Abstract

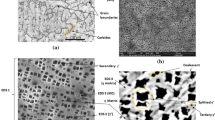

CM247LC, a Ni-based superalloy, is employed in the high-temperature components of gas turbines, such as the blades. However, the welds of CM247LC are highly susceptible to various types of cracking, thereby limiting the applicability of this superalloy. To overcome this critical limitation, in this paper, we propose a novel Varestraint test procedure for evaluating the susceptibility of oscillated CM247LC welds to solidification cracking. By visualizing the temperature in real time during testing, we quantitatively evaluate changes in the susceptibility of CM247LC to solidification cracking owing to arc oscillation. The solidification cracking temperature range (SCTR) for the CM247LC alloy is 400 K in the case of linear welding, whereas it is 275 and 475 K in the case of oscillation welding at frequencies of 0.6 and 1.2 Hz, respectively. Notably, the SCTR narrows or widens depending on the oscillation conditions. By contrast, almost no changes in the mushy zone range are theoretically calculated via the diffusion-controlled Scheil equation. This result suggests that the SCTR must be closely examined according to the oscillation conditions in the welding-based manufacturing of gas turbine blades from CM247LC. The mechanism underlying the reduction in the SCTR under oscillation welding (0.6 Hz) is clarified based on the relationship between the solidification microstructure in the crack path and propagation behavior of the solidification crack. This mechanism is also explained by the equiaxed dendritic subgrain structure, the formation of which is attributed to the lower ratio between the obtained temperature gradient (G) and the sonification rate (R), i.e., G/R (47.26 K∙s/mm2) of the oscillated welds compared with those of the linear welds (146.34 K∙s/mm2), which enhances the crack propagation resistance. Furthermore, solidification grain refinement, which also could have enhanced the solidification crack propagation resistance, is detected.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- SCTR:

-

Solidification cracking temperature range

- GTAW:

-

Gas tungsten arc welding

- IPF:

-

Inverse pole figure

- IQ:

-

Image quality

- CRS:

-

Critical strain rate

- G:

-

Temperature gradient

- R:

-

Sonification rate

- EBDS:

-

Electron backscatter diffraction

- SEM:

-

Scanning electron microscope

- EPMA:

-

Electron probe microanalysis

- OM:

-

Optical microscopy

References

E.J. Chun, Y.S. Jeong, K.M. Kim, H. Lee, S.M. Seo, J. Adv. Join. Proc. 4, 100069 (2021). https://doi.org/10.1016/j.jajp.2021.100069

S. Griffiths, H. Ghasemi Tabasi, T. Ivas, X. Maeder, A. De Luca, K. Zweiacker, R. Wróbel, J. Jhabvala, R.E. Logé, C. Leinenbach, Addit. Manuf. 36, 101443 (2020). https://doi.org/10.1016/j.addma.2020.101443

K.B. Na, C.I. Lee, J.H. Park, S.M. Cho, J. Weld. Join. 37(4), 357 (2019). https://doi.org/10.5781/JWJ.2019.37.4.10

C.H. Lee, Met. Mater. Int. 2, 81 (1996). https://doi.org/10.1007/BF03025950

G. Bidron, A. Doghri, T. Malot, F. Fournier-dit-Chabert, M. Thomas, P. Peyre, J. Mater. Process. Tech. 277, 116461 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116461

K.-T. Hsu, H.-S. Wang, H.-G. Chen, P.-C. Chen, Metals 6, 238 (2016). https://doi.org/10.3390/met6100238

S. Griffiths, H. Ghasemi-Tabasi, A. De Luca, J. Pado, S.S. Joglekar, J. Jhabvala, R.E. Logé, C. Leinenbach, Mater. Charact. 171, 110815 (2021). https://doi.org/10.1016/j.matchar.2020.110815

M. Gerstgrasser, M. Cloots, J. Stirnimann, K. Wegener, J. Mater. Process. Tech. 289, 116948 (2021). https://doi.org/10.1016/j.jmatprotec.2020.116948

J.H. Boswell, D. Clark, W. Li, M.M. Attallah, Mater. Design 174, 107793 (2019). https://doi.org/10.1016/j.matdes.2019.107793

S. Kim, C.-K. Chun, J. Weld. Join. 38(4), 359 (2020). https://doi.org/10.5781/JWJ.2020.38.4.4

S.-Y. Park, Y. Kang, D. Oh, S. Song, H.-U. Hong, J. Weld. Join. 39(1), 45 (2021). https://doi.org/10.5781/JWJ.2021.39.1.5

S. Lee, J. Kim, J. Choe, S.-W. Kim, J.-K. Hong, Y.S. Choi, Met. Mater. Int. 27, 78 (2021). https://doi.org/10.1007/s12540-020-00770-1

J.C. Lippold, in Welding Metallurgy and Weldability, 1st edn. (Wiley, Hoboken, 2015), pp. 84–119

J.N. Dupont, J.C. Lippold, S.D. Kiser, in Welding Metallurgy and Weldability of Nickel-Base Alloys, 1st edn. (Wiley, Hoboken, 2009), pp. 100–117

S. Kou, in Welding Metallurgy, 2nd edn. (Wiley, Hoboken, 2003), pp. 263–300

S. Kou, Acta Mater. 88, 366 (2015). https://doi.org/10.1016/j.actamat.2015.01.034

E.-J. Chun, K. Nishimoto, K. Saida, Weld. World 60, 217 (2016). https://doi.org/10.1007/s40194-016-0293-0

J.H. Lee, S. Yamashita, T. Ogura, K. Saida, Mater. Today Commun. 24, 101094 (2020). https://doi.org/10.1016/j.mtcomm.2020.101094

S. Yamashita, K. Saida, Weld. Int. 34, 405 (2020). https://doi.org/10.1080/09507116.2021.1922002

T. Yuan, Z. Luo, S. Kou, Acta Mater. 116, 166 (2016). https://doi.org/10.1016/j.actamat.2016.06.036

Y.C. Lim, X. Yu, J.H. Cho, J. Sosa, D.F. Farson, S.S. Babu, S. McCracken, B. Flesner, Sci. Technol. Weld. Join. 15, 583 (2010). https://doi.org/10.1179/136217110X12720264008277

Y.C. Lim, X. Yu, J.H. Cho, J. Sosa, D.F. Farson, S.S. Babu, S. McCracken, B. Flesner, Sci. Technol. Weld. Join. 15, 400 (2010). https://doi.org/10.1179/136217110X12720264008231

X. Wang, Z. Zhang, Q. Zhang, Q. Sun, Z. Wang, Opt. Laser Technol. 143, 107387 (2021). https://doi.org/10.1016/j.optlastec.2021.107387

X. Zhou, H. Zhao, F. Liu, B. Yang, B. Xu, B. Chen, C. Tan, Opt. Laser Technol. 144, 107389 (2021). https://doi.org/10.1016/j.optlastec.2021.107389

B.-H. Kim, N.-H. Kang, Y.-H. Park, Y.-N. Ahn, C.-H. Kim, J.-H. Kim, J. Weld. Join. 27(4), 49 (2009). https://doi.org/10.5781/KWJS.2009.27.4.049

S.K. Dinda, J. Kar, S. Jana, G.G. Gopal Roy, P. Srirangam, J. Mater. Process. Tech. 265, 191 (2019). https://doi.org/10.1016/j.jmatprotec.2018.10.026

J. Kar, D. Chakrabarti, S.K. Roy, G.G. Roy, J. Mater. Process. Tech. 266, 165 (2019). https://doi.org/10.1016/j.jmatprotec.2018.10.040

C. Chen, D. Wanyong Wang, Y. Li, Y. Cai, K. Zhang, J. Manuf. Proc. 57, 798 (2020). https://doi.org/10.1016/j.jmapro.2020.07.048

Y. Meng, Y. Lu, Z. Li, S. Zhao, M. Gao, Intermetallics 133, 107175 (2021). https://doi.org/10.1016/j.intermet.2021.107175

S. Kou, Y. Le, Metall. Trans. A 16, 1345 (1985). https://doi.org/10.1007/BF02670338

X. Yu, Y.C. Lim, R. Smith, S.S. Babu, D.F. Farson, J.C. Lippold, S. McCracken, Mater. Sci. Technol. 30, 930 (2014). https://doi.org/10.1179/1743284713Y.0000000358

C. Kim, M. Kang, N. Kang, Sci. Technol. Weld. Join. 18, 57 (2013). https://doi.org/10.1179/1362171812Y.0000000073

M. Kang, H.N. Han, Cheolhee Kim. Materials 11, 648 (2018). https://doi.org/10.3390/ma11040648

T. Sun, P. Franciosa, F. Conghui Liu, D.C. Pierro, Appl. Sci. 11, 4522 (2021). https://doi.org/10.3390/app11104522

T. Kannengiesser, T. Boellinghaus, Weld. World 58, 397 (2014). https://doi.org/10.1007/s40194-014-0126-y

J.S. Lee, J.H. Gu, H.M. Jung, E.H. Kim, Y.G. Jung, J.H. Lee, Mater. Today Proc. 1, 3 (2014). https://doi.org/10.1016/j.matpr.2014.09.002

T. Campanella, C. Charbon, M. Rappaz, Metall. Mater. Trans. A 35, 3201 (2004). https://doi.org/10.1007/s11661-004-0064-1

M. Asta, C. Beckermann, A. Karma, W. Kurz, R. Napolitano, M. Plapp, G. Purdy, M. Rappaz, R. Trivedi, Acta Mater. 57, 941 (2009). https://doi.org/10.1016/j.actamat.2008.10.020

A. Kumar, P. Dutta, J. Phys. D: Appl. Phys. 41, 155501 (2008). https://doi.org/10.1088/0022-3727/41/15/155501

Funding

This work was supported by the Ministry of Trade, Industry, and Energy of the Republic of Korea [Grant Number: 20011103].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, KM., Lee, U., Lee, H. et al. Quantifying Susceptibility to Solidification Cracking in Oscillated CM247LC Superalloy Welds via Varestraint Testing. Met. Mater. Int. 29, 777–794 (2023). https://doi.org/10.1007/s12540-022-01250-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01250-4