Abstract

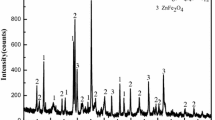

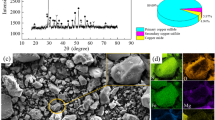

A large amount of acid-leaching residue is produced during the conventional Zn hydrometallurgy process, and this residue has a large concentration of a variety of valuable metals. The purpose of this study was to evaluate the ability of a procedure that entails the use of sulfation roasting, water leaching, and chlorination leaching (blowing oxygen technique) to recover Pb and Ag, followed by cooling crystallization and the replacement of Ag with lead sheet, to realize the full recovery of all valuable metals from zinc acid-leaching residue; consequently, good results were achieved. The best results were obtained under the following conditions: a sulfuric acid at 70% of the raw material quality, roasting temperature of 300 °C and roasting time of 2 h, followed by the process of leaching the roasted residue for 1 h by applying a water-to-solid ratio of 5:1 at room temperature. The recovery rates of Zn and Fe were 98.69% and 92.36%, respectively. The main parameters of the chlorine salt leaching system were as follows: Cl− concentration of 300 g/L, Fe3+ concentration of 25 g/L, acid concentration of 2 mol/L, liquid-to-solid ratio of 9 mL:1 g, temperature of 90 °C, and leaching time of 0.5 h; this leaching process was followed by filtration separation. These conditions resulted in high extents of leaching for Pb and Ag (i.e., 98.87% and 96.74%, respectively). Finally, the kinetics of the process of Ag leaching using Cl− ions in an oxygen-rich medium was investigated. It was found that the leaching process was controlled by the diffusion of the product layers, and the activation energy was 19.82 kJ/mol.

摘要

常规湿法炼锌过程中会产生大量的酸浸渣, 该残渣含有大量各种有价值的金属. 本研究的目的是评估使用硫酸熟化、 水浸和氯化浸出(吹氧技术)回收铅和银的能力, 接着通过冷却结晶并用铅片置换出银, 实现酸浸锌渣中所有有价金属的全面回收, 该工艺取得了良好的效果. 条件实验研究得出最佳工艺条件如下: 硫酸用量为原样质量的 70%, 焙烧温度 300 °C, 焙烧时间 2 h, 焙烧渣按液固比 5:1 室温水浸 1 h, 此时锌、 铁的浸出率最高(锌: 98.69%, 铁: 92.36%). 氯化浸出系统主要参数如下: Cl−浓度 300 g/L, Fe3+浓度 25 g/L, 酸浓度 2 mol/L, 液固比 9 mL:1 g, 温度 90 °C, 浸出时间 0.5 h, 该条件下铅和银浸出率分别高达 98.87%和 96.74%; 最后, 对在富氧介质下使用 Cl−浸出银进行动力学研究, 发现浸出过程受内扩散控制, 活化能为 19.82 kJ/mol.

Similar content being viewed by others

References

DUTRIZAC J E, DINARDO O. The co-precipitation of copper and zinc with lead jarosite [J]. Hydrometallurgy, 1983, 11(1): 61–78. DOI: https://doi.org/10.1016/0304-386X(83)90016-6.

LUO W, FENG Q, OU L, ZHANG G, CHEN Y. Kinetics of saprolitic laterite leaching by sulphuric acid at atmospheric pressure [J]. Minerals Engineering, 2010, 23(6): 458–462. DOI: https://doi.org/10.1016/j.mineng.2009.10.006.

LI Chun-cheng, XIE Feng-chun, MA Yang, CAI Ting-ting, LI Hai-ying, HUANG Zhi-yuan, YUAN Gao-qing. Multiple heavy metals extraction and recovery from hazardous electroplating sludge waste via ultrasonically enhanced two-stage acid leaching [J]. Journal of Hazardous Materials, 2010, 178(1–3): 823–833. DOI: https://doi.org/10.1016/j.jhazmat.2010.02.013.

NAGIB S, INOUE K. Recovery of lead and zinc from fly ash generated from municipal incineration plants by means of acid and/or alkaline leaching [J]. Hydrometallurgy, 2000, 56(3): 269–292. DOI: https://doi.org/10.1016/S0304-386X(00)00073-6.

ZVERD A, ERDEM M. Environmental risk assessment and stabilization/solidification of zinc extraction residue: I. Environmental risk assessment [J]. Hydrometallurgy, 2010, 100(3–4): 103–109. DOI: https://doi.org/10.1016/j.hydromet.2009.10.011.

TURAN M D, ALTUNDOGAN H S, TUMEN F. Recovery of zinc and lead from zinc plant residue [J]. Hydrometallurgy, 2004, 75(1): 169–176. DOI: https://doi.org/10.1016/j.hydromet.2004.07.008.

STEER J M, GRIFFITHS A J. Investigation of carboxylic acids and non-aqueous solvents for the selective leaching of zinc from blast furnace dust slurry [J]. Hydrometallurgy, 2013: 34–41. DOI: https://doi.org/10.1016/j.hydromet.2013.08.011.

RUŞEN A, SUNKAR A S, TOPKAYA Y A. Zinc and lead extraction from Çinkur leach residues by using hydrometallurgical method [J]. Hydrometallurgy, 2008, 93(1, 2): 45–50. DOI: https://doi.org/10.1016/j.hydromet.2008.02.018.

ZHANG Yu-hui, JIN Bing-jie, SONG Qing-he, CHEN Bu-ming, WANG Cheng-yan. Leaching behavior of lead and silver from lead sulfate hazardous residues in NaCl-CaCl2-NaClO3 media [J]. JOM, 2019, 71(7): 2388–2395. DOI: https://doi.org/10.1007/s11837-019-03472-1.

APARAJITH B, MOHANTY D B, GUPTA M L. Recovery of enriched lead-silver residue from silver-rich concentrate of hydrometallurgical zinc smelter [J]. Hydrometallurgy, 2010, 105(1, 2): 127–133. DOI: https://doi.org/10.1016/j.hydromet.2010.08.010.

ZHENG Yong-xing, LV **-fang, LIU Wei, QIN Wen-qing, WEN Shu-ming. An innovative technology for recovery of zinc, lead and silver from zinc leaching residue [J]. Physicochemical Problems of Mineral Processing, 2016, 52(2): 943–954. DOI: https://doi.org/10.5277/ppmp160233.

XING Peng, MA Bao-zhong, ZENG Peng, WANG Cheng-yan, WANG Ling, ZHANG Yong-lu, CHEN Yong-qiang, WANG Shuo, WANG Qiu-yin. Deep cleaning of a metallurgical zinc leaching residue and recovery of valuable metals [J]. International Journal of Minerals, Metallurgy, and Materials, 2017, 24(11): 1217–1227. DOI: https://doi.org/10.1007/s12613-017-1514-2.

BEHNAJADY B, MOGHADDAM J. Optimization of lead and silver extraction from zinc plant residues in the presence of calcium hypochlorite using statistical design of experiments [J]. Metallurgical and Materials Transactions B, 2014, 45(6): 2018–2026. DOI: https://doi.org/10.1007/s11663-014-0130-z.

RODRIGUEZ N, ONGHENA B, BINNEMANS K. Recovery of lead and silver from zinc leaching residue using methanesulfonic acid [J]. ACS Sustainable Chemistry & Engineering, 2019, 7(24): 19807–19815. DOI: https://doi.org/10.1021/acssuschemeng.9b05116.

JIANG Guo-min, PENG Bing, LIANG Yan-jie, CHAI Li-yuan, WANG Qing-wei, LI Qing-zhu, HU Ming. Recovery of valuable metals from zinc leaching residue by sulfate roasting and water leaching [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(5): 1180–1187. DOI: https://doi.org/10.1016/S1003-6326(17)60138-9.

HAN Hai-sheng, SUN Wei, HU Yue-hua, JIA Bao-liang, TANG Hong-hu. Anglesite and silver recovery from jarosite residues through roasting and sulfidization-flotation in zinc hydrometallurgy [J]. Journal of Hazardous Materials, 2014, 278: 49–54. DOI: https://doi.org/10.1016/j.jhazmat.2014.05.091.

NADIROV R K. Recovery of valuable metals from copper smelter slag by sulfation roasting [J]. Transactions of the Indian Institute of Metals, 2018, 72(3): 603–607. DOI: https://doi.org/10.1007/s12666-018-1507-5.

LIU W F, YANG T Z, XIA X. Behavior of silver and lead in selective chlorination leaching process of gold-antimony alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(2): 322–329. DOI: https://doi.org/10.1016/S1003-6326(09)60141-2.

ZHANG Ya-li, YU **an-**, LI **ao-bin. Leaching of silver and lead by chloride simultaneously from residue after zinc extraction of low-grade zinc oxide ores [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 296–303. (in Chinese)

WANG Rui-xiang, TANG Mo-tang, YANG Sheng-hai, ZHAGN Wen-hai, TANG Chao-bo, HE **g, YANG Jian-guang. Leaching kinetics of low grade zinc oxide ore in NH3-NH4Cl-H2O system [J]. Journal of Central South University of Technology, 2008, 15(5): 679–683. DOI: https://doi.org/10.1007/s11771-008-0126-4.

JU Shao-hua, TANG Mo-tang, YANG Sheng-hai, LI Ying-nian. Dissolution kinetics of smithsonite ore in ammonium chloride solution [J]. Hydrometallurgy, 2005, 80(1): 67–74. DOI: https://doi.org/10.1016/j.hydromet.2005.07.003.

LIU Jia-nan, ZHAI Yu-chun, WU Yan, ZHANG Jun, SHEN **ao-yi. Kinetics of roasting potash feldspar in presence of sodium carbonate [J]. Journal of Central South University, 2017, 24(7): 1544–1550. DOI: https://doi.org/10.1007/s11771-017-3559-9.

WANG Hai-dong, ZHOU An-an, GUO Hui, LÜ Meng-hua, YU Hai-zhao. Kinetics of leaching lithium from lepidolite using mixture of hydrofluoric and sulfuric acid [J]. Journal of Central South University, 2020, 27(1): 27–36. DOI: https://doi.org/10.1007/s11771-020-4275-4.

GUO Yue-dong. Complex gold ore roasting-acid leaching-fluoride salt pretreatment-cyanidaton process[D]. Ganzhou: Jiangxi University of Science and Technology, 2019: 42–43. (in Chinese)

YANG Hui-bin, PAN **ao-lin, YU Hai-yan, TU Gan-feng, SUN Jun-min. Effect of ferrite content on dissolution kinetics of gibbsitic bauxite under atmospheric pressure in NaOH solution [J]. Journal of Central South University, 2017, 24(3): 489–495. DOI: https://doi.org/10.1007/s11771-017-3451-7.

Author information

Authors and Affiliations

Contributions

WANG Rui-xiang conducted conceptualization, methodology, data curation, writing-original draft, writing-review and editing; YANG Yu-dong and LIU Cha-xiang finished methodology, investigation and data curation; ZHOU Jie and FANG Zhuang helped to perform the analysis with constructive discussions; YAN Kang conducted data curation, software and validation; TIAN Lei and XU Zhi-feng provided writing-review and editing, resources, project administration and funding acquisition.

Corresponding authors

Ethics declarations

All authors declare that they have no conflict of interest.

Additional information

Foundation item: Projects(51804136, 52064021, 52074136, 51564021, 52064022) supported by the National Natural Science Foundation of China; Projects(2019T120625, 2019M652276) supported by the China Postdoctoral Science Foundation; Project(20202ACB213002) supported by the Jiangxi Province Science Fund for Distinguished Young Scholars, China; Project(2019KY09) supported by the Program for Excellent Young Talents, JXUST Young **ggang Scholars of Jiangxi Province, Merit-based Postdoctoral Research in Jiangxi Province, China; Projects supported by the Distinguished Professor Program of **ggang Scholars, Chinain Institutions of Higher Learning, Jiangxi Province, China

Rights and permissions

About this article

Cite this article

Wang, Rx., Yang, Yd., Liu, Cx. et al. Recovery of lead and silver from zinc acid-leaching residue via a sulfation roasting and oxygen-rich chlorination leaching method. J. Cent. South Univ. 27, 3567–3580 (2020). https://doi.org/10.1007/s11771-020-4569-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4569-6