Abstract

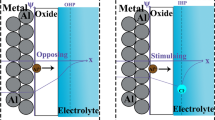

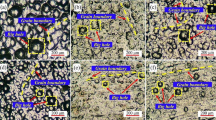

Understanding the influence of purities on the electrochemical performance of pure aluminum (Al) in alkaline media for Al—air batteries is significant. Herein, we comprehensively investigate secondary phase precipitate (SPP)-induced localized corrosion of pure Al in NaOH solution mainly based on quasi-in-situ and cross-section observations under scanning electron microscopy coupled with finite element simulation. The experimental results indicate that Al—Fe SPPs appear as clusters and are coherent with the Al substrate. In alkaline media, Al—Fe SPPs exhibit more positive potentials than the substrate, thus aggravating localized galvanic corrosion as cathodic phases. Moreover, finite element simulation indicates that the irregular geometry coupled with potential difference produces the non-uniform current density distribution inside the SPP cluster, and the current density on the Al substrate gradually decreases with distance.

Similar content being viewed by others

References

K. Huang, D.D. Peng, Z.X. Yao, et al., Cathodic plasma driven self-assembly of HEAs dendrites by pure single FCC FeCoNiMnCu nanoparticles as high efficient electrocatalysts for OER, Chem. Eng. J., 425(2021), art. No. 131533.

S.M. Han, C.H. He, Q.B. Yun, et al., Pd-based intermetallic nanocrystals: From precise synthesis to electrocatalytic applications in fuel cells, Coord. Chem. Rev., 445(2021), art. No. 214085.

S. Zhang, Q. Fan, R. **a, and T.J. Meyer, CO2 reduction: From homogeneous to heterogeneous electrocatalysis, Acc. Chem. Res., 53(2020), No. 1, p. 255.

X.D. Li, S.M. Wang, L. Li, Y.F. Sun, and Y. **e, Progress and perspective for in situ studies of CO2 reduction, J. Am. Chem. Soc., 142(2020), No. 21, p. 9567.

H.B. Yang, L. Wu, B. Jiang, et al., Discharge properties of Mg—Sn—Y alloys as anodes for Mg—air batteries, Int. J. Miner. Metall. Mater., 28(2021), No. 10, p. 1705.

S.G. Wu, S.Y. Hu, Q. Zhang, et al., Hybrid high-concentration electrolyte significantly strengthens the practicability of alkaline aluminum—air battery, Energy Storage Mater., 31(2020), p. 310.

S.G. Wu, Q. Zhang, D. Sun, et al., Understanding the synergistic effect of alkyl polyglucoside and potassium stannate as advanced hybrid corrosion inhibitor for alkaline aluminum—air battery, Chem. Eng. J., 383(2020), art. No. 123162.

Y.S. Liu, L.S. Yang, B. **e, et al., Ultrathin Co3O4 nanosheet clusters anchored on nitrogen doped carbon nanotubes/3D graphene as binder-free cathodes for Al—air battery, Chem. Eng. J., 381(2020), art. No. 122681.

S.J. Liu, X.H. Wan, Y. Sun, et al., Cobalt-based multicomponent nanoparticles supported on N-doped graphene as advanced cathodic catalyst for zinc—air batteries, Int. J. Miner. Metall. Mater., 29(2022), No. 12, p. 2212.

G.S. Peng, J. Huang, Y.C. Gu, and G.S. Song, Self-corrosion, electrochemical and discharge behavior of commercial purity Al anode via Mn modification in Al—air battery, Rare Met., 40(2021), No. 12, p. 3501.

R. Mori, Recent developments for aluminum—air batteries, Electrochem. Energy Rev., 3(2020), No. 2, p. 344.

R. Buckingham, T. Asset, and P. Atanassov, Aluminum—air batteries: A review of alloys, electrolytes and design, J. Power Sources, 498(2021), art. No. 229762.

Q.F. Li and N.J. Bjerrum, Aluminum as anode for energy storage and conversion: A review, J. Power Sources, 110(2002), No. 1, p. 1.

M.L. Doche, F. Novel-Cattin, R. Durand, and J.J. Rameau, Characterization of different grades of aluminum anodes for aluminum/air batteries, J. Power Sources, 65(1997), No. 1–2, p. 197.

M.L. Doche, J.J. Rameau, R. Durand, and F. Novel-Cattin, Electrochemical behaviour of aluminium in concentrated NaOH solutions, Corros. Sci., 41(1999), No. 4, p. 805.

Y.J. Cho, I.J. Park, H.J. Lee, and J.G. Kim, Aluminum anode for aluminum—air battery—Part I: Influence of aluminum purity, J. Power Sources, 277(2015), p. 370.

Z.X. Yu, S.X. Hao, and Q.S. Fu, Electrochemical behaviors of different grades of pure aluminum in alkaline solution, Adv. Mater. Res., 652–654(2013), p. 853.

Y.R. Liu, Q.L. Pan, H. Li, Z.Q. Huang, J. Ye, and M.J. Li, Revealing the evolution of microstructure, mechanical property and corrosion behavior of 7A46 aluminum alloy with different ageing treatment, J. Alloys Compd., 792(2019), p. 32.

P. **e, S.Y. Chen, K.H. Chen, et al., Enhancing the stress corrosion cracking resistance of a low-Cu containing Al—Zn—Mg—Cu aluminum alloy by step-quench and aging heat treatment, Corros. Sci., 161(2019), art. No. 108184.

S.Q. Liu, X. Wang, Y.R. Tao, X. Han, and C.X. Cui, Enhanced corrosion resistance of 5083 aluminum alloy by refining with nano-CeB6/Al inoculant, Appl. Surf. Sci., 484(2019), p. 403.

W.J. Liang, Q.L. Pan, Y.B. He, Y.C. Li, Y.C. Zhou, and C.G. Lu, Effect of aging on the mechanical properties and corrosion susceptibility of an Al—Cu—Li—Zr alloy containing Sc, Rare Met., 27(2008), No. 2, p. 146.

S.S. Singh, J.J. Williams, T.J. Stannard, X.H. **ao, F.D. Carlo, and N. Chawla, Measurement of localized corrosion rates at inclusion particles in AA7075 by in situ three dimensional (3D) X-ray synchrotron tomography, Corros. Sci., 104(2016), p. 330.

A. Chemin, D. Marques, L. Bisanha, A.D.J. Motheo, W.W. Bose Filho, and C.O.F. Ruchert, Influence of Al7Cu2Fe intermetallic particles on the localized corrosion of high strength aluminum alloys, Mater. Des., 53(2014), p. 118.

A.C. Vieira, A.M. Pinto, L.A. Rocha, and S. Mischler, Effect of Al2Cu precipitates size and mass transport on the polarisation behaviour of age-hardened Al—Si—Cu—Mg alloys in 0.05 M NaCl, Electrochim. Acta, 56(2011), No. 11, p. 3821.

H.W. Shi, Z.H. Tian, T.H. Hu, et al., Simulating corrosion of Al2CuMg phase by measuring ionic currents, chloride concentration and pH, Corros. Sci., 88(2014), p. 178.

H.W. Shi, E.H. Han, F.C. Liu, T. Wei, Z.W. Zhu, and D.K. Xu, Study of corrosion inhibition of coupled Al2Cu—Al and Al3Fe—Al by cerium cinnamate using scanning vibrating electrode technique and scanning ion-selective electrode technique, Corros. Sci., 98(2015), p. 150.

A. Kosari, F. Tichelaar, P. Visser, H. Zandbergen, H. Terryn, and J.M.C. Mol, Dealloying-driven local corrosion by intermetallic constituent particles and dispersoids in aerospace aluminium alloys, Corros. Sci., 177(2020), art. No. 108947.

S.S. Wang, I.W. Huang, L. Yang, et al., Effect of Cu content and aging conditions on pitting corrosion damage of 7xxx series aluminum alloys, J. Electrochem. Soc., 162(2015), No. 4, p. C150.

Y.K. Zhu, K. Sun, and G.S. Frankel, Intermetallic phases in aluminum alloys and their roles in localized corrosion, J. Electrochem. Soc., 165(2018), No. 11, p. C807.

G.S. Peng, J. Huang, Y.C. Gu, and G.S. Song, The discharge and corrosion behavior of Al anodes with different purity in alkaline solution, Int. J. Electrochem. Sci., 15(2020), p. 6892.

K. Törne, A. Örnberg, and J. Weissenrieder, Influence of strain on the corrosion of magnesium alloys and zinc in physiological environments, Acta Biomater., 48(2017), p. 541.

R. Ly, K.T. Hartwig, and H. Castaneda, Effects of strain localization on the corrosion behavior of ultra-fine grained aluminum alloy AA6061, Corros. Sci., 139(2018), p. 47.

C. Örnek and D.L. Engelberg, SKPFM measured Volta potential correlated with strain localisation in microstructure to understand corrosion susceptibility of cold-rolled grade 2205 duplex stainless steel, Corros. Sci., 99(2015), p. 164.

S.K. Kairy, P.A. Rometsch, C.H.J. Davies, and N. Birbilis, On the electrochemical and quasi in situ corrosion response of the Q-phase (AlxCuyMgzSiw) intermetallic particle in 6xxx series aluminum alloys, Corrosion, 73(2017), No. 1, p. 87.

J.S. Wu, D.D. Peng, Y.T. He, et al., In situ formation of decavanadate-intercalated layered double hydroxide films on AA2024 and their anti-corrosive properties when combined with hybrid sol gel films, Materials (Basel), 10(2017), No. 4, art. No. 426.

X.Q. Li, L.W. Wang, L. Fan, Z.Y. Cui, and M.X. Sun, Effect of temperature and dissolved oxygen on the passivation behavior of Ti—6Al—3Nb—2Zr—1Mo alloy in artificial seawater, J. Mater. Res. Technol., 17(2022), p. 374.

Z.P. Wang, Y. Wang, B.W. Zhang, et al., Passivation behavior of 316L stainless steel in artificial seawater: Effects of pH and dissolved oxygen, Anti-Corros. Methods Mater., 68(2021), No. 2, p. 122.

M.T. Wang, L.W. Wang, K. Zhao, Y.X. Liu, and Z.Y. Cui, Understanding the passivation behavior and film chemistry of four corrosion-resistant alloys in the simulated flue gas condensates, Mater. Today Commun., 31(2022), art. No. 103567.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51901018), the Young Elite Scientists Sponsorship Program by the China Association for Science and Technology (YESS, No. 2019 QNRC001), the Fundamental Research Funds for the Central Universities, China (No. FRF-AT-20-07, 06500119), the Natural Science Foundation of Bei**g Municipality, China (No. 2212037), the National Science and Technology Resources Investigation Program of China (No. 2019FY 101400), and the Southwest Institute of Technology and Engineering Cooperation Fund, China (No. HDHDW59 02020107).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, B., Wang, H., Su, Y. et al. Secondary phase precipitate-induced localized corrosion of pure aluminum anode for aluminum—air battery. Int J Miner Metall Mater 30, 977–987 (2023). https://doi.org/10.1007/s12613-022-2533-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2533-1