Abstract

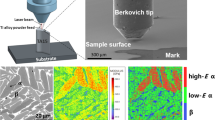

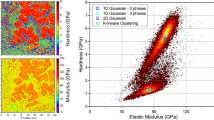

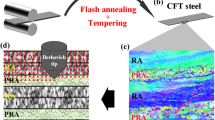

This work aims to adapt nanoindentation map** combined with a k-means algorithm as a high-throughput technique to study the nano-scale spatial changes in mechanical properties for a heterogeneous material. This technique can also classify the individual data points based on their properties. Hundreds to thousands of indents were performed on additively manufactured T91 at room temperature, 300°C, 400°C, and 500°C across a square area with a side length of 120 μm to 400 μm. From this data, the hardness and reduced modulus at each point could be calculated and mapped. Using k-means clustering, we were able to arrange the data into three or four clusters corresponding roughly to the ferritic and martensitic phases as well as one or two intermediate clusters sampling both the phases. The hardness of these two phases appears to be quite stable as a function of temperature. Nanoindentation map** and the k-means algorithm can therefore be used to rapidly assess the feasibility of heterogeneous materials under extreme conditions, such as nuclear reactor steels.

Similar content being viewed by others

References

In (U.S. DOE Nuclear Energy Research Advisory Committee, 2002), pp. 1.

D. Buckthorpe, In Struct. Mater. Gener. IV Nucl. React. (Elsevier, 2017), pp. 1.

G. Locatelli, M. Mancini, and N. Todeschini, Energy Policy 61, 1503. (2013).

K.L. Murty, and I. Charit, J. Nucl. Mater. 383, 189. (2008).

L.K. Mansur, A.F. Rowcliffe, R.K. Nanstad, S.J. Zinkle, W.R. Corwin, and R.E. Stoller, J. Nucl. Mater. 166, 329. (2004).

S.L. Mannan, S.C. Chetal, B. Raj, and S.B. Bhoje, Trans. Indian Inst. Met. 56, 155. (2003).

R.L. Klueh, Int. Mater. Rev. 50, 287. (2005).

F. Abe, In Coal Power Plant Mater. Life Assess. Dev. Appl. (Woodhead Publishing Limited, 2014), pp. 3–51.

R.L. Klueh and D.R. Harries, In High-Chromium Ferritic Martensitic Steels Nucl. Appl. (ASTM International, 2001), pp. 28.

S.A. Maloy, M.R. James, and M.B. Toloczko, In Seventh Inf. Exch. Meet. Actin. Fission Prod. Partitioning Transm. (2002), pp. 669.

R.L. Klueh, and A.T. Nelson, J. Nucl. Mater. 371, 37. (2007).

N. Sridharan, and K. Field, Fusion Sci. Technol. 75, 264. (2019).

K. Terrani, Nucl. News 63, 34. (2020).

X. Jia, and Y. Dai, J. Nucl. Mater. 343, 212. (2005).

S.-H. Lee, H.-S. Na, K.-W. Lee, Y. Choe, and C. Kang, Metals (Basel). 8, 170. (2018).

B. Huang, Y. Zhai, S. Liu, and X. Mao, J. Nucl. Mater. 500, 33. (2018).

W.C. Oliver, and G.M. Pharr, J. Mater. Res. 7, 1564. (1992).

W.C. Oliver, and G.M. Pharr, J. Mater. Res. 19, 3. (2004).

A.C. Fischer-Cripps, in Nanoindentation (Springer, 2011), pp. 77–103.

J.M. Wheeler, D.E.J. Armstrong, W. Heinz, and R. Schwaiger, Curr. Opin. Solid State Mater. Sci. 19, 354. (2015).

A. Barnoush, P. Hosemann, J. Molina-Aldareguia, and J.M. Wheeler, MRS Bull. 44, 471. (2019).

M.S. Bobji, and S.K. Biswas, J. Mater. Res. 14, 2259. (1999).

W.G. Jiang, J.J. Su, and X.Q. Feng, Eng. Fract. Mech. 75, 4965. (2008).

D.Q. Doan, T.H. Fang, and T.H. Chen, Int. J. Mech. Sci. 185, 105865. (2020).

B. Yang, and H. Vehoff, Mater. Sci. Eng. A 400, 467. (2005).

T. Chen, L. Tan, Z. Lu, and H. Xu, Acta Mater. 138, 83. (2017).

N.X. Randall, M. Vandamme, and F.-J. Ulm, J. Mater. Res. 24, 679. (2009).

E.D. Hintsala, U. Hangen, and D.D. Stauffer, JOM 70, 494. (2018).

G. Constantinides, K.S.R. Chandran, F.-J. Ulm, and K.J. Van Vliet, Mater. Sci. Eng. A 430, 189. (2006).

F.-J. Ulm, M. Vandamme, H.M. Jennings, J. Vanzo, M. Bentivegna, K.J. Krakowiak, G. Constantinides, C.P. Bobko, and K.J. Van Vliet, Cem. Concr. Compos. 32, 92. (2009).

F.J. Ulm, M. Vandamme, C. Bobko, J. Alberto Ortega, K. Tai, and C. Ortiz, J. Am. Ceram. Soc. 90, 2677. (2007).

Y. Chen, E. Hintsala, N. Li, B.R. Becker, J.Y. Cheng, B. Nowakowski, J. Weaver, D. Stauffer, and N.A. Mara, JOM 71, 3368. (2019).

E. Koumoulos, G. Konstantopoulos, and C. Charitidis, Fibers 8, 3. (2019).

G. Konstantopoulos, E.P. Koumoulos, and C.A. Charitidis, Mater. Des. 192, 108705. (2020).

G. Konstantopoulos, E.P. Koumoulos, and C.A. Charitidis, Nanomaterials 10, 645. (2020).

B.P. Eftink, D.A. Vega, O. El Atwani, D.J. Sprouster, Y. Suk, J. Yoo, T.E. Steckley, E. Aydogan, C.M. Cady, M. Al-Sheikhly, T.J. Lienert, and S.A. Maloy, J. Nucl. Mater. 544, 152723. (2021).

O. El-Atwani, B.P. Eftink, C.M. Cady, D.R. Coughlin, M.M. Schneider, and S.A. Maloy, Scr. Mater. 199, 113888. (2021).

U.D. Hangen, D.D. Stauffer, S.A. Syed Asif, In Nanomechanical Anal. High Perform. Mater. Solid Mech. Its Appl. (Springer, 2014), pp. 85–103.

Acknowledgements

The custom nanoindentation system at Bruker’s Hysitron was built under DOE SBIR In Operando SPM: Variable Pressure and Temperature, under DE-SC0013218. This work was supported by the Department of Energy, Nuclear Engineering University Programs grant NE-000008888. Support from Bruker NANO is also gratefully acknowledged. EDH and DDS are supported by Bruker. Work was performed in part at Los Alamos National Laboratory. Los Alamos National Laboratory is an affirmative action/equal opportunity employer, and is operated by Triad National Security, LLC for the National Nuclear Security Administration of U.S. Department of Energy under contract 89233218CNA000001

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sau, M., Hintsala, E.D., Chen, Y. et al. High-Throughput Nanoindentation Map** of Additively Manufactured T91 Steel. JOM 74, 1469–1476 (2022). https://doi.org/10.1007/s11837-022-05189-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05189-0