Abstract

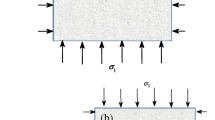

A new wing crack model subjected to hydraulic pressure and far-field stresses was proposed considering the effect of hydraulic pressure in wing crack and the connected part of the main crack on the stress intensity factor at the wing crack tip. With the equivalent crack length l eq of the wing crack introduced, the stress intensity factor K I at the wing crack tip was assumed to the sum of two terms: on one hand a component K (1)I for a single isolated straight wing crack of length 2l, and subjected to hydraulic pressure in the wing crack and far-field stresses; on the other hand a component K (2)I due to the effective shear stress induced by the presence of the equivalent main crack. The lateral tensile stress and hydraulic high pressure are the key factors that induce crack propagation unsteadily. The new wing crack theoretical model proposed can supply references for the study on hydraulic fracture in fractured masses, hydraulic fracturing in rock masses.

Similar content being viewed by others

References

Ashby M F, Hallam S D, 1986. The failure of brittle solids containing small cracks under compressive stress states. Acta Metall., 34: 497–510.

Ashby M F, Sammis, 1990. The damage mechanics of brittle solids in compression. Pageoph., 133(3): 489–518.

Baud P, Reuschle T, Charlez P, 1996. An improved wing crack model for the deformation and failure of rock in compression. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 33(5): 539–542.

Cai M, 2008. Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries: insight from numerical modeling. International Journal of Rock Mechanics & Mining Sciences, 45: 763–772.

Cai M, Kaiser P K, 2005. Assessment of excavation damaged zone using micromechanics model. Tunnell Undergr Space Tech nology, 20(4): 301–310.

Horii H, Nemat-Nasser S, 1985. Compression-induced micro-crack growth in brittle solids: axial splitting and shear failure. J. Geophys.Res., 90: 3 105–3 125.

Horri H, Nemat-Nasswer S, 1986. Brittle failure in compression: splitting, faulting and brittle-ductile transition. Phil. Trans. R. Soc. Lond, 139(A): 337–374.

Katsumi N, Hirokazu M, Hiroaki N, Noriyoshi T, 2008. Mechanical and hydraulic coupling of injection-induced slip along pre-existing fractures. Geothermics, 37: 157–172.

Lee M Y, Haimson B C, 1989. Statistical evaluation of hydraulic fracturing stress measurement parameters. Int. J. Rock Mech. Min. Sci. & Geomech. Abstr., 26: 447–56.

Luo X R, Guy V, 2002. Natural hydraulic cracking: numerical model and sensitivity study. Earth and Planetary Science Letters, 201: 431–446.

Papanastasiou P C, 1997. A coupled elastoplastic hydraulic fracturing model. Int. J. Rock Mech. & Min. Sci., 34: 3–4.

Sahouryeh E, Dyskin A V, Germanovich L N, 2002. Crack growth under biaxial compression. Eng. Fract. Mech., 69(18): 2 187–2 198.

Steif P S, 1984. Crack extension under compressive loading. Engng. Fract. Mech., 20: 463–473.

Tang L S, Zhang P C, Wang S J, 2002. Testing study on effects of chemical action of Aqueous solution on crack propagation in rock. Chinese Journal of Rock Mechanics and Engineering, 21(6): 822–827.

Wang Y H, Xu Y, Tang G H, 2000. An improved calculative model for wing crack. Chinese Journal of Geotechnical Engineering, 22(5): 612–615.

Yoshito N, 1993. Buoyancy-driven propagation of an isolated fluid-filled crack in rock: implication for fluid transport in metamorphism. Contributions to Mineralogy and Petrology, 114: 289–295.

Zhao Y L, Cao P, Wang Y X, Liu Y K, 2008a. Coupling model of seepage-damage-fracture in fractured rock masses and its application. Chinese Journal of Rock Mechanics and Engineering, 27(8): 1 634–1 643.

Zhao Y L, Cao P, Wen Y D, 2008b. Damage fracturefailure mechanism of compressive-shear rock cracks underseepage pressure. Journal of Central South University: Science and Technology, 39(4): 838–844.

Zhuang N, 2006. Propagation rule of crack rock mass and its mathematics model research under the hydraulic-stress coupling. Doctors’thesis: Tongji University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Basic Research Program of China(2007CB209400); Hunan Provincial Natural Science Foundation of China(10JJ3007)

Rights and permissions

About this article

Cite this article

Zhao, Yl., Wang, Wj. Wing crack propagation model under high hydraulic pressure in compressive-shear stress state. J Coal Sci Eng China 17, 34–38 (2011). https://doi.org/10.1007/s12404-011-0107-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12404-011-0107-3