Abstract

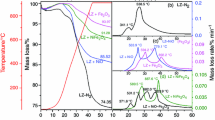

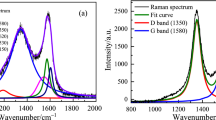

The mechanism of additive ZC-1 for catalyzing combustion of coke breeze in sintering of iron ore fines was studied by using X-ray Diffraction, TGA and GC(Gas Chromatographer), by which energy saving was achieved on sinter pot test. The results show that the distance between cleavage planes is enlarged and the π-electrons are re-distributed because of the insertion of cations/molecules of ZC-1 into the cleavage planes of carbon, resulting in the weakening of C-C bond, improving the adsorption of oxygen and lowering the activation energy of gasification of carbon from 25.8 kJ/mol to 18.9 kJ/mol, and the burning rate being increased and combustion residual reduced, all of which can lead to lower solid fuel consumption. Compared with the sintering test without addition of additives, the solid fuel consumption is reduced by 16.0%, meanwhile, the rate of finished sinter, the output of finished sinter and the tumbling index are increased by 2.03%, 7.0% and 3.71%, respectively, with incorporating 0.2% of additive ZC-1 in the sintering mixture, which is in agreement with the catalyzing mechanism of ZC-1.

Similar content being viewed by others

References

LI Shou-bao, PAN Bao-ju, REN Zi-guo. Approaches to lower energy consumption in sintering[J]. Sintering and Pelletizing (in Chinese), 1996, 21(3): 5–8.

CHEN Chong-bao, The present situation of energy consumption and the future countermeasure for energy saving for sintering[J]. Sintering and Pelletizing(in Chinese), 1997, 22(5): 11–15.

Ball D F. Agglomeration of iron ores[M]. London: Heinemann Educational Books Limited, 1972.

FU Ju-ying, JIANG Tao, ZHU De-qing. Principle and technology of sintering and pelletizing(in Chinese) [M]. Changsha: Central South University of Technology Press, 1996: 48–57.

FU Ju-ying. Investigation of the mechanism of catalyst’s strengthening sinter process[J]. Sintering and Pelletizing(in Chinese), 1999,24(5):11–14.

ZHU Shen-yong, WEI Zhen-qian, TANG Zhuan-liu. Catalysis and combustion-supporting agents to reduce fuel consumption of sinterin[J]. Sintering and Pelletizing(in Chinese), 1997, 22(6): 9–12.

HAN Zhao-can. Fuel and Combustion[M]. Bei**g: Metallurgical Industry Press(in Chinese), 1993:92–94.

Mckee D W. Chemistry and physics of carbon [M]. New York: Marcel Dekker, 1991: 173.

Mark E Vincett, Tsamopoulos J A, Lund C R F. Carbon gasification by group VIII metal catalysts[J]. J Catal, 1990, 126: 279.

ZHANG Zen-ru. Modern measurement techniques for rocks and minerals (in Chinese) [M]. Changsha: Central South University of Technology Press, 1986:8–9.

Author information

Authors and Affiliations

Additional information

Foundation item: The Foundation for the Teaching and Research Program for Outstanding Young Teachers in Higher Education Institutions of MOE, P.R.C.

Biography of the first author: ZHU De-qing, doctor, professor, born in Oct. 1964, majoring in pyrometallurgy.

Rights and permissions

About this article

Cite this article

Zhu, Dq., Qiu, Gz., Jiang, T. et al. Effect of the catalyzing combustion of coke breeze on the energy saving in sinter process. J Cent. South Univ. Technol. 8, 234–238 (2001). https://doi.org/10.1007/s11771-001-0061-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11771-001-0061-0