Abstract

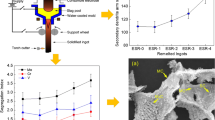

Two high-strength low-alloyed steels alloyed with various Nb contents were prepared using continuous casting (CC) technology. In the round Steel 30Nb CC billet, it was the segregation of C and Nb in the central equiaxed zone that promoted the precipitation of primary NbC carbides at grain boundaries. After processing into seamless tubes, micron-sized primary NbC carbides were located in the middle of the segregation bands, surrounded by many nano-sized NbC carbides formed during the post-solidification cooling and/or hot-piercing rolling. Even when the Nb content was decreased down to 0.006 wt.%, there were still coarse primary NbC carbides in the segregation bands. However, no primary NbC carbide was found in the round Steel 30Nb billet prepared using the electroslag remelting technology. Therefore, this study revealed that a rapid solidification rate was relatively effective in eliminating primary NbC carbides compared with merely decreasing the Nb content.

Similar content being viewed by others

References

X.D. Wang, W.Z. Xu, Z.H. Guo, L. Wang, and Y.H. Rong, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2010.02.026 (2010).

X. Li, Z. Cai, M. Hu, K. Li, M. Hou, and J. Pan, J. Mater. Res. Technol. https://doi.org/10.1016/j.jmrt.2021.02.049 (2021).

K. Xu, B.G. Thomas and R. O’malley, Metall. Mater. Trans. A. (2011). https://doi.org/10.1007/s11661-010-0428-7.

G. Krauss, Metall. Mater. Trans. B. 34B, 781. (2003).

C.Z. Zhu, Y. Yuan, J.M. Bai, P. Zhang, J.B. Yan, C.Y. You, and Y.F. Gu, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2018.10.084 (2019).

W.K. Kim, G. Park, S.U. Koh, H.G. Jung and K.Y. Kim, Determination of critical factors affecting on hydrogen induced cracking and type i sulfide stress cracking of high strength linepipe steel. In Paper Presented at the Proceedings of the Twentieth International Offshore and Polar Engineering Conference, The International Society of Offshore and Polar Engineers (ISOPE) (Bei**g, 2010)

R. Case, Electrochemical study of the Austenitic Stainless-Steel Susceptibility to Sulfide Stress Cracking in H2S-Containing Brines, Paper presented at CORROSION 2019 (NACE International, Nashville, Tennessee, USA, 2019)

M. Luo, M. Liu, X.T. Wang, M.C. Li, X. Li, Z.M. Ren, G.H. Cao, and Z.H. Zhang, Eng. Fail. Anal. https://doi.org/10.1016/j.engfailanal.2019.06.095 (2019).

Y. Song, C. Feng, L. Zhu, Y. Cao, and H. Ge, Mater. Sci. Forum. https://doi.org/10.4028/www.scientific.net/MSF.993.1203 (2020).

J. Wang, D. Kuanhai, Y. Zhi**, L. Bing, Y. Lin, and Y. Feng, Eng. Failure Anal. https://doi.org/10.1016/j.engfailanal.2019.01.033 (2019).

Z. Zhang, Y. Zheng, J. Li, W. Liu, M. Liu, W. Gao, and T. Shi, Eng. Fail. Anal. https://doi.org/10.1016/j.engfailanal.2018.09.030 (2019).

T. Zeng, S. Zhang, X. Shi, W. Wang, W. Yan, and K. Yang, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.141845 (2021).

S. Luo, M. Liu, Y. Shen, and X. Lin, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-019-03913-7 (2019).

M. Ohnuma, J.I. Suzuki, F.G. Wei, and K. Tsuzaki, Scr. Mater. https://doi.org/10.1016/j.scriptamat.2007.09.026 (2008).

Thermo-Calc Software TCFE7, Iron and Steel Database (Thermo-Calc Software AB, Stockholm, 2013).

H. Halfa, Steel Res. Int. https://doi.org/10.1002/srin.201200332 (2013).

H. Geng, Z. Zhang, H. Tang, P. Lan, M. Luo, and J. Zhang, J. Iron Steel Res. 31, 387. ((in Chinese)) (2019).

B. Li, M. Luo, Z. Yang, F. Yang, H. Liu, H. Tang, Z. Zhang, and J. Zhang, Materials. https://doi.org/10.3390/ma12203310 (2019).

Atlas for bainitic microstructures. (Tokyo, ISIJ, 1992)

H. Najafi, J. Rassizadehghani, and S. Norouzi, Mater. Des. https://doi.org/10.1016/j.matdes.2010.08.007 (2011).

P. Tao, H. Yu, Y. Fan, and Y. Fu, Mater. Des. https://doi.org/10.1016/j.matdes.2013.08.103 (2014).

R.C. Giacomin, and B.A. Webler, ISIJ Int. https://doi.org/10.2355/isi**ternational.ISIJINT-2018-598 (2019).

A. Golpayegani, F. Liu, H. Svensson, M. Andersson, and H.O. Andren, Metall. Mater. Trans. A. https://doi.org/10.1007/s11661-010-0555-1 (2011).

C.L. Davis, and M. Strangwood, Mater. Sci. Technol. https://doi.org/10.1179/174328409X453262 (2009).

T. Zeng, S. Zhang, X. Shi, W. Wang, W. Yan, Y. Tian, and M. Zhao, Materials. https://doi.org/10.3390/ma14185301 (2021).

M.G. Lage, and A.L.V. Silva, J. Mater. Res. Technol. https://doi.org/10.1016/j.jmrt.2015.06.002 (2015).

D. Chakrabarti, C. Davis, and M. Strangwood, Metall. Mater. Trans. A. https://doi.org/10.1007/s11661-008-9535-0 (2008).

S. Zheng, C. Davis, and M. Strangwood, Mater. Charact. https://doi.org/10.1016/j.matchar.2014.06.008 (2014).

Z. Li, Principles of Electroslag Metallurgy, Electroslag Metallurgy Theory and Practice (Metallurgical Industry Press, Bei**g, 2010), p 17. (in Chinese).

Acknowledgement

One of authors, Tian-Yi Zeng, appreciates the helpful advice from Prof. Ying Tang at Hebei University of Technology. The authors appreciate the financial support from Youth Innovation Promotion Association of Chinese Academy of Sciences (2017233).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tian, Y., Zhao, MC., Zeng, YP. et al. Elimination of Primary NbC Carbides in HSLA Steels for Oil Industry Tubular Goods. JOM 74, 2409–2419 (2022). https://doi.org/10.1007/s11837-022-05202-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05202-6