Abstract

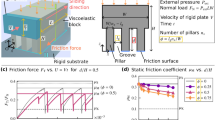

In this study, friction noise according to whether grooves exist was measured using a reciprocating sliding device, and the relationship between the groove and friction noise mechanism was investigated. Experimental results revealed that both non-groove textured and groove textured surfaces produced friction noise at approximately 5 kHz. However, the friction noise onset time was relatively faster and the sound pressure level was higher for the non groove textured surface. The tribo-surfaces of the plate and ball which change in time for the non-groove textured and groove textured surfaces were observed using a microscope. For the non-groove textured surface, adhesive wear was commonly observed on the tribo-surface, and for the groove textured surface, wear particles accumulated within the groove due to the movement of the ball, and adhesive wear appeared more slowly. As a result, the friction coefficient was relatively larger for the non-groove textured surface, facilitating the mode coupling instability. Using the pin-on-disk system, the propensity for the negative friction-velocity slope was also measured with regard to the non-groove textured surface.

Similar content being viewed by others

References

Chen, G. X., Zhou, Z. R., Kapsa, P., and Vincent, L., “Effect of Surface Topography on Formation of Squeal Under Reciprocating Sliding,” Wear, Vol. 253, No. 3, pp. 411–423, 2002.

Chen, G. X., Zhou, Z. R., Kapsa, P., and Vincent, L., “Experimental Investigation into Squeal Under Reciprocating Sliding,” Tribology International, Vol. 36, No. 12, pp. 961–971, 2003.

Jibiki, T., Shima, M., Akita, H., and Tamura, M., “A Basic Study of Friction Noise Caused by Fretting,” Wear, Vol. 251, No. 1, pp. 1492–1503, 2001.

Yuan, S., Huang, W., and Wang, X., “Orientation Effects of Micro-Grooves on Sliding Surfaces,” Tribology International, Vol. 44, No. 9, pp. 1047–1054, 2011.

Mo, J. L., Wang, Z. G., Chen, G. X., Shao, T. M., Zhu, M. H., and Zhou, Z. R., “The Effect of Groove-Textured Surface on Friction and Wear and Friction-Induced Vibration and Noise,” Wear, Vol. 301, Nos. 1-2, pp. 671–681, 2013.

Saeidi, F., Meylan, B., Hoffmann, P., and Wasmer, K., “Effect of Surface Texturing on Cast Iron Reciprocating Against Steel Under Starved Lubrication Conditions: A Parametric Study,” Wear, Vol. 348, pp. 17–26, 2016.

Zhang, H., Hua, M., Dong, G.-n., Zhang, D.-y., and Chin, K.-S., “A Mixed Lubrication Model for Studying Tribological Behaviors of Surface Texturing,” Tribology International, Vol. 93, Part B, pp. 583–592, 2016.

Wang, D. W., Mo, J. L., Wang, Z. G., Chen, G. X., Ouyang, H., and Zhou, Z. R., “Numerical Study of Friction-Induced Vibration and Noise on Groove-Textured Surface,” Tribology International, Vol. 64, pp. 1–7, 2013.

Wang, D. W., Mo, J. L., Ouyang, H., Chen, G. X., Zhu, M. H., and Zhou, Z. R., “Experimental and Numerical Studies of Friction-Induced Vibration and Noise and the Effects of Groove-Textured Surfaces,” Mechanical Systems and Signal Processing, Vol. 46, No. 2, pp. 191–208, 2014.

He, B., Chen, W., and Jane Wang, Q., “Surface Texture Effect on Friction of a Microtextured Poly (Dimethylsiloxane)(PDMS),” Tribology Letters, Vol. 31, No. 3, pp. 187–197, 2008.

Wang, X., Liu, W., Zhou, F., and Zhu, D., “Preliminary Investigation of the Effect of Dimple Size on Friction in Line Contacts,” Tribology International, Vol. 42, No. 7, pp. 1118–1123, 2009.

Bergman, F., Eriksson, M., and Jacobson, S., “Influence of Disc Topography on Generation of Brake Squeal,” Wear, Vols. 225-229, Part 1, pp. 621–628, 1999.

Sherif, H., “Investigation on Effect of Surface Topography of Pad/ Disc Assembly on Squeal Generation,” Wear, Vol. 257, No. 7, pp. 687–695, 2004.

Kang, J., “Squeal Analysis of Gyroscopic Disc Brake System Based on Finite Element Method,” International Journal of Mechanical Sciences, Vol. 51, No. 4, pp. 284–294, 2009.

Kang, J., Krousgrill, C. M., and Sadeghi, F., “Analytical Formulation of Mode-Coupling Instability in Disc-Pad Coupled System,” International Journal of Mechanical Sciences, Vol. 51, No. 1, pp. 52–63, 2009.

Kang, J., Krousgrill, C. M., and Sadeghi, F., “Dynamic Instability of a Thin Circular Plate with Friction Interface and Its Application to Disc Brake Squeal,” Journal of Sound and Vibration, Vol. 316, No. 1, pp. 164–179, 2008.

Kang, J., Krousgrill, C. M., and Sadeghi, F., “Comprehensive Stability Analysis of Disc Brake Vibrations Including Gyroscopic, Negative Friction Slope and Mode-Coupling Mechanisms,” Journal of Sound and Vibration, Vol. 324, No. 1, pp. 387–407, 2009.

Ouyang, H., Mottershead, J. E., Cartmell, M. P., and Friswell, M. I., “Friction-Induced Parametric Resonances in Discs: Effect of a Negative Friction-Velocity Relationship,” Journal of Sound and Vibration, Vol. 209, No. 2, pp. 251–264, 1998.

Straffelini, G., “A Simplified Approach to the Adhesive Theory of Friction,” Wear, Vol. 249, Nos. 1-2, pp. 78–84, 2001.

Stachowiak, G. P., Stachowiak, G. W., and Podsiadlo, P., “Automated Classification of Wear Particles Based on their Surface Texture and Shape Features,” Tribology International, Vol. 41, No. 1, pp. 34–43, 2008.

Rusli, M. and Okuma, M., “Effect of Surface Topography on Mode-Coupling Model of Dry Contact Sliding Systems,” Journal of Sound and Vibration, Vol. 308, No. 3, pp. 721–734, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nam, JH., Do, HC. & Kang, JY. Effect of groove surface on friction noise and its mechanism. Int. J. Precis. Eng. Manuf. 18, 1165–1172 (2017). https://doi.org/10.1007/s12541-017-0136-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0136-y