Abstract

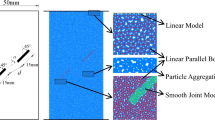

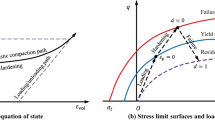

In this paper, the dynamic fracture characteristics and mechanism of the medium with compound defect under blast loading are studied by varying the relative positions of the void and pre-crack in the compound defect. A transmission caustics experimental system was used, while polymethyl methacrylate (PMMA) was selected as the experimental material. The void and crack were integrated into the same defect form, defined as a compound defect. The experimental results indicate that the end of the pre-crack is the weakest point of the defect, while the cracks are more likely to appear in the stress concentration area. By combining the interaction mechanism between the explosion stress wave and the end of the pre-crack, two modes of action for the medium containing compound defect under the blast loading were identified. One is that the stress wave directly acts at the end of the pre-crack, and the other is that the stress wave acts at the end of the pre-crack after circling around the void. As the relative positions of the void and the pre-crack change, the two forms of initiation and non-initiation were observed at the end of the pre-crack. The difficulty of initiating cracks at the end of prefabricated cracks is constantly changing which is indicated by the differences in crack tip initiation time and the stress intensity factor (the peak stress intensity factor when the crack had not initiated). At the same time, combined with the LS-DYNA finite element numerical simulation, the JH-2 material damage model is used to reproduce the dynamic damage evolution process of the composite defect, and the experimental results of the model are highly restored. The pressure values of the end element of the pre-crack under different defect structures are extracted from the numerical simulation results, and the possible reasons for the defect initiation in the composite are explained from the numerical simulation perspective. In future research, the JH-2 damage model can be widely used to solve issues pertaining to brittle materials such as PMMA. In practical blasting design processes, the relative position of the blasthole and compound defect should be considered as the basis of blasting parameter design.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Ayatollahi MR, Torabi AR (2010) Investigation of mixed mode brittle fracture in rounded-tip V-notched components. Eng Fract Mech 77(16):3087–3104

Ayatollahi MR, Torabi AR, Firoozabadi M (2015) Theoretical and experimental investigation of brittle fracture in V-notched PMMA specimens under compressive loading. Eng Fract Mech 135:187–205

Baranowskia P, Kucewicza M, Gieletaa R, Stankiewicza M, Konarzewskia M, Bogusza P, Pytlikb M, Małachowskia J (2020) Fracture and fragmentation of dolomite rock using the JH-2 constitutive model: parameter determination, experiments and simulations. Int J Impact Eng 140:103543

Bendezu M, Romanel C, Roehl D (2017) Finite element analysis of blast-induced fracture propagation in hard rocks-ScienceDirect. Comput Struct 182(Apr.):1–13

Berto F, Elices M, Lazzarin P, Zappalorto M (2013) Fracture behaviour of notched round bars made of PMMA subjected to torsion at room temperature. Eng Fract Mech 102:271–287

Ding CX, Yang RS, **ao CL, Zhao Y, Wang Y, Chen C (2020) Influence of the notch curvature on the impact fracture of the three-point bending beam-ScienceDirect. Eng Fract Mech 241(1):107419

Freund LB (1974) Crack propagation in an elastic solid subjected to general loading-IV. Obliquely incident stress pulse. J Mech Physics Solids 22(3):137–146

Hashemi AS, Katsabanis P (2020) The effect of stress wave interaction and delay timing on blast-induced rock damage and fragmentation. Rock Mech Rock Eng 53(3):1–20

Li M, Zhu ZM, Liu RF (2018a) Influences of holes on dynamic propagation behaviors of blasting cracks. Chin J Geotech Eng 40(12):2191–2199

Li Q, Xue YD, Yu Q (2018b) Experimental study on impact fracture of cantilever beam-column specimen with prefabricated crack. J Min Sci Technol 3(02):139–147

Li Q, Zhang SX, Wan MH, Guo Y, Xu WL, Fen DD (2019) Study on the influence of length- diameter ratio on the mechanical characteristics of cracks at the end of linear charges. J Min Sci Technol 4(02):112–119

Lin P, Tang CA, Huang KZ, Zhou W (2002) Classification and size effect of flaw and pore in brittle medium. Chin J Rock Mech Eng S2:2296–2300

Panin SV, Maruschak PO, Vlasov IV, Moiseenko DD, Berto F, Bishchak RT, Vinogradov A (2017a) The role of notch tip shape and radius on deformation mechanisms of 12Cr1MoV steel under impact loading. Part 1. Energy parameters of fracture. Fatigue Fract Eng Mater Struct 40(4):586–596

Panin SV, Maruschak PO, Vlasov IV, Moiseenko DD, Maksimov PV, Berto F, Bishchak RT, Vinogradov A (2017b) The role of notch tip shape and radius on deformation mechanisms of 12Cr1MoV steel under impact loading. Part 2. Influence of strain localization on fracture and numeric simulations. Fatigue Fract Eng Mater Struct 40(11):1838–1853

Ren F, Fang T, Cheng X (2020) Study on rock damage and failure depth under particle water-jet coupling impact. Int J Impact Eng 139(2020):103504

Rossmanith HP (1983) Rock Fracture Mechanics. Springer, Berlin

Rossmanith HP, Shukla A (1981) Dynamic photoelastic investigation of interaction of stress waves with running cracks. Exp Mech 21(11):415–422

Torabi AR, Fakoor M, Pirhadi E (2014) Fracture analysis of U-notched disc-type graphite specimens under mixed mode loading. Int J Solids Struct 51(6):1287–1298

Wan DY, Zhu ZM, Liu RF (2019) Effect of two parallel cracks on main propagating cracks under blasting. Expl Shock Waves 39(08):96–107

Xu P, Yang RS, Ju Y (2019a) Experimental study on influences of inclined weak interface on the dynamic crack propagation behavior. Chin J Geotech Eng 41(09):1645–1652

Xu P, Chen C, Guo Y, Zhu RY, Zhao ZW, Luo SL (2019b) Experimental study on crack propagation of slit charge blasting in media with vertical bedding plane. J Min Sci Technol 4(06):498–505

Yang LY, Zhang YJ, Sun JC, Liu N, Chen TL, Chen QF (2017a) The effect of offset distance on dynamic fracture behavior of PMMA with double cracks. J Min Sci Technol 2(4):330–335

Yang RS, Ding CX, Yang GL, Yang LY, Wang YB (2017b) Tests for blasting induced crack propagation characteristics of short-delay blasting. J Vibr Shock 36(24):97–101

Yang LY, Ding CX, Zheng LS, Bao SJ, Liu ZK (2018) Evolution of blasting cracks in different static compression fields. Chin J Geotech Eng 40(07):1322–1327

Yang RS, Xu P, Chen C (2019) Interaction between blast stress waves and cracks. Expl Shock Waves 39(08):30–40

Yang RS, Zhao Y, Ding CX, Zuo JJ, Liu YT, Ding LY (2021) Numerical simulations of lowering boulder yield based on delay time and double-primer initiation. Arab J Geosci 14(8):1–11

Yue ZW, Hu QW, Wang X, Zhang W (2017a) On the dynamic fracture behavior of three-point bending beam with empty hole and subjected to impact. J Exp Mech 32(04):463–471

Yue ZW, Song Y, Wang X, Li MY, Li ML (2017b) Interaction between a pre-existing crack defect with different angles and a running crack. Expl Shock Waves 37(01):162–168

Zhu ZM, Mohanty B, **e HP (2007) Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int J Rock Mech Min Sci 44(3):412–424

Funding

This research is supported by the National Natural Science Foundation of China (grant no. 51934001), China Postdoctoral Science Foundation (grant no. 2020M680354), the Fundamental Research Funds for the Central Universities (grant no. FRF-TP-20-044A1), National Natural Science Foundation of China (grant no. 52074301), China Postdoctoral Science Foundation (2021M700386), and the Project Funded by China Postdoctoral Science Foundation (no. 2020TQ0032).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Zhao, Y., Ma, X., Zuo, J. et al. Dynamic response of medium with compound defect under blast loading. Arab J Geosci 15, 902 (2022). https://doi.org/10.1007/s12517-022-10196-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-10196-1