, et al., Investigation into improving microstructure and properties of plasma sprayed Ni coating via electromechanical treatment, J. Mater. Process. Technol., 266(2019), p. 442.

M. Aghili, M.K. Yazdi, Z. Ranjbar, and S.H. Jafari, Anticorrosion performance of electro-deposited epoxy/amine functionalized graphene oxide nanocomposite coatings, Corros. Sci., 179(2021), art. No. 109143.

L.H. Guo, Q. Huang, C. Zhang, et al., Study on the formation of Mn−P coatings with significant corrosion resistance on Q235 carbon steels by adjusting the ratio of phosphorus to manganese, Corros. Sci., 178(2021), art. No. 108960.

J.C. Pereira, L.P.M. dos Santos, A.A.C. Alcanfor, et al., Effects of electrodeposition parameters on corrosion resistance of Zn−Sn coatings on carbon steel obtained from eutectic mixture based on choline chloride and ethylene glycol, J. Alloys Compd., 886(2021), art. No. 161159.

A.M.K. Kirubaharan and P. Kuppusami, Corrosion behavior of ceramic nanocomposite coatings at nanoscale, [in] S. Rajendran, T.A. Nguyen, S. Kakooei, M. Yeganeh, and Y.X. Li, eds., Corrosion Protection at the Nanoscale, Elsevier, Amsterdam, 2020, p. 295.

A. Bigos, M. Janusz-Skuza, M.J. Szczerba, et al., The effect of heat treatment on the microstructural changes in electrodeposited Ni−Mo coatings, J. Mater. Process. Technol., 276(2020), art. No. 116397.

P. Kar, Anticorrosion and antiwear, [in] P.N. Tri, S. Rtimi, and C.M.O. Plamondon, eds., Nanomaterials-Based Coatings — Fundamentals and Applications, Elsevier, Amsterdam, 2019, p. 195.

N.B. Singh and S. Agarwal, Nanocomposites: An overview, Emerg. Mater. Res., 5(2016), No. 1, p. 5.

M. Boroujerdnia, H. Ghayour, A. Monshi, R. Ebrahimi-Kahrizsangi, and F. Jamali-Sheini, Electroplating of Ni/Co-pumice multilayer nanocomposite coatings: Effect of current density on crystal texture transformations and corrosion behavior, Int. J. Miner. Metall. Mater., 26(2019), No. 10, p. 1299.

H. Caliskan, P. Panjan, and C. Kurbanoglu, 3.16 hard coatings on cutting tools and surface finish, [in] M. Hashmi, ed., Comprehensive Materials Finishing, Elsevier, Amsterdam, 2017, p. 230.

J. Li, O.C. Lin, C. Cheng, W.B. Wang, C.Y. Xu, and L.Q. Ren, Fabrication of a Ni/SiC composite coating on steel surface with excellent corrosion inhibition performance, J. Mater. Process. Technol., 290(2021), art. No. 116987.

R.A. Hussain and I. Hussain, Fabrication and applications of nickel selenide, J. Solid State Chem., 277(2019), p. 316.

K.J. Joshi and N.M. Shah, Study of hydroxyapatite nanoparticles synthesized using sono-chemical supported hydrothermal method, Mater. Today Proc., 47(2021), p. 505.

M. Messaoud, F. Trabelsi, P. Kumari, A. Merenda, and L.F. Dumée, Recrystallization and coalescence kinetics of TiO2 and ZnO nano-catalysts towards enhanced photocatalytic activity and colloidal stability within slurry reactors, Mater. Chem. Phys., 252(2020), art. No. 123235.

H. Mohammadzadeh and M. Barati, A comprehensive evaluation of non-isothermal simultaneous reduction and carburization kinetics of W−Ni oxide nano-composite powder, Mater. Chem. Phys., 272(2021), art. No. 125027.

G.Y. Wei, J.K. Qu, Y.D. Zheng, T. Qi, and Q. Guo, Preparation of Cr2O3 precursors by hydrothermal reduction in the abundant Na2CO3 and Na2CrO4 solution, Int. J. Miner. Metall. Mater., 19(2012), No. 11, p. 978.

H. Mohammadzadeh, H. Rezaie, H. Samim, M. Barati, and H. Razavizadeh, Synthesis of WC−Ni composite powders by thermochemical processing method based on co-precipitation, Mater. Chem. Phys., 149–150(2015), p. 145.

S.Q. Wang, F.Q. **e, X.Q. Wu, and L.Y. Chen, CeO2 doped Al2O3 composite ceramic coatings fabricated on γ-TiAl alloys via cathodic plasma electrolytic deposition, J. Alloys Compd., 788(2019), p. 632.

G. Jena, R.P. George, and J. Philip, Fabrication of a robust graphene oxide-nano SiO2-polydimethylsiloxane composite coating on carbon steel for marine applications, Prog. Org. Coat., 161(2021), art. No. 106462.

D. Jiang, H.Z. Cui, H. Chen, X.F. Zhao, G.L. Ma, and X.J. Song, Wear and corrosion properties of B4C-added CoCrNiMo high-entropy alloy coatings with in-situ coherent ceramic, Mater. Des., 210(2021), art. No. 110068.

N. Rojas, M. Sánchez-Molina, G. Sevilla, et al., Coated stainless steels evaluation for bipolar plates in PEM water electrolysis conditions, Int. J. Hydrogen Energy, 46(2021), No. 51, p. 25929.

S. Arcaro, F.A. Berutti, A.K. Alves, and C.P. Bergmann, MW-CNTs produced by electrolysis of molten carbonate: Characteristics of the cathodic products grown on galvanized steel and nickel chrome electrodes, Appl. Surf. Sci., 466(2019), p. 367.

Y.H. Zhang, S.H. Zhang, Y. He, et al., Mechanical properties and corrosion resistance of pulse electrodeposited Ni-B/B4C composite coatings, Surf. Coat. Technol., 421(2021), art. No. 127458.

H.M.A. El-Lateef and M.M. Khalaf, Fabrication and characterization of alumina-silica/poly(o-toluidine) nanocomposites as novel anticorrosive epoxy coatings films on carbon steel, Microchem. J., 158(2020), art. No. 105129.

E. Ghahabi, Y. Shajari, M. Razavi, I. Mobasherpour, and S.A.T. Fard, Effect of iron content on the wear behavior and adhesion strength of TiC−Fe nanocomposite coatings on low carbon steel produced by air plasma spray, Ceram. Int., 46(2020), No. 3, p. 2670.

U.K. Chanda, A. Behera, S. Roy, and S. Pati, Evaluation of Ni−Cr−P coatings electrodeposited on low carbon steel bipolar plates for polymer electrolyte membrane fuel cell, Int. J. Hydrogen Energy, 43(2018), No. 52, p. 23430.

V.S. Kathavate, D.N. Pawar, N.S. Bagal, and P.P. Deshpande, Role of nano ZnO particles in the electrodeposition and growth mechanism of phosphate coatings for enhancing the anti-corrosive performance of low carbon steel in 3.5% NaCl aqueous solution, J. Alloys Compd., 823(2020), art. No. 153812.

R.P. Oliveira, D.C. Bertagnolli, E.A. Ferreira, L. da Silva, and A.S. Paula, Influence of Fe2+ oxidation and its antioxidant ascorbic acid as additive in Zn-Ni-Fe electrodeposition process on a low carbon steel, Surf. Coat. Technol., 349(2018), p. 874.

D. Pritima, P. Padmanabhan, S. Marichamy, C. Sivakandhan, B. Stalin, and V. Dhinakaran, Material characterization and parametric effect on nickel-coated mild steel sheets by electroplating process, [in] A. Arockiarajan, M. Duraiselvam, and R. Raju, eds., Advances in Industrial Automation and Smart Manufacturing, Lecture Notes in Mechanical Engineering, Springer, Singapore, 2020, p. 465.

K. An, Y. Sui, Y.Q. Qing, et al., Synergistic reinforcement coating with anti-corrosion and UV aging resistance by filling modified CeO2 nanoflakes, Colloids Surf. A, 625(2021), art. No. 126904.

V.P.M. Shajudheen, K.A. Rani, V.S. Kumar, A.U. Maheswari, M. Sivakumar, and S.S. Kumar, Comparison of anticorrosion studies of titanium dioxide and nickel oxide thin films fabricated by spray coating technique, Mater. Today Proc., 5(2018), No. 2, p. 8889.

M. Li, Z.X. **, W. Zhang, et al., Comparison of chemical stability and corrosion resistance of group IV metal oxide films formed by thermal and plasma-enhanced atomic layer deposition, Sci. Rep., 9(2019), No. 1, art. No. 10438.

A.A. Aal, Hard and corrosion resistant nanocomposite coating for Al alloy, Mater. Sci. Eng. A, 474(2008), No. 1–2, p. 181.

I.U. Haq, K. Akhtar, T.I. Khan, and A.A. Shah, Electrodeposition of Ni−Fe2O3 nanocomposite coating on steel, Surf. Coat. Technol., 235(2013), p. 691.

S. Shanmugasamy, K. Balakrishnan, A. Subasri, S. Ramalingam, and A. Subramania, Development of CeO2 nanorods reinforced electrodeposited nickel nanocomposite coating and its tribological and corrosion resistance properties, J. Rare Earths, 36(2018), No. 12, p. 1319.

S.A.N. Mehrabani, R. Ahmadzadeh, N. Abdian, A.T. Tabrizi, and H. Aghajani, Synthesis of Ni−GO nanocomposite coatings: Corrosion evaluation, Surf. Interfaces, 20(2020), art. No. 100546.

A. Rasooli, M.S. Safavi, and M.K. Hokmabad, Cr2O3 nanoparticles: A promising candidate to improve the mechanical properties and corrosion resistance of Ni−Co alloy coatings, Ceram. Int., 44(2018), No. 6, p. 6466.

M.T. Uddin, Y. Nicolas, C. Olivier, et al., Band alignment investigations of heterostructure NiO/TiO2 nanomaterials used as efficient heterojunction earth-abundant metal oxide photocatalysts for hydrogen production, Phys. Chem. Chem. Phys., 19(2017), No. 29, p. 19279.

A.M. Oje, A.A. Ogwu, A.I. Oje, N. Tsendzughul, and S.U. Rahman, A comparative study of the corrosion and ion release behaviour of chromium oxide coatings exposed to saline, Ringer’s and Hank’s physiological solutions, Corros. Sci., 167(2020), art. No. 108533.

M. Sajjadnejad, S.M.S. Haghshenas, V.T. Targhi, et al., Wear behavior of alkaline pulsed electrodeposited nickel composite coatings reinforced by ZnO nanoparticles, Wear, 468–469(2021), art. No. 203591.

M. Koroghli, V. Alimirzaloo, H. Mohammadzadeh, and M. Kavanlouei, Sintering behavior of WC−Co with additives of TiC, VC, and (Ta,Nb)C: Microstructural and mechanical features, J. Mater. Eng. Perform., 31(2022), No. 1, p. 814.

S.A. Bakar, N. Soltani, W.M.M. Yunus, E. Saion, and A. Bahrami, Structural and paramagnetic behavior of spinel NiCr2O4 nanoparticles synthesized by thermal treatment method: Effect of calcination temperature, Solid State Commun., 192(2014), p. 15.

N.A. Noshahi, K. Nadeem, and M. Kamran, Role of Mn do** on magnetic properties of multiferroic NiCr2O4 nanoparticles, Ceram. Int., 47(2021), No. 8, p. 10643.

A. Yousef and R. Tali, Preparation and characterization of spinel NiCr2O4 by co-precipitation method, Chem. Mater. Res., 9(2017), No. 4, p. 1.

D. Chen, Y. Yang, X.Q. Zhang, X.N. Wang, Y. Xu, and G.R. Qian, Mesoporous composite NiCr2O4/Al−MCM−41: A novel photocatalyst for enhanced hydrogen production, Int. J. Hydrogen Energy, 44(2019), No. 33, p. 18123.

R.Z. Rasool, K. Nadeem, M. Kamran, F. Zeb, N. Ahmad, and M. Mumtaz, Comparison of anomalous magnetic properties of non-collinear CoCr2O4 and NiCr2O4 nanoparticles, J. Magn. Magn. Mater., 514(2020), art. No. 167225.

H. Mohammadzadeh, H. Rezaie, M. Barati, D.W. Yu, and H.R. Samim, Kinetics of nonisothermal reduction and carburization of WO3−NiO nano-composite powders by CO−CO2, Int. J. Chem. Kinet., 51(2019), No. 7, p. 463.

A. Saraby-Reintjes and M. Fleischmann, Kinetics of electrode-position of nickel from Watts baths, Electrochim. Acta, 29(1984), No. 4, p. 557.

B.R. Tian and Y.F. Cheng, Electrolytic deposition of Ni−Co−Al2O3 composite coating on pipe steel for corrosion/erosion resistance in oil sand slurry, Electrochim. Acta, 53(2007), No. 2, p. 511.

K. Aniołek, M. Kupka, and A. Barylski, Sliding wear resistance of oxide layers formed on a titanium surface during thermal oxidation, Wear, 356–357(2016), p. 23.

K.H. Hou, H.T. Wang, H.H. Sheu, and M.D. Ger, Preparation and wear resistance of electrodeposited Ni-W/diamond composite coatings, Appl. Surf. Sci., 308(2014), p. 372.

H. Gül, F. Kılıç, S. Aslan, A. Alp, and H. Akbulut, Characteristics of electro-co-deposited Ni−Al2O3 nano-particle reinforced metal matrix composite (MMC) coatings, Wear, 267(2009), No. 5–8, p. 976.

R.A. Shakoor, R. Kahraman, U. Waware, Y.X. Wang, and W. Gao, Properties of electrodeposited Ni−B−Al2O3 composite coatings, Mater. Des., 64(2014), p. 127.

P. Baghery, M. Farzam, A.B. Mousavi, and M. Hosseini, Ni−TiO2 nanocomposite coating with high resistance to corrosion and wear, Surf. Coat. Technol., 204(2010), No. 23, p. 3804.

R. Badrnezhad, H. Pourfarzad, A.R. Madram, and M.R. Ganjali, Study of the corrosion resistance properties of Ni−P and Ni−P−C nanocomposite coatings in 3.5 wt % NaCl solution, Russ. J. Electrochem., 55(2019), No. 4, p. 272.

A. Saadati, B.N. Khiarak, A.A. Zahraei, A. Nourbakhsh, and H. Mohammadzadeh, Electrochemical characterization of electrophoretically deposited hydroxyapatite/chitosan/graphene oxide composite coating on Mg substrate, Surf. Interfaces, 25(2021), art. No. 101290.

M.M.K. Azar, H.S. Gugtapeh, and M. Rezaei, Evaluation of corrosion protection performance of electroplated zinc and zinc-graphene oxide nanocomposite coatings in air saturated 3.5 wt. % NaCl solution, Colloids Surf. A, 601(2020), art. No. 125051.

R.Q. Li, J. Liang, Y.Y. Hou, and Q.W. Chu, Enhanced corrosion performance of Zn coating by incorporating graphene oxide electrodeposited from deep eutectic solvent, RSC Adv., 5(2015), No. 75, p. 60698.

M.Y. Rekha and C. Srivastava, Microstructure and corrosion properties of zinc-graphene oxide composite coatings, Corros. Sci., 152(2019), p. 234.

B. Szczygieł and M. Kołodziej, Corrosion resistance of Ni/Al2O3 coatings in NaCl solution, Trans. IMF, 83(2005), No. 4, p. 181.

M.R. Barbosa, J.A. Bastos, J.J. García-Jareño, and F. Vicente, Chloride role in the surface of nickel electrode, Electrochim. Acta, 44(1998), No. 6–7, p. 957.

J.O’M. Bockris and S.U.M. Khan, Surface Electrochemistry: A Molecular Level Approach, Springer Science & Business Media, New York, 1993.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

All authors declare that they have no conflicts of interest.

Supplementary Information

12613_2022_2584_MOESM1_ESM.docx

Effect of NiO–NiCr2O4 nano-oxides on the microstructural, mechanical and corrosion properties of Ni-coated carbon steel, approximately 1.42 MB.

Rights and permissions

About this article

Cite this article

Mojallal, S., Mohammadzadeh, H., Aghaeinejad-Meybodi, A. et al. Effect of NiO–NiCr2O4 nano-oxides on the microstructural, mechanical and corrosion properties of Ni-coated carbon steel. Int J Miner Metall Mater 30, 1078–1092 (2023). https://doi.org/10.1007/s12613-022-2584-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2584-3