Abstract

In the prediction of the end-point molten steel temperature of the ladle furnace, the influence of some factors is nonlinear. The prediction accuracy will be affected by directly inputting these nonlinear factors into the data-driven model. To solve this problem, an improved case-based reasoning model based on heat transfer calculation (CBR-HTC) was established through the nonlinear processing of these factors with software Ansys. The results showed that the CBR-HTC model improves the prediction accuracy of end-point molten steel temperature by 5.33% and 7.00% compared with the original CBR model and 6.66% and 5.33% compared with the back propagation neural network (BPNN) model in the ranges of [−3, 3] and [−7, 7], respectively. It was found that the mean absolute error (MAE) and root-mean-square error (RMSE) values of the CBR-HTC model are also lower. It was verified that the prediction accuracy of the data-driven model can be improved by combining the mechanism model with the data-driven model.

Similar content being viewed by others

References

F. He, D.F. He, H.B. Wang, A.J. Xu, and N.Y. Tian, Prediction of molten steel temperature in BOF→LF→CC route, Steelmaking, 28(2012), No. 3, p. 53.

Z.B. Gao, Study on Non-contact Temperature Measurement Technology of Molten Steel in LF Furnace [Dissertation], Anhui University, Hefei, 2020, p. 42.

M. Sugiura, T. Yamazaki, R. Nakao, T. Tanaka, S. Nagata, H. Kumazawa, E. Tsubota, and W. Nagai, Development of new technique for continuous molten steel temperature measurement, Nippon Steel Tech. Rep., 2004, No. 89, p. 23.

Y. Gao, Research on Temperature Prediction Model of Molten Steel in LF [Dissertation], Northeastern University, Shenyang, 2008, p. 34.

J.Z. Luo, C.Y. Huang, L. Qiu, Y.J. Li, G.G. Zhao, B.L. Fan, K.F. Lian, and W.P. **n, Research on temperature field of energy-saving ladle with adding lid by thermal coupling numerical simulation, Iron Steel Vanadium Titanium, 38(2017), No. 2, p. 98.

G.F. Li, J. Liu, G.Z. Jiang, and H.H. Liu, Numerical simulation of temperature field and thermal stress field in the new type of ladle with the nanometer adiabatic material, Adv. Mech. Eng., 7(2015), No. 4, p. 30.

P. Samuelsson and B. Sohlberg, ODE-based modeling and calibration of temperatures in steelmaking ladles, IEEE Trans. Contr. Sys. Technol., 18(2010), No. 2, p. 474.

S.X. Tian, G.Z. Gao, and D.F. Li, Research on reducing heat loss of ladle, Refractories, 50(2016), No. 1, p. 51.

A. Tripathi, J.K. Saha, J.B. Singh, and S. Ajmani, Numerical simulation of heat transfer phenomenon in steel making ladle, ISIJ Int., 52(2012), No. 9, p. 1591.

O. Davila, L. Garcia-Demedices, and R.D. Morales, Mathematical simulation of fluid dynamics during steel draining operations from a ladle, Metall. Mater. Trans. B, 37(2006), No. 1, p. 71.

H.L. Zhao, X. Zhao, L.Z. Mu, L.F. Zhang, and L.Q. Yang, Gas-liquid mass transfer and flow phenomena in a peirce-smith converter: a numerical model study, Int. J. Miner. Metall. Mater., 26(2019), No. 9, p. 1092.

B. Ni, T. Zhang, H.Q. Ni, and Z.G. Luo, Mechanism and simulation of droplet coalescence in molten steel, Int. J. Miner. Metall. Mater., 24(2017), No. 11, p. 1251.

S. Sonoda, N. Murata, H. Hino, H. Kitada, and M. Kano, A statistical model for predicting the liquid steel temperature in ladle and tundish by bootstrap filter, ISIJ Int., 52(2012), No. 6, p. 1086.

Q.D. Yang, J. Zhang, and Z. Yi, Predicting molten steel endpoint temperature using a feature-weighted model optimized by mutual learning cuckoo search, Appl. Soft Comput., 83(2019), art. No. 105675.

X.J. Wang, Ladle furnace temperature prediction model based on large-scale data with Random Forest, IEEE J. Autom. Sin., 4(2017), No. 4, p. 770.

X.J. Wang, P. Yuan, Z.Z. Mao, and M.S. You, Molten steel temperature prediction model based on bootstrap feature subsets ensemble regression trees, Knowl.-Based Syst., 101(2016), p. 48.

C. Gao, M.G. Shen, and H.Q. Wang, End-point prediction of BOF steel making based on twin support vector regression, China Metall., 29(2019), No. 4, p. 12.

C. Gao and M.G. Shen, End-point static prediction of bof steel making based on unconstrained wavelet weighted twin support vector regression, Steelmaking, 35(2019), No. 2, p. 20.

W. Lv, Z.Z. Mao, and M.X. Jia, ELM based lf temperature prediction model and its online sequential learning, [in] 24th Chinese Control and Decision Conference, Taiyuan, 2012, p. 2362.

X.J. Wang, M.S. You, Z.Z. Mao, and P. Yuan, Tree-structure ensemble general regression neural networks applied to predict the molten steel temperature in ladle furnace, Adv. Eng. Inform., 30(2016), No. 3, p. 368.

H.X. Tian and Z.Z. Mao, An ensemble elm based on modified adaboost.rt algorithm for predicting the temperature of molten steel in ladle furnace, IEEE Trans. Autom. Sci. Eng., 7(2010), No. 1, p. 73.

X.Z. Zhang, Temperature Prediction of LandlwFurnace Based on ADABOOST Algorithm and Elmalgorithm [Dissertation], Northeastern University, Shenyang, 2015, p. 31.

K. Feng, H.B. Wang, A.J. Xu, D.F. He, and N.Y. Tian, LF endpoint temperature prediction of molten steel by gmdh neural network based on material model, Steelmaking, 29(2013), No. 2, p. 38.

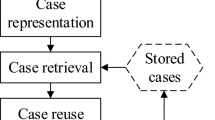

K. Feng, D.F. He, A.J. Xu, and H.B. Wang, End temperature prediction of molten steel in LF based on CBR-BBN, Steel Res. Int., 87(2016), No. 1, p. 79.

K. Feng, A.J. Xu, D.F. He, and H.B. Wang, An improved CBR model based on mechanistic model similarity for predicting end phosphorus content in dephosphorization converter, Steel Res. Int., 89(2018), No. 6, art. No. 1800063.

K. Feng, A.J. Xu, P.F. Wu, D.F. He, and H.B. Wang, Case-based reasoning model based on attribute weights optimized by genetic algorithm for predicting end temperature of molten steel in RH, J. Iron Steel Res. Int., 26(2019), No. 6, p. 585.

Y.M. Hou and C.Y. Xu, The review of case-based reasoning research, J. Yanshan Univ. Philos. Soc. Sci. Ed., 12(2011), No. 4, p. 102.

F. Yuan, Simulating Research on Temperature and Effects on Temperature Drop of Molten Steel of Turnover Ladles in Qiangang [Dissertation], University of Science and Technology Bei**g, Bei**g, 2013, p. 55.

Z.Z. Liu, Y.H. Jiang, and H.Z. Guo, Research on numerical simulation of ladle conduction in the steel-making plant, Wisco Technol., 45(2007), No. 4, p. 20.

O. Volkova and D. Janke, Modelling of temperature distribution in refractory ladle lining for steelmaking, ISIJ Int., 43(2003), No. 8, p. 1185.

J. Li, J. Fu, P. Wang, C.G. Huang, P. Zhang, and Z.C. Zhang, Effect of slag on liquid steel temperature, Res. Iron Steel, 1998, No. 6, p. 19.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51674030) and the Fundamental Research Funds for the Central Universities (Nos. FRF-TP-18-097A1 and FRF-BD-19-022A).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, F., Xu, Aj. & Gu, Mq. Development of an improved CBR model for predicting steel temperature in ladle furnace refining. Int J Miner Metall Mater 28, 1321–1331 (2021). https://doi.org/10.1007/s12613-020-2234-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2234-6