Abstract

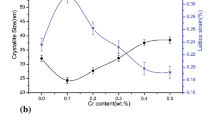

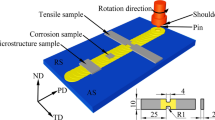

Cu–36 wt% Zn alloy is widely used in valves of water and heating and auto parts, etc. Nevertheless, the structure is still coarse, and performances are much poor. The structure and performances of Cu–36 wt% Zn alloy were investigated by adding Al2O3 nanoparticles and stirring. Results indicate that by Al2O3 nanoparticles coupling electromagnetic stirring, the Cu–36 wt% Zn alloy with refined microstructure was successfully prepared. The average grain size is refined by 99 % compared with that without nanoparticles and stirring. The tensile strength (Rm) and percentage elongation after fracture (A11.3) increase by 20.58 % and 19.40 %, respectively, compared with that without nanoparticles and stirring. Nanoparticles increase heterogeneous nucleation rate by 50 % compared with that without nanoparticles. The depth of dezincification layer decreases by 78.71 % compared with that without nanoparticles and stirring, as protective layer (Cu–Al2O3–Zn) is completely formed around the grain boundaries.

Similar content being viewed by others

References

Wang ZJ, Zhang TL. Research and development of free-cutting nonleaded brass rod. Nonferrous Met Process. 2004;33(6):10.

Kobayashi T. Strength and fracture of aluminum alloys. Mater Sci Eng. 2000;280(1):8.

Zhang AS, Xu P. Refinement and metamorphism of HPb59-1 brass by trace boron. Tech Hot Work. 2005;89(7):22.

Cao YQ. Application of high melting point elements Fe and Ni in casting brass. Foundry Tech. 2004;7:563.

Gan FX, Guo H, Yao L. Mechanism of arsenic inhibition dezincification in brass. Chin J Corros Prot. 1991;11(1):75.

Zhao HF, Dai WG, Ding JY. Effects of heat treatment on dezincification corrosion properties of C46500 brass. Shanghai Non Met. 2014;35(1):24.

Han QY, Ludtka G, Zhai QJ. Materials Processing under the Influence of External Fields. New Jersey: Wiley Press; 2007. 20.

Zi BT, Ba QX, Cui JZ, Xu GM. Study on axial changes of as- cast structures of Al alloy sample treated by the novel SPMF technique. Script Mater. 2000;43(3):377.

Yan ZM, Li XT, Cao ZQ, Zhang XL, Li TJ. Grain refinement of horizontal continuous casting of the CuNi10Fe1Mn alloy hollow billets by rotating magnetic field (RMF). Mater Lett. 2008;62(28):4389.

Ma XP, Li YJ, Yang YS. Influence of pulsed magnetic field on microstructures and macro-segregation in 2124 Al-alloy. J Mater Res. 2009;24(8):2670.

Fu Y, Park J, Wang TM, Kim J, Cao ZQ, Li TJ. Modification of solidification structure under DC pulse magnetic field. J Iron Steel Res Int. 2012;S1:226.

Chen Z, Wang T, Gao L, Fu H, Li T. Grain refinement and tensile properties improvement of aluminum foundry alloys by inoculation with Al-B master alloy. Mater Sci Eng A. 2012;553:32.

Zhu J, Wang T, Cao F, Huang W, Fu H, Chen Z. Real time observation of equiaxed growth of Sn-Pb alloy under an applied direct current by synchrotron microradiography. Mater Lett. 2012;89:137.

Brush LN, Richard N. The effect of an electric on rod-eutectic solidification in Sn–0.9 wt% Cu alloys. Mater Sci Eng A. 1997;238(1):176.

Rodriguez JM, Esteva A, Meza S. A note on the control of the solidification front in the continuous casting of copper tubes. J Mate Proc Tech. 1999;96(1–3):42.

Li XT, Zhao XW, Wei B, Chen FB, Yan ZM, Li TJ. Effect of rotating electromagnetic field on solidification structures and mechanical properties of tube billets of BFe10-1-1 alloy. Chin J Non Met. 2007;17(6):922.

Yan Z, Liu H, Li T, Zhang X, Cao Z. Effects of alternating magnetic field and casting parameters on solidification structure and mechanical properties of copper hollow billets. Mater Des. 2009;30(4):1245.

Song KX, Liu P, Tian BH. Stabilization of nano-Al2O3p/Cu composite after high temperature annealing treatment. Mater Sci Forum. 2005;475–479:993.

Chen ML, Kang L, Yang J, Yang L, Gao H. Microstructure and mechanical properties of reinforced cast aluminum bronze by modified nano-SiC powder. Foundry. 2008;57(4):330.

Flemings MC. Solidification processing. Metall Trans. 1974;5(10):2121.

Liu LZ, Ying GB, Zhu J, Lin H, Zhu CC. High-temperature compressive properties of TiC–TiB2Cu composites prepared by self-propagating high-temperature synthesis. Rare Met. 2014;33(1):95.

Kurz W, Fisher DJ. Fundamentals of Solidification. 3rd ed. Switzerland: Trans Tech Publications Ltd; 1992. 71.

Chalmers B. Principles of Solidification. New York: Wiley; 1964. 6.

Li J, Ma JH, Gao YL, Zhai QJ. Research on solidification structure refinement of pure aluminum by electric current pulse with parallel electrodes. Mater Sci Eng A. 2008;490(1–2):452.

Zhou BL. Some non-equilibrium thermo physical problems to be studied in materials processing. Mater Sci Eng A. 2000;292(2):133.

Liao X, Zhai Q, Luo J, Chen W, Gong Y. Refining mechanism of the electric current pulse on the solidification structure of pure aluminum. Acta Mater. 2007;55(9):3103.

Suda M, Iwai K, Asai S. Ultra-high-strength bainitic steels. ISIJ Int. 2005;45(11):1736.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51571160), the Fundamental Research Fund for Taizhou Science and Technology (No. 131KY02), the Public Welfare Projects of Science and Technology Department of Zhejiang Province (No. 2015C31143), and the Pivot Innovation Team of Shaanxi Electric Materials and Infiltration Technique (No. 15JS071).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, YB., Lu, YP., Wang, ZJ. et al. Microstructural refinement and performance improvement of Cu–36 wt% Zn alloy by Al2O3 nanoparticles coupling electromagnetic stirring. Rare Met. 41, 3560–3565 (2022). https://doi.org/10.1007/s12598-016-0723-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0723-6