Abstract

Nylon fabric possesses high strength, good resilience, abrasion resistance and moisture absorption which is widely used as the textile materials. However, there are some potential safety risks due to its high flammability, poor heat and light stability, and melt-drip** phenomenon during combustion. In this paper, nylon fabric was multifunctional modified by bio-based tannic acid (TA) and phytic acid (PA) to obtain flame retardancy, ultraviolet protection and antibacterial properties simultaneously. The multifunctional coating was constructed on nylon fabric using the simple finishing method. The limiting oxygen index (LOI) of treated nylon fabric significantly increased to 39%, and its drip** was completely eliminated, showing excellent flame retardancy and anti-drip** property. In order to improve the washing durability of the multifunctional coating, polyethyleneimine (PEI) was introduced to form covalent and ionic bonds with TA, PA and nylon fabric to enhance the interfacial binding strength. After four times washing, the LOI value of treated fabric was still higher than 29% showing good washing durability. The antibacterial rates of treated nylon fabric against E. coli and S. aureus were higher than 99%. And the ultraviolet protection factor (UPF) value of treated nylon fabric increased from 12.105 to 264.82, showing excellent antibacterial and ultraviolet protection properties. This research provides the experimental basis for multifunctional modification of textile fabrics by using bio-based compounds.

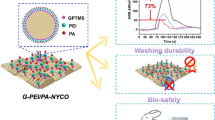

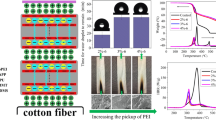

Graphical Abstract

Similar content being viewed by others

Data Availability

The data related to this research can be obtained from the corresponding author by email request.

References

B.L. Deopura, N.V. Padaki, Synthetic textile fibres: polyamide, polyester and aramid fibres, in Sinclair, R, Textiles and Fashion. (Woodhead Publishing, Cambridge, 2015), pp.97–114. https://doi.org/10.1016/B978-1-84569-931-4.00005-2

M. Tian, Z. Wang, L. Qu, K. Wang, S. Zhu, X. Zhang, R. Liu, Enhanced UV photo-stabilization of Nylon 6 filament with reduced graphene oxide/polyurethane nanocomposite inks. In. J. Cloth. Sci. Tech. 30, 817–827 (2018). https://doi.org/10.1108/IJCST-07-2017-0107

W.J. **, X.W. Cheng, W.L. He, W. Chen, J.P. Guan, Q.F. Qian, J.L. Xu, Sustainable modification of polyamide 6 fabric by Maillard reaction product for mitigating fire hazards and molten-drip**. Polym. Test.. Test. 111, 107595 (2022). https://doi.org/10.1016/j.polymertesting.2022.107595

Y.C. Chen, B. Sun, H.X. Zhang, X.D. Zhou, Synthesis and application of a sulfur-containing phosphoric amide flame retardant for nylon fabric. Fire Mater. 40, 959–972 (2016). https://doi.org/10.1002/fam.2354

C.K. Kundu, Z. Li, L. Song, Y. Hu, An overview of fire retardant treatments for synthetic textiles: from traditional approaches to recent applications. Eur. Polym. J.Polym. J. 137, 109911 (2020). https://doi.org/10.1016/j.eurpolymj.2020.109911

X. Guo, L. Liu, H. Feng, D. Li, Z. **a, R. Yang, Flame retardancy of nylon 6 fibers: a review. Polymers 15, 2161 (2023). https://doi.org/10.3390/polym15092161

M.S. Subbulakshmi, N. Kasturiya, P. Hansraj, A.K. Bajaj, Agarwal., Production of flame-retardant nylon 6 and 6.6. J. Macromol. Sci. C 40, 85–104 (2000). https://doi.org/10.1081/MC-100100580

J. Alongi, F. Carosio, G. Malucelli, Current emerging techniques to impart flame retardancy to fabrics: an overview. Polym. Degrad. Stabil. 106, 138–149 (2014). https://doi.org/10.1016/j.polymdegradstab.2013.07.012

O.Y. Wen, M.Z.M. Tohir, T.C.S. Yeaw, M.A. Razak, H.S. Zainuddin, M.R.A. Hamid, Fire-resistant and flame-retardant surface finishing of polymers and textiles: a state-of-the-art review. Prog. Org. Coat.. Org. Coat. 175, 107330 (2023). https://doi.org/10.1016/j.porgcoat.2022.107330

S.T. Lazar, T.J. Kolibaba, J.C. Grunlan, M.A. Razak, H.S. Zainuddin, M.R.A. Hamid, Flame-retardant surface treatments. Nat. Rev. Mater. 5, 259–275 (2020). https://doi.org/10.1038/s41578-019-0164-6

W. Zhang, R.C. Tang, Adsorption and flame retardant properties of potassium diphenyl sulfonate on nylon 6 fabric. React. Funct. Polym.Funct. Polym. 126, 36–43 (2017). https://doi.org/10.1016/j.react-functpolym.2018.03.005

X.Y. Li, X.Y. Gu, S. Zhang, H.F. Li, Q.L. Feng, J. Sun, Q. Zhao, Improving the fire performance of nylon 6,6 fabric by chemical grafting with acrylamide. Ind. Eng. Chem. Res. 52, 2290–2296 (2013). https://doi.org/10.1021/ie302452e

M. Wang, G.Z. Yin, Y. Yang, W. Fu, J.L.D. Palencia, J. Zhao, N. Wang, Y. Jiang, D. Wang, Bio-based flame retardants to polymers: a review. Adv. Ind. Eng. Polym. Res. 6, 132–155 (2023). https://doi.org/10.1016/j.aiepr.2022.07.003

S. Basak, A.S.M. Raja, S. Saxena, P.G. Patil, Tannin based polyphenolic bio-macromolecules: creating a new era towards sustainable flame retardancy of polymers. Polym. Degrad. Stabil. 189, 109603 (2021). https://doi.org/10.1016/j.polymdegradstab.2021.109603

L. Costes, F. Laoutid, S. Brohez, P. Dubois, Bio-based flame retardants: when nature meets fire protection. Mat. Sci. Eng. R 117, 1–25 (2017). https://doi.org/10.1016/j.mser.2017.04.001

X.H. Liu, H.L. Liu, Y.C. Fang, High-efficiency and durable flame retardant cotton fabric with good physical and mechanical properties by Layer-by-Layer assembly polyethylenimine/phytic acid coating. J. Nat. Fibers. 19, 11790–11801 (2022). https://doi.org/10.1080/15440478.2022.2044428

Y.C. Fang, W.H. Sun, H.L. Liu, X.H. Liu, Construction of eco-friendly flame retardant and drip**-resistant coating on polyester fabrics. Surf. Eng. 37, 1067–1073 (2021). https://doi.org/10.1080/02670844.2021.1911458

C.K. Kundu, W. Wang, S. Zhou, X. Wang, H. Sheng, Y. Pan, L. Song, Y. Hu, A green approach to constructing multilayered nanocoating for flame retardant treatment of polyamide 66 fabric from chitosan and sodium alginate. Carbohyd. Polym.. Polym. 166, 131–138 (2017). https://doi.org/10.1016/j.carbpol.2017.02.084

C.K. Kundu, X. Wang, Y. Hou, Y. Hu, Construction of flame retardant coating on polyamide 6.6 via UV grafting of phosphorylated chitosan and sol-gel process of organo-silane. Carbohyd. Polym.. Polym. 181, 833–840 (2018). https://doi.org/10.1016/j.carbpol.2017.11.069

Z.Y. **a, W. Kiratitanavit, P. Facendola, S.R. Yu, J. Kumar, R. Mosurkal, R. Nagarajan, A bio-derived char forming flame retardant additive for nylon 6 based on crosslinked tannic acid. Thermochim. Acta. Acta 693, 178750 (2020). https://doi.org/10.1016/j.tca.2020.178750

X. Wang, G. Yang, H. Guo, Tannic acid as biobased flame retardants: a review. J. Anal. Appl. Pyrol.Pyrol. 174, 106111 (2023). https://doi.org/10.1016/j.jaap.2023.106111

S. Kulkarni, Z.Y. **a, S. Yu, W. Kiratitanavit, A.B. Morgan, J. Kumar, R. Mosurkal, R. Nagarajan, Bio-based flame-retardant coatings based on the synergistic combination of tannic acid and phytic acid for nylon-cotton blends. ACS Appl. Mater. Inter. 51, 61620–61628 (2021). https://doi.org/10.1021/acsami.1c16474

S. Qiu, J. Sun, H. Li, X. Sun, B. Fei, S. Zhang, A green way to simultaneously enhance the mechanical, flame retardant and anti-ultraviolet aging properties of polylactide composites by the incorporation of tannic acid derivatives. Polym. Degrad. Stabil. 196, 109831 (2022). https://doi.org/10.1016/j.polymdegradstab.2022.109831

Y. Yin, Z. Huang, P. Wang, Z. Zhu, J. Xu, S. Chen, H. Wang, The use of copper ions and tannic acid to enhance the UV protection of cotton fabrics. J. Nat. Fibers 19, 3492–3501 (2022). https://doi.org/10.1080/15440478.2020.1848708

W. Zhang, Z.Y. Yang, R.C. Tang, J.P. Guan, Y.F. Qiao, Application of tannic acid and ferrous ion complex as eco-friendly flame retardant and antibacterial agents for silk. J. Cleaner Prod. 250, 119545 (2020). https://doi.org/10.1016/j.jclepro.2019.119545

W. Zhang, Z.Y. Yang, X.W. Cheng, R.C. Tang, Y.F. Qiao, Adsorption, antibacterial and antioxidant properties of tannic acid on silk fiber. Polymers 11, 970 (2019). https://doi.org/10.3390/polym11060970

X.L. Luo, Y.N. Ma, H. Chen, L. Liu, Z.Q. Hu, Z.Y. Li, J.M. Yao, Highly fireproof, antimicrobial and UV-resistant cotton fabric functionalized with biomass tannic acid and phytic acid. J. Mater. Sci. 57, 14528–14542 (2022). https://doi.org/10.1007/s10853-022-07536-7

X. Zhou, Y.K. Yin, Z.Y. Huang, L. Fu, L.X. Wang, S.H. Chen, H. Wang, Chemical reaction intumescent flame retardant cotton fabric with flame retardancy and UV resistance prepared from phytic acid, tannic acid and diethylenetriamine. Int. J. Cloth. Sci. Technol. 34, 716–731 (2022). https://doi.org/10.1108/IJCST-09-2021-0134

Acknowledgements

This work was supported by the Natural Science Foundation of Anhui Province (No. 1908085QE225), the Key Research and Development Project of Anhui Province (No. 202004a06020023), the Innovation Team Project of Anhui Polytechnic University and the Young and middle-aged Top Talent Project of Anhui Polytechnic University.

Funding

This article is funded by Natural Science Foundation of Anhui Province, 1908085QE225, Yinchun Fang, Key Research and Development Project of Anhui Province, 202004a06020023, **nhua Liu, Innovation Team Project of Anhui Polytechnic University, No, **nhua Liu, Young and middle-aged Top Talent Project of Anhui Polytechnic University, No, Yinchun Fang.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No conflicts of interest to declare.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lei, C., Fang, Y. & Liu, X. Durable Multifunctional Modification of Nylon Fabric with Excellent Flame Retardancy, Antibacterial and UV-Resistant Properties. Fibers Polym 25, 515–523 (2024). https://doi.org/10.1007/s12221-023-00442-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00442-y