Abstract

Pore structure characterization and its effect on methane adsorption on shale kerogen are crucial to understanding the fundamental mechanisms of gas storage, transport, and reserves evaluation. In this study, we use 3D scanning confocal microscopy, scanning electron microscopy (SEM), X-ray nano-computed tomography (nano-CT), and low-pressure N2 adsorption analysis to analyze the pore structures of the shale. Additionally, the adsorption behavior of methane on shales with different pore structures is investigated by molecular simulations. The results show that the SEM image of the shale sample obviously displays four different pore shapes, including slit pore, square pore, triangle pore, and circle pore. The average coordination number is 4.21 and the distribution of coordination numbers demonstrates that pores in the shale have high connectivity. Compared with the adsorption capacity of methane on triangle pores, the adsorption capacity on slit pore, square pore, and circle pore are reduced by 9.86%, 8.55%, and 6.12%, respectively. With increasing pressure, these acute wedges fill in a manner different from the right or obtuse angles in the other pores. This study offers a quantitative understanding of the effect of pore structure on methane adsorption in the shale and provides better insight into the evaluation of gas storage in geologic shale reservoirs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The extraction of gas from shale is regarded as an energy game-changer (Hughes 2013). As a transition fuel, shale gas offsets reducing of conventional gas production (Vidic et al. 2013). Horizontal drilling coupled with multi-stage hydraulic fracturing makes it possible to extract hydrocarbons from shale reservoirs (Ren et al. 2016; Shi et al. 2019). Gas in shale reservoirs mainly exists in three forms: free gas, adsorbed gas, and dissolved gas. Particularly, about 20%‒85% of the total gas-in-place is adsorbed gas (Curtis 2002). In shale gas production, the desorption of adsorbed gas can compensate for the loss of free gas, which is a significant reason that shale gas maintains long-term stable production (Wang et al. 2019a). Therefore, understanding the adsorption of hydrocarbons in shale is essential for reliable resource assessment and shale gas recovery.

In general, pores in shale are much smaller than those in conventional sandstone reservoirs (Loucks et al. 2012; Shen et al. 2019). Pore structure characterization has attracted great attention. Nitrogen adsorption tests are used to measure pore size distribution in shale samples (Feng et al. 2018; Groen et al. 2003). Also, the non-local-density functional theory is also used to characterize the pore structures in shale media (Wei et al. Full size image

3.2 Analysis of pore characteristics

The size distribution and shape of shale pores and throats determine the reserves and transmission capacity of shale gas. Figure 2a plots the nano-CT image of a shale block with a diameter of 38.4 μm. The pore size distribution and shape factor are determined using the attribute extraction method. The red part in Fig. 2b represents the pores and throats. The largest maximal balls are identified as pores, while the smallest balls are throats (Dong and Blunt 2009). The pore network is simplified using the ball-and-stick model, and the parameters of pores and throats are obtained. The statistical sizes of pores and throats include their inscribed radius and shape factors. The statistical comparisons of the inscribed radius, shape factors of pores and throats are plotted in Fig. 2c-2d, respectively. The radii of most of the pores and throats are less than a micron, including the organic pores and inorganic pores in shale media. The peak values of the radii of pores and throats are 8.22 × 10−8 m and 1.46 × 10−7 m, respectively. The throat is a continuous channel between the nanopores and a key parameter of shale transport capacity.

The connectivity of the pore network is expressed by coordination numbers. The coordination numbers of pores and throats are shown in Fig. 3. The average coordination number is 4.21 and the distribution of coordination numbers demonstrates that the pores in shale samples have high connectivity (Zhang et al. 2015). The presence of pores with high connectivity may be attributed to the existence of more tortuous paths that join a large number of pores together (Al-Kharusi and Blunt 2007).

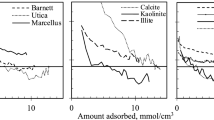

In the previous section, it has been shown that the shale samples have complicated pore structures. In this section, we are primarily concerned with the quantitative analysis of pore structure parameters. N2 adsorption isotherms are used to measure the specific surface area, pore volume, average pore diameter, and micro-pore volume of four shale samples. N2 adsorption isotherms of the four shale samples can be seen in Fig. 4. The adsorption and desorption isotherms are almost overlapped under relatively low pressures. However, with increasing relative pressure, the adsorption and desorption isotherms do not overlap, which results in a hysteresis loop. This is because the capillary condensation occurs within the meso-pores (Sing 1985). N2 adsorption/desorption isotherms with hysteresis loops indicate that the shale samples contain both meso-pores and macro-pores (**ong et al. 2015). Table 1 displays the pore structure parameters calculated by the Brunauer–Emmett–Teller method. The specific surface area is 9.83–22.84 m2/g with an average value of 14.03 m2/g, and the pore volume ranges from 1.34 × 10−2 to 2.27 × 10−2 cm3/g with an average value of 1.61 × 10−2 cm3/g. The average pore diameter and micro-pore volume range from 3.97 to 5.44 nm with an average value of 4.785 nm and from 3.19 × 10−4 to 4.59 × 10−3 cm3/g with an average value of 1.81 × 10−3 cm3/g, respectively. Some previously published experimental data (Sun et al. 2016; Yang et al. 2016) are also included in Fig. 5 and it can be seen that the specific surface area positively correlates with the pore volume (Fig. 5a). In contrast, the average pore size is in a negative correlation to the pore volume and specific surface area (Fig. 5b, c), which is consistent with previous studies (Chalmers et al. 2012). In addition, the pore shape is also an important factor that affects the adsorption capacity of methane on shale, which can be observed directly from the SEM image, as shown in Fig. 6. The SEM image of the shale sample obviously displays four different pore shapes, including slit pore, square pore, triangle pore, and circle pore. We use GCMC simulations to study the adsorption behavior of methane on shale with these four pore shapes.