Abstract

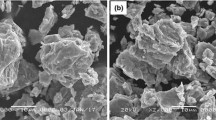

V85Ni15 (at%) alloy was proposed as a promising candidate for hydrogen separation membranes. To date, investigations of V85Ni15 alloy have concentrated on hydrogen permeation characteristics, and little work has been done on the microstructural development. In the present study, various fabrication and heat-treatment techniques were used to develop different microstructures which would then be tailored to achieve a desired candidate for acceptable mechanical stability while maintaining high hydrogen permeability. The arc-melted (AM) V85Ni15 alloy are supersaturated solid solution with dendritic segregation of Ni-solute atoms. Cold rolling (CR) followed by annealing at 1050 °C and 850 °C can produce a two-phase (V + σ) microstructure and a three-phase (V + σ + NiV3) microstructure, respectively. Very fine two-phase microstructure obtained at 1050 °C involves a simultaneous reaction of second-phase precipitation and V-matrix recrystallization. Sigma phase is formed via primary precipitation, while NiV3 phase is formed by peritectoidal reaction. When AMCR samples were homogenized at 1250 °C for 2 h and sequential heat-treated at 850 °C or 900 °C for 2 h, precipitation-strengthening microstructure is obtained: large grain structure of V-matrix with uniform distribution of second-phase particles produced by recrystallization and grain growth followed by precipitation process.

Graphic abstract

Similar content being viewed by others

References

Dolan MD. Non-Pd BCC alloy membranes for industrial hydrogen separation. J Membr Sci. 2010;362(1):12.

Jiang P, Yuan TX, **ao SJ, Li XY, Chen J, Kong DJ. Microstructure and mechanical properties of V–Ti–Ni alloy for hydrogen separation with heat treatment process. Chin J Rare Met. 2018;42(12):1260.

Wipf H. Solubility and diffusion of hydrogen in pure metals and alloys. Phys Scr. 2001;T94(1):43.

Jiang P, Song GS, Liang D, Wu WP, Hua TS. Vanadium-based alloy membranes for hydrogen purification. Rare Met Mater Eng. 2017;03:285.

Phair JW, Donelson R. Developments and design of novel (non-palladium-based) metal membranes for hydrogen separation. Ind Eng Chem Res. 2006;45(16):5657.

Nishimura C, Komaki M, Hwang S, Amano M. V–Ni alloy membranes for hydrogen purification. J. Alloys Compd. 2002;330–332(1):902.

Nishimura C, Komaki M, Amano M. Hydrogen permeation characteristics of vanadium–nickel alloys. Mater. Trans. JIM. 1991;32(5):501.

Amano M, Komaki M, Nishimura C. Hydrogen permeation characteristics of palladium-plated V–Ni alloy membranes. J. Less Common Met. 1991;172–174(91):727.

Oh JY, Ko WS, Suh JY, Lee YS, Lee BJ, Yoon WY, Shim JH. Enhanced high temperature hydrogen permeation characteristics of V–Ni alloy membranes containing a trace amount of yttrium. Scripta Mater. 2016;116(4):122.

Song G, Kellam ME, Liang D, Dolan MD. Influence of processing conditions on the microstructure and permeability of BCC V–Ni membranes. J Membr Sci. 2010;363(11):309.

Smith JF, Carlson ON, Nash PG. Phase Diagrams of Binary Vanadium Alloys. Edited by Smith JF. Cleveland: ASM International. 1989. 25.

Waterstrat RM, Dickens B. Atomic ordering in A 15-type phases in the vanadium–nickel and vanadium–cobalt systems. J Appl Phys. 1974;45(9):3726.

Stevens ER, Carlson ON. V-Ni system. Metall Mater Trans B. 1970;1(5):1267.

Saito R, Nakada N, Yabu S, Hayashi K. Effects of initial structure and reversion temperature on austenite nucleation site in pearlite and ferrite–pearlite. Metall Mater Trans A. 2018;49(10):6001.

Sun F, Gu YF, Yan JB, Xu YX, Zhong ZH, Yuyama M. Creep deformation and rupture mechanism of an advanced wrought NiFe-based superalloy for 700 °C class A-USC steam turbine rotor application. J Alloy Compd. 2016;687(6):3891.

Chen C, Chen J, Yan H, Su B, Song M, Zhu S. Dynamic precipitation, microstructure and mechanical properties of Mg–5Zn–1Mn alloy sheets prepared by high strain-rate rolling. Mater Des. 2016;100(6):58.

Lange WF, Enomoto M, Aaronson HI. Precipitate nucleation kinetics at grain boundaries. Metall Rev. 1989;34(1):125.

Dhal A, Panigrahi SK, Shunmugam MS. Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment. J Alloy Compd. 2015;649(11):229.

Siebert P, Werner M, Löffler H. Heterogeneous nucleation of precipitates in an Al–12 at% Zn alloy at dislocation loops. Phys Status Solidi. 2010;86(2):543.

Beaven PA, Butler EP. Precipitate nucleation on dislocations in Fe–N. Acta Metall. 1980;28(10):1349.

Varin RA. Effect of extrinsic grain-boundary dislocations on M23C6 precipitate nucleation in an austenitic stainless steel. J Mater Sci. 1979;14(4):811.

Mirzakhani B, Payandeh Y. Combination of sever plastic deformation and precipitation hardening processes affecting the mechanical properties in Al–Mg–Si alloy. Mater Des. 2015;68(3):127.

Malopheyev S, Kulitskiy V, Kaibyshev R. Deformation structures and strengthening mechanisms in an Al–Mg–Sc–Zr alloy. J Alloy Compd. 2017;698(3):957.

Sun W, Zhu Y, Marceau R, Wang L, Zhang Q, Gao X, Hutchinson C. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity. Science. 2019;363(6430):972.

Gong QJ, Yang M, Liang YL, Xu X, Zhang SW. Hot formability and dynamic recrystallization behavior of new high performance aluminum alloy 211Z-X. Chin J Rare Met. 2018;42(1):36.

Wang D, Gao C, Luo HY, Yang YH, Ma Y. Texture evolution behavior and anisotropy of 2A97 Al–Li alloy during recrystallization at elevated temperature. Rare Met. 2018. https://doi.org/10.1007/s12598-018-0997-y.

ASTM. Annual Book of ASTM Standards. Philadelphiap: ASTM International. 1998. 229

Jiang P, Yu YD, Song GS, Liang D, Kellam M, Dolan M. Effect of heat treatment on microstructure, hardness and rollability of V55Ti30Ni15 alloy membranes. Mater Des. 2014;63(11):136.

Jiang P, Liang D, Kellam M, Song GS, Yuan TX, Wu WP, Li XY. Effect of rolling and annealing on microstructures and mechanical properties of V–Ti–Ni alloy for hydrogen separation. J Alloy Compd. 2017;728(12):63.

Reimer L. Scanning Electron Microscopy-Physics of Image Formation and Microanalysis. Berlin: Springer. 1998. 39.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Nos. 51875002 and 51705038), China Postdoctoral Science Foundation (No. 2019M652158) and the Natural Science Foundation of Jiangsu Province of China (No. BK20150268).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, P., Shi, XB., Sun, BL. et al. Microstructural development of vanadium–nickel crystalline alloy membranes. Rare Met. 40, 1932–1939 (2021). https://doi.org/10.1007/s12598-020-01448-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01448-8