Abstract

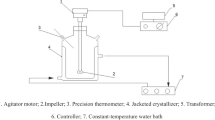

In the crystallization process, the quality of crystal formation is significantly affected by the stirring mechanism. Typically, the efficiency of mixing is directly correlated with the rotational speed of the stirrer. Nevertheless, elevated stirring speeds can lead to the fragmentation of crystal nuclei, thereby exerting a detrimental influence on the overall crystallization quality. To address such issue, a glass-lined V-shaped stirrer with a better stirring effect under low-speed conditions was developed in the present study. Particular attention was paid to providing a better stirring effect under low-speed conditions. The computational fluid dynamics (CFD) numerical simulation method was employed to conduct a comparative analysis of the flow field distribution when subjected to the influence of a V-shaped stirrer in comparison with two frequently employed stirrers. The velocity field, turbulence intensity, particle distribution and heat transfer rate were analyzed, and experimental measurements of the mixing time were conducted. The findings from the present study reveal that when the stirring paddle was operated at a speed of 80 rpm, the V-shaped stirrer exhibited a larger circulation range compared with the other two stirrers. Further, the overall turbulence intensity in the flow field was higher, ensuring a more homogeneous distribution of crystal nuclei. Additionally, the heat transfer rate was found to be significantly faster, contributing to improved crystallization efficiency and higher-quality crystallization products. The utilization of the glass-lined V-shaped stirrer offers the advantage of improved mixing efficiency in the crystallization process, while maintaining the crystal quality. This innovation has the potential to bring about a transformative shift in manufacturing processes and contribute to advancements in the field of crystallization.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

M.G. Pi, Preparation of copper sulfate solution from copper slag using sulfuric acid solution. Adv. Mater. Res. 2569, 773–773 (2013)

N. Miguel, D. Gonzalo, L. Ana et al., Comparative study on bubbling and shearing techniques for the crystallization of xylitol in TES systems. Results Eng. 17, 100909 (2023)

Z. Dan, X. Menglin, W. Jiao et al., Nonisothermal crystallization kinetics of potassium chloride produced by stirred crystallization. J. Cryst. Growth 603, 127035 (2023)

M. Majid, N. Ali, K. Masoud, The effect of agitation and temperature on crystallization of calcium carbonate in water injection process. Pet. Sci. Technol. 39, 23–24 (2021)

H.S. Mumtaz, M.J. Hounslow, N.A. Seaton et al., Orthokinetic aggregation during precipitation: a computational model for calcium oxalate monohydrate. Chem. Eng. Res. Des. 75(A2), 152–159 (1997)

M. Liiri, T. Koiranen et al., Secondary nucleation due to crystal impeller and crystal vessel collisions by population balances in CFD-modelling. J. Cryst. Growth 237(237), 2188–2193 (2002)

Y. Guo, C. Wassgren, B. Hancock et al., Predicting breakage of high aspect ratio particles in an agitated bed using the discrete element method. Chem. Eng. Sci. 158, 314–327 (2017)

G. Liu, D. Wang, Z. Cui et al., Influence of agitation intensity on solution stability for rapidly grown KDP crystal through theoretical and experimental research. Mater. Today Commun. 24, 101007 (2020)

L. Shishu, W. Yan, Li. Jichang et al., Study on the corrosion results of austenitic stainless steel between sulfuric acid and copper sulfate solution liquid crystals. Machine 45(S2), 108–110 (2018)

J. Xu, X. **sha, R. Facai et al., Effect of glaze composition on the impact resistance of glass lining of glass-lined vessels. J. Phys. Conf. Ser. 1676(1), 012016 (2020)

H.H. Kak, O.J. Hee, M.L. Hee et al., Effect of RPM and temperature on the CSD in the CMSMPR calcium carbonate crystallizer. Korean Chem. Eng. Res. 44(3), 289–293 (2006)

Z. Zhaoyou, Q. Bin, L. Shuhua et al., Multi-dimensional analysis of turbulence models for immiscible liquid–liquid mixing in stirred tank based on numerical simulation. Sep. Sci. Technol. 56(2), 411–424 (2021)

R. Kevin, L. Martin, W. Dominic et al., 3D flow simulation of a baffled stirred tank for an assessment of geometry simplifications and a scale-adaptive turbulence model. Chem. Eng. Sci. 231, 116262 (2020). (prepublish)

X. **a, L. Zuohua, T. Changyuan et al., Numerical simulation of dense solid-liquid mixing in stirred vessel with improved dual axial impeller. Separations 9(5), 122–122 (2022)

K. Guirong, W. **, Z. Kai, Numerical simulation study on three-dimensional flow field of copper sulfate crystallization stirring equipment. New Technol. Process. 01, 55–58 (2017)

Acknowledgements

This work was sponsored by the Postgraduate Research & Practice Innovation Program of Jiangsu Province [grant number SJCX23_1502] and National Natural Science Foundation of China [grant number 2021YFC3001104].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, S., Zhao, T., Tao, L. et al. Influence of Glass-Lined V-Shaped Stirrers on Crystallization Properties. Korean J. Chem. Eng. 41, 1625–1636 (2024). https://doi.org/10.1007/s11814-024-00153-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00153-x