Abstract

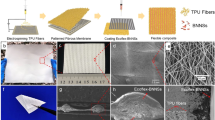

Recently, the development of material technology for application to wearable devices has been promoted. In particular, as core technologies for e-skin, Internet of Things, and AI robots, studies on flexible circuits required for connection and operation between devices are attracting attention. In this study, an epoxy-based flexible electrical conductor (EFEC) that can be applied to flexible circuits was developed. It was made by mixing a 2-µm Ag flake, epoxy resin, epoxy hardener, and IPA at a ratio of 50:10:5:5. Flexibility can be achieved by adjusting the ratio of the epoxy base and hardener. IPA, a volatile solvent, was added to lower the viscosity of the epoxy, and Ag flakes were added to increase the electrical conductivity. It was dispersed with a sonicator and magnetic stirrer for overall resistance uniformity. A specific resistance of \(2.85 \times 10^{ - 3} \,\Omega \,{\text{cm}}\) was measured. Through scanning electron microscopy and energy-dispersive X-ray spectra analyses, the cause of the low resistance was identified. In addition, 100% strain was achieved in all cases through the tensile test and resistance deviation results. Among them, the lowest resistance deviation was confirmed in CASE 4. Although the specific resistance of the EFEC was approximately 10 times higher than those of electrically conductive adhesives (ECAs) (\(3.6 \times 10^{ - 4} \,\Omega \,{\text{cm}}\)), it could efficiently be used as a conducting material. ECAs become brittle after hardening. However, we observed that the EFEC exhibited flexibility and that hardening did not proceed even after an extended period. Therefore, the applicability of the EFEC’s flexible circuit was confirmed by securing high electrical conductivity and flexibility.

Similar content being viewed by others

References

Choi, J. Y., Park, D. W., & Oh, T. S. (2014). Variation of elastic stiffness of polydimethylsiloxane (PDMS) stretchable substrates for wearable packaging applications. Journal of the Microelectronics and Packaging Society, 21(4), 125–131.

Choi, J. Y., & Oh, T. S. (2013). Flip chip process on CNT-Ag composite pads for stretchable electronic packaging. Journal of the Microelectronics and Packaging Society, 20(4), 17–23.

Ahn, J. H., Lee, H., & Choa, S. H. (2013). Technology of flexible semiconductor/memory device. Journal of the Microelectronics and Packaging Society, 20(2), 1–9.

**ao, J., Carlson, A., Liu, Z. J., Huang, Y., Jiang, H., & Rogers, J. A. (2008). Stretchable and compressible thin films of stiff materials on compliant wavy substrates. Applied Physics Letters, 93(1), 013109.

Yun, T. G., Park, M., Kim, D. H., Kim, D., Cheong, J. Y., Bae, J. G., Han, S. M., & Kim, I.-D. (2019). All-transparent stretchable electrochromic supercapacitor wearable patch device. ACS Nano, 13(3), 3141–3150.

Rogers, J. A., Someya, T., & Huang, Y. (2010). Materials and mechanics for stretchable electronics. Science, 327(5973), 1603–1607.

Sung, K. S., & Kim, N. (2019). Comparative performances of electrically conductive adhesives by incorporation of silver, silver-coated copper, and graphene. Polymer, 43(5), 728–734.

Oh, D.-H., Lim, D. J., Lee, J. E., Park, Y. H., & Oh, S. M. (2014). Electrical properties of conductive nickel powder-epoxy resin composites. Journal of the Korean Applied Science and Technology, 31(2), 329–336.

Nam, H. J., Lim, J. Y., Lee, C. H., & Park, S. H. (2020). Development of epoxy-based stretchable conductive adhesive. Journal of the Microelectronics and Packaging Society, 27(3), 49–54.

A. S. T. M. Standard. (2010). D638-10, 2010. Standard test methods for tensile properties of plastics. ASTM International.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No.2021R1A4A1033141) and (No.2021R1F1A1064238), and Korea Evaluation Institute of Industrial Technology (KEIT) grant funded by the Korea government (MOTIE) (No.20015926) and (No.20022438), and the BK21 Four program through the National Research Foundation (NRF) funded by the Ministry of Education of Korea (No. 2020142354).

Author information

Authors and Affiliations

Contributions

All authors have contributed to this study. The experiments were conducted by GL, JJ, and SH. Data analysis and result considerations were performed by GL, S-WH, IL, and JC. The first draft of the manuscript was written by GL, and all authors commented on previous versions of the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, G., Jeon, J., Han, S. et al. Development of Epoxy-Based Flexible Electrical Conductor. Int. J. Precis. Eng. Manuf. 24, 1033–1039 (2023). https://doi.org/10.1007/s12541-023-00800-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00800-z